A kind of low temperature resistant epoxy resin material and preparation method

A technology of epoxy resin and low temperature resistance, which is applied in the field of low temperature resistant epoxy resin materials and preparation, can solve the problem that the low temperature resistance performance of epoxy resin cannot be improved, and the impact resistance and stress resistance performance, impact resistance and stress resistance performance cannot be improved. Poor and other problems, to achieve the effect of increasing the upper limit of use temperature, good low temperature toughening effect, and good ultra-low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

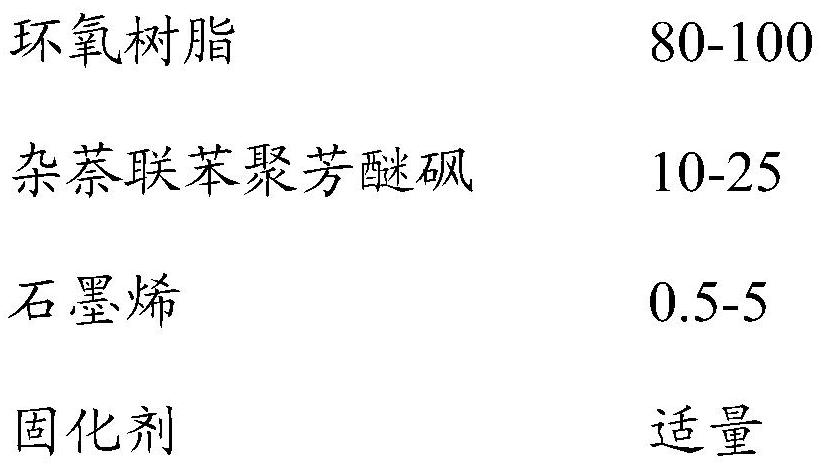

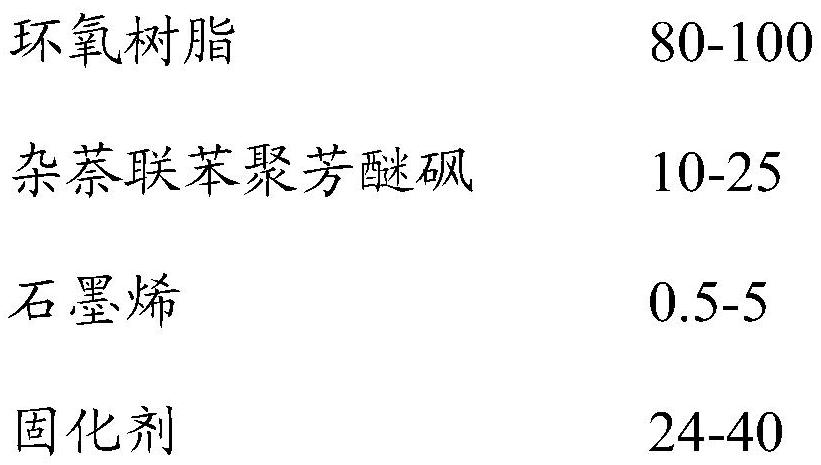

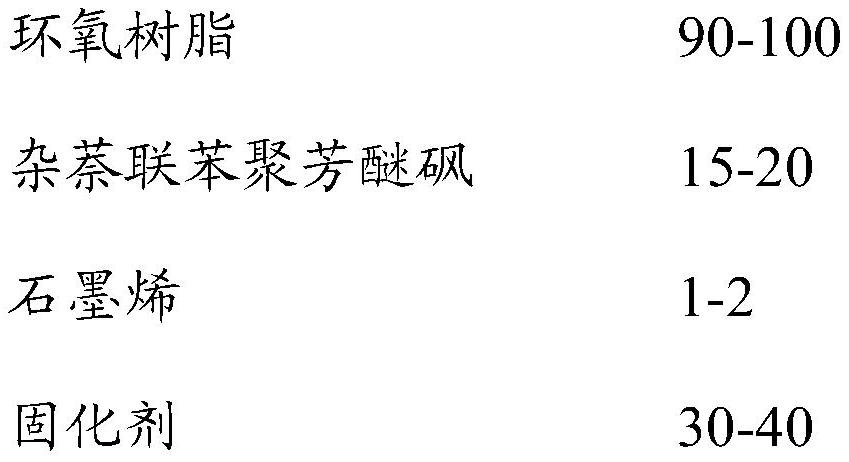

Method used

Image

Examples

Embodiment 1

[0031] Three functional fat ring epoxy resin 100 parts

[0032] 10 copies of hexanedylphenyl polyaryl ether sulfone

[0033] Graphene 0.5

[0034] Curing agent: 4,4'-diaminobenzylmethane, add amount of 30% of epoxy resin

[0035] Preparation Process:

[0036] In the first step, a certain amount of epoxy resin and graphene were weighed, and the epoxy resin was heated to 120 ° C, graphene, stirred for 10 hours, to obtain a mixture 1.

[0037] In the second step, the mixture 1 is poured into the conical bottle, and in the ultrasonic pool, the water bath temperature is controlled at 80 ° C, and the ultrasonic vibration is 4 hours to obtain a mixture 2.

[0038] In the third step, a quantitative hemolinophenyl polyarylene ether sulfone is weighing, and the mixture 2 is heated to 140 ° C, and the hemoliphenyl polyaryl ether sulfone is slowly added, and the stirring speed is 600r / min, and stirred for 100 minutes It is mixed uniform to give mixture 3;

[0039] In the fourth step, the cu...

Embodiment 2

[0042] Tri-functional epoxy resin TGAP 100 parts

[0043] 20 copies of hexaphenyl polyaryl ether sulfone

[0044] Graphie 0.8

[0045] Curing agent: 4,4'-diaminobenzylmethane, add amount of 30% of epoxy resin

[0046] Preparation Process:

[0047] The preparation process is the same as in Example 1. Tensile strength, impact strength, fracture toughness, and glass transition temperature of the liquid nitrogen temperature resistant to low temperature epoxy resin composites, as shown in Table 1.

Embodiment 3

[0049] Bisphenol F-type epoxy resin 100 parts

[0050] Two-formalne polysyl ether sulfone

[0051] Curing agent: 4,4'-di amino diphenylmethane, add amount of 30% of the epoxy resin mass,

[0052] Gradene Ethylene 0.7

[0053] The preparation process is the same as in Example 1. Tensile strength, impact strength, fracture toughness, and glass transition temperature of the liquid nitrogen temperature resistant to low temperature epoxy resin composites, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com