Geological survey ore crushing device

A technology of ore crushing and geological survey, applied in grain processing, etc., can solve the problems of uneven particle size, low production efficiency, small crushing ratio, etc., and achieve the effect of short working time, high production efficiency and large crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

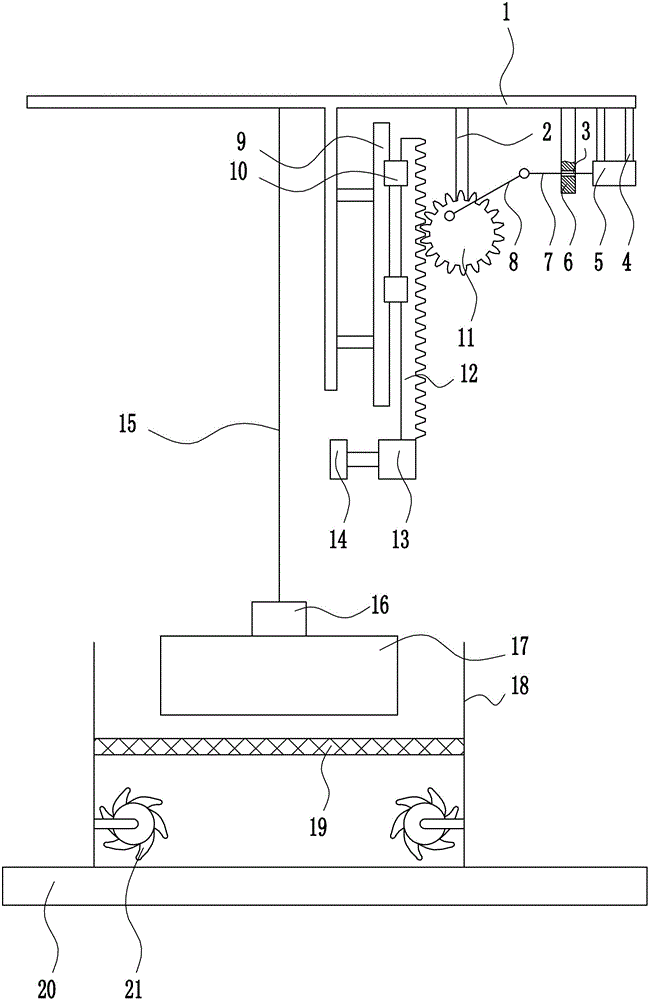

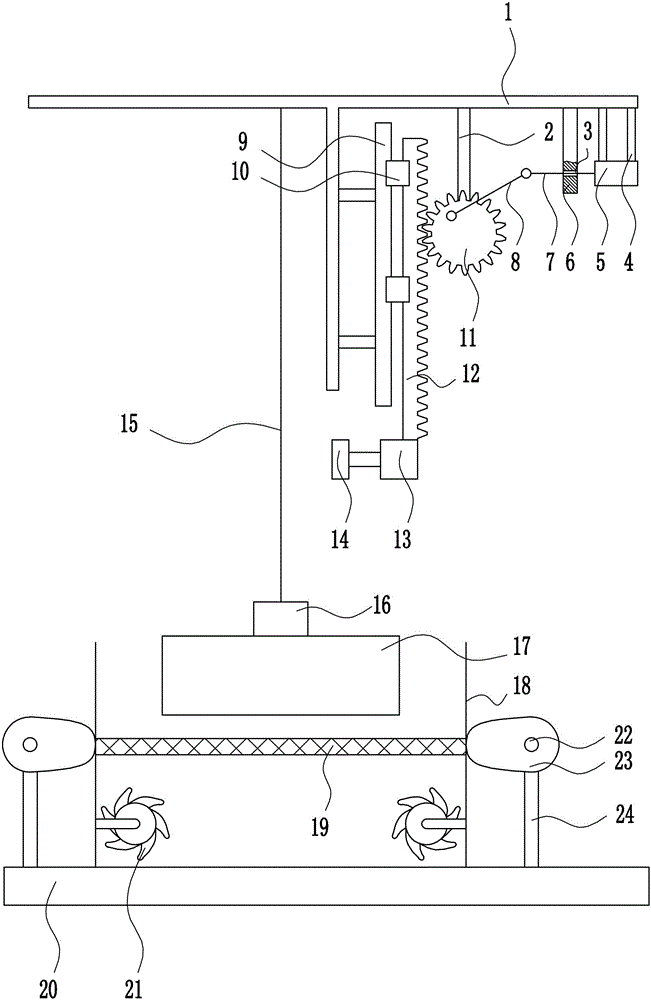

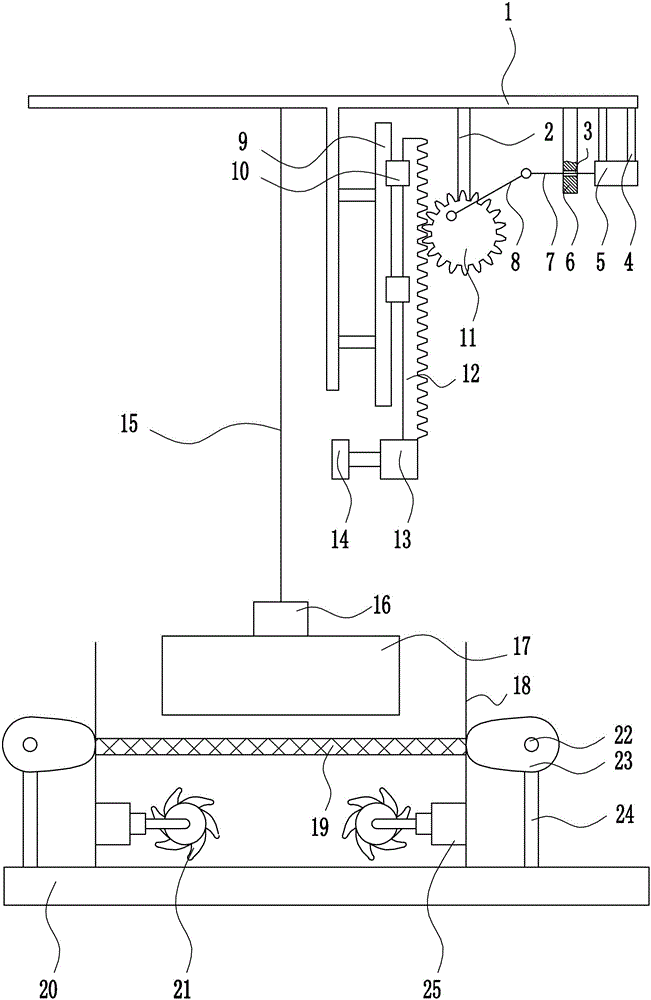

Embodiment 1

[0031] A geological prospecting ore crushing device, such as Figure 1-4 As shown, it includes a bracket 1, a first pole 2, a second pole 4, a first electric push rod 5, a guide block 6, a first connecting rod 7, a second connecting rod 8, a slide rail 9, and a slider 10 . There is a crushing tank 18, the left and right sides of the crushing tank 18 are equipped with electric grinding wheels 21, the grinding tank 18 is provided with a wire mesh 19, and the wire mesh 19 is located above the electric grinding wheel 21, and the inner top of the bracket 1 is arranged in turn from left to right. Stay rope 15, first pole 2, guide block 6 and second pole 4, stay rope 15 bottoms are provided with iron block 16, and iron block 16 bottoms are connected with weight 17, and weight 17 is positioned at the barbed wire mesh in crushing tank 18 19, the bottom end of the first pole 2 is provided with a gear 11, the guide block 6 is provided with a small hole 3, the bottom end of the second po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com