Welding electrode and coating for welding under wading environment, and preparation methods of welding electrode and coating

A coating and welding rod technology, which is applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve problems such as excessive smoke and gas, reduced welding efficiency, cooling cracks, etc., and achieves simple preparation process and smooth weld The effect of beautiful shape and convenient test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

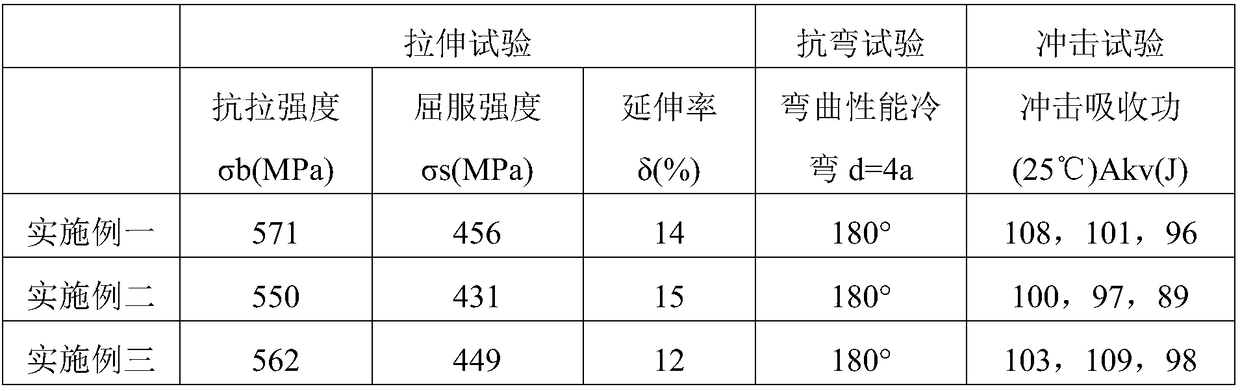

Examples

Embodiment 1

[0023] Embodiment one: adopt commercially available H08E steel wire as welding core, the composition and weight percent of powder are: rutile 37%, calcium carbonate 20%, fluorite 13%, mica 12%, ferrosilicon 5%, ferromanganese 5%, Titanium 6%, Yttrium 2%. Potassium-sodium water glass with a potassium-to-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 20% of the total weight of the coating.

Embodiment 2

[0024] Embodiment two: adopt commercially available H08E steel wire as welding core, the composition and weight percent of powder are: rutile 45%, calcium carbonate 15%, fluorite 8%, mica 10%, ferrosilicon 6%, ferromanganese 6%, Titanium 5%, Yttrium 5%. Potassium-sodium water glass with a potassium-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 25% of the total weight of the coating.

Embodiment 3

[0025] Embodiment three: adopt commercially available H08E steel wire as welding core, the composition and weight percent of powder are: rutile 50%, calcium carbonate 10%, fluorite 10%, mica 8%, ferrosilicon 5%, ferromanganese 8%, Titanium 4%, Yttrium 5%. Potassium-sodium water glass with a potassium-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 28% of the total weight of the coating.

[0026] Weigh the above-mentioned component raw materials respectively by weight, put them into a mixing tank, and dry mix for 3-6 hours; then add potassium sodium water glass as a binder, and wet mix and stir for 1-2 hours. Evenly coat the wet-mixed and uniform coating on the steel wire, the diameter of the steel wire is 4mm, and the outer diameter of the welding rod is 6.2-6.7m. After grinding out the clamping end and arc striking end, the electrode is dried in three stages in the electrode drying furnace: low temperature 40-80°C, medium temperature 100-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com