Crusher rotor block and crusher

A rotor body and crusher technology, applied in the field of machinery, can solve the problems of increasing the distance between the hammer head and the discharge grating bar, reducing the output yield, and fast wear of the hammer head, so as to increase the crushing ratio, reduce weight, The effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

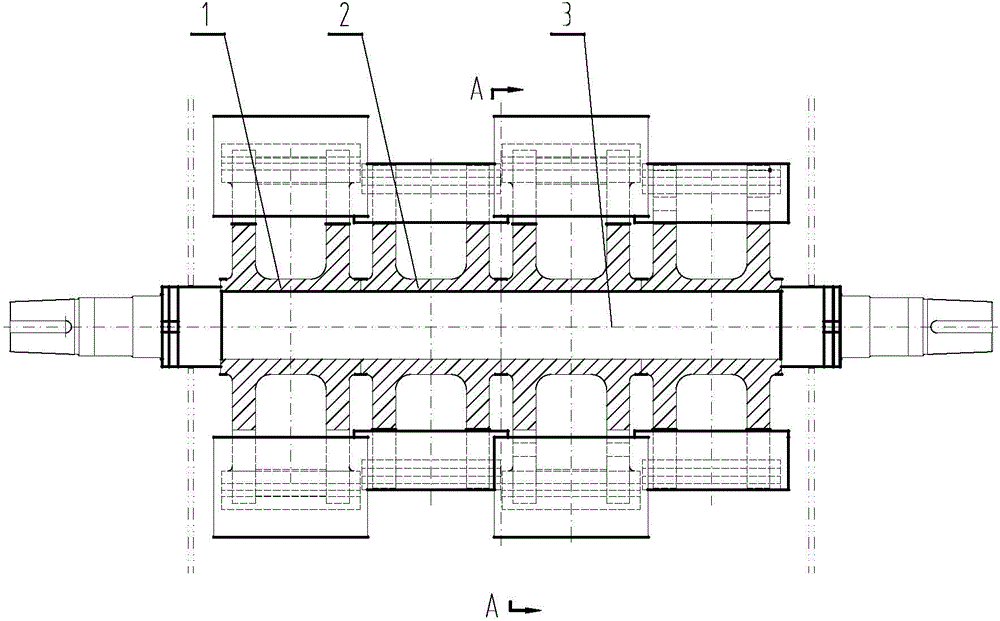

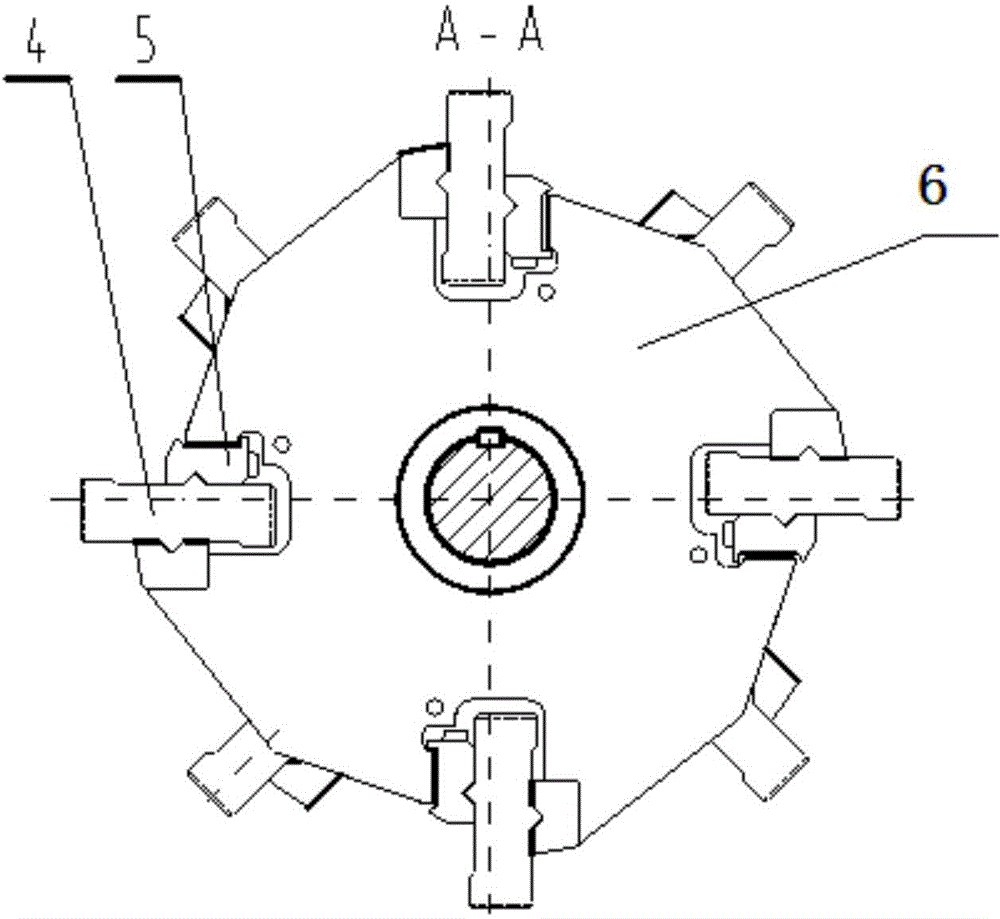

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention is composed of multiple sets of rotor disks 16, each rotor disk 1 is provided with an integral web 6, and multiple sets of blow bar support structures 5 are provided on the web 6; each rotor disk 1 is fixedly mounted on On the same shaft 3, there is a certain angle difference between each rotor disk 1.

[0019] The optimal angle between the blow bars of each rotor disk 1 is 45°.

[0020] The support structure 5 and the blow bar 4 are fixed through a keyway.

[0021] In order to ensure consistent crushing efficiency of the crusher, the number of hammerheads installed on each group of rotor disks is inconsistent according to different materials. Such a structure can ensure a greater probability of collision between materials, thereby improving the crushing efficiency.

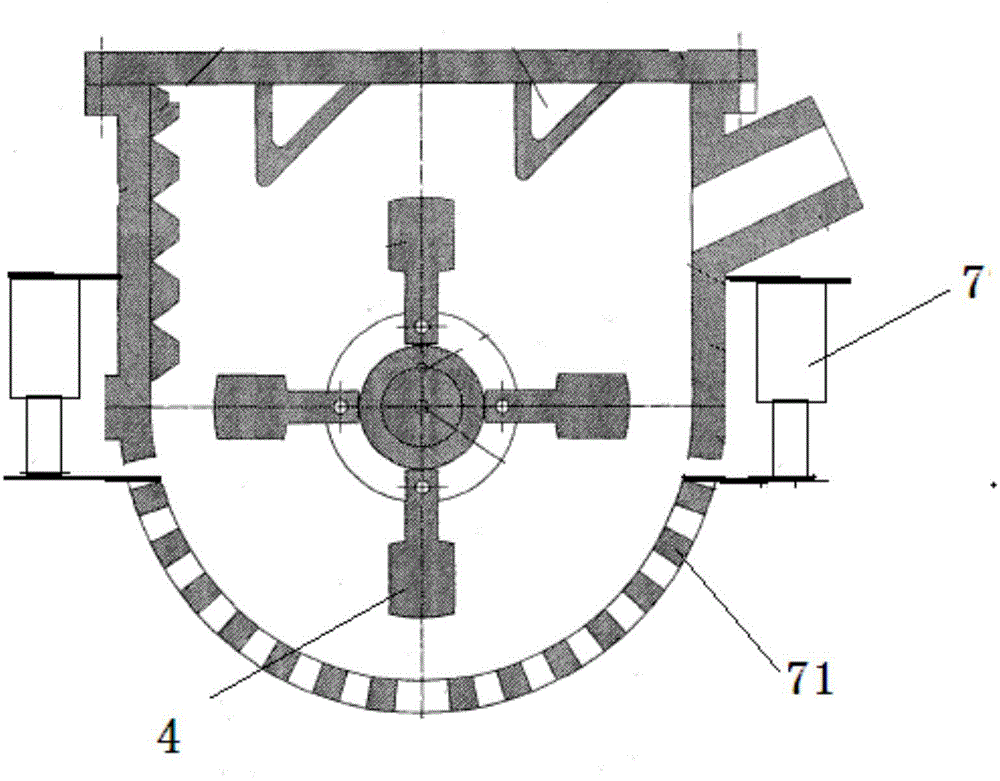

[0022] Such as image 3 As shown, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com