A welding method for improving ultra-low temperature toughness of 304ln austenitic stainless steel submerged arc welding joints

A technology of austenitic stainless steel and welded joints, which is applied in the direction of welding/welding/cutting articles, welding equipment, welding accessories, etc., which can solve the problems of failing to meet the requirements, unable to improve the ultra-low temperature toughness of 304LN welded joints, and reduce the ultra-low temperature toughness of welded joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The new submerged arc welding process, the process steps are as follows:

[0054] (1) Preparation before welding

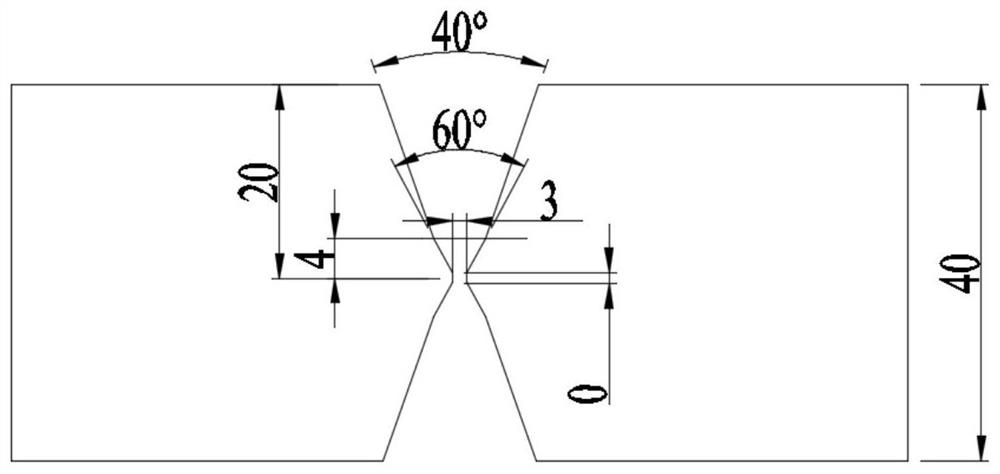

[0055] The 500×150×40mm (2 pieces) 304LN austenitic stainless steel test plate was prepared with a double-sided symmetrical V-V combined bevel using a beveling machine. The bevel angle is as follows: image 3 As shown; use a grinder (stainless steel grinding wheel) to grind and clean the groove and the 20mm range on both sides to remove oil and impurities; use oxyacetylene neutral flame to quickly clean the 304LN groove and the 30mm range on both sides of the base metal Heat to remove moisture; assemble the two test plates to be welded in pairs, with a blunt edge of 0mm and a gap of 3mm, using double-sided argon tungsten arc welding and double-sided filler wire for spot welding, welding materials for spot welding , The welding process is the same as that of double-sided argon tungsten arc welding and double-sided filler wire backing welding. After the spo...

Embodiment 2

[0065] Traditional submerged arc welding welding process, the steps are as follows:

[0066] (1) Preparation before welding

[0067] A 500×150×40mm (2 pieces) 304LN austenitic stainless steel test plate was prepared with a beveling machine to prepare an asymmetrical X-shaped bevel. The bevel angle is as follows: Figure 4 As shown; use a grinder (stainless steel grinding wheel) to grind and clean the groove and the 20mm range on both sides to remove oil and impurities; use oxyacetylene neutral flame to quickly clean the 304LN groove and the 30mm range on both sides of the base metal Heat to remove moisture; assemble the two test plates to be welded in pairs, the blunt edge is 4mm, the gap is 0mm, and E308L-16 welding rod is used for spot welding at both ends of the test plate.

[0068] (2) Welding

[0069]Submerged arc welding is used for bottom filling and cover welding, welding current is 400-450A, welding voltage is 29-33V, welding speed is 360-560mm / min, and line energy ...

Embodiment 3

[0075] Groove form and angle such as Figure 5 As shown, a symmetrical X-shaped groove is used. φ2.4mm double-sided tungsten argon arc welding double-sided filler wire is used for backing, the welding arc voltage is 12V, the welding current is 160A, the welding speed is 60-80mm / min, and the line energy is 14.4-19.2KJ / cm; The welding process is consistent with the first embodiment.

[0076] After testing, 2 of the 4 side bending samples are intact, and 2 have cracks, and the cracks are all at the bottom weld of argon arc welding. The length of a single crack is less than 3mm, which meets the qualified standard of NB / T 47014-2011, but the existing cracks also indicate that the double-sided argon arc welding must not use too much heat input, otherwise the shape of the weld will be reduced.

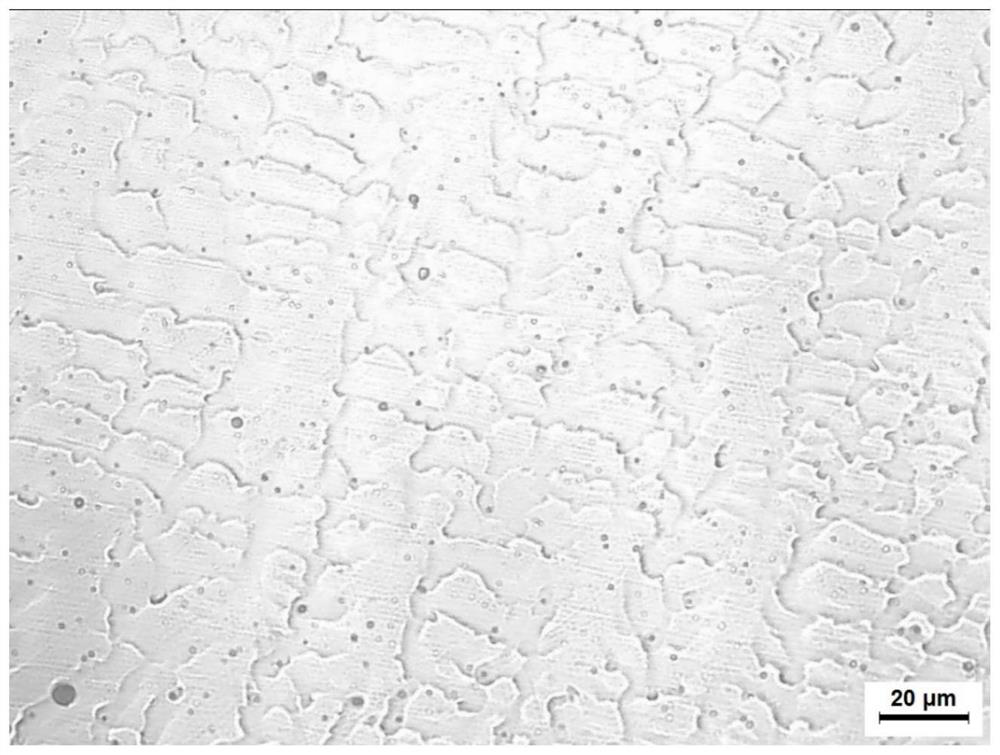

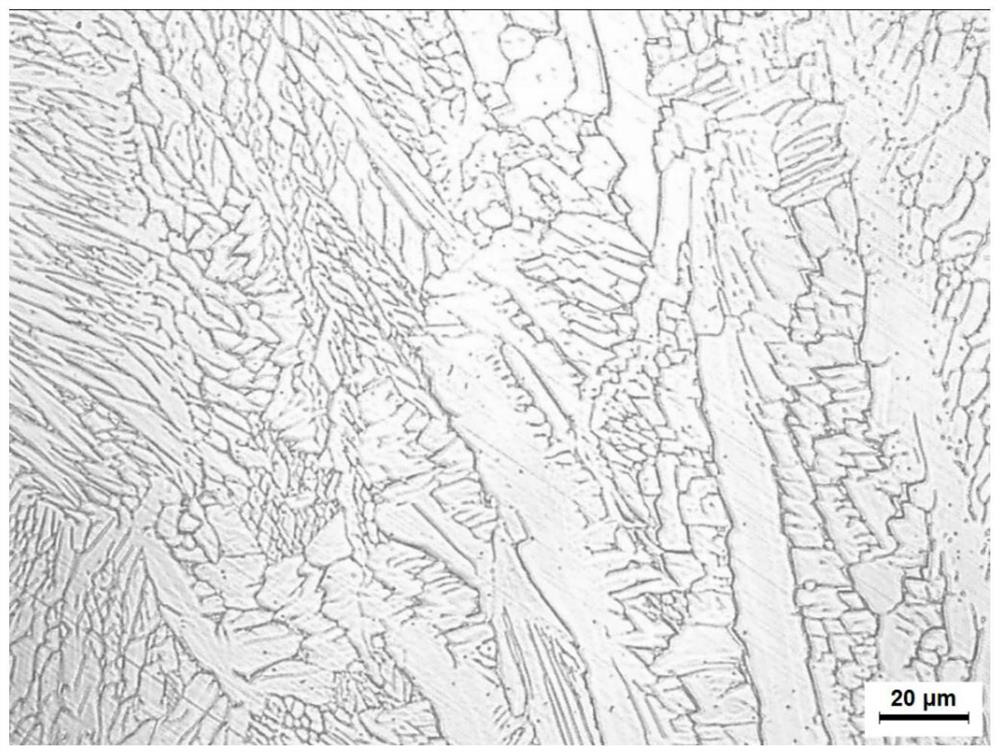

[0077] The weld structure of embodiment 1 is as figure 1 shown. The weld structure is composed of dendritic austenite and trace ferrite, which is the A solidification mode. The trace ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com