Length-adjustable and flange-plate-angle-adjustable clamp for track welding of finished shaft heads

A technology for adjusting length and angle, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated flange welding, high cost, and low efficiency, so as to save processing time and reduce production cost , Reduce the effect of tooling investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

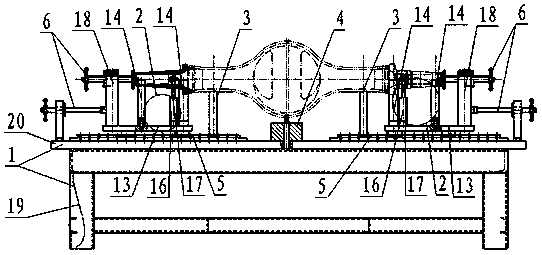

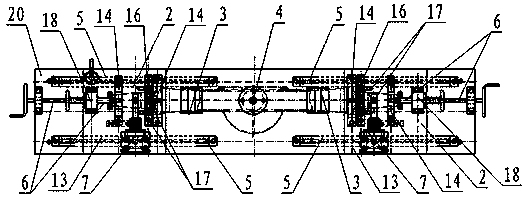

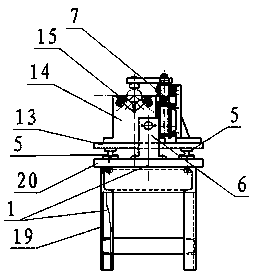

[0016] Embodiment 1: see figure 1 , 2 , 3, 4, 5, according to the design needs to process and make the table top 1, flange plate and shaft head positioning assembly 2, support levelers at both ends of the axle housing 3, positioning pin of the oil drain hole of the axle housing 4, linear slide rail 5, Lead screw moving assembly 6 and shaft head cylinder pressing 7;

[0017] The table top 1 is composed of a workbench 19 and a bottom plate 20. The workbench 19 mainly plays a supporting role. The bottom plate 20 is connected with the workbench 19. The threaded holes and pin holes are processed on the bottom plate 20 for the positioning pin 4 of the oil drain hole of the axle housing. Positioning installation of linear slide rail 5 and lead screw moving assembly 6;

[0018] The flange and shaft head positioning assembly 2 is composed of a mounting plate 13, a shaft head positioning V-shaped iron 14, an insert 15, a flange angle positioning seat 16 and a flange positioning pin 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com