Flux cored wire for ultra-low temperature stainless steel welding

A technology of flux-cored welding wire and stainless steel, applied in welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of strong corrosion resistance, excellent ultra-low temperature impact toughness, and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

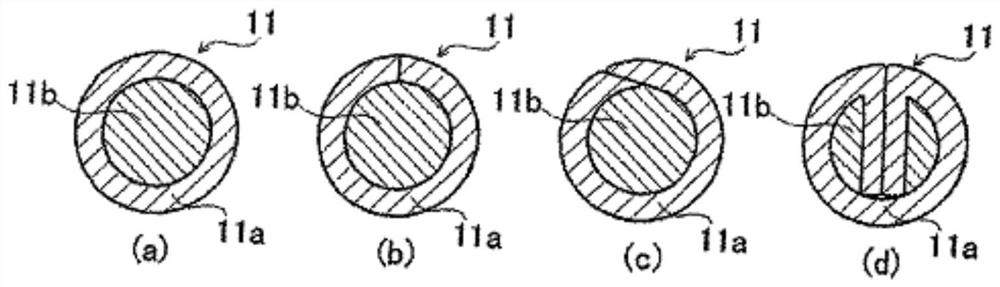

Image

Examples

Embodiment 1

[0109] Embodiment 1: Preparation of flux-cored welding wire

[0110] The drug core powder is filled in the stainless steel strip (304L stainless steel) with a filling rate of 20%, and the contained drug core mass percentage composition is as follows:

[0111] 17% metal chromium powder, 10% metal nickel powder, 10% metal manganese powder, 23% rutile, 4% silicon-calcium alloy,

[0112] 6% feldspar, 5% quartz, 2% rare earth fluoride, 2% chromium nitride powder, 2% aluminum-magnesium alloy,

[0113] The rest is iron powder so that it is added to 100%.

[0114] After the flux-cored wire is rolled and drawn into the flux-cored wire by the flux-cored wire production line, the flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80% Ar+20% CO 2 Mixed gas, 100% Ar) are used to weld various stainless steels (304L, 316L, 904L), and the chemical composition of the deposited metal after welding is within the following range: C≤0.025%, Si≤ 0.8%, Mn is 1.0-2.5%, P≤0.03%, S...

Embodiment 2

[0115] Embodiment 2: Preparation of flux-cored welding wire

[0116] The drug core powder is filled in the stainless steel strip (316L stainless steel) with a filling rate of 22%, and the contained drug core mass percentage composition is as follows:

[0117] 20% metal chromium powder, 9% metal nickel powder, 7% metal manganese powder, 20% rutile, 3% silicon-calcium alloy,

[0118] 3% feldspar, 4% quartz, 3% rare earth fluoride, 3% chromium nitride powder, 3% aluminum-magnesium alloy,

[0119] The rest is iron powder so that it is added to 100%.

[0120] After the flux-cored wire is rolled and drawn into the flux-cored wire by the flux-cored wire production line, the flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80% Ar+20% CO 2 Mixed gas, 100% Ar) are used to weld various stainless steels (304L, 316L, 904L), and the chemical composition of the deposited metal after welding is within the following range: C≤0.025%, Si≤ 0.8%, Mn is 1.0-2.5%, P≤0.03%, S≤0...

Embodiment 3

[0121] Embodiment 3: Preparation of flux-cored welding wire

[0122] The drug core powder is filled in the stainless steel strip (904L stainless steel) with a filling rate of 23%, and the contained drug core mass percentage composition is as follows:

[0123] 15% metal chromium powder, 6% metal nickel powder, 4% metal manganese powder, 25% rutile, 2% silicon-calcium alloy,

[0124] 5% feldspar, 3% quartz, 1% rare earth fluoride, 5% chromium nitride powder, 3% aluminum-magnesium alloy,

[0125] The rest is iron powder so that it is added to 100%.

[0126] After the flux-cored wire is rolled and drawn into the flux-cored wire by the flux-cored wire production line, the flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80% Ar+20% CO 2 Mixed gas, 100% Ar) are used to weld various stainless steels (304L, 316L, 904L), and the chemical composition of the deposited metal after welding is within the following range: C≤0.025%, Si≤ 0.8%, Mn is 1.0-2.5%, P≤0.03%, S≤0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com