Oil-base mud treatment process

A treatment process, oil-based mud technology, applied in water/sludge/sewage treatment, treatment of hydrocarbon oil, petroleum industry, etc., to achieve the effect of thorough treatment, extensive reuse, and improved treatment efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

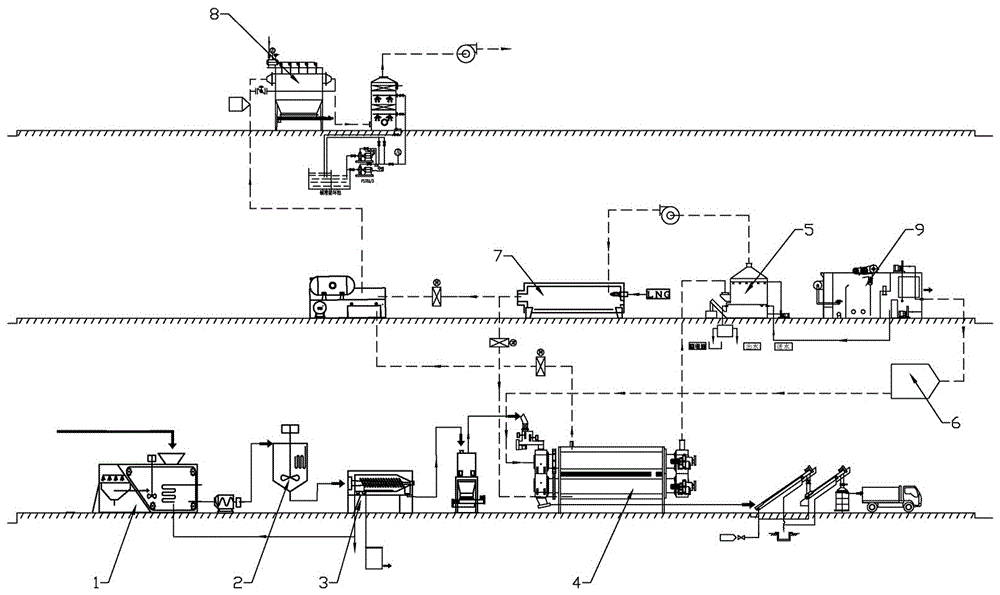

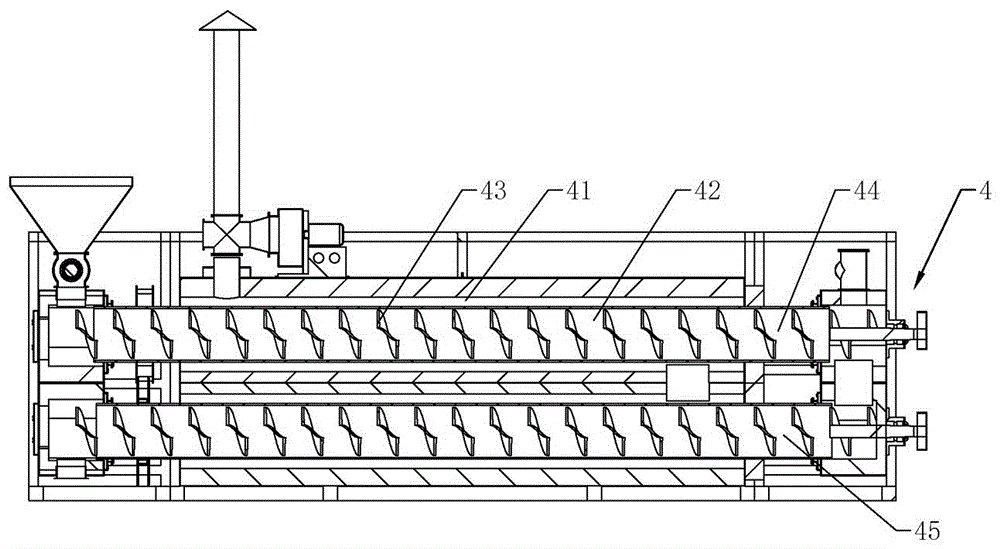

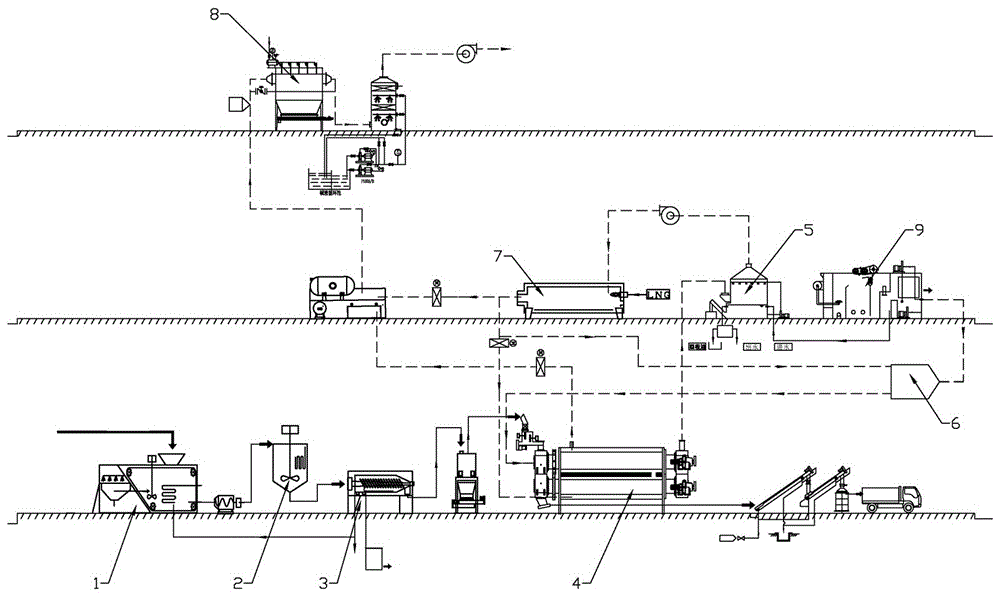

[0042] according to Figure 1 ~ Figure 2 Shown, a kind of treatment process of oil-based mud comprises the following steps:

[0043] aPretreatment: including sorting, tempering and preliminary separation:

[0044] Sorting: The oily sludge is disposed of through the foreign matter separation system 1, which includes a vibrating screen and a hot water injection device to wash away the oil on the surface of sand and gravel, and sort out large particles with a particle size greater than 5mm The impurities are piled up separately, and the liquid oily sludge is sent to the conditioning reaction system 2 after preheating and homogenizing, and the conditioning reaction system 2 can be protected from the influence of feed changes through sorting;

[0045] Conditioning: In the conditioning reaction system 2, the oily sludge is heated to 50-180°C by a heat source, and the sludge is tempered by physical and chemical methods to initially reduce the moisture content of the sludge and reduce ...

Embodiment 2

[0053] The difference from the above-mentioned embodiment 1 is that, according to image 3 As shown, in step d, the heat generated by the combustion of the smokeless combustion device 7 is divided into two parts, one part is used to heat the superheated steam generated by the steam generator 6, and the other part enters the external heating area of the thermal desorption system 4 along with the high-temperature gas 41 for indirect heating.

Embodiment 3

[0055] The difference from the above-mentioned embodiment 2 is that, according to Figure 4 As shown, in the tempering stage in step a, the heat source is provided through the heat exchanger 10, the heat transfer oil is arranged in the heat exchanger 10, and the heat exchanger 10 is arranged between the thermal desorption system 4 and the flue gas treatment system 8, and the heat The tail gas generated by the desorption system 4 heats the heat transfer oil in the heat exchanger 10. During the sorting stage in step a, the heat transfer oil is also passed into the foreign matter sorting system 1 for heating, and the heating temperature is 45°C-90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com