Semisolid die casting forming method for broken tooth radiator

A heat sink, semi-solid technology, applied in the field of die-casting, can solve problems such as mold cracks, achieve the effect of improving service life and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

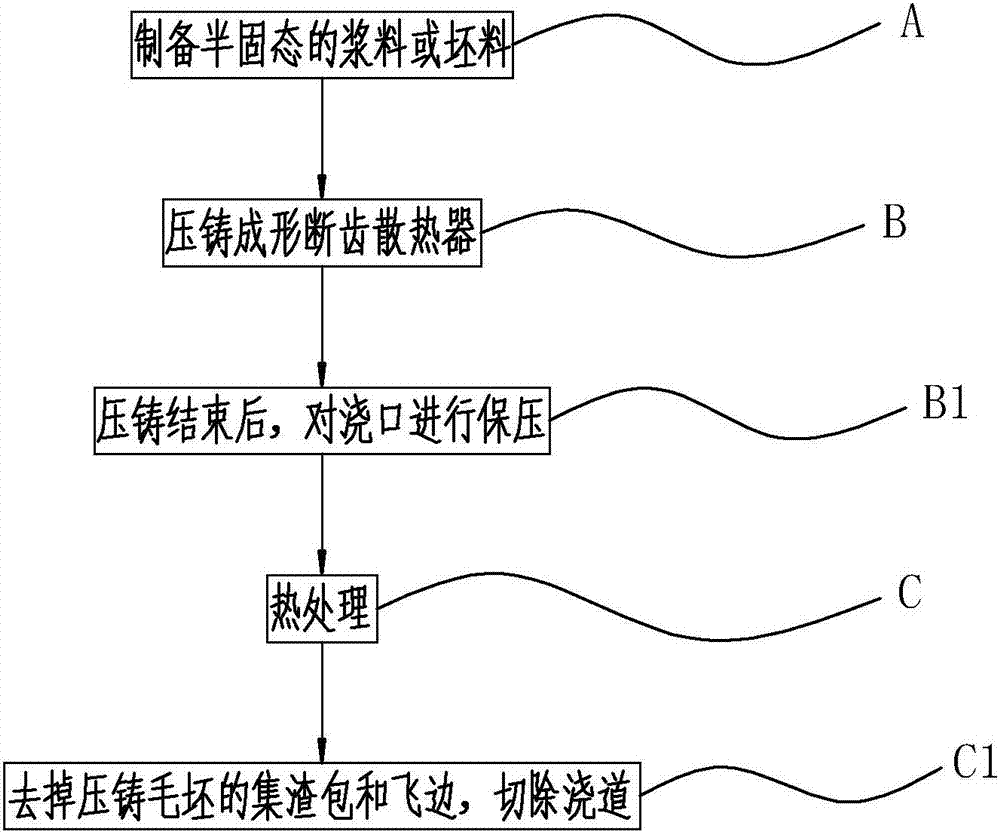

[0027] Such as figure 1 As shown, a semi-solid die-casting forming method of a broken-tooth radiator includes the following steps:

[0028] A. Prepare a semi-solid slurry or blank; in step A, the solid rate of the slurry or blank is 20%-80%, the silicon content of the slurry or blank is in the range of 1%-10%, the thermal conductivity of the alloy is high, and the product Good heat dissipation;

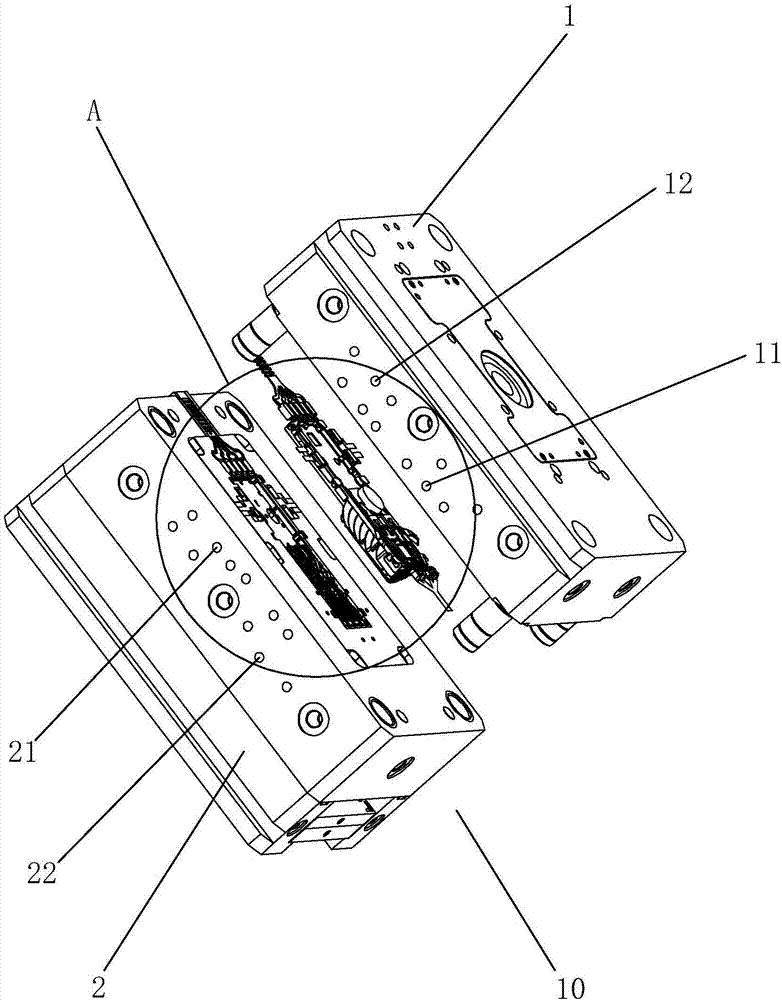

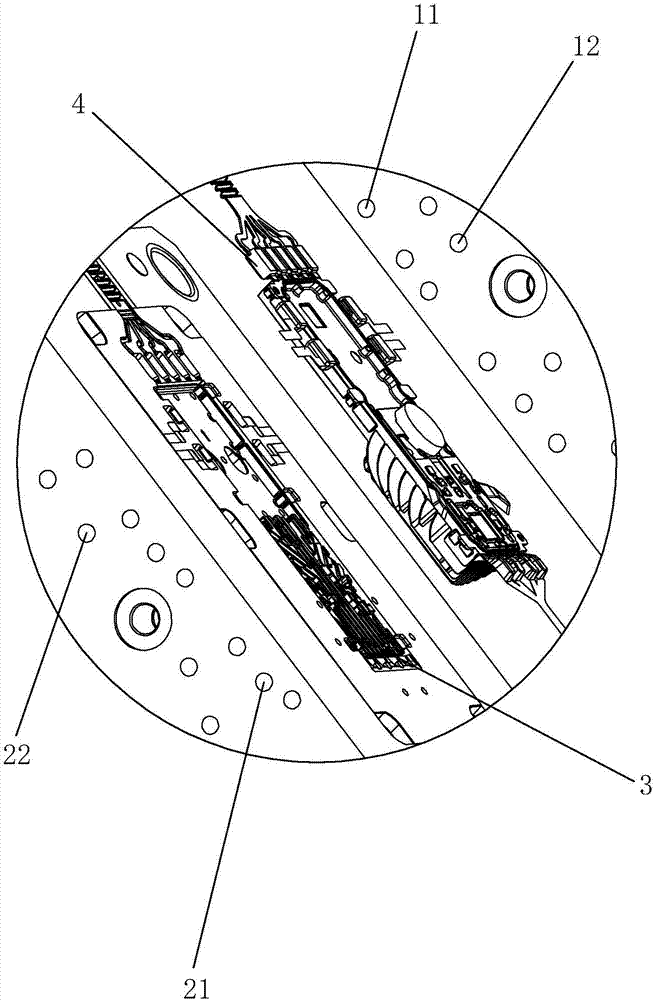

[0029] B. Die-casting forming broken-tooth radiator; In step B, a special die-casting mold is used to form the radiator. When die-casting, the gate of the mold is located at the geometric center of the broken-tooth radiator, which shortens the semi-solid slurry injection distance and reduces the filling flow. fluctuations, the speed ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com