Installing and welding fixture device for upper link of wagon

A technology for railway freight cars and welding tires, which is applied to auxiliary devices, welding equipment, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

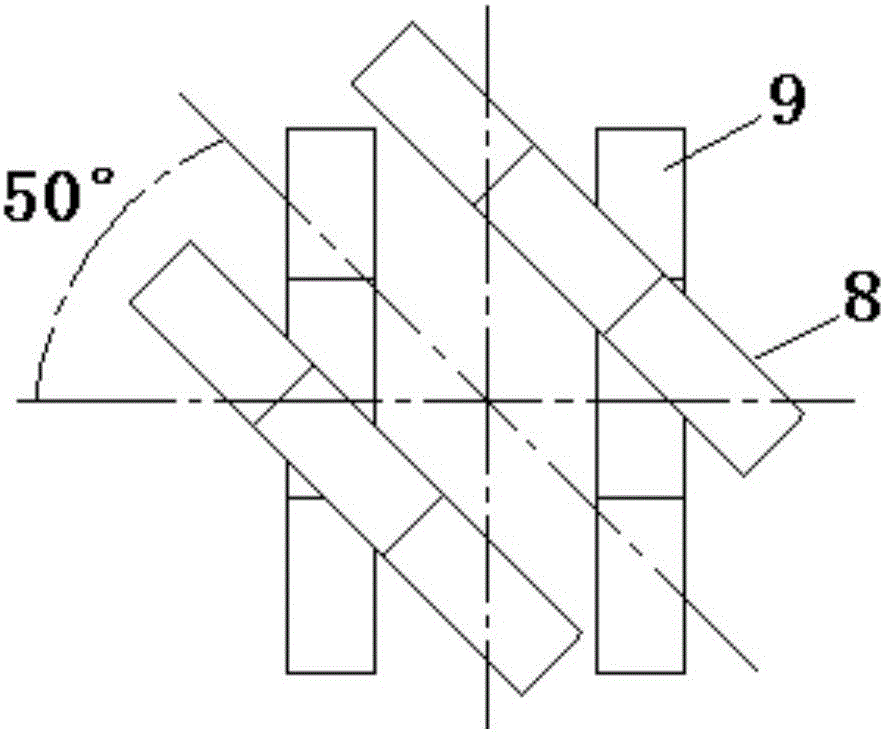

[0016] Such as figure 2 As shown, the present invention includes a frame 1 , a chute 11 is arranged on the top of the frame 1 , and a pull rod support 2 for connecting the pull rod head 9 is slidably arranged on the chute 11 . A rotating bracket composition 3 is connected on the frame 1 at one end of the chute 11. The rotating bracket composition 3 includes a bracket 31 fastened to the frame 1, and a rotation bracket for connecting the pull rod head 8 is installed on the bracket 31. Pull rod seat 32. Wherein, the tie rod support 2 and the rotating tie rod seat 32 are at the same level.

[0017] In the above example, if image 3 As shown, the tie rod support 2 includes a channel steel 21 with an opening downwards, and a vertical plate 22 is set on the top surface of the channel steel 21 away from the end of the rotating bracket composition 3, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com