High-crushing-ratio double-tooth-roller crusher

A crusher and crushing ratio technology, which is applied in the field of mining machinery and equipment, can solve the problems of easy wear and bending of toothed rolls, low crushing, and small number of roll teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manner of the present technology is further described below according to the accompanying drawings:

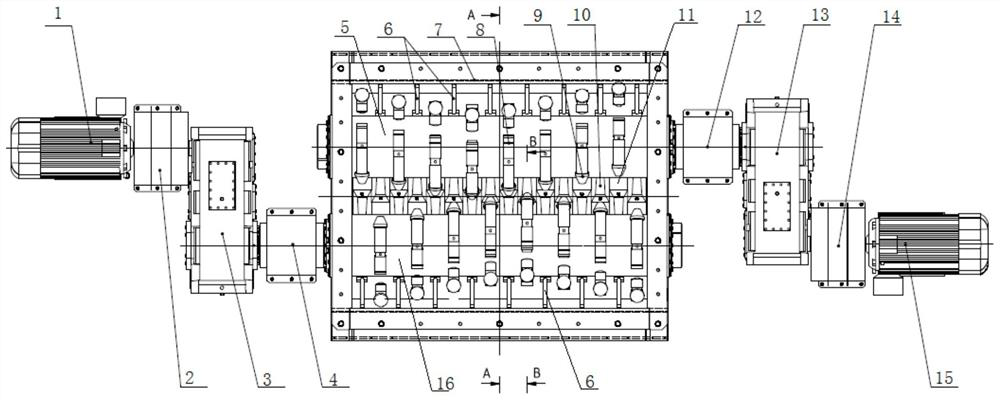

[0050] Such as figure 1 with Figure 12 As shown, a double-toothed roller crusher with a high crushing ratio includes a crusher housing 7, a first toothed roller shaft 5, a second toothed roller shaft 16, a first coupling 12, a second coupling 4, a first A reducer 13, a second reducer 3, a first hydraulic coupler 14, a second hydraulic coupler 2, a first motor 15, a second motor 1, a hydraulic jack 24, a bolt bracket 27, and a broken beam fixing bolt 26 , Adjust the shim 28, the broken beam 11 and the lower broken tooth 10.

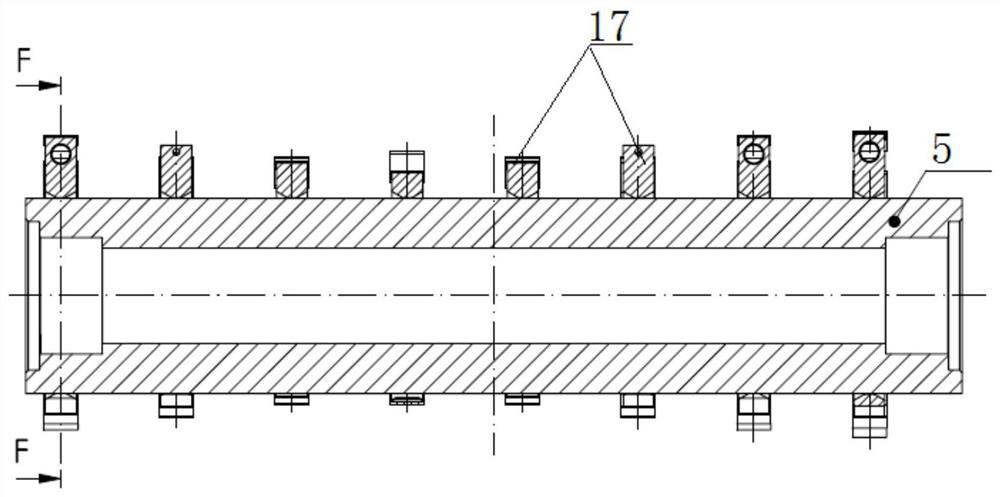

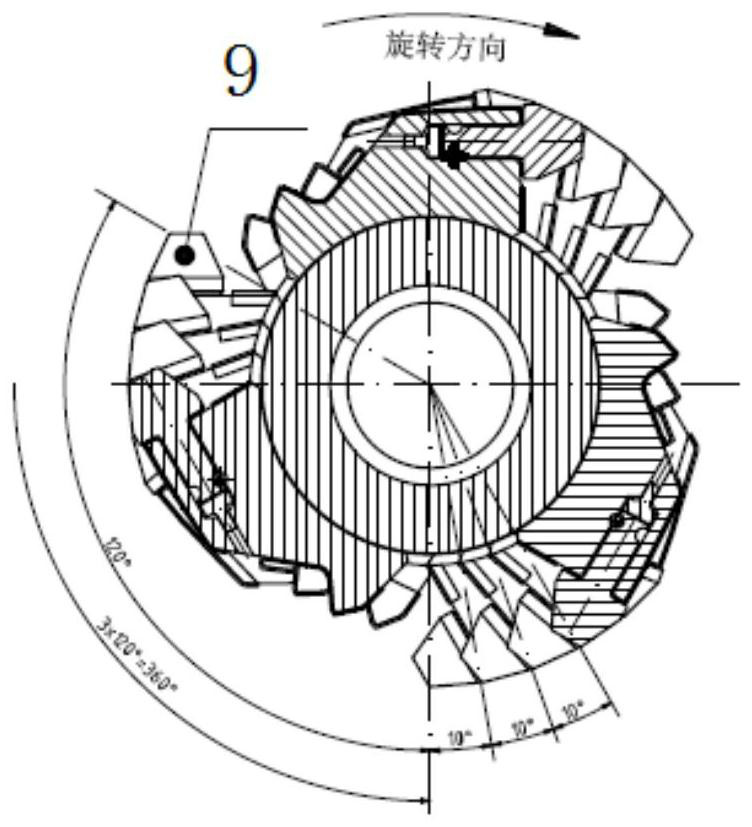

[0051] Such as figure 2 with image 3 As shown, the first toothed roller shaft 5 is equidistantly distributed with multiple rows of roller teeth 17 along the axial direction, and the starting angles of the multiple rows of roller teeth 17 are gradually decreased by 10 from the center of the first toothed roller shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com