Multi-stage composite crusher

A composite crusher and frame technology, which is applied in the direction of grain processing, etc., can solve the problems of affecting the service life of the crushing device, damage to the crushing device, and different sizes of materials, and achieve the effects of high cost performance, improved efficiency, and large crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The multi-stage compound crusher of the present invention will be further described below according to the drawings and embodiments.

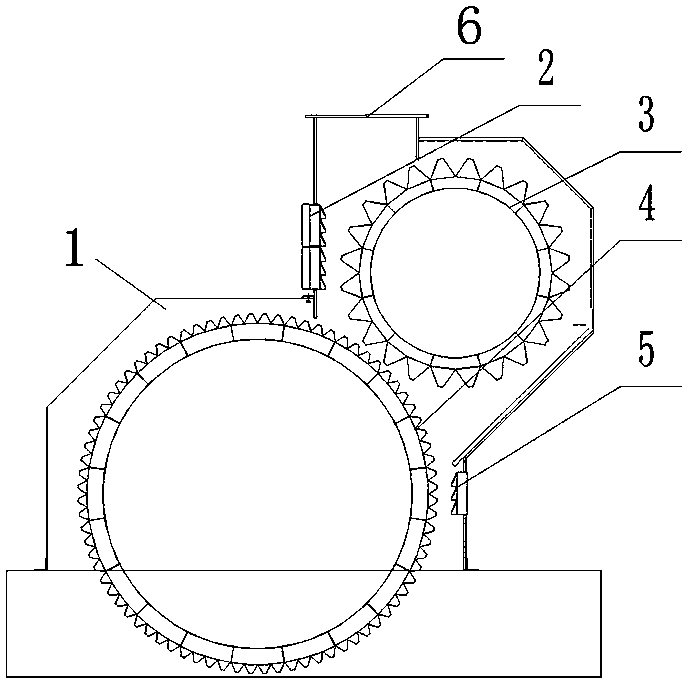

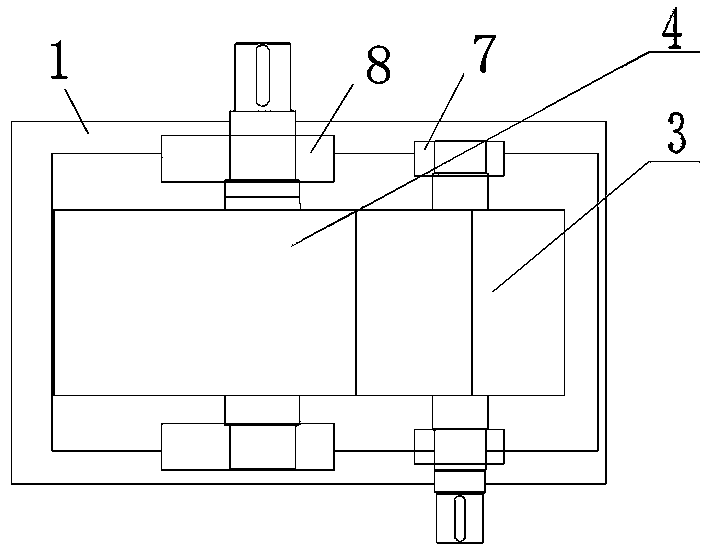

[0017] In this embodiment, the above movable toothed roller 3 rotates counterclockwise as an example, as figure 1 with figure 2 As shown, the multi-stage compound crusher includes a frame 1, an upper fixed tooth plate 2, an upper movable toothed roller 3, a lower movable toothed roller 4 and a lower fixed toothed plate 5, and the upper fixed toothed plate 2 is arranged on the upper On the left side of the movable toothed roller 3, the upper fixed toothed plate 2 is arranged close to the axis level of the upper movable toothed roller 3, and the rack side of the upper fixed toothed plate 2 is arranged towards the upper movable toothed roller 3; The lower movable toothed roller 4 is arranged obliquely below the left side of the upper movable toothed roller 3, the lower fixed toothed plate 5 is arranged on the right side of the lower movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com