Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "Broken tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

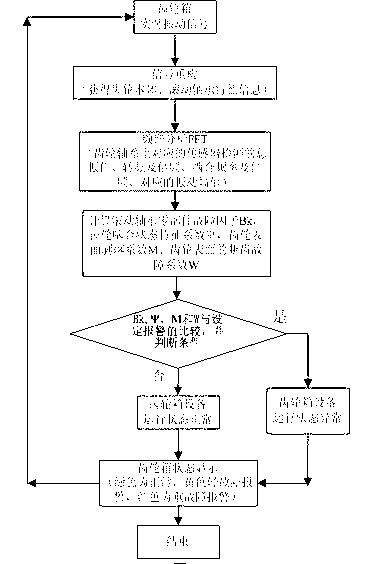

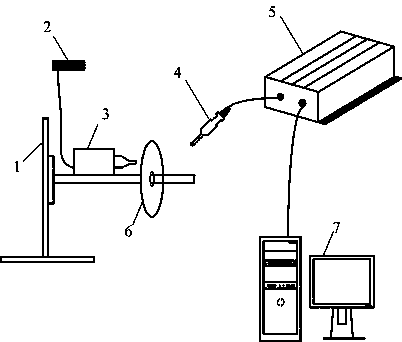

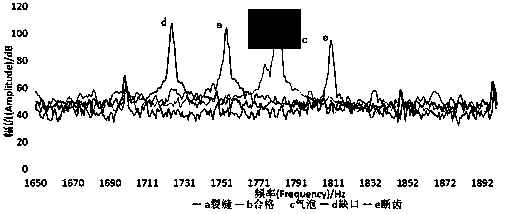

On-line monitoring and early-warning method for operating state of gearbox

ActiveCN103134676AReal-time monitoring of running statusGuaranteed uptimeMachine gearing/transmission testingMachine bearings testingVibration amplitudeFrequency spectrum

The invention relates to an on-line monitoring and early-warning method for the operating state of gearbox equipment. A device with the method comprises a gearbox, rolling bearings and vibration sensors which are arranged on bearing seats and used for monitoring vibration signals of the rolling bear. The method includes: collecting signals of the vibration sensors and reconstructing the signals; carrying out spectral analysis on the total vibration value, the rotation frequency and the multiplication frequency, the mesh frequency and the multiplication frequency and the corresponding vibration amplitude which are all detected by a corresponding sensor on a gear shaft set; and calculating fault factors of parts of the rolling bearings, stripping coefficients of surfaces of gears and fault factors of broken teeth on the surfaces of the gears to be compared with preset warning values respectively, if the preset values are exceeded, the gearbox operates in an abnormal state, if the preset values are not exceeded, the gearbox operates in a normal state, and the results are displayed for reference by a maintainer. The on-line monitoring and early-warning method is developed to judge and locate the gear faults with multi-parameter characteristics to ensure the normal operation of the gearbox equipment.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Hardened-tooth-surface gear and hardened-tooth-surface gear repair technology

ActiveCN103075490AReduce scrap rateReduce noisePortable liftingMetallic material coating processesSocial benefitsRejection rate

Owner:WUHAN KAIMING HIGH TECH

Special welding electrode for surfacing and repairing broken teeth of cast steel gear

InactiveCN101920414AReduce hardnessLow costWelding/cutting media/materialsSoldering mediaCrack resistanceHigh carbon

The invention relates to a welding electrode for surfacing and repairing broken teeth of a cast steel gear, belonging to the materials science and engineering field. The welding electrode comprises the following chemical components: 45-55wt% of marbles, 4-7wt% of chalk, 20-30wt% of fluorite, 1-3wt% of quartz, 2-4wt% of rutile, 6-10wt% of ferrotitanium, 3-5wt% of high carbon ferromanganese, 1-2wt% of ferrosilicon, 2-4wt% of yttrium oxide and 1-3wt% of metallic nickel. The core wire is H08A steel welding wire. An adopted water glass binder has modulus of 2.7-3.0 and concentration (Baume degree) of 48-50. The surfacing welding electrode can be used for surfacing and repairing the broken teeth of the cast steel gear without preheating before welding and heat treatment after welding. The surfacing metal has higher crack resistance, certain hardness (HB160-260) and abrasive resistance and simultaneously certain processability.

Owner:YANSHAN UNIV

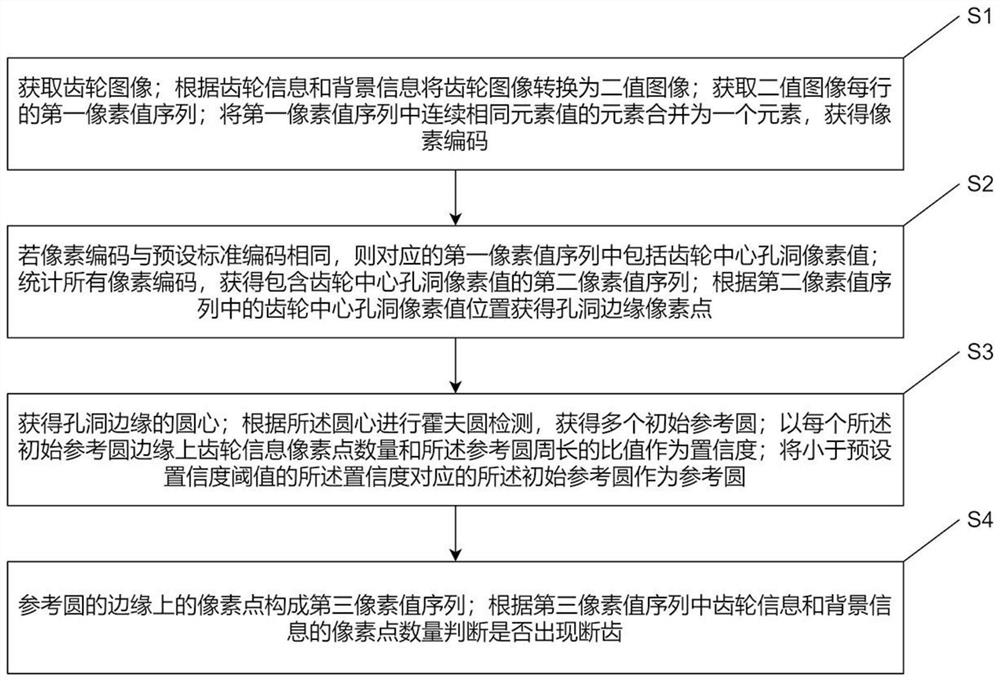

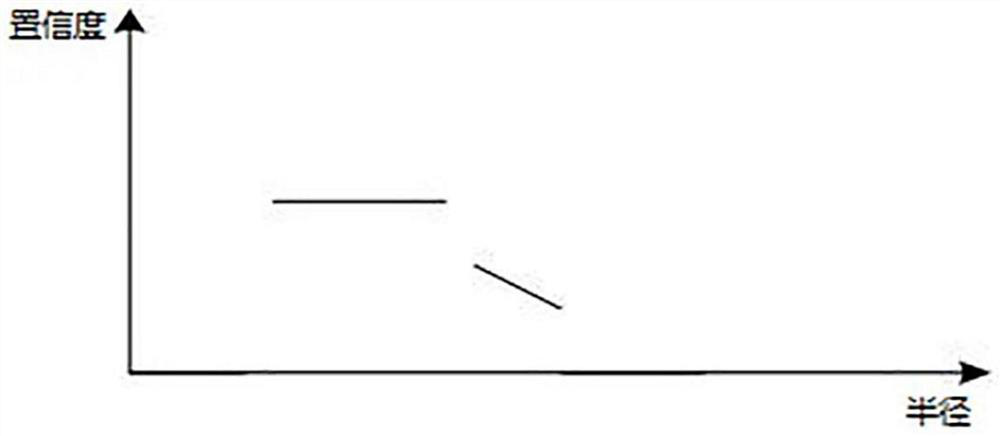

Gear broken tooth detection method based on Hough circle detection

ActiveCN114764790AQuick analysisShorten the lengthImage enhancementImage analysisPattern recognitionGraphics

The invention relates to the technical field of data processing, in particular to a gear broken tooth detection method based on Hough circle detection. According to the method, a pixel code of each line is obtained through line-by-line analysis of a gear binary image; and obtaining a second pixel value sequence corresponding to the pixel code which is the same as the standard code. According to the gear center hole pixel value position in the second pixel value sequence, hole edge pixel points are obtained, and then the circle center is obtained. Performing Hough circle detection on the circle center to obtain a plurality of initial reference circles, and screening out reference circles according to the number of gear information on the edges of the initial reference circles. According to the number of the pixel points of the gear information and the background information on the edge of the reference circle, whether tooth breakage occurs is judged. According to the method, the edge acquisition process is simplified in pattern recognition by combining related electronic equipment, and the detection of the position and degree of the broken tooth is quickly and effectively realized through the analysis of the pixel value on the reference circle.

Owner:河北鹰眼智能科技有限公司

Special welding electrode for surfacing and repairing broken teeth of cast iron gear

InactiveCN101920404AWelding/cutting media/materialsWelding/soldering/cutting articlesCrack resistanceHigh carbon

The invention relates to a special welding electrode for surfacing and repairing broken teeth of a cast iron gear, belonging to the materials science and engineering field. The welding electrode comprises the following chemical components: 35-50wt% of marbles, 3-6wt% of chalk, 20-30wt% of fluorite, 1-3wt% of quartz, 2-4wt% of rutile, 4-7wt% of ferrotitanium, 2-5wt% of ferromolybdenum, 1-3wt% of high carbon ferromanganese, 1-3wt% of ferrosilicon, 4-7wt% of yttrium oxide and 10-14wt% of metallic nickel. The core wire is H08A steel welding wire. An adopted water glass binder has modulus of 2.7-3.0 and concentration (Baume degree) of 48-50. The surfacing welding electrode can be used for surfacing and repairing the broken teeth of the cast iron gear without preheating before welding and heat treatment after welding. The surfacing metal has higher crack resistance and has proper hardness (HB120-220) and abrasive resistance through alloying.

Owner:YANSHAN UNIV

Large spur gear online welding repairing process

ActiveCN108555468AGuaranteed cycle qualityShorten maintenance timeWelding apparatusSurface layerGear wheel

The invention discloses a large spur gear online welding repairing process. The large spur gear online welding repairing process is characterized in that the process is performed according to preparation before welding, welding treatment, and treatment after welding. The welding treatment comprises weldment position adjusting and pre-welding washing, welding broken tooth part flattening and weldment heating, transition base coat welding, and surfacing layer welding; and after welding is finished, comparing is performed through a pre-manufactured tooth template, residual weld joints are cut andflattened through a plasma gouge, then coping is roughly performed through a corner grinding machine, the size of the tooth template is met, and stress is eliminated finally. The large spur gear online welding repairing process has the advantages that online welding repairing of the to-be-welded gear part is finished in a narrow space, a spur gear after surfacing meets the operation size throughmanual grinding, the surface of the spur gear has no welding defect, the subsequent operation period quality is ensured, the maintenance time is shortened, the maintenance cost is reduced, the halt loss is reduced, and reasonable assembly and production are guaranteed.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

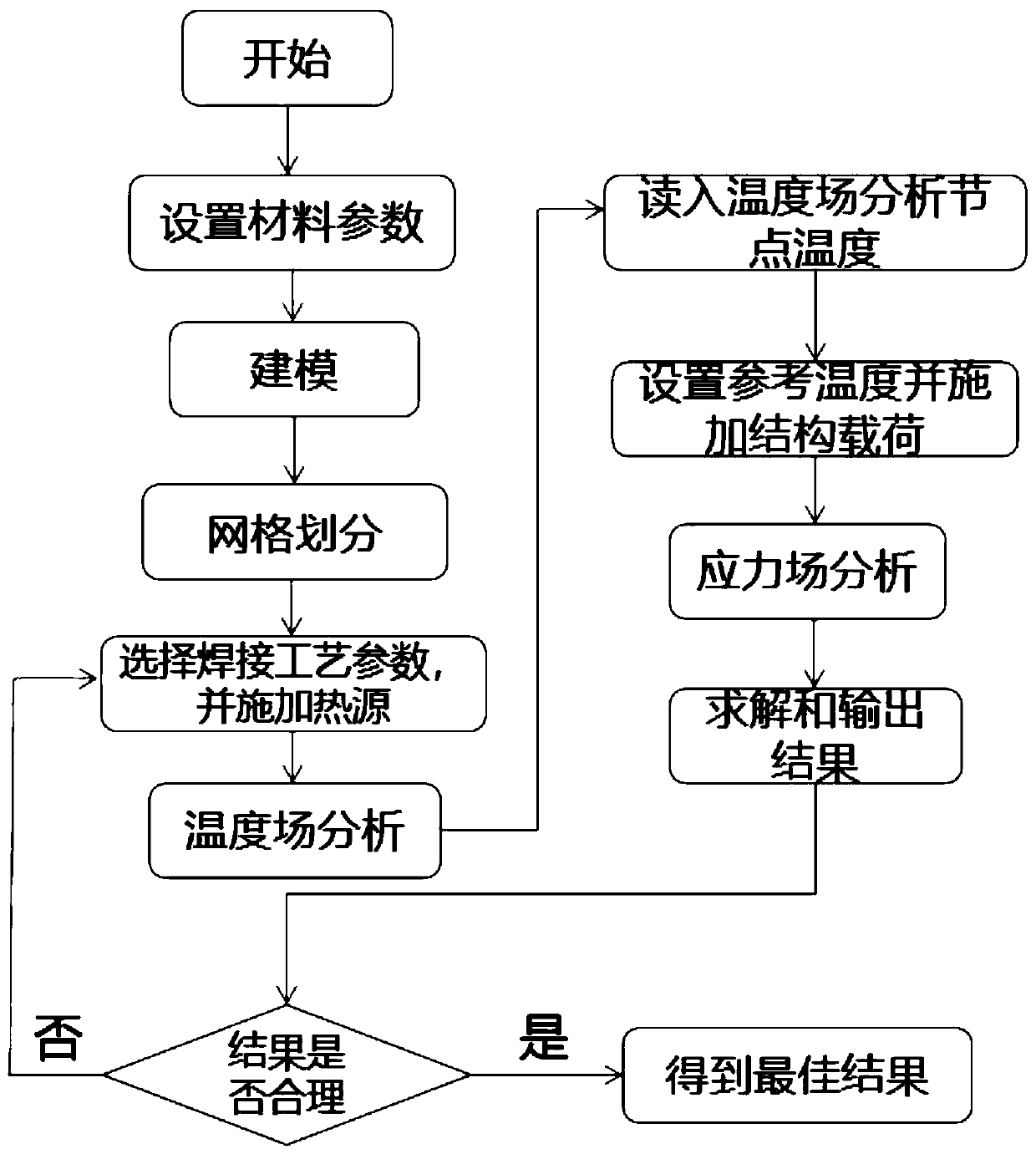

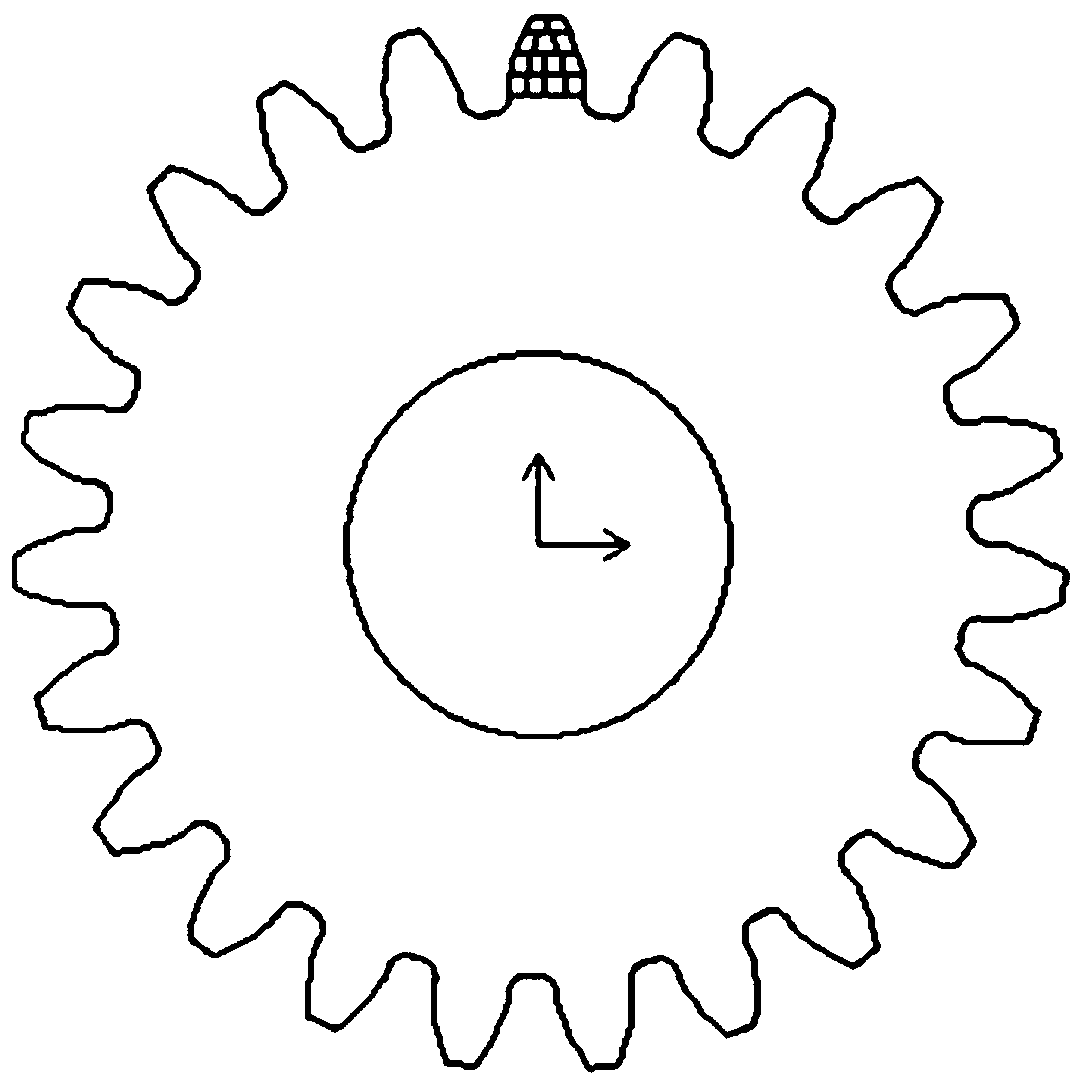

Gear broken tooth laser cladding welding process optimization method based on ansys

ActiveCN110334469AQuality assuranceEfficient repairGeometric CADDesign optimisation/simulationStructure analysisMaterial resources

The invention provides a gear broken tooth laser cladding welding process optimization method based on ansys. The gear broken tooth laser cladding welding process optimization method comprises the steps of S1, determining thermal analysis and stress analysis parameters of a gear material and weld metal powder; S2, determining size parameters of the gear, creating a two-dimensional planar graph ofthe gear, and storing and importing the two-dimensional planar graph into ansys; S3, defining a thermal analysis unit and a structure analysis unit, and then performing mesh generation; S4, taking a heat source model, selecting a heat source calculation formula, and then defining welding process parameters including welding current, voltage, speed and time; S5, on the basis of the step S4, applying a dead unit to a heat source load, wherein the dead unit is used for solving the nonlinear problem of the unit; S6, simulating a temperature field, a stress field and deformation conditions under different welding process parameters by utilizing ansys, and finding out the welding process parameter with the minimum residual stress and deformation. According to the method, the temperature field, the stress field and deformation after gear repairing are directly obtained through a process optimization method. The manpower and material resources are saved, and the cost is reduced.

Owner:FOSHAN UNIVERSITY

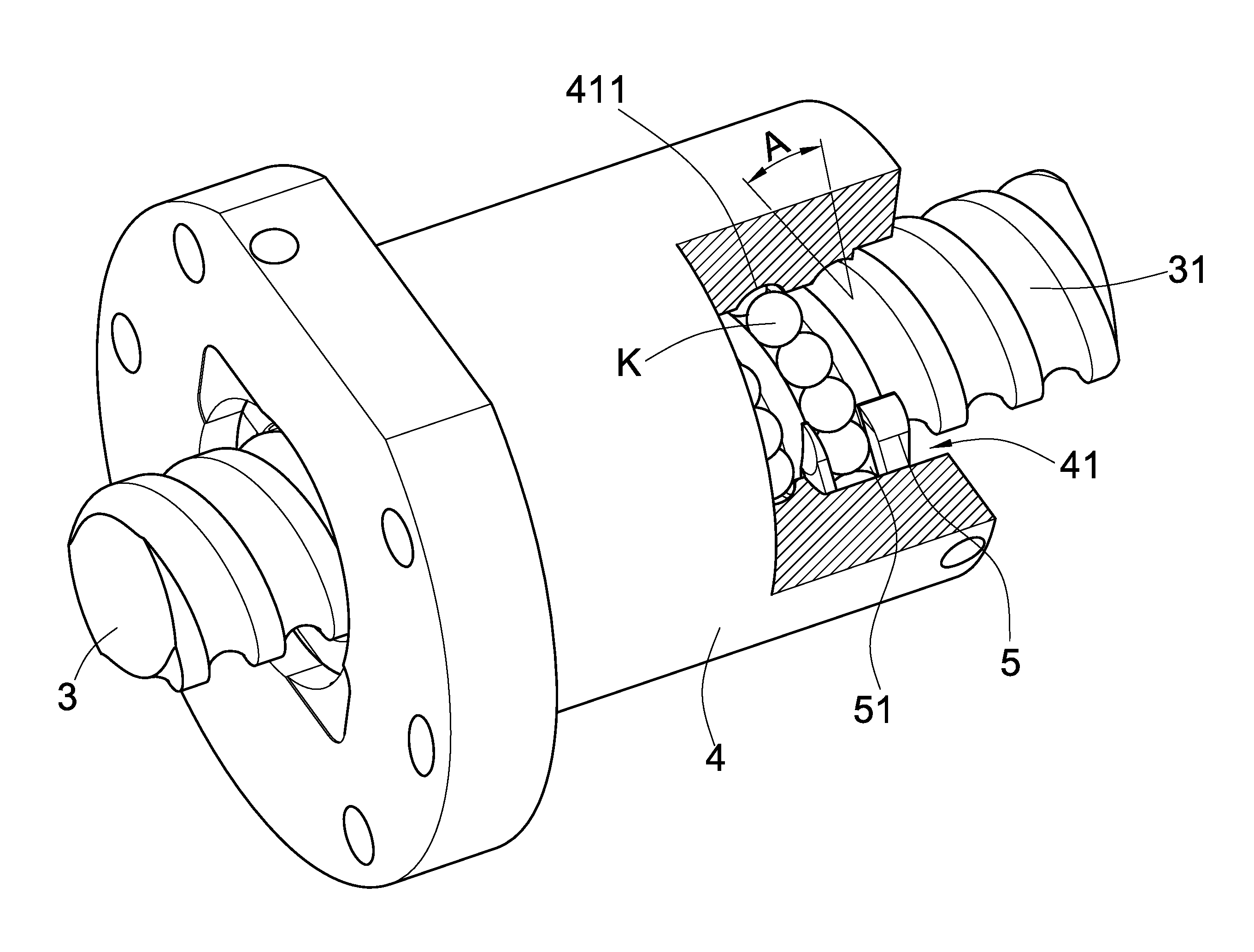

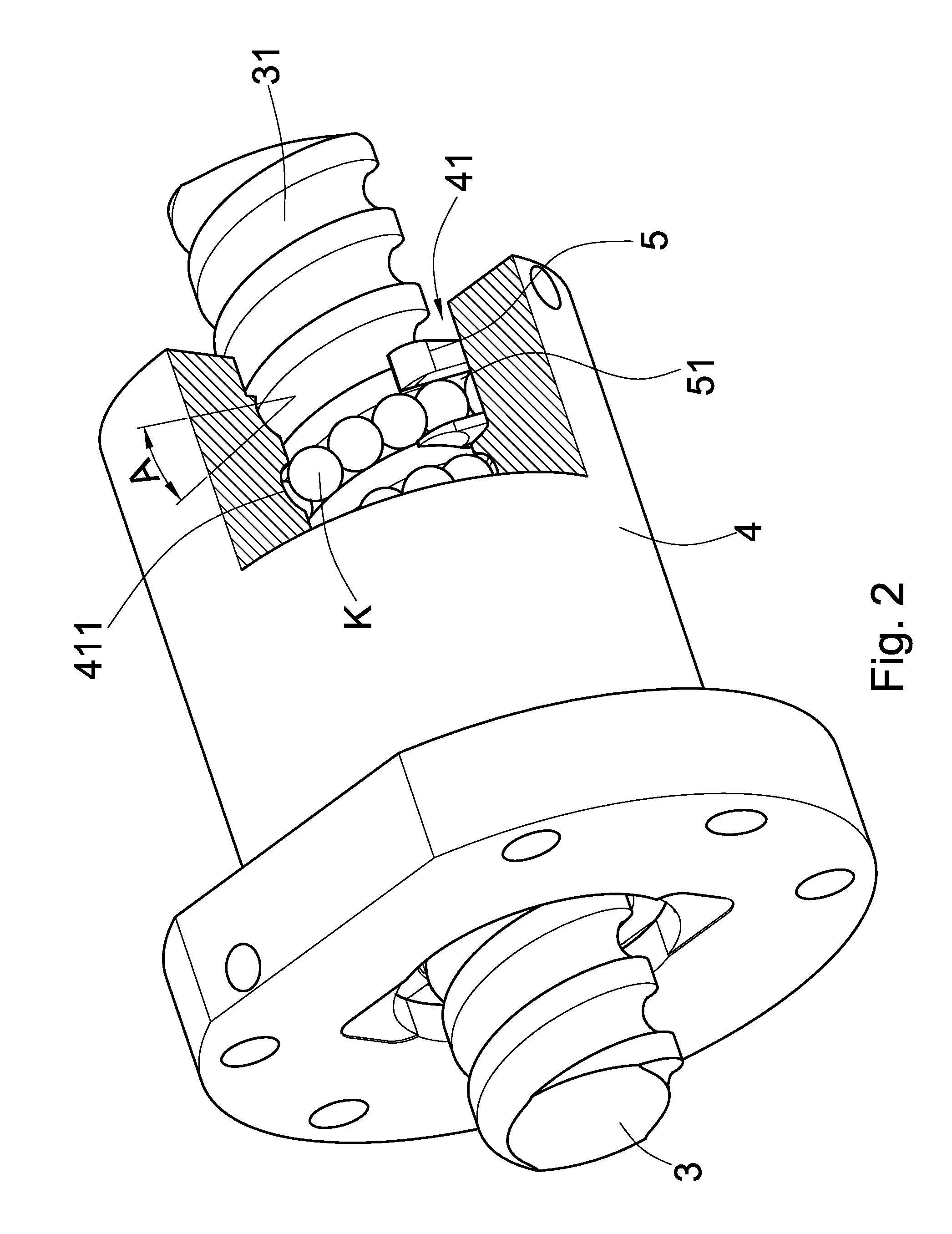

Circulation Element for Ball Screw

ActiveUS20110154926A1Reduce manufacturing costReduce running noiseToothed gearingsPortable liftingBall screwDitch

This invention is revises the cap nut which the custom knows to suppose it to install trough's outline, will cause to install the dadoing to lead (lead angle to be small) lowly or on two above trundle ditch cap nut will not have the broken tooth's question, when will process should install the trough, only need use the face cutter then to process the forming, will reduce the production cost; And return circuit of this invention all establishes in the backflow part, therefore may promote and the cap nut supposes the backflow hole and the load way grade of fit, causes to roll the moving parts movement to be smoother, and reduces the noise production.

Owner:HIWIN TECH

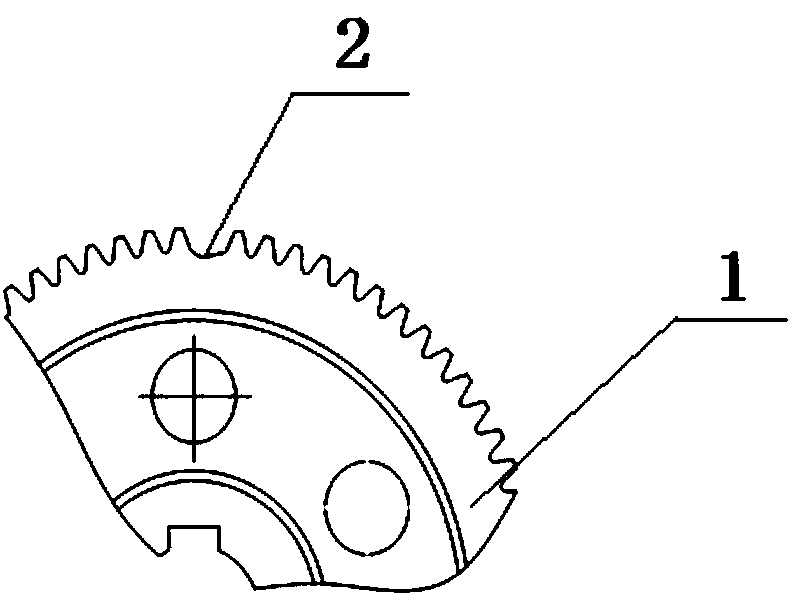

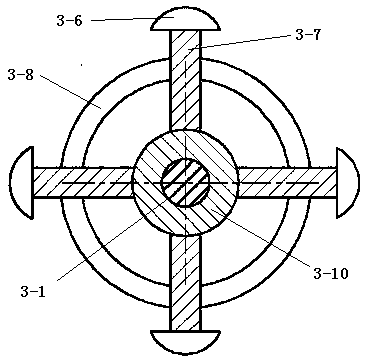

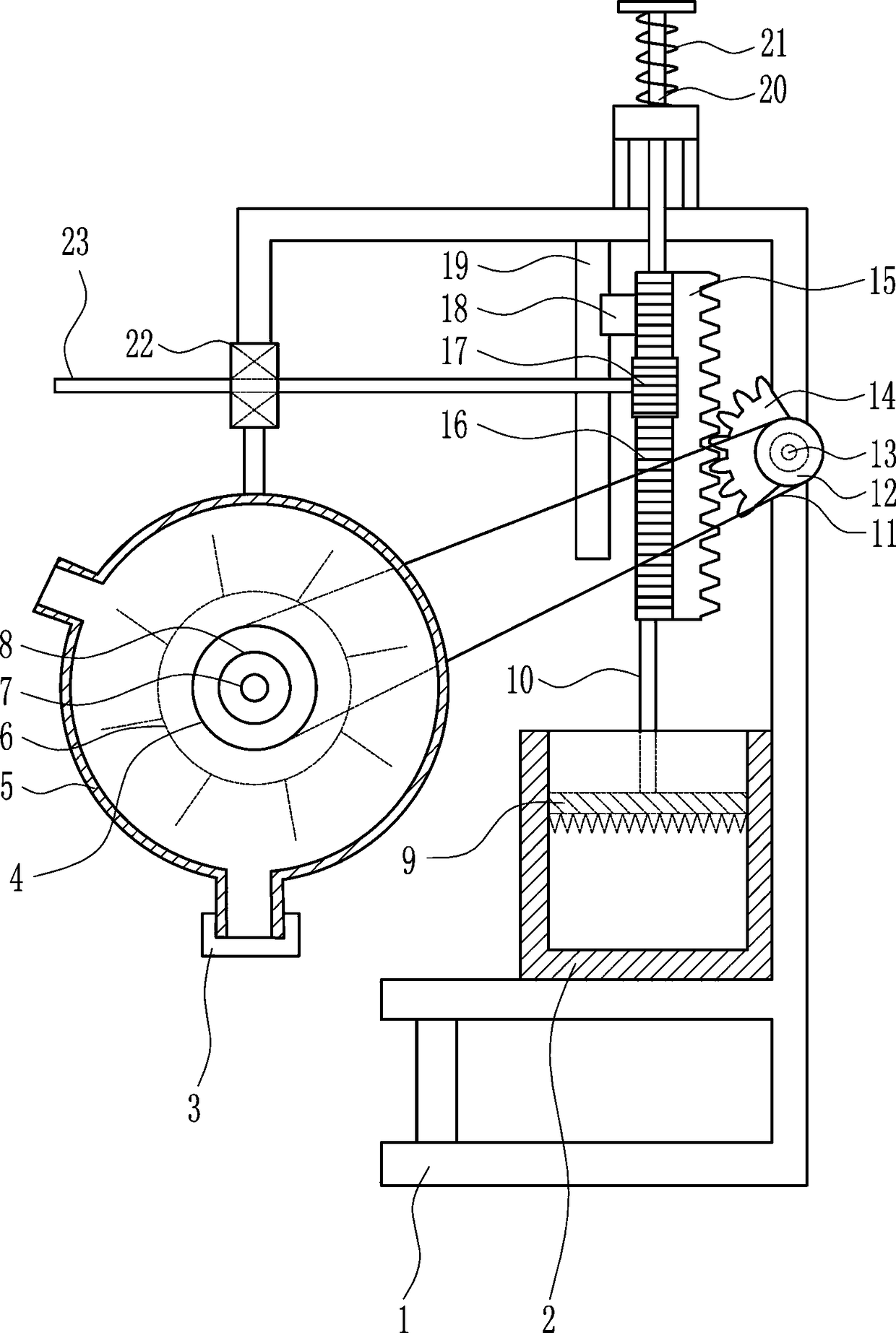

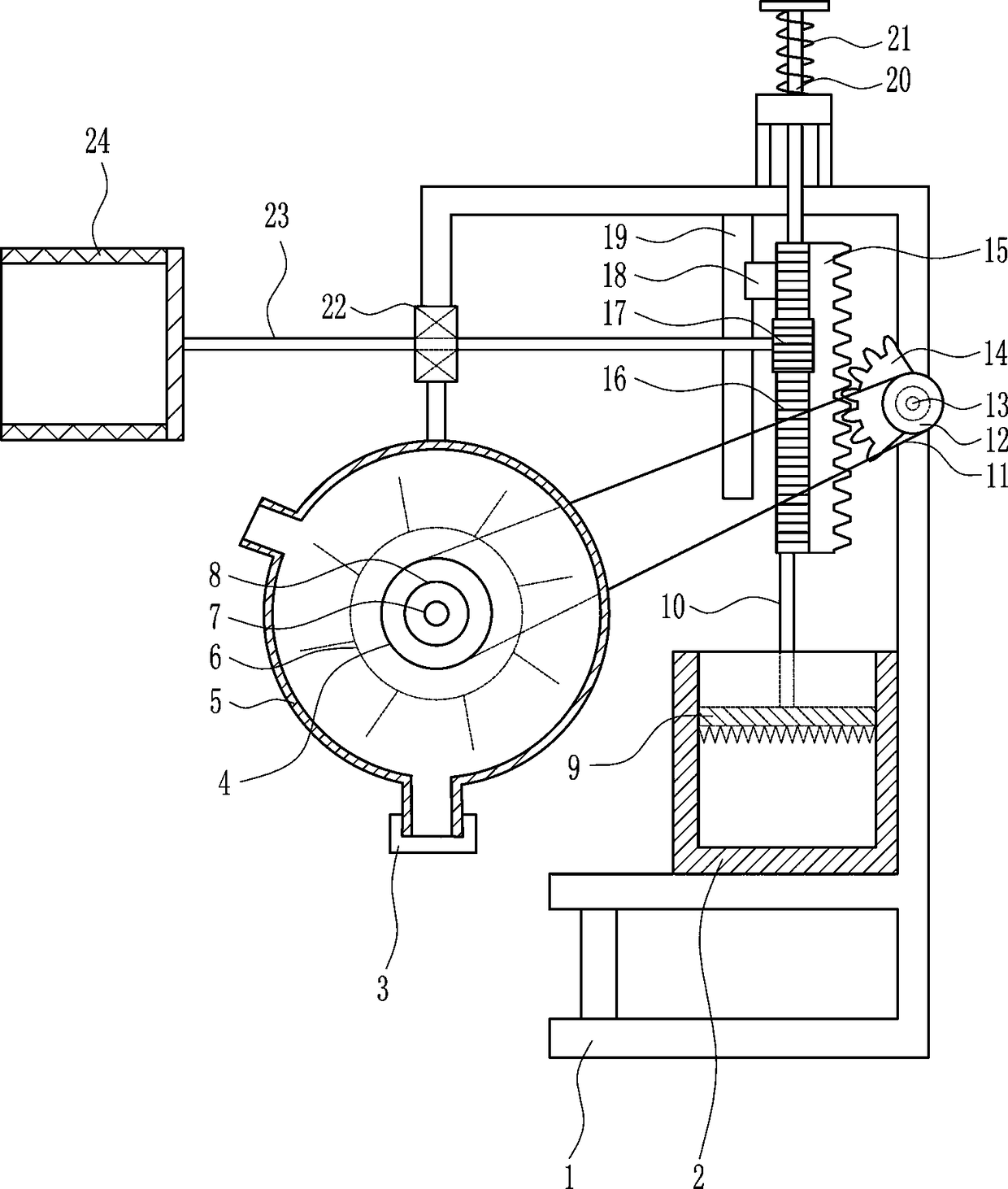

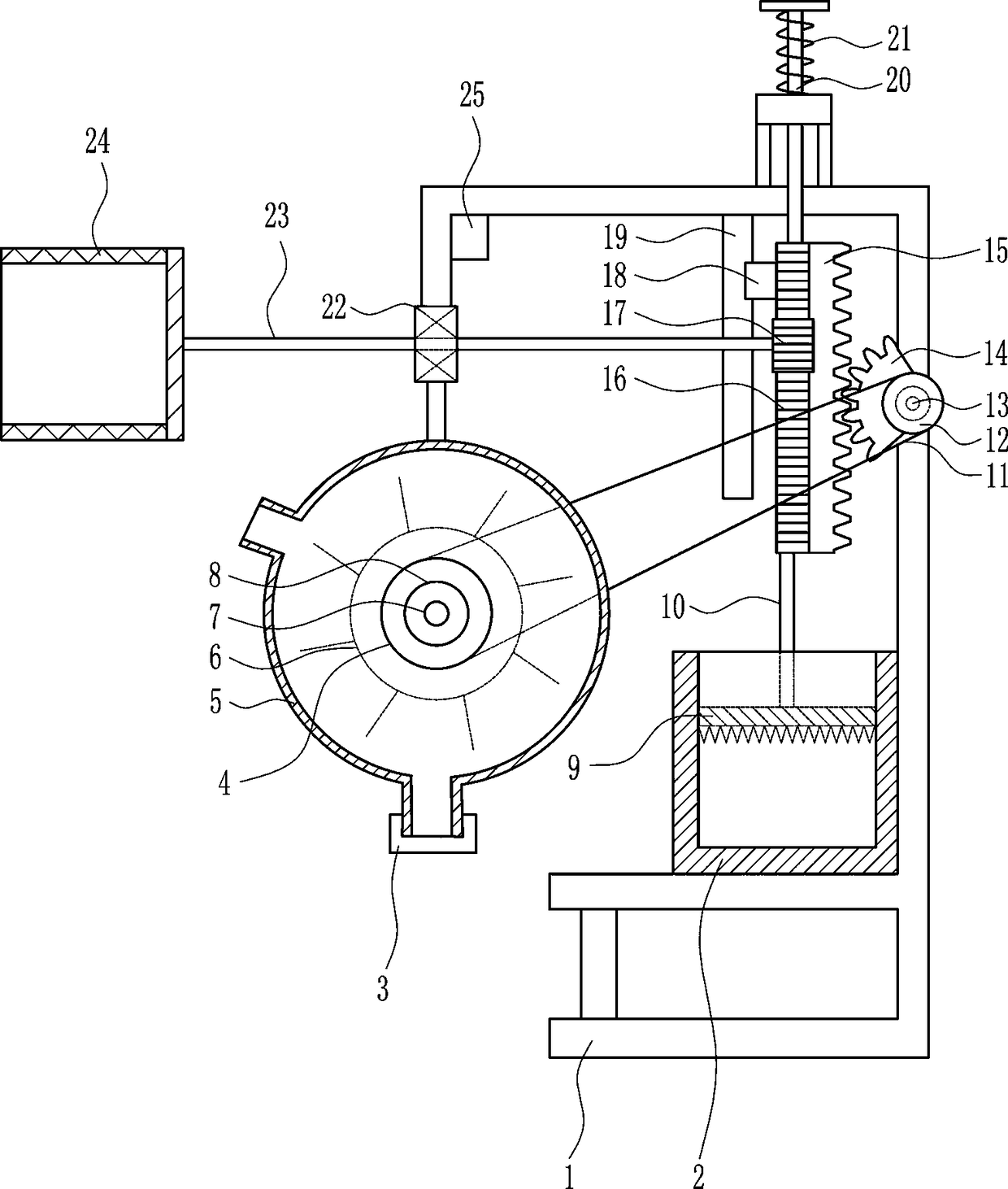

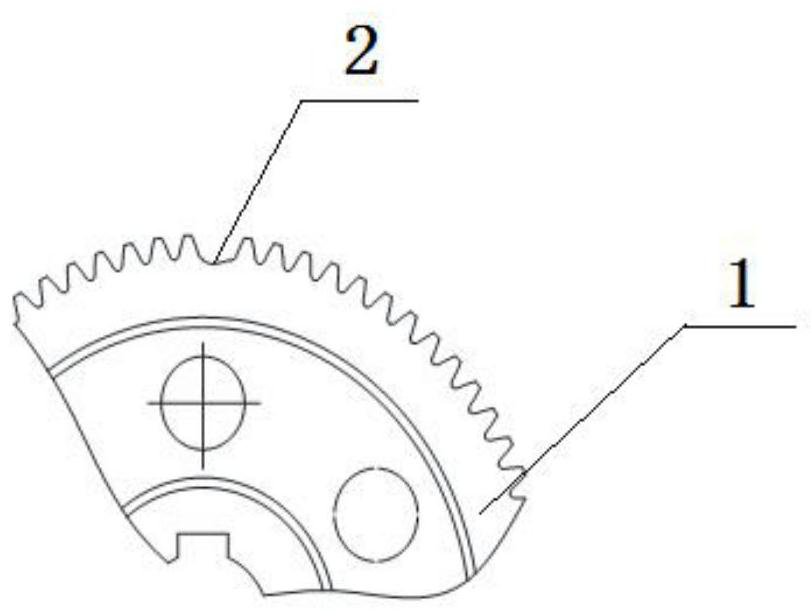

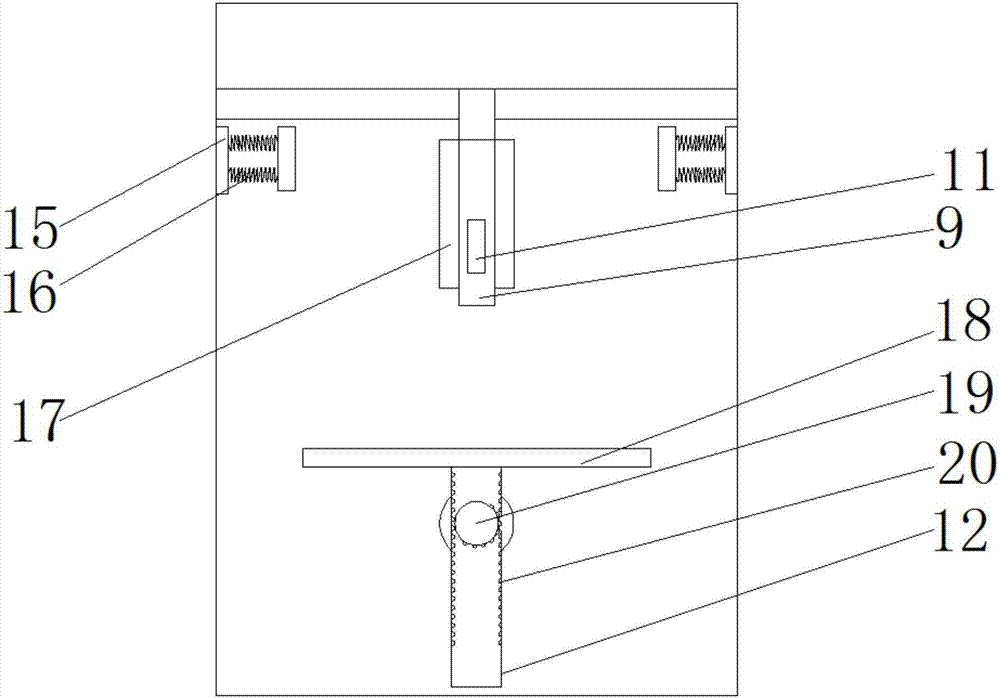

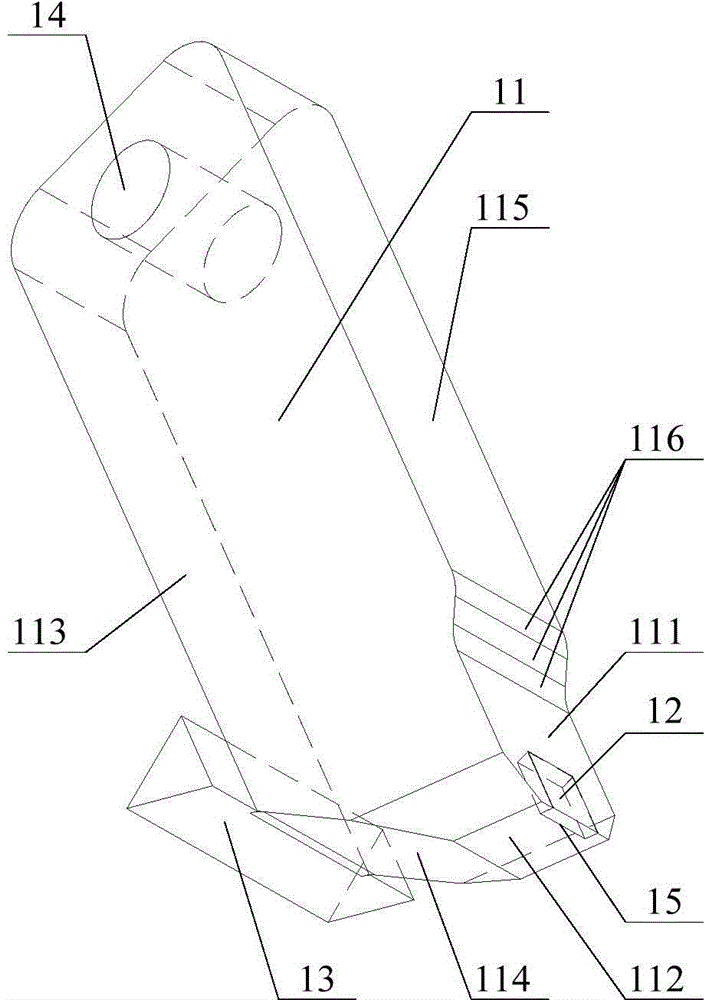

A medical minimally invasive dental forceps

A medical minimally invasive dental forceps is disclosed and overcomes problems of long time, a sense of fear of patients and slow postoperation healing of traditional tooth extraction. The dental forceps is characterized in that an upper forceps handle (1), a lower forceps handle (2) and a supporting shaft (3) form an open-mouth forceps, two wings of an end of the lower forceps handle (2) are provided with a left-wing metal plate (5) and a right-wing metal plate (4), the left-wing metal plate (5) is provided with a left silica gel pad (7) through a fixing bolt (6), the right-wing metal plate (4) is provided with a right silica gel pad (8) through the fixing bolt (6), a needle cone shaped root canal screw (10) is provided, the large head of the needle cone shaped root canal screw (10) is connected to a ratchet wheel (11) into one part through a connecting shaft (9), the ratchet wheel (11) is disposed on an opening of the upper forceps handle (1), and the small head of the needle cone shaped root canal screw (10) is disposed below an opening of the lower forceps handle (2). The dental forceps has advantages of a simple structure, convenient and flexible using, and capability of simplifying a tooth extraction process, shortening operation time and reducing intranperative and postoperative complications, and is suitable for extracting broken teeth and affected teeth.

Owner:杜建涛

Method for repairing broken tooth chain wheel

The invention discloses a method for repairing a broken tooth chain wheel. The method comprises the following steps: step I, acquiring a dimension parameter and a material of the chain wheel; step II, polishing a broken tooth position; step III, preheating the broken tooth position to 300 to 400 DEG C and performing heat preservation; step IV, preheating a welding rod to 300 to 400 DEG C, and setting current of a welding machine to 80 to 100 A, performing repair welding on the broken tooth position of the chain wheel, and enabling the part after repair welding to cover an original chain wheel tooth part and making machining allowance; step V, performing annealing treatment on the chain wheel after repair welding; step VI, performing flaw detection on a repair welding part of a broken tooth, if a flaw appears, removing the flaw part by using carbon arc gouging, and repairing the flaw part by using steps II to V; and step VII, machining the contour of the repair welding part into a wheel tooth size by using a machining mode. According to the method for repairing the broken tooth chain wheel provided by the invention, the repair welding part and the chain wheel body have high fusibility; the whole chain wheel is prevented from being changed by separate repair on a chain tooth, so that cost is greatly reduced.

Owner:卢志旭

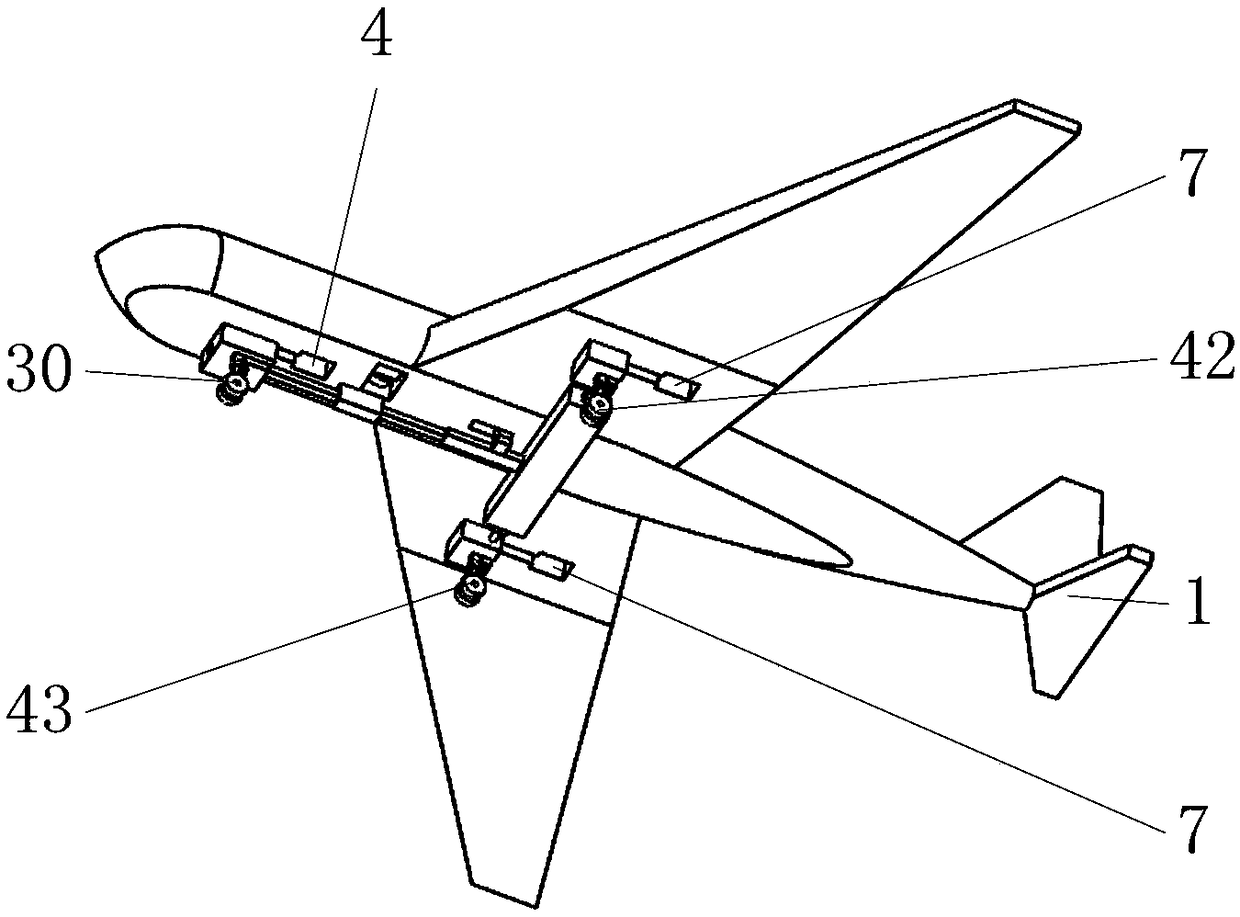

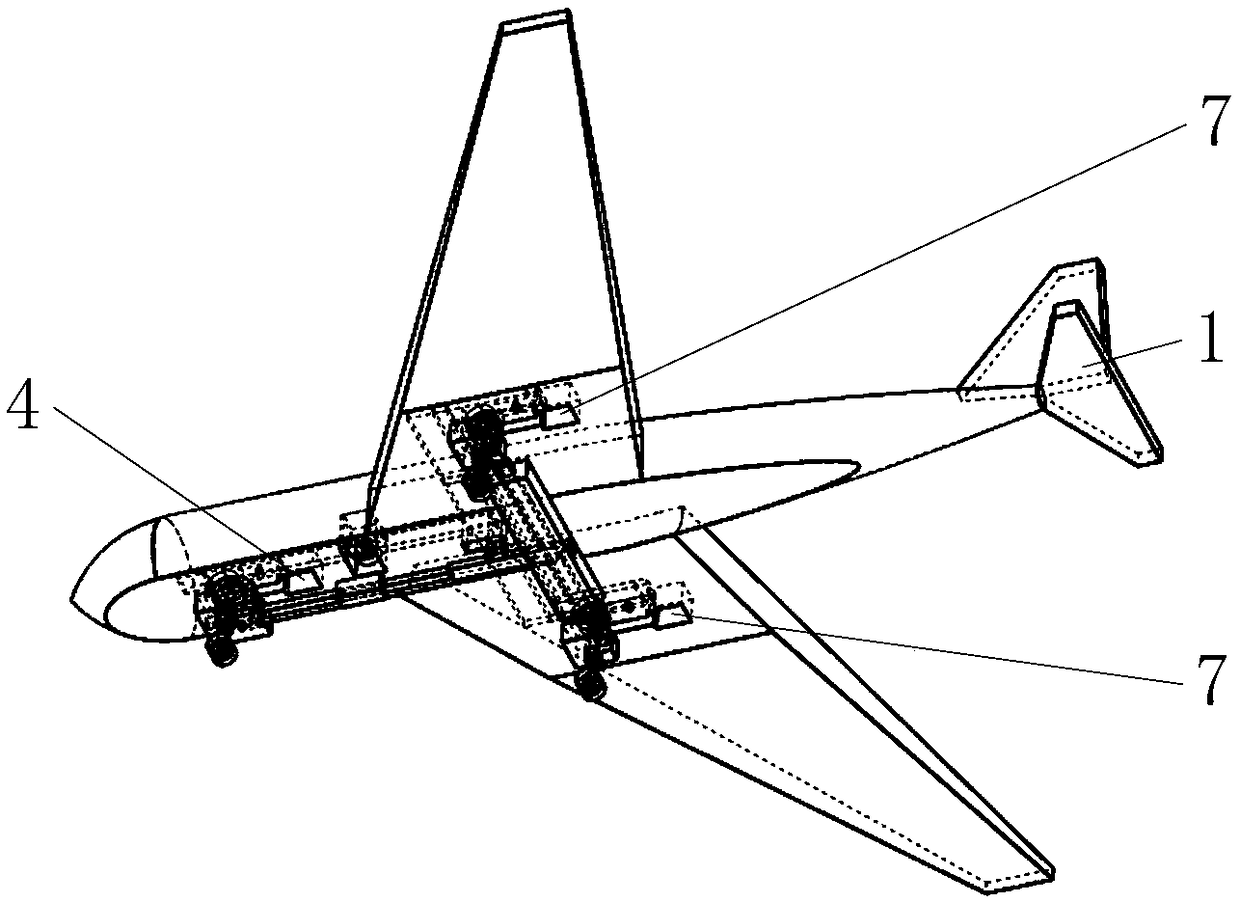

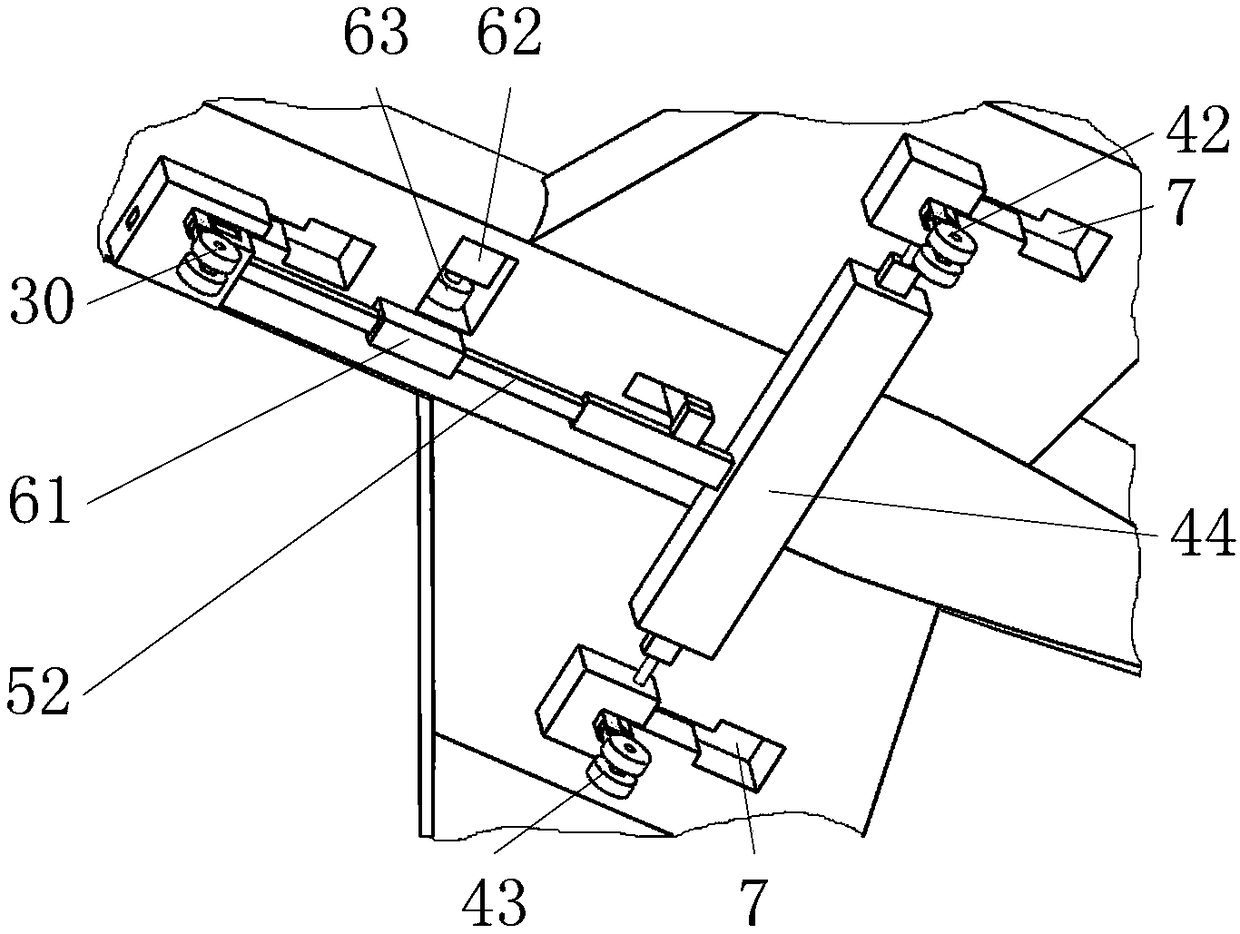

Unmanned aerial vehicle with foldable landing gear

InactiveCN109292080AExtended service lifeAvoid the phenomenon of impact damageWheel arrangementsUndercarriagesGear wheelUncrewed vehicle

The invention belongs to the field of unmanned aerial vehicles, and particularly relates to an unmanned aerial vehicle with a foldable landing gear. The unmanned aerial vehicle with the foldable landing gear comprises an engine body, a front wheel mechanism, a first rear wheel mechanism and a rack mechanism, and the engine body is an existing unmanned aerial vehicle body with a fixed wing; meanwhile, when the unmanned aerial vehicle lands, the front wheel mechanism, the first rear wheel mechanism and a second rear wheel mechanism have a certain buffering function; the steering engine is proneto being damaged under attack due to high rotating speed of a part of gear parts in the steering engine in the working process; and therefore, the buffering function of the front wheel mechanism, thefirst rear wheel mechanism and the second rear wheel mechanism can avoid the occurrence of a phenomenon of broken teeth of high-speed gears in the steering engine caused by the attack of the ground and sliding wheels when the unmanned aerial vehicle lands, so that a driving device on the unmanned aerial vehicle is ensured not to be damaged, and the service life of the unmanned aerial vehicle is furthest prolonged.

Owner:深圳市富裕泰贸易有限公司

Medicine for odontopathy

InactiveCN101204484AGood curative effectAnti-inflammatoryDigestive systemInanimate material medical ingredientsMyrrhBarberries

The invention discloses a medicine used for treating odontopathy, which can be made from the following materials in definite proportion: :8-12 shares of cortex kadsurae radicis, 3-5 shares of barberry root bark, 3-5 shares of dragon bone, 3-5 shares of dahurian angelica root, 3-5 shares of acacia catechu, 3-4 shares of frankincense, 3-4 shares of myrrh, 2-3 shares of dragons blood, 1 share of asarum, Chinese wild ginger, 3-5 shares of amber, 3-5 shares of dahurian angelica root, 3-5 shares of halite, 3-5 shares of figwortflower picrorhiza rhizome. The invention has the effects of treating anti-inflammation, alleviating pain, detumescence and hemostasia and has good effect to peridentitis, gingivitis, teeth loosening and broken tooth owing to tumbling. The invention can be applied to preventing the tooth disease and achieving the effect of not losing teeth for the old people.

Owner:罗冬桂

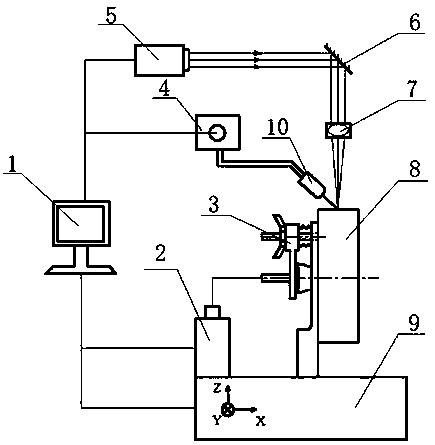

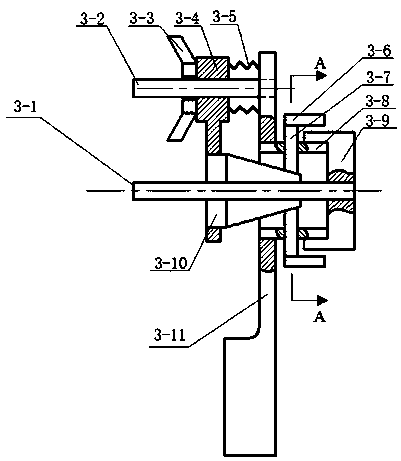

Device for repairing gears by means of laser cladding

ActiveCN108866546AQuality improvementImprove efficiencyMetallic material coating processesLaser processingProgrammable logic controller

The invention discloses a device for repairing gears by means of laser cladding, belonging to the field of laser processing. The device comprises a three-dimensional mobile platform, a programmable logic controller (PLC) system, a laser metal deposition system, a fixture and a motor. When the device is in use, the gear to be repaired is fixed on the fixture, and the broken teeth of the gear are enabled to be placed on a horizontal plane by controlling the motor. The device has the advantages of being simple in structure and convenient to operate, improving gear repairing quality and efficiency, having higher flexibility, and being capable of clamping the gears with different inner hole sizes.

Owner:JIANGSU UNIV

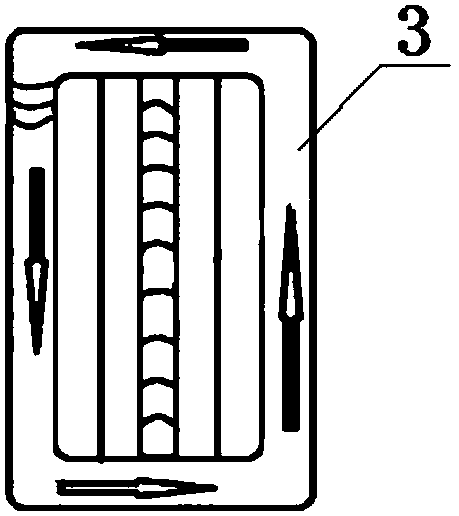

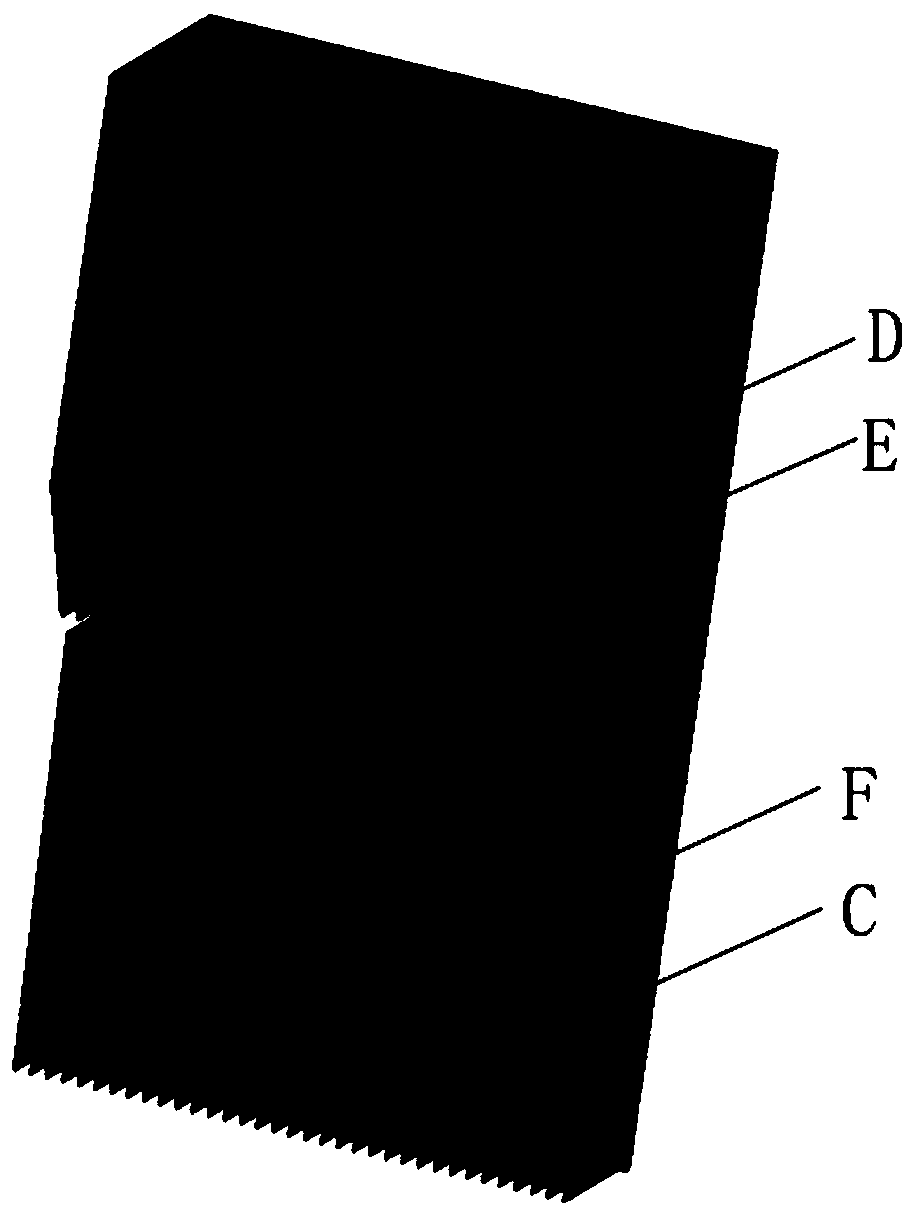

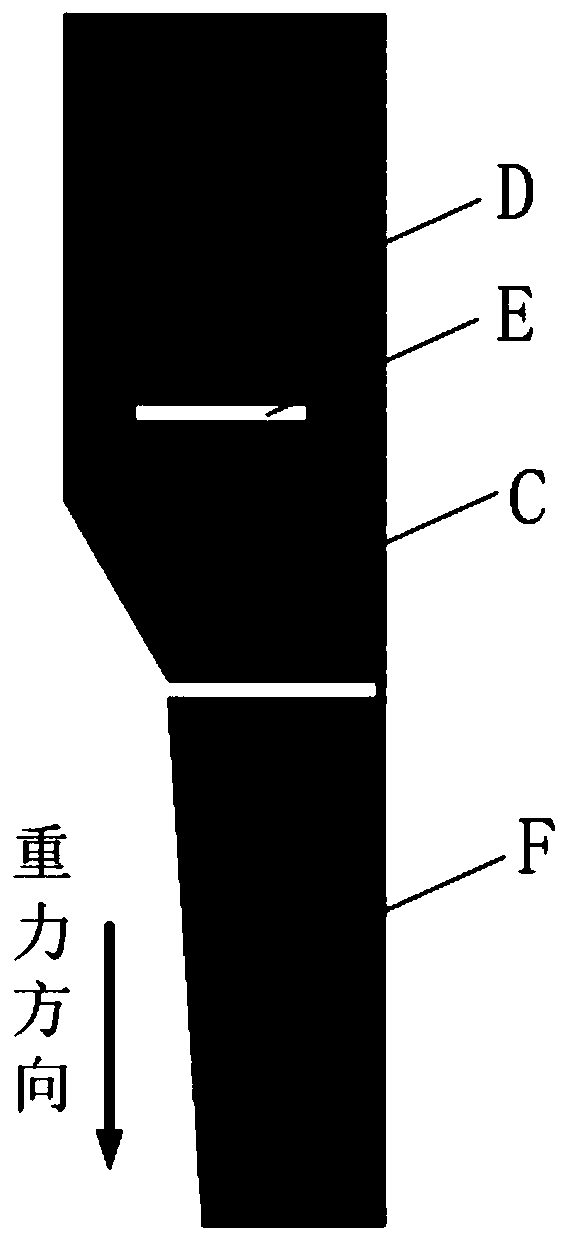

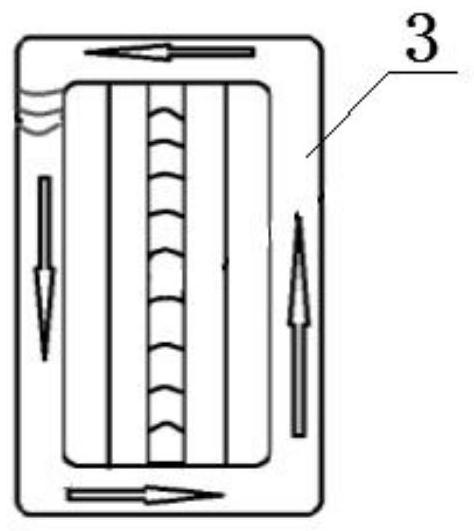

Natural convection enhanced heat dissipation structure with non-uniform heat source distribution and heat dissipation method thereof

InactiveCN110149783ALow densityReduce the temperatureCooling/ventilation/heating modificationsHeat conductingNatural convection

The invention relates to a natural convection enhanced heat dissipation structure with non-uniform heat source distribution and a heat dissipation method thereof. The structure comprises a heat dissipation thin substrate, spline teeth with vent holes arranged at the upper portion of the front surface of the heat dissipation thin substrate, inclination teeth arranged at the lower portion of the front surface of the heat dissipation thin substrate, low-power heat sources uniformly distributed at the back surface of the heat dissipation thin substrate, and a plurality of high-power heat sources distributed at the back surface of the heat dissipation thin substrate. A VC (Vapor Chamber) is inlaid in the heat dissipation thin substrate in the high-power heat source distribution dense area and an anisotropic graphene sheet is inlaid in the heat dissipation thin substrate in the high-power heat source sparse area; the VC and the anisotropic graphene sheet have good power flattening effect toeffectively reduce the local temperature at the high-power heat sources, the whole radiator is forming by processing light aluminum so that the weight is light, the heat conducting performance is good, the staggered tooth and broken tooth structures of the spline teeth and the inclination teeth are beneficial to strengthening heat dissipation, and the radiator is simple in structure, convenient toprocess and high in reliability.

Owner:XI AN JIAOTONG UNIV

Method for preventing and treating tooth loss or tooth breakage of bamboo rats

InactiveCN103636557AReduce in quantityImprove the immunityAnimal feeding stuffTooth lossBreakage rate

The invention discloses a method for preventing and treating tooth loss or tooth breakage of bamboo rats. The method mainly comprises the following steps of 1 preparing a specially-made feed; 2 timely disinfecting feed to improve feed quality; 3 using traditional Chinese medicine anti-inflammatory powder to treat gingival. A formula and a preparation method of the specially-made feed for preventing and treating the tooth loss or the tooth breakage of the bamboo rats are innovated, the gingival is treated and the supplied feed is improved timely when the bamboo rat teeth are in unusual condition, gingival disinfection is performed on the bamboo rats losing teeth or provided with broken teeth and then the traditional Chinese medicine anti-inflammatory powder is coated on the teeth, prevention and treatment are tightly combined, the formula is appropriate, and the method has the remarkably effect on reduction of the tooth loss rate and the tooth breakage rate of the bamboo rats.

Owner:思南县邵家桥镇腾鸿竹鼠养殖场

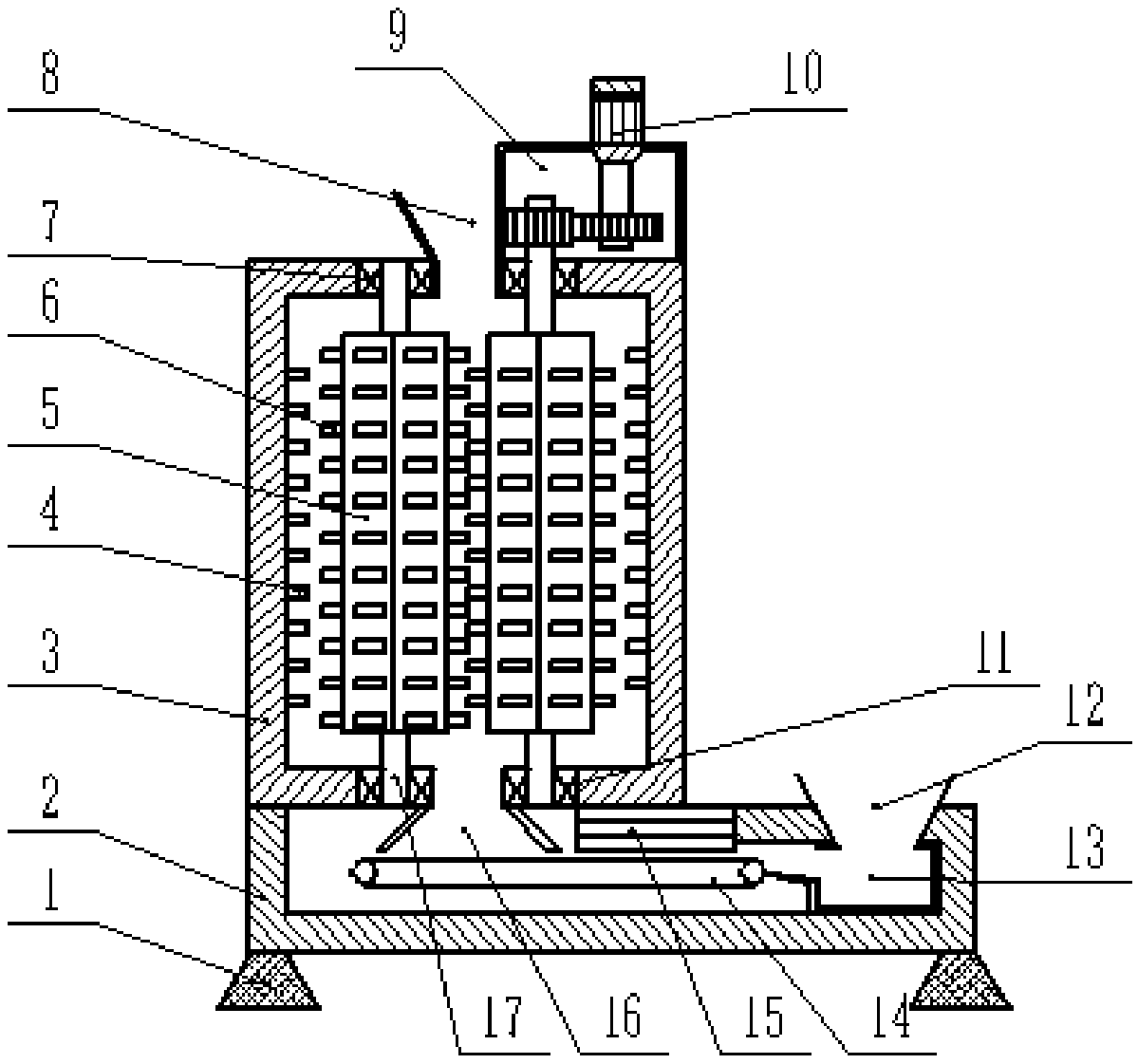

Fixing device for grinding of crushing tooth of crushing machine

The invention discloses a fixing device for grinding teeth of a crusher, comprising a base, an electric push rod is fixedly connected to the upper surface of the base, and the top of the electric push rod overlaps with the lower surface of a first movable plate, The lower surface of the first movable plate is fixedly connected with the upper surface of the base through two elastic devices, and a first rubber pad is fixedly connected to the upper surface of the first movable plate. The fixing device for grinding the crushing teeth of the crusher, through the cooperation between the electric push rod, the second telescopic rod, the driving device, the threaded cap, the fixing rod, the rotating device and the connecting rod, the worker can place the crushing teeth to be polished first. On the first movable plate, then by operating the control panel to extend the electric push rod, and at the same time make the motor rotate forward, the first movable plate and the second movable plate can move close to each other, so that the first movable plate and the second movable plate can move closer to each other. The movable plate can quickly fix the crushing teeth, thereby improving the grinding efficiency of the crushing teeth to a certain extent.

Owner:WUXI HENGDA MINE MACHINERY

Welding repair method for broken teeth of large gear of ball mill

The invention discloses a welding repair method for broken teeth of a large gear of a ball mill. The method comprises the steps that 1, a welding rod is dried and placed in a heat preservation barrelfor standby application; 2, a groove is prepared, specifically, the shape and size of the groove need to be considered when cracks are dug, the groove size needs to be small and no sharp corners or dead corners exist under the condition that the cracks are thoroughly removed, welding is facilitated, and the groove and the two sides of the edge of the groove are ground to have metallic luster within the range of 15-20mm; 3, manual arc welding is adopted for welding; 4, hammering is conducted in time after welding of each section is completed so as to eliminate welding stress; and 5, grinding treatment is conducted after welding is completed. According to the field conditions, in order to obtain a welding seam with the mechanical property meeting the requirement, a proper welding material isselected, and the gear is repaired through a cold welding method. After welding repair, no crack defect is found in dye penetrant inspection, the hardness value meets the requirement, and a good using effect is achieved.

Owner:贵州西能电力建设有限公司

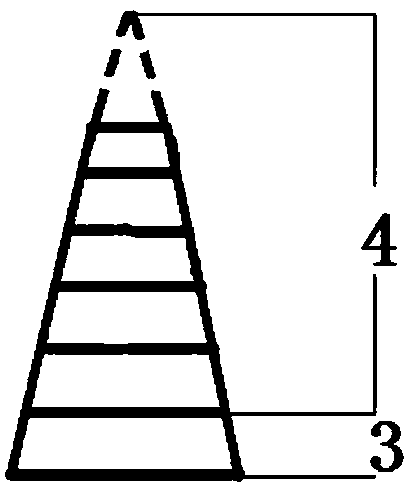

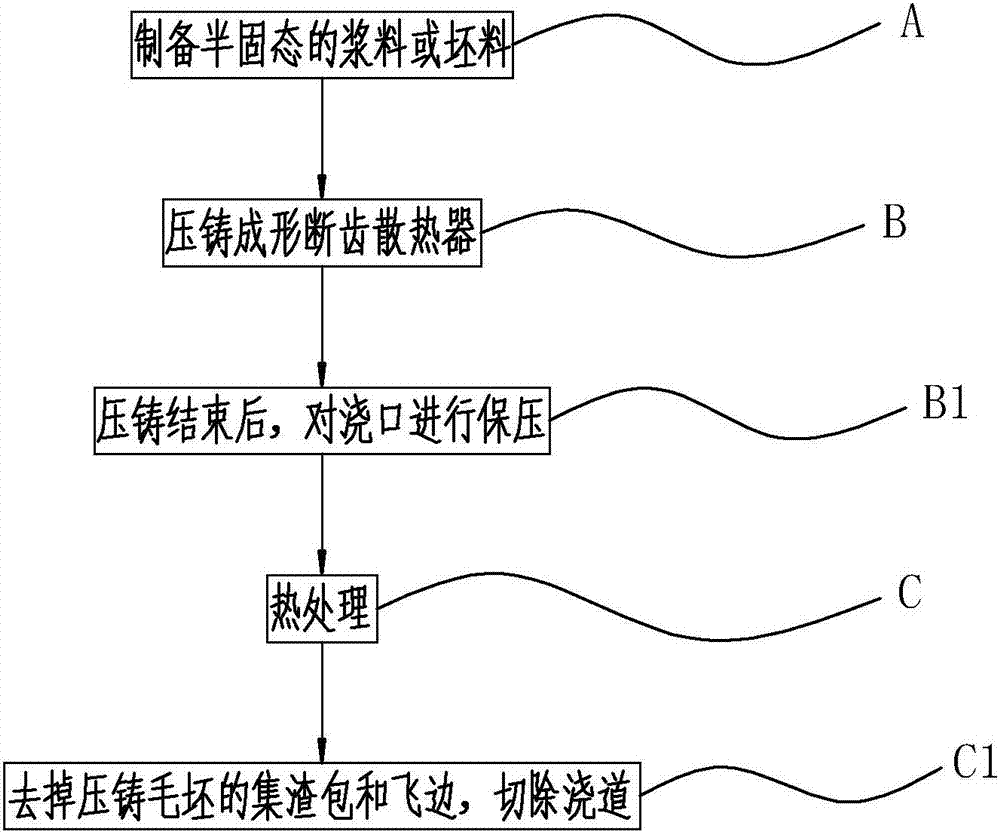

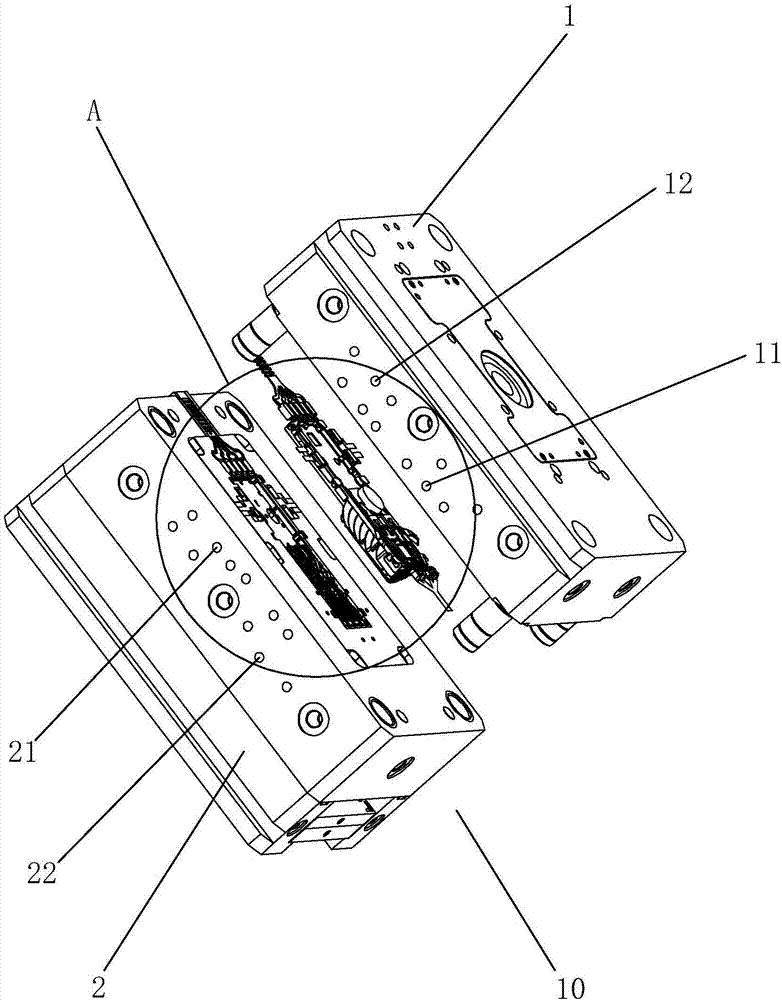

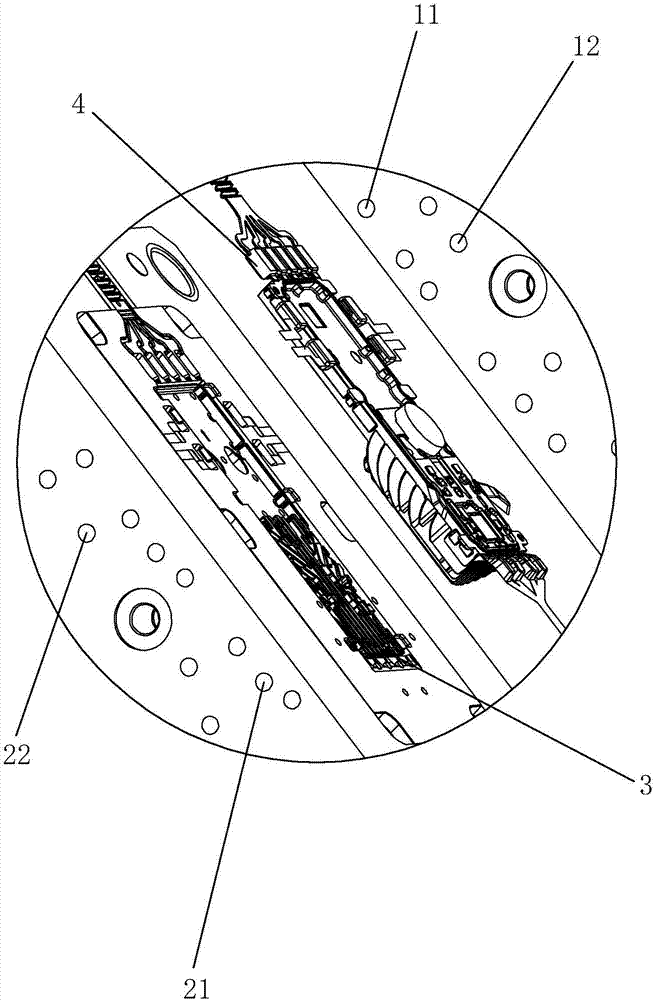

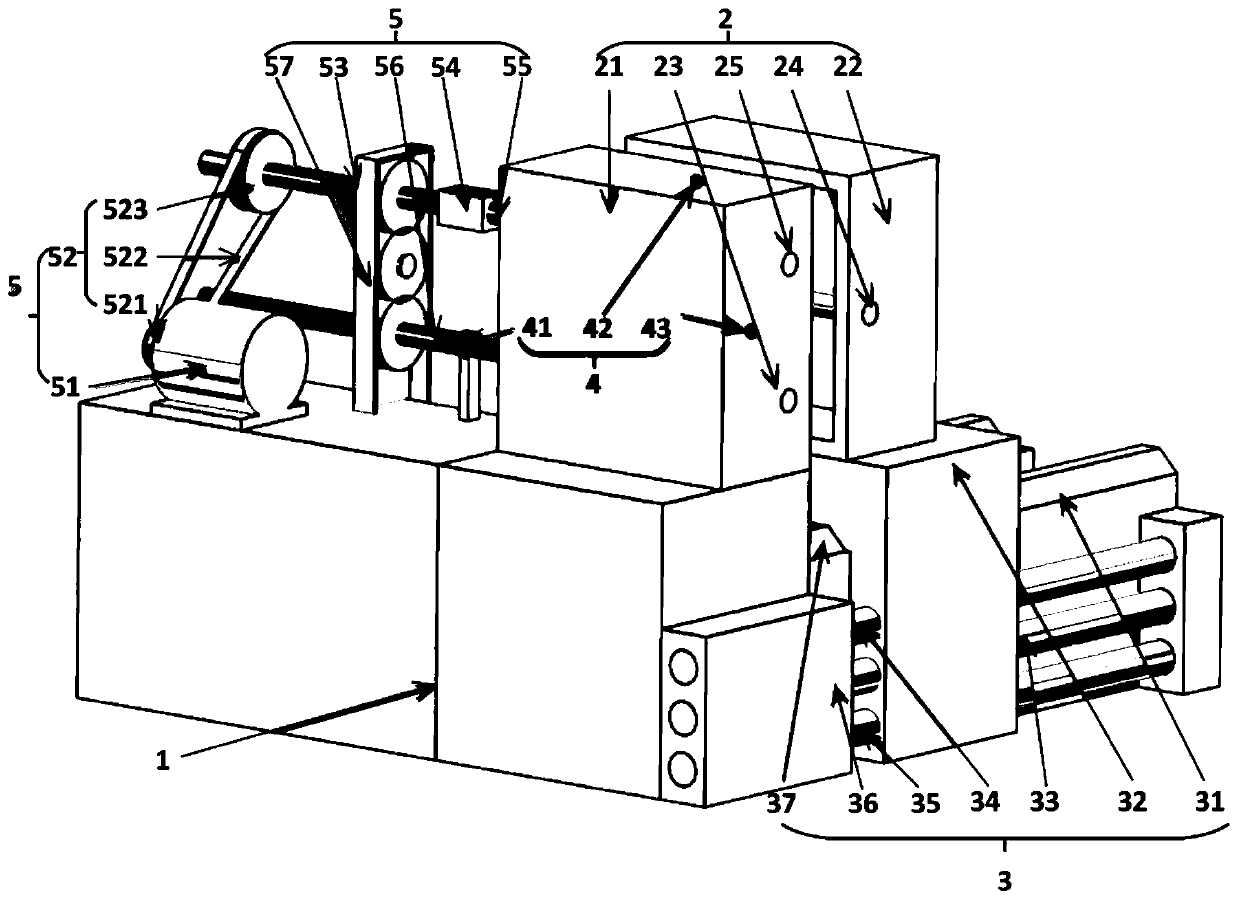

Semisolid die casting forming method for broken tooth radiator

The invention discloses a semisolid die casting forming method for a broken tooth radiator. The semisolid die casting forming method comprises the following steps that A, semisolid slurry or a semisolid blank is prepared; B, the broken tooth radiator is formed through die casting; and C, heat treatment is conducted, and in the step A, the solid rate of the slurry or the blank ranges from 20% to 80%. By means of the semisolid die casting forming method, the service life of the die is prolonged, solid solution heat treatment can be conducted, meanwhile, semisolid slurry layer is in laminar filling, sequential solidification is formed, an inner dense solidification structure in the radiator is guaranteed, and the requirement of communication products for the radiator can be met.

Owner:深圳市银宝山新压铸科技有限公司

Combined comb made of natural materials

The invention provides a combined comb made of natural materials which is characterized in that the comb teeth are made of calthrop, bones and hooves; the comb body is made of animal bones, animal horns and wood or is complexly made by selecting two or three of animal bones, animal horns and wood; and the comb teeth are planted and glued on the comb body, or screwed and combined onto the comb body. The comb teeth and the comb body have the advantages of abundant material and high strength, uneasy broken and replaceable broken teeth. The whole comb is made of natural materials, is beneficial to human health when contacting hair and scalp, and conforms to the requirements for environmental protection. The calthrop, bones and hooves of animals are utilized, thereby enriching the materials, changing wastes into valuables, enhancing the added value, being beneficial to relieving the consumption of rare timber resources in the manufacturing process of combs, and satisfying the requirements for sustainable development.

Owner:徐秋原

Broken tooth and spindle wear repair process for single-tooth roller of crusher

InactiveCN110158079AReduce labor intensityAvoid it happening againMetallic material coating processesGrain treatmentsEngineeringCrusher

The invention discloses a broken tooth and spindle wear repair process for a single-tooth roller of a crusher. The process comprises the following steps: S1, cutting two sides of the broken tooth or aspindle wear part by oxygen, wherein the cutting depth is 20 mm higher than a wear surface, and cutting a damaged surface into a groove, the section of which is U-shaped, wherein the bottom surface of the groove is arc-shaped; S2, polishing the groove by a grinding machine till a bright and clean surface of a metal is exposed to the inner wall and the bottom surface; S3, carrying out online cladding on the groove by using a laser cladding welding machine; and S4, grinding and polishing a cladding layer. By carrying out online repair on the wear part by adopting the laser cladding welding machine, an original manual welding operating mode is improved, the labor intensity of a welding worker is reduced, and the welding efficiency and the utilization ratio of materials are improved and increased. In addition, the laser cladding welding machine can be adjusted and prepared intelligently, and generation of interlaminar oxides during welding can be avoided by means of a stable welding pointspot power principle of the laser cladding welding machine, so that the cladding welding precision is improved favorably.

Owner:湖北开明高新科技有限公司

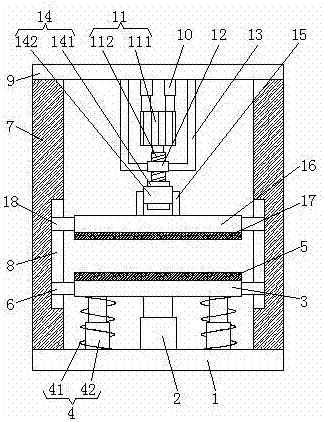

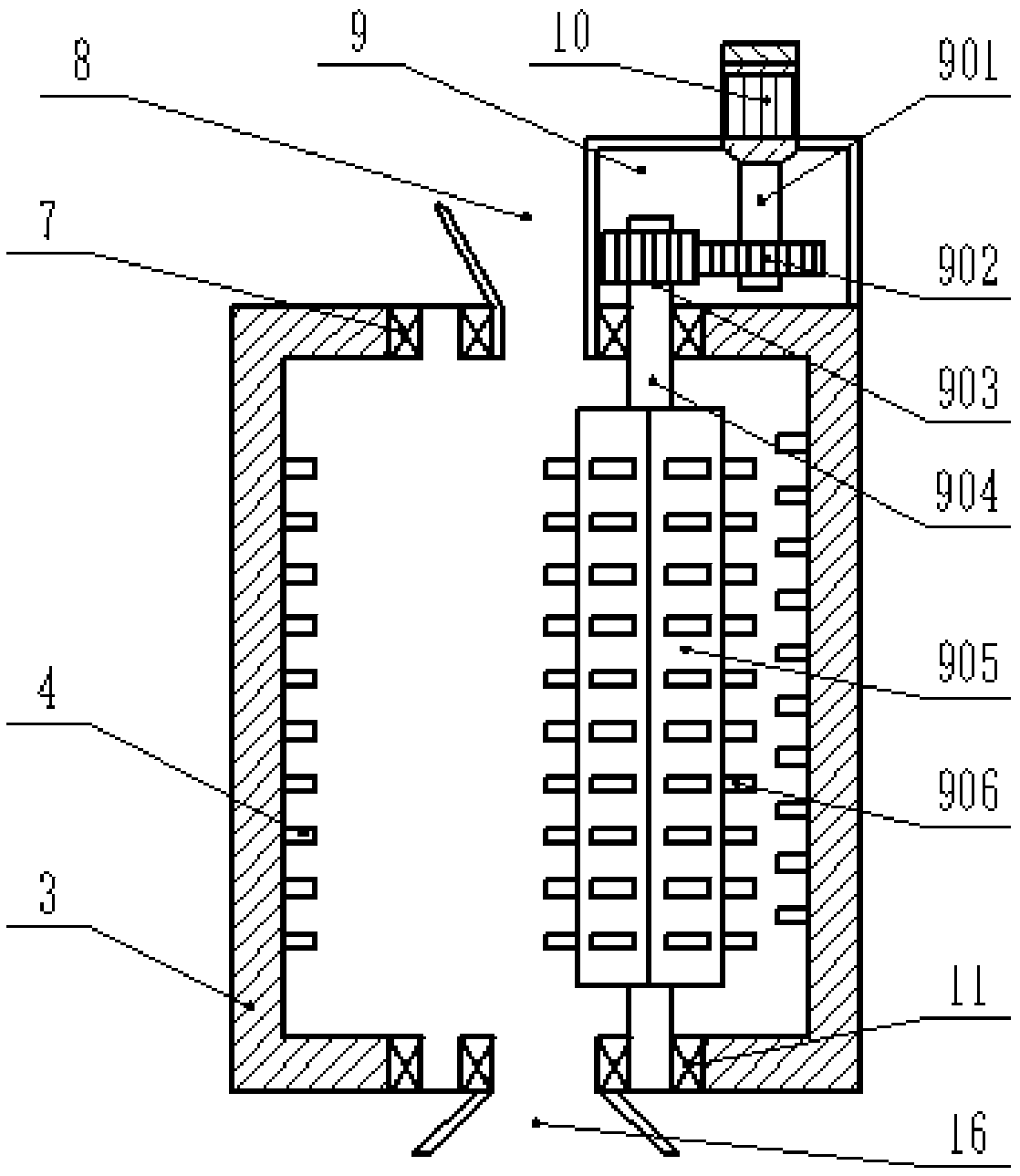

Numerical control system based center distance variable gear contact fatigue test bed

The invention relates to a numerical control system based center distance variable gear contact fatigue test bed, and belongs to the technical field of numerical control. The test bed comprises a support assembly, a feeding movement assembly, a transmission assembly, a detector, a test gear case and a tested gear set, a torque sensor is positioned in an input shaft, and the torque of the input shaft is detected and compared with a set torque to compensate or reduce torque adjustment. In the feeding movement assembly, a carriage is positioned in different positions of a guide rail via a servo motor and a ballscrew, the center distance between two pairs of engaged gears is changed, and gears of different modulus are tested. A laminated push-and-pull structure on a casing of the test gear case enables that two half-open type test gear cases form an enclosed space, and oil is prevented from splashing and broken teeth are prevented from flying off during operation of the test bed. A vibration sensor can collect vibration signals of the different modulus of gears in the contact fatigue intensity test.

Owner:CHONGQING UNIV

A multifunctional device for construction

ActiveCN106925371BImprove work efficiencySave spaceRotating receptacle mixersSievingFixed frameEngineering

The invention relates to a construction equipment, in particular to a multifunctional equipment for construction. The technical problem to be solved by the present invention is to provide a multifunctional building equipment with high working efficiency, which can carry out various construction work at the same time and save space. In order to solve the above technical problems, the present invention provides such a multifunctional equipment for construction, which includes a fixed frame, a crushing tank, a cover, a first pulley, a mixing tank, a mixing drum, a first rotating shaft, a first bearing seat, The crushing tooth plate, the first lifting rod, etc.; the right part of the fixed frame is provided with a crushing tank, a first motor and a slide rail in sequence from bottom to top. The crushing tank is equipped with a crushing tooth plate, and the top of the crushing tooth plate is equipped with a lifting rod. The invention achieves the effects of high working efficiency, multiple construction works can be performed simultaneously, and space saving. The equipment can be used for mixing, crushing and screening at the same time, realizing the integration of multiple functions.

Owner:河北建设集团天辰建筑工程有限公司 +1

An Online Welding Repair Process for Large Spur Gears

ActiveCN108555468BGuaranteed cycle qualityShorten maintenance timeWelding apparatusAngle grinderWelding defect

The invention discloses a large spur gear online welding repairing process. The large spur gear online welding repairing process is characterized in that the process is performed according to preparation before welding, welding treatment, and treatment after welding. The welding treatment comprises weldment position adjusting and pre-welding washing, welding broken tooth part flattening and weldment heating, transition base coat welding, and surfacing layer welding; and after welding is finished, comparing is performed through a pre-manufactured tooth template, residual weld joints are cut andflattened through a plasma gouge, then coping is roughly performed through a corner grinding machine, the size of the tooth template is met, and stress is eliminated finally. The large spur gear online welding repairing process has the advantages that online welding repairing of the to-be-welded gear part is finished in a narrow space, a spur gear after surfacing meets the operation size throughmanual grinding, the surface of the spur gear has no welding defect, the subsequent operation period quality is ensured, the maintenance time is shortened, the maintenance cost is reduced, the halt loss is reduced, and reasonable assembly and production are guaranteed.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Cold precision forging tooth die for bevel gear

InactiveCN101628315AAvoid damage accidentsExtended service lifeForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention discloses a cold precision forging tooth die for a bevel gear, which comprises a lower die core, a bevel die cavity and a round through hole, wherein the lower die core forms a round disk shape, and an upper end face and a lower end face of the lower die core are parallel to each other; the round through hole with a vertical central part is communicated with the bevel die cavity; the upward end face of the lower die core is of a plate shape; and the bevel die cavity uses the upper end face of the lower die core as a plane standard to recess downwards. The bevel die cavity in the cold precision forging tooth die for the bevel gear entirely recesses in a lower die, so that the entire structural strength is high, the stress is uniform to avoid the accident of die damage caused by broken teeth, and the die has long service life.

Owner:JIANGSU AIRSHIP GEAR

Special welding rod for repairing and overlaying heavy-duty high-speed broken gear teeth

InactiveCN102441748AEasy to use on siteEasy to weldWelding/cutting media/materialsSoldering mediaHigh carbonGear wheel

Disclosed is a special welding rod for repairing and overlaying heavy-duty high-speed broken gear teeth. According to weight percentage wt%, chemical components of the coating of the special welding rod include 25-35% of marble, 14-20% of fluorite, 3-5% of quartz, 2-4% of chalk, 6-8% of high-carbon ferrochrome, 1-3% of high-carbon ferromanganese, 5-7% of graphite, 1-3% of ferrosilicon, 1-3% of ferrotitanium, 5-7% of ferromolybdenum, 3-5% of lanthanum trioxide, 7-9% of metallic nickel, 4-6% of medium-carbon chromium iron and 3-5% of ferrovanadium, and a core wire is made of H08A steel. A gear with broken teeth needing repair is preheated at the temperature of 300-400 DEG C before welding, and is tempered at the temperature of 100-200 DEG C after welding. The special welding rod is convenient in field use and easy in welding, cracking is avoided after welding, welding quality is obviously improved, the surface hardness of the welded gear ranges from HRC (Rockwell hardness) 58 to HRC 63, and the service life of the repaired gear is 3-4 times of that of the original gear.

Owner:YANSHAN UNIV

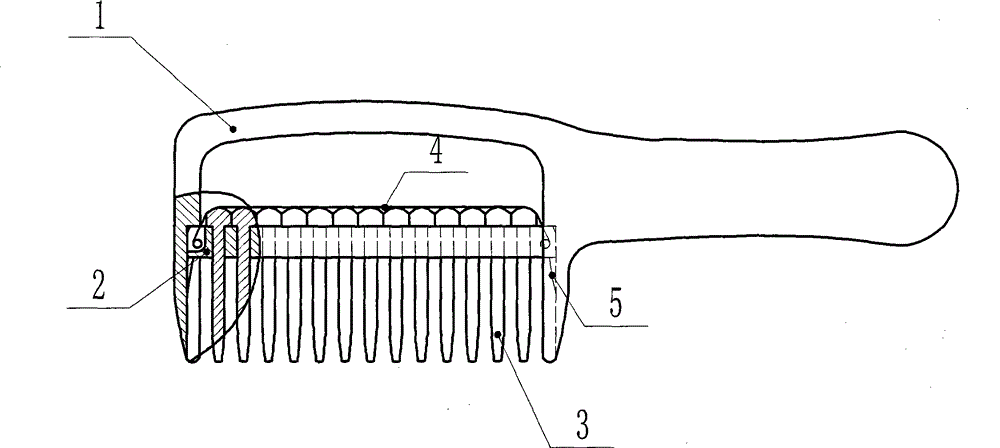

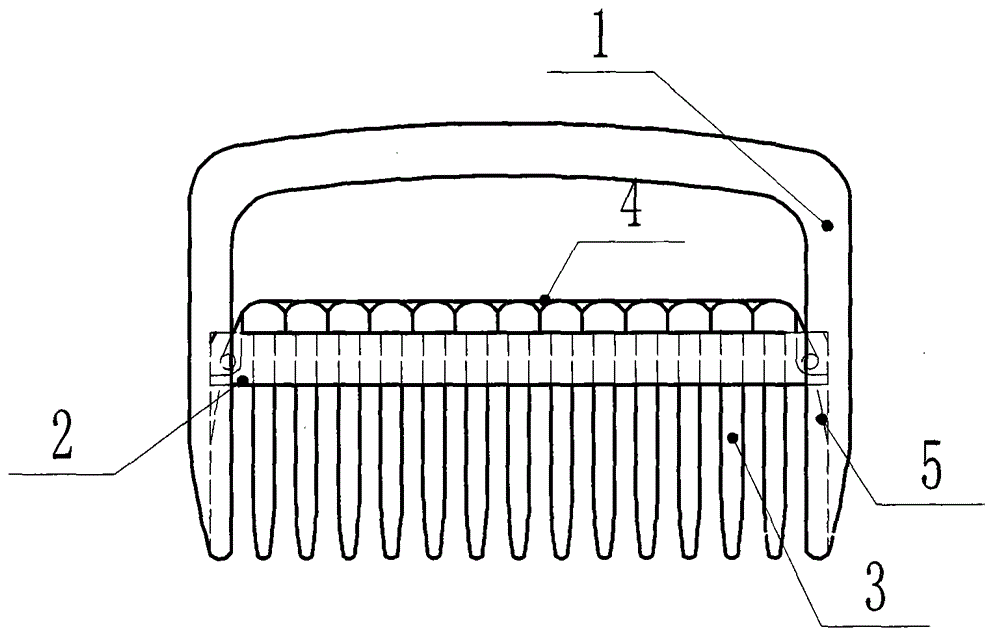

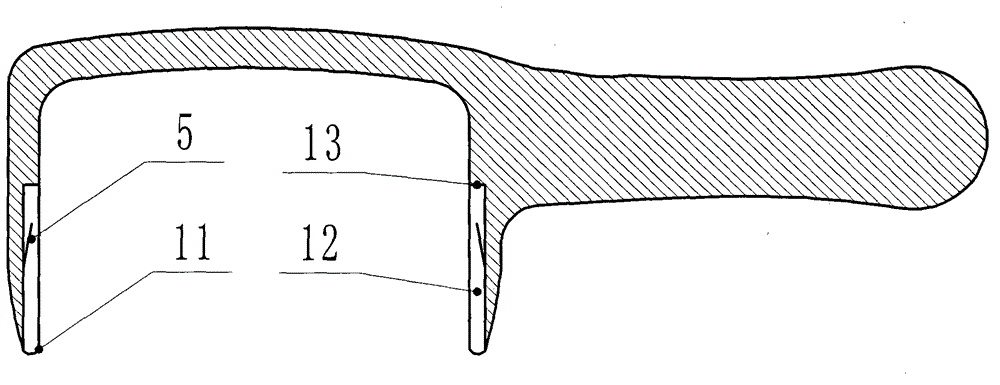

Flexible comb fitting scalp

The invention discloses a flexible comb fitting scalp. The flexible comb fitting the scalp is composed of a comb body and a telescopic comb tooth device, wherein the telescopic comb tooth device comprises a tooth frame, combing teeth and an elastic strip; a plurality of through holes in the same shape as the sections of the combing teeth are formed in the tooth frame, the tooth tips of the combing teeth are inserted into the holes and penetrate through the tooth frame to the lower surface of tooth caps and attached to the upper surface of the tooth frame, the elastic strip presses the tops of the tooth caps uniformly, and the two ends of the elastic strip are connected with the two ends of the tooth frame. In use, the tooth tips of the telescopic combing teeth form a curve along the outline of the scalp under the function of external force, every combing tooth can make flexible contact with the scalp, the scalp is avoided being scratched, and meanwhile the massage function of the comb can be fully played; since all the tooth tips of the telescopic combing teeth are arrayed according to the curve of the outline of the scalp, the contact area is increased, and the parasite in dandruff and hairs of human or pets can be more effectively removed; since the combing teeth serve as independent components, only the combing teeth are needed to be replaced when broken teeth occur, the phenomenon that a comb with a broken tooth is abandoned is avoided, therefore, the material is saved, and the environment is protected.

Owner:高文朋

Non-destructive testing device for circular saw blade based on acoustic resonance spectrum

InactiveCN109142535AAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveMicrocontroller

The invention discloses a non-destructive testing device for a circular saw blade based on an acoustic resonance spectrum. The device is mainly used for quality inspection of the circular saw blade before leaving a factory. The device is characterized by comprising a bracket, a microcontroller, an electrodynamic hammer, an audio collector, a signal acquisition and data processing smart controllerand a personal computer. The electrodynamic hammer is fixed to the bracket for tapping the circular saw blade to generate vibration and sound, the micro controller is connected with the electrodynamichammer, so that the electrodynamic hammer generates taping force with the same magnitude each time, and the audio collector and the smart controller are used for collecting audio signals generated bythe vibration of the circular saw blade and performing data processing. The non-destructive testing device for the circular saw blade can detect inferior circular saw blades with cracks, notches, bubbles, broken teeth and the like, the unqualified circular saw blades are screened out before leaving the factory, the device has high detection precision and comprehensive defect detection, and a reliable and comprehensive automatic detection method is provided for circular saw blade manufacturers.

Owner:HARBIN UNIV OF SCI & TECH

Wood cutting device

InactiveCN107379120ASave time and effortImprove securityFeeding devicesGripping devicesFistEngineering

The invention discloses a wood cutting device. The wood cutting device includes a connection rod, a fixed block, a table board, a sawdust box, a dust prevention cover, a cutting blade, a sleeve rod, a second motor, a transverse plate, a cavity, a slidable plate, a broken teeth gear and a rack; firstly, wood is placed on the upper surface of the table board, a clamp spring at a connection board is pulled, the second motor is switched on to drive the broken teeth gear to rotate, the sleeve rod pushes the wood to move in the direction of the cutting blade to arrive at a position, the second motor is switched off, the clamp spring is loosened, the wood is fixed, a first motor is switched on, through the connection among a second rotation shaft, a first conveying belt, a fist rotation shaft and a second conveying belt, the cutting blade is driven to rotate, the hand can move the cutting blade to complete wood cutting by pressing the dust prevention cover, and in the process of cutting, produced sawdust falls into the sawdust box. In the process of operation, the wood cutting device is driven by the motors and fixed by a clamping mechanism so that operators can save time and labor during usage, the safety is improved, and the operation is simple and convenient.

Owner:SHENZHEN ZHIHUI QIANXIAN TECH CO LTD

Broken tooth assembly and its broken teeth

ActiveCN103406181BImprove structure transition effectReduce extrusionGrain treatmentsAcute angleEngineering

Owner:HUNAN WANTONG TECH

Medical breaking and recycling device for abandoned dental tooth molds used for oral cavities

InactiveCN110496845AEfficient crushingEasy to storeSolid waste disposalMedical waste disposalDrive shaftUv disinfection

The invention relates to a medical breaking and recycling device for abandoned dental tooth molds used for oral cavities. The medical breaking and recycling device comprises supports. The supports areconnected with a recycling box. The recycling box is connected with a breaking box. The breaking box is connected with box wall breaking rods. The breaking box is connected with driven bearing pedestals. Each driven bearing pedestal is connected with a driven shaft. Each driven shaft is connected with a driven roller. Each driven roller is connected with a driven breaking rod. The breaking box isconnected with a feed port and is connected with a drive mechanism. The breaking box is connected with driving bearing pedestals and is connected with a discharge port. The recycling box is connectedwith an ultraviolet disinfector. The recycling box is connected with a material taking port. According to the medical breaking and recycling device, by using the breaking box and the recycling box, the aim of effectively breaking the tooth molds and the aim of disinfecting the broken tooth molds are achieved, and the functions of breaking and recycling the abandoned tooth molds used for the oralcavities are achieved.

Owner:LIUZHOU HUANSHAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com