Natural convection enhanced heat dissipation structure with non-uniform heat source distribution and heat dissipation method thereof

A technology of heat dissipation structure and natural convection, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

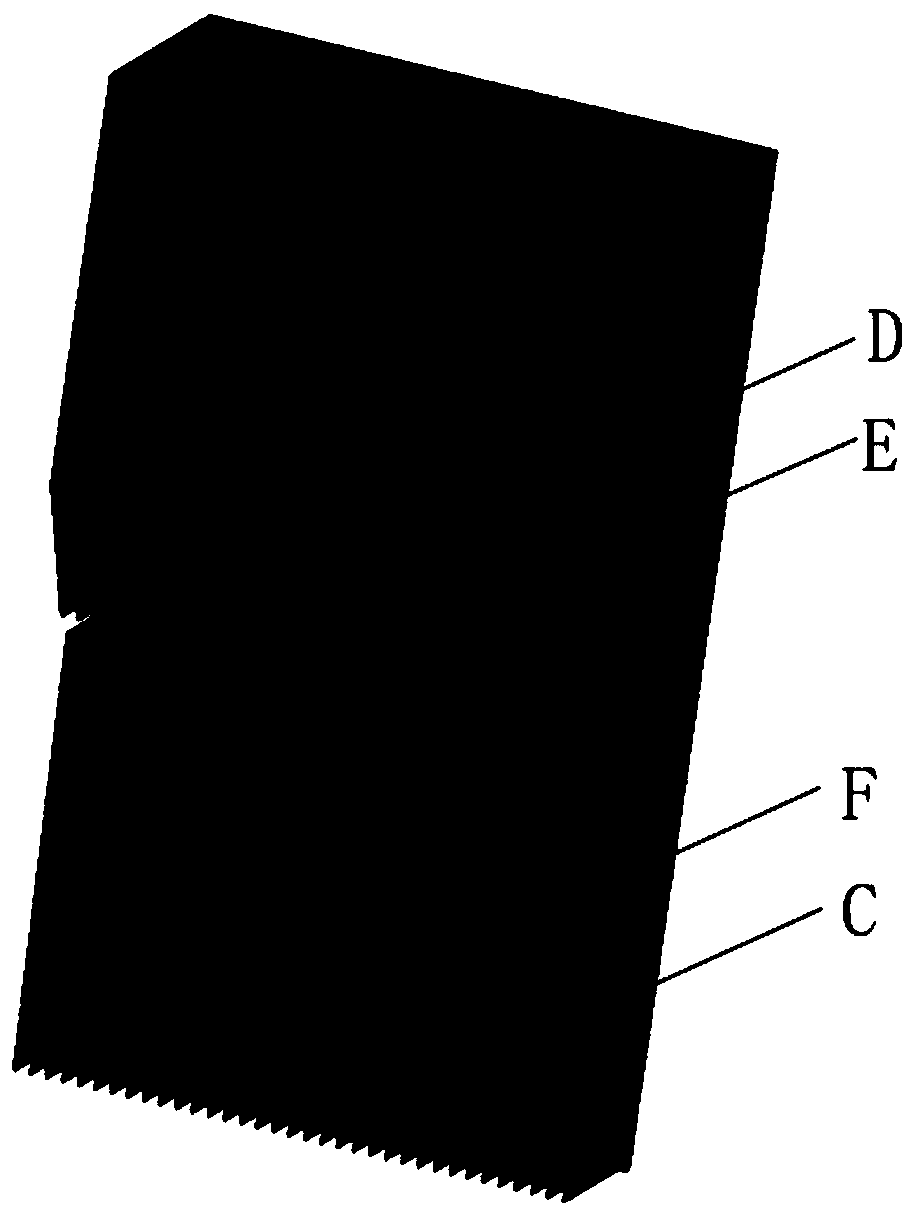

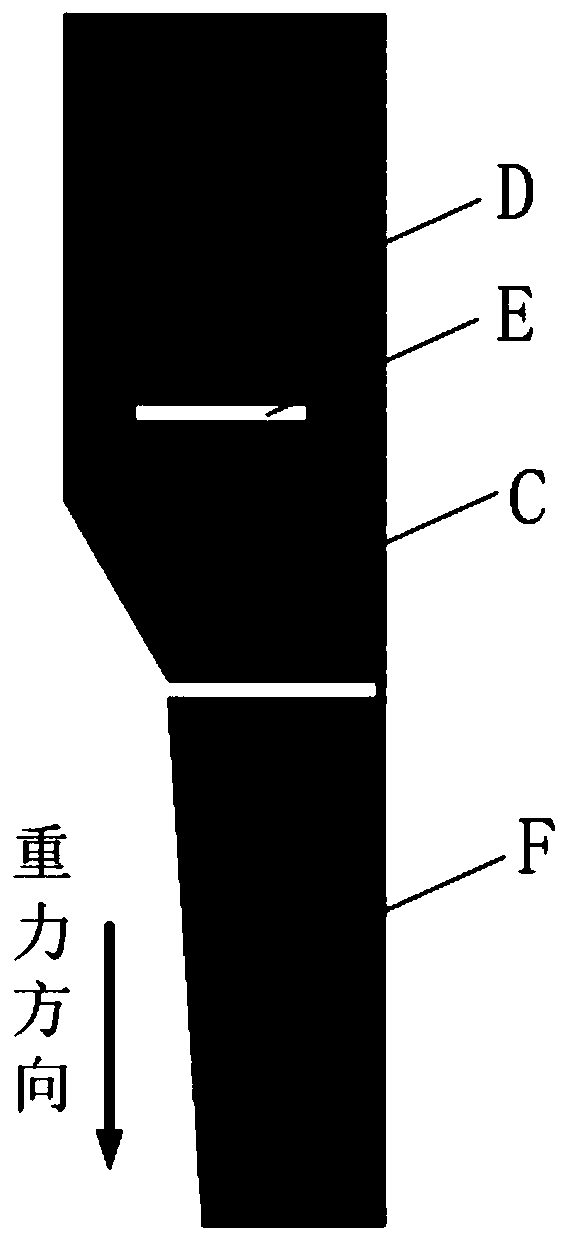

[0031] Such as figure 1 , figure 2 with image 3 As shown, the present invention has a natural convection enhanced heat dissipation structure with non-uniform heat source distribution, including a heat dissipation thin substrate C (the heat dissipation thin substrate C is a lightweight thin aluminum substrate, which is the most basic component of the entire heat dissipation structure, and all other components are related to it. connected), placed on the upper part of the heat dissipation thin substrate C with a flowering tooth D with ventilation holes E, placed on the inclined tooth F on the lower part of the heat dissipation thin substrate C, and on the back of the heat dissipation thin substrate C is provided with a low-power heat source S0, the heat dissipation thin There are multiple high-power heat sources distributed on the back of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com