Inertial ball mill

An inertia ball milling and grinding technology, applied in the industrial field, can solve the problems of bulky and heavy body, no further increase, heat waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

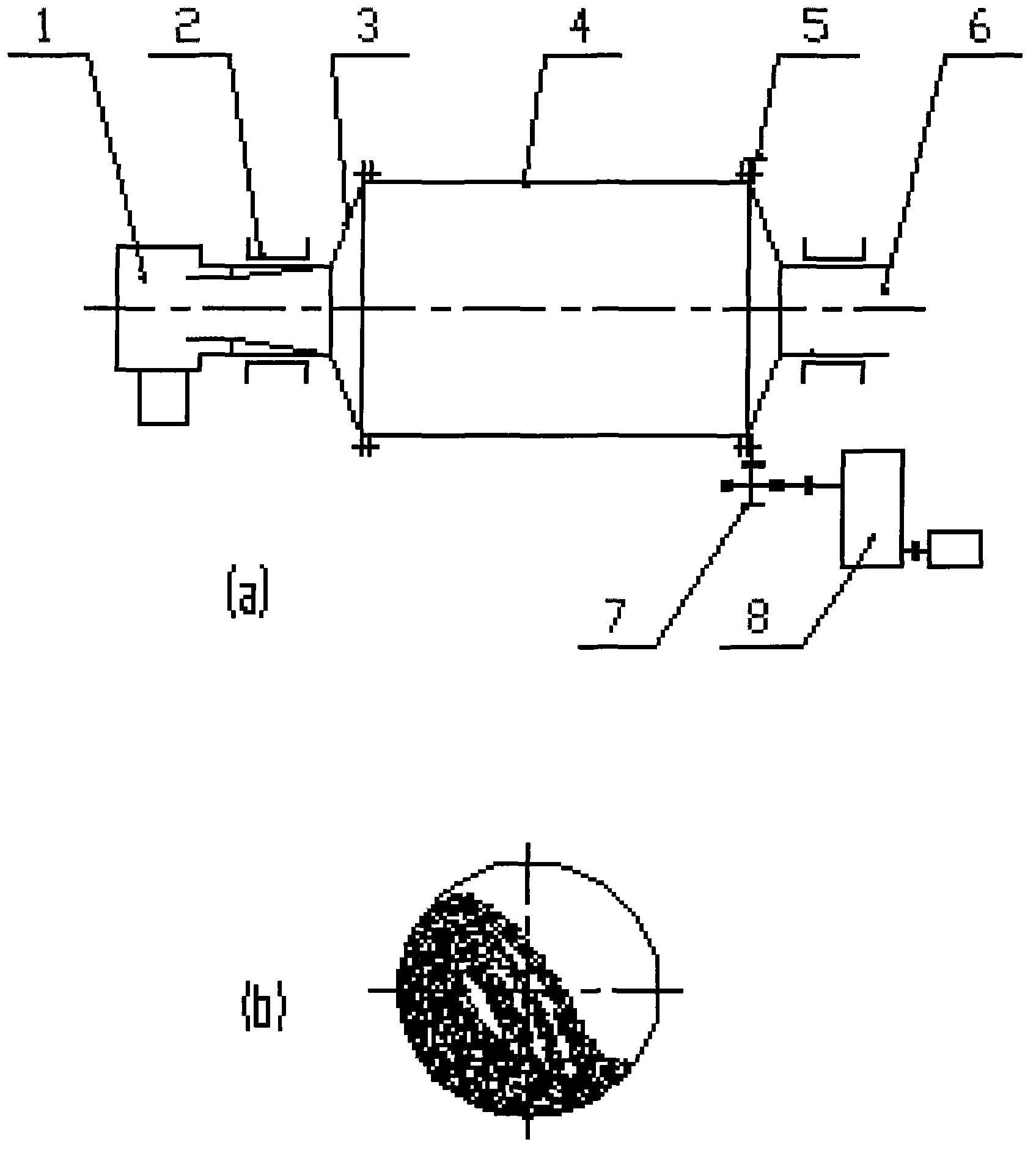

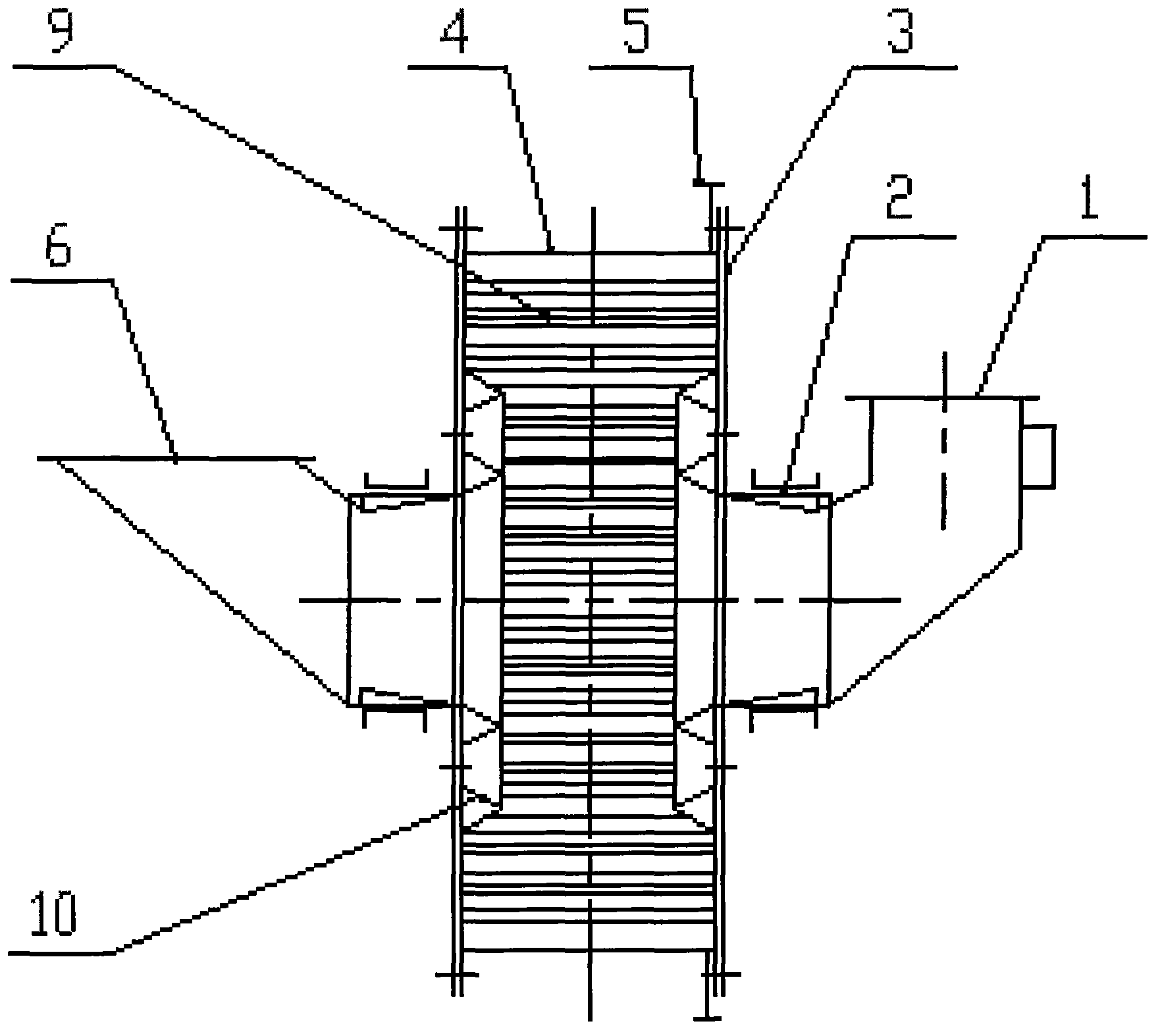

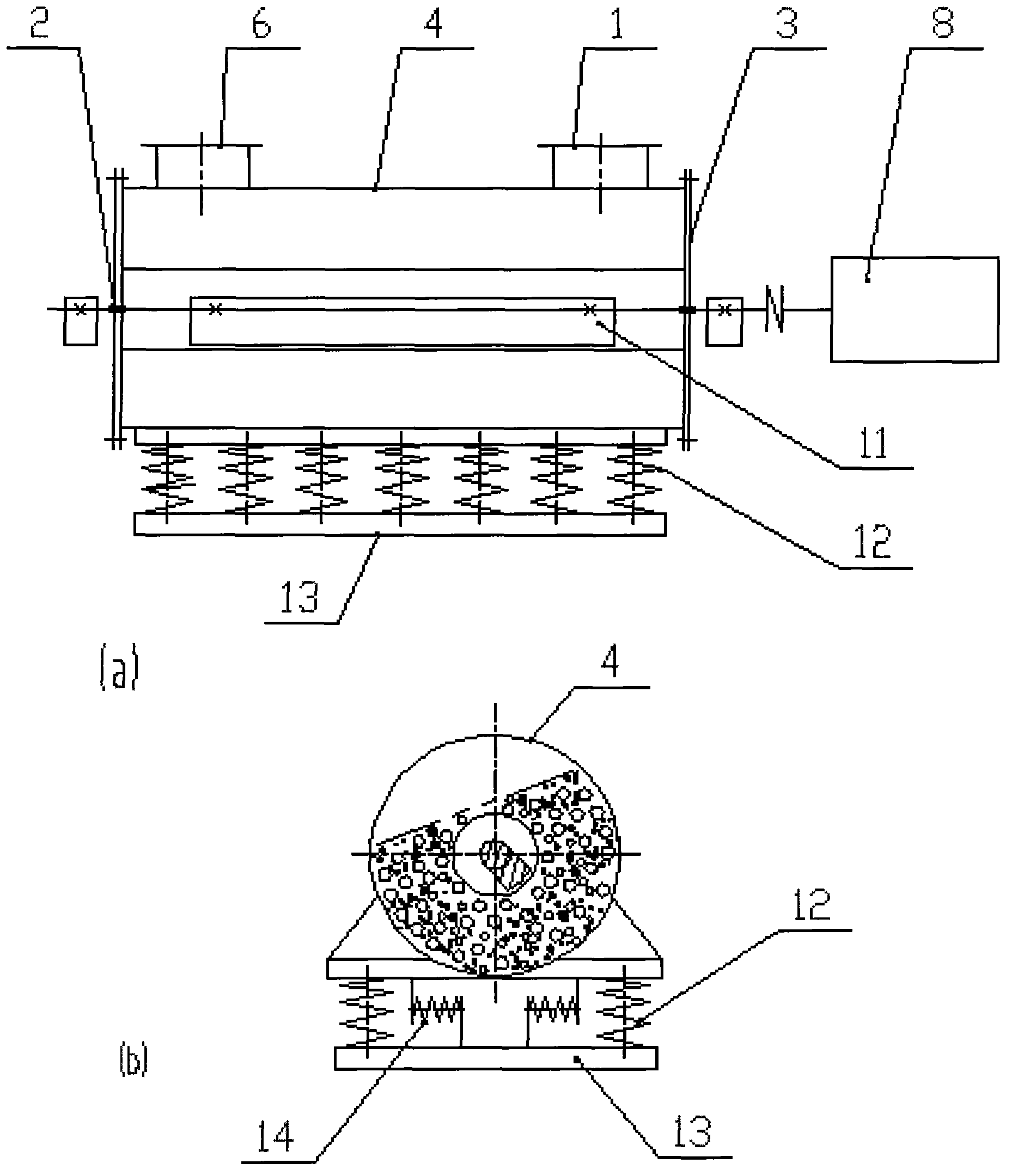

[0041] According to the present invention Figure 4 to Figure 9 According to the technical solution, the cylinder 4 is installed on the elastic base composed of the spring 12 and the base 13, the cylinder 4 is fixed, and two vibrating bodies 17 and an intermediate ring 18 are arranged in the cylinder, and the intermediate ring is located between the two vibrating bodies. Between them, each vibrating body 17 is flexibly connected to the cylinder body through three pull cables 25 at 120° to each other. The flexible shaft II21 connects the main shafts 31 of the two vibrating bodies 17 together, and ensures that the eccentric blocks at the two proximal ends The direction is the same, and the flexible shaft I15 connects the main shaft 31 of the left vibrating body with the output shaft of the transmission device 8 outside the cylinder. The transmission device 8 can decide whether to install a deceleration device according to the needs, and the intermediate ring 18 passes through its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com