Spot welding workstation for automobile welding

A workstation, spot welding technology, applied in manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of complex welding equipment structure, low welding efficiency, difficult operation, etc., to save equipment investment costs, improve welding efficiency, and easy operation. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

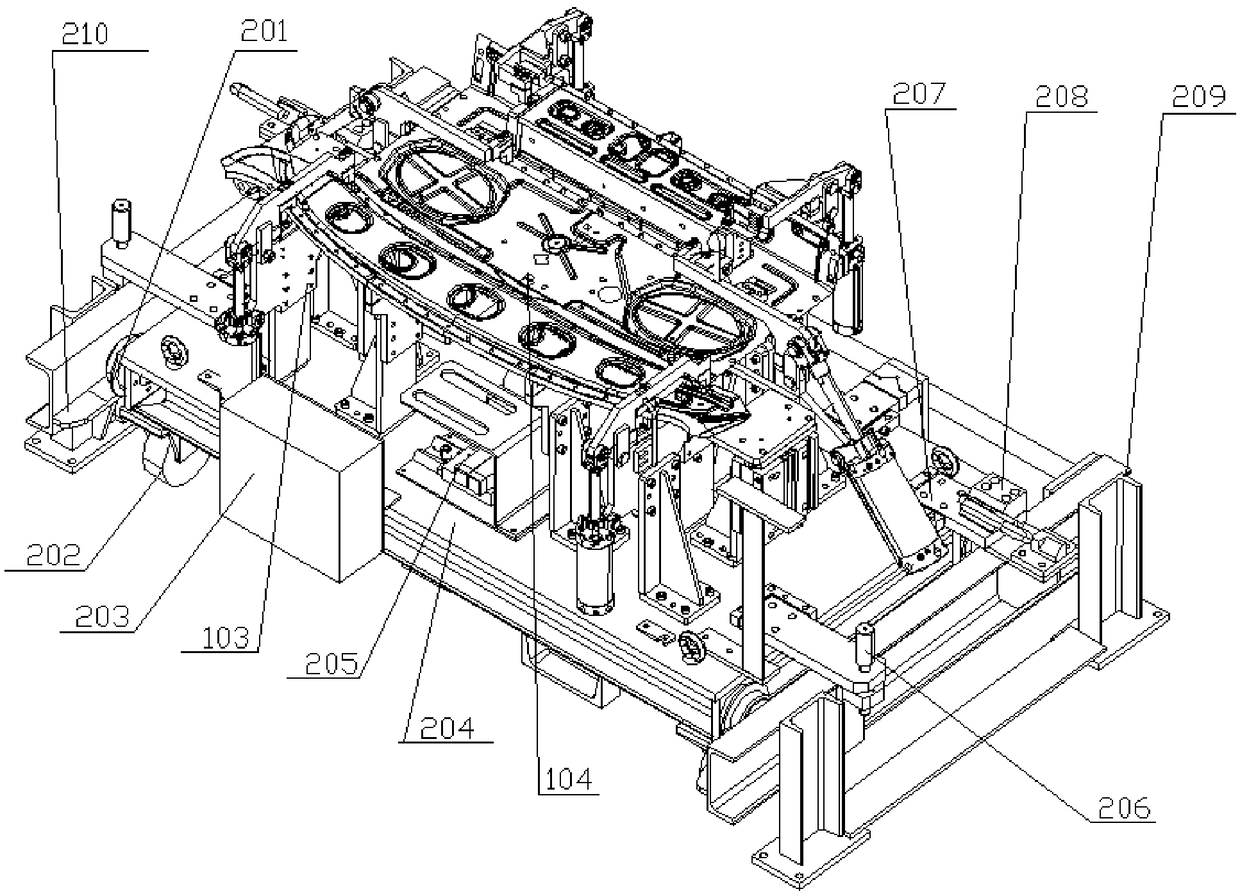

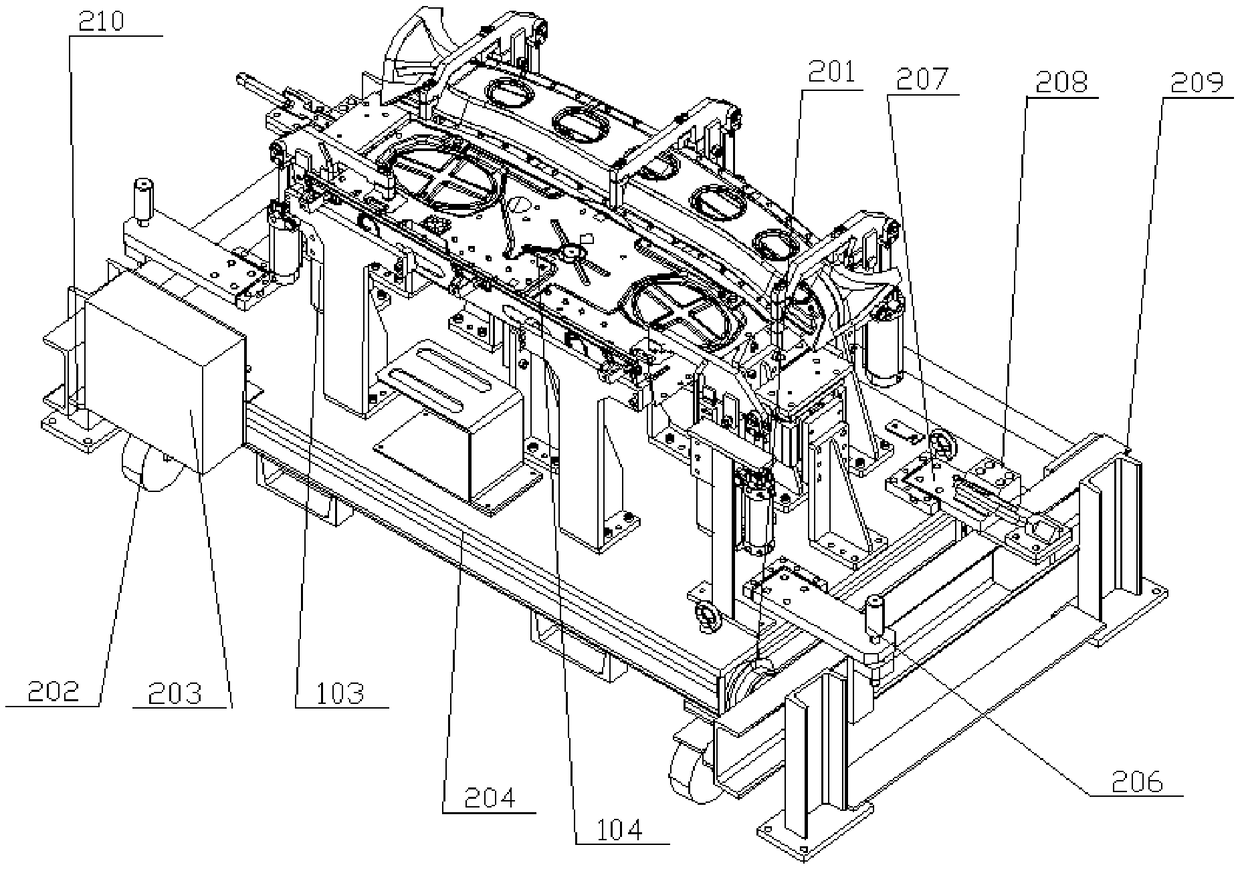

[0026] The specific embodiment of the present invention is like this: as Figure 1-7 As shown, a spot welding workstation for automobile welding includes a special spot welding machine 3 and a protective structure 1 arranged around the special spot welding machine 3. The protective structure 1 is a protective fence, and a grating 101 is arranged at the entrance of the protective fence. Welding machine 3 comprises horizontal conveying rail 318, is located at the walking platform 322 on the horizontal conveying rail 318, is located at the lifting guide rail 305 of walking platform 322, is provided with longitudinal conveying rail 309 on the lifting guide rail 305, and the end of longitudinal conveying rail 309 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com