Steel used at lower temperature and method for manufacturing same

A technology for low-temperature steel and manufacturing methods, which is applied in metal rolling and other directions, and can solve problems such as the difficulty in reaching the low-temperature ductile-brittle transition temperature in the heat-affected zone, low-temperature toughness, and low-temperature toughness deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

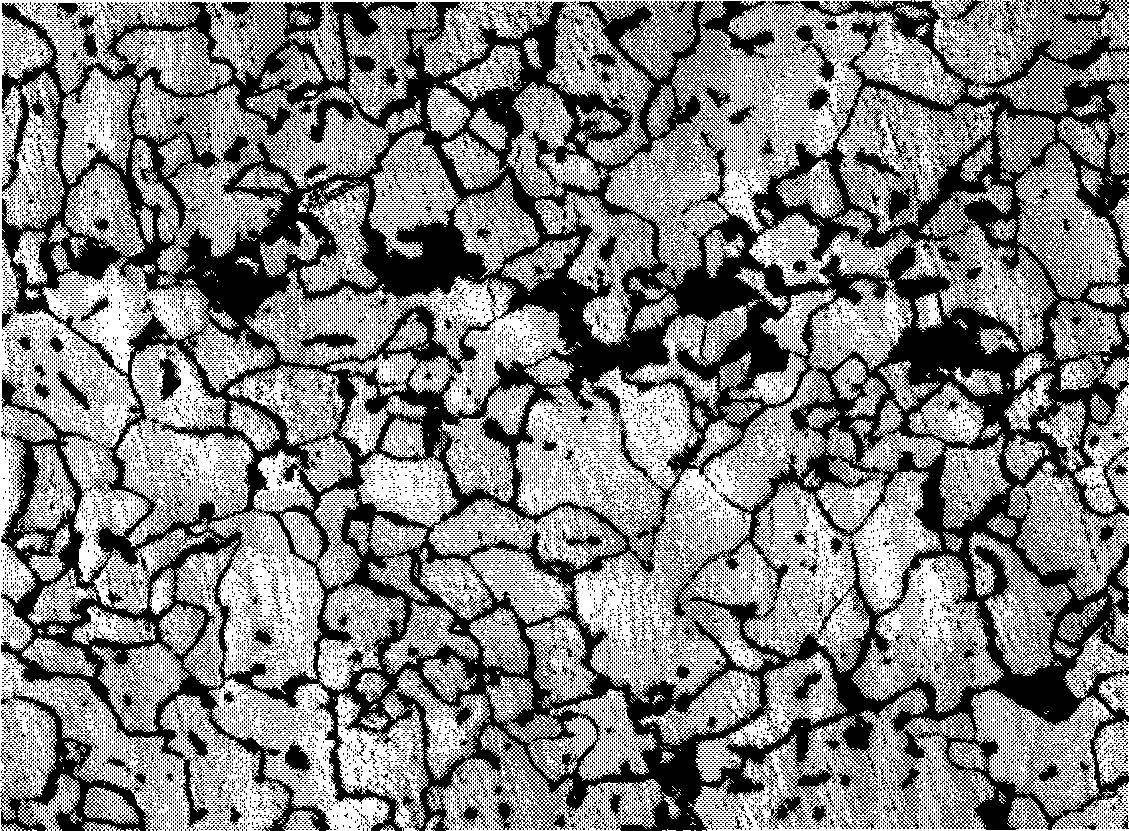

Image

Examples

Embodiment Construction

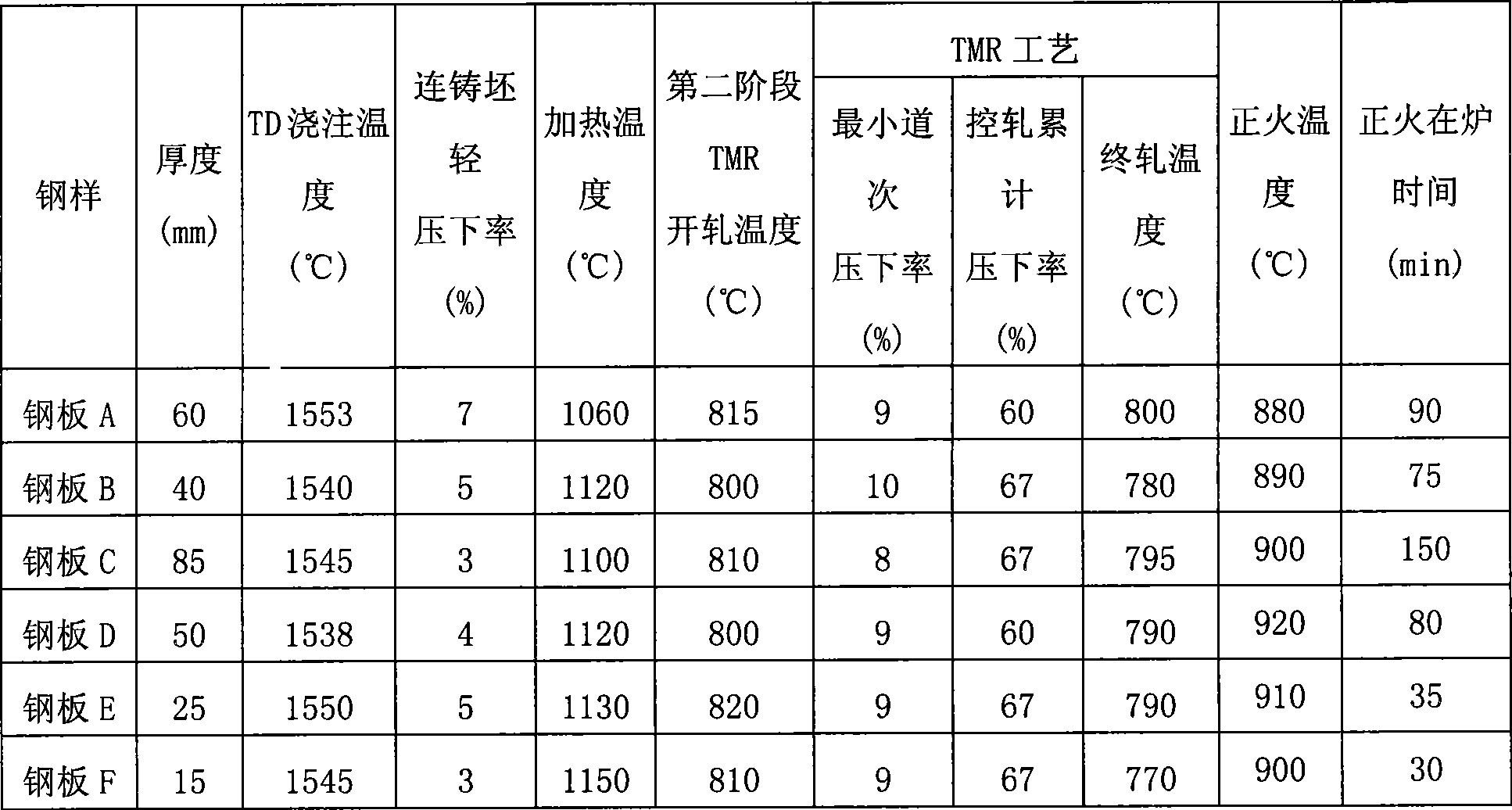

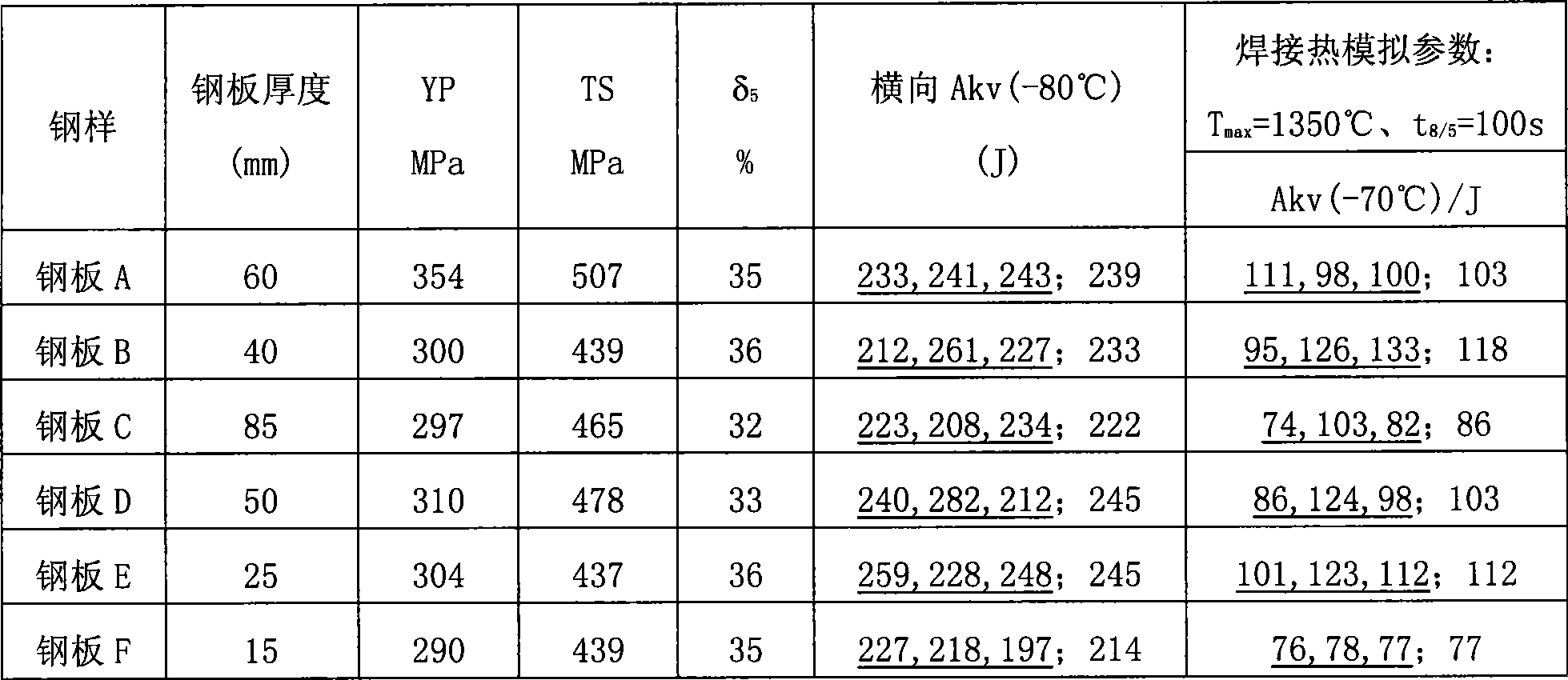

[0045] In the form of three tables, Tables 1, 2, and 3, the weight proportions, process parameters and mechanical properties of the steel plates of the six embodiments A-F are described below.

[0046] Table 1 Chemical composition

[0047]

steel

Sample

C(%)

Si(%)

Mn(%)

P(%)

S(%)

Al s (%)

N(%)

Ti(%)

Nb(%)

Cr(%)

Cu(%)

Ni(%)

Ca(%)

mn

Equivalent

/ C no reason

Second Ni

equivalent steel

plate

A

0.060

0.14

1.45

0.011

0.0027

0.053

0.0035

0.011

0.017

0.10

0.15

0.33

0.0036

28.7

0.542

steel

plate

B

0.085

0.10

1.20

0.010

0.0015

0.065

0.0036

0.009

0.010

0.06

0.40

0.23

0.0026

17.3

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com