Shaping type crusher

A crusher and crushing mechanism technology, applied in grain processing and other directions, can solve the problems of low work efficiency, unreasonable structure, easy wear and tear of the whole machine parts, etc., and achieve the effects of high production efficiency, good grain shape and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

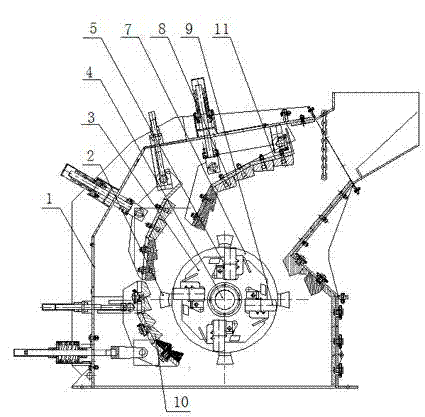

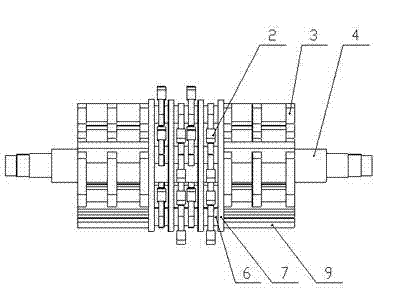

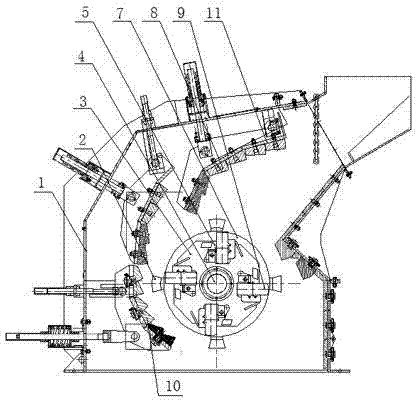

[0012] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , 2 As shown, the crusher includes a body 1, a crushing mechanism and a counterattack mechanism, and a crushing mechanism and a counterattack mechanism that cooperate with each other are installed in the body 1 to form a crusher; The main shaft 4 is installed on the body 1 through bearings and tension sleeves, and the hammer rotor and counter rotor are installed on the main shaft 4 in the body 1; the hammer rotor includes a circular flower disc 7 and a hammer Head 2, circular faceplate 7 are installed in the center of main shaft 4, a group of hammerheads 2 are installed on the circular faceplate 7 through pin holes 6 through pin holes, and hammerheads 2 are symmetrically distributed along the main shaft 4 on the circular faceplate 7; The counterattack rotor described above includes an eight-sided faceplate 3 and an im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com