Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Reduce local temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

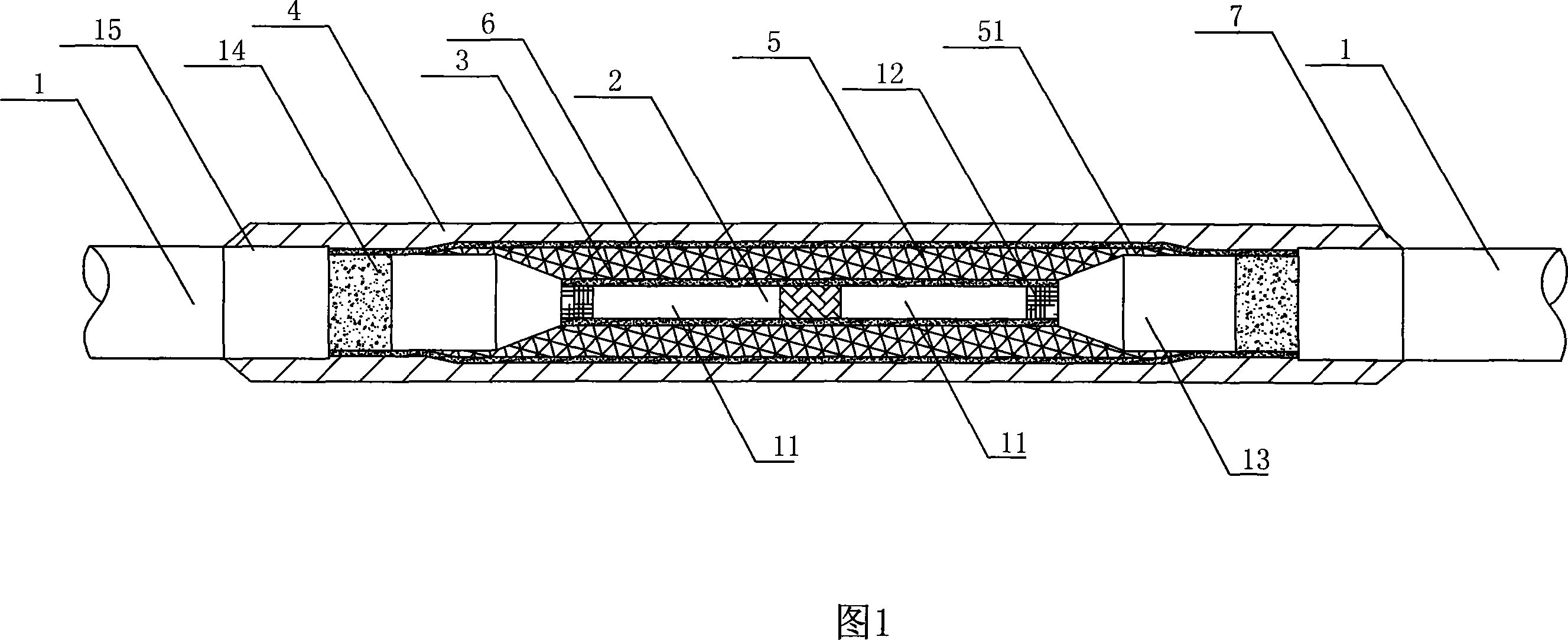

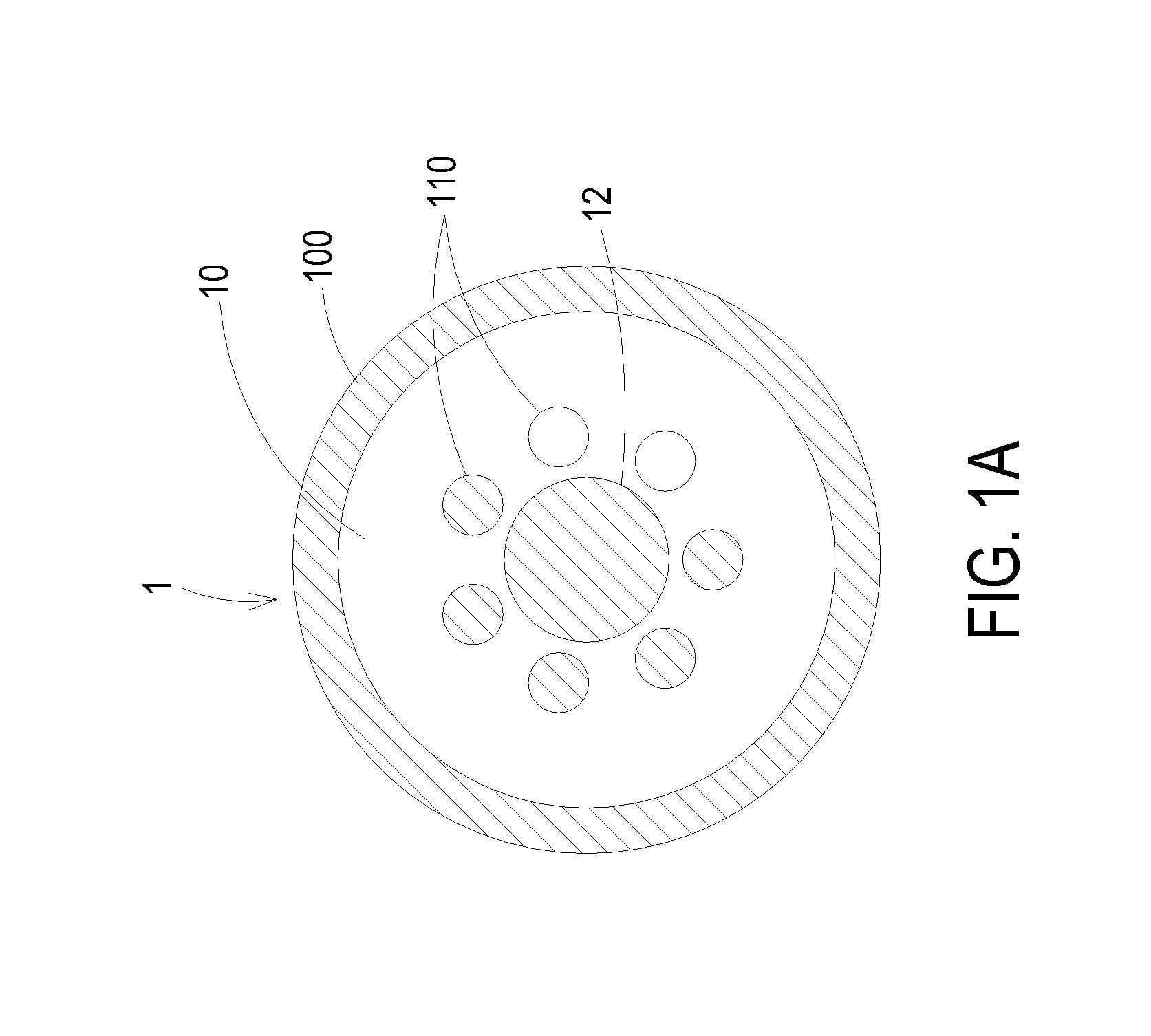

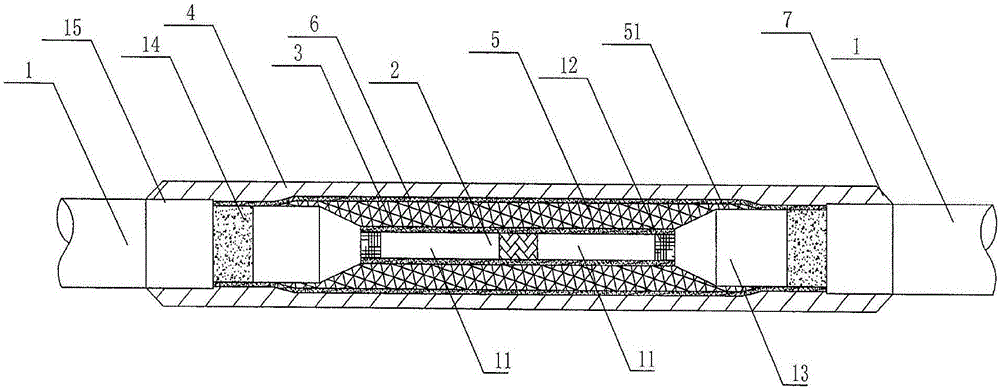

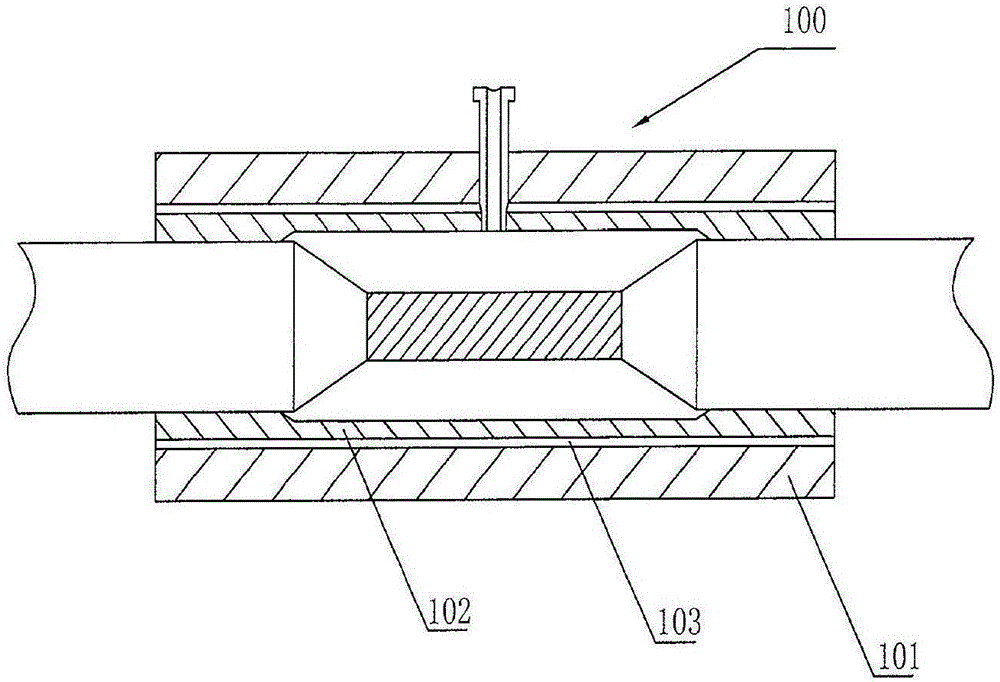

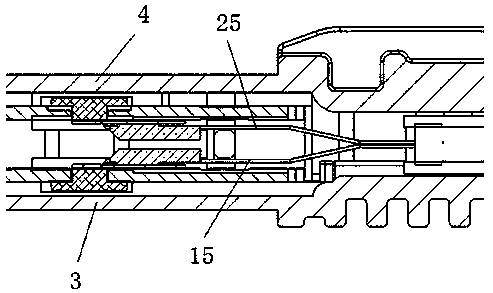

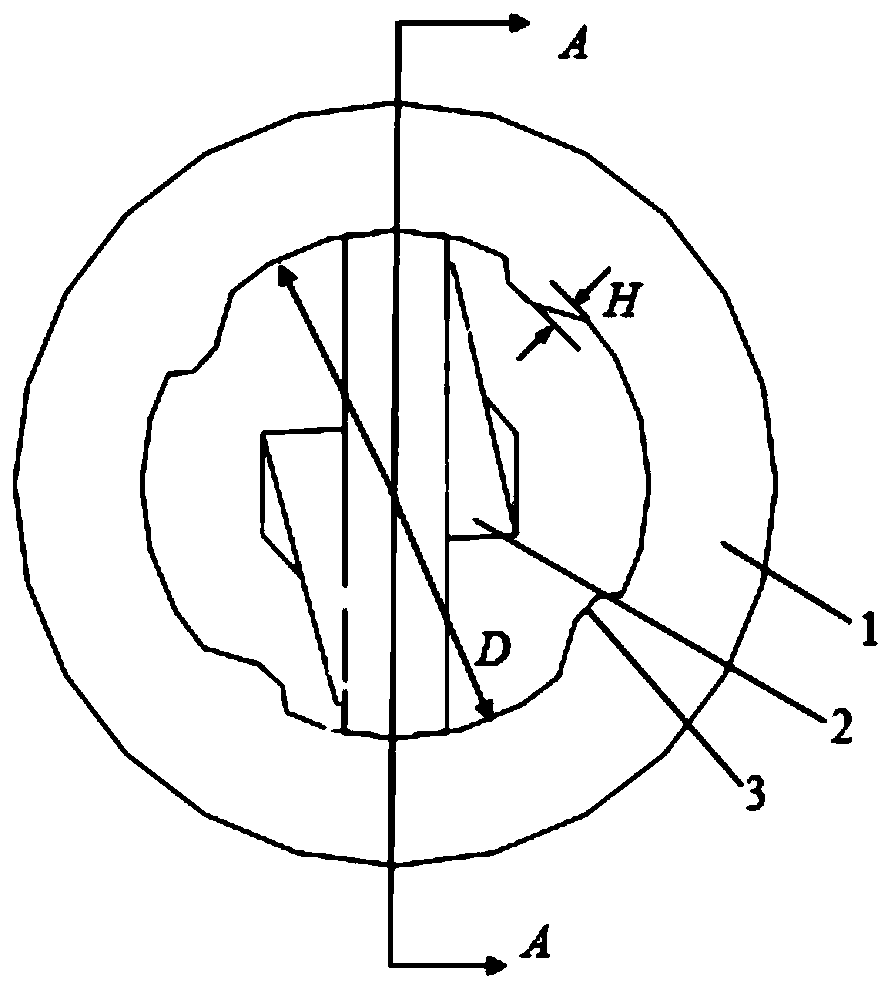

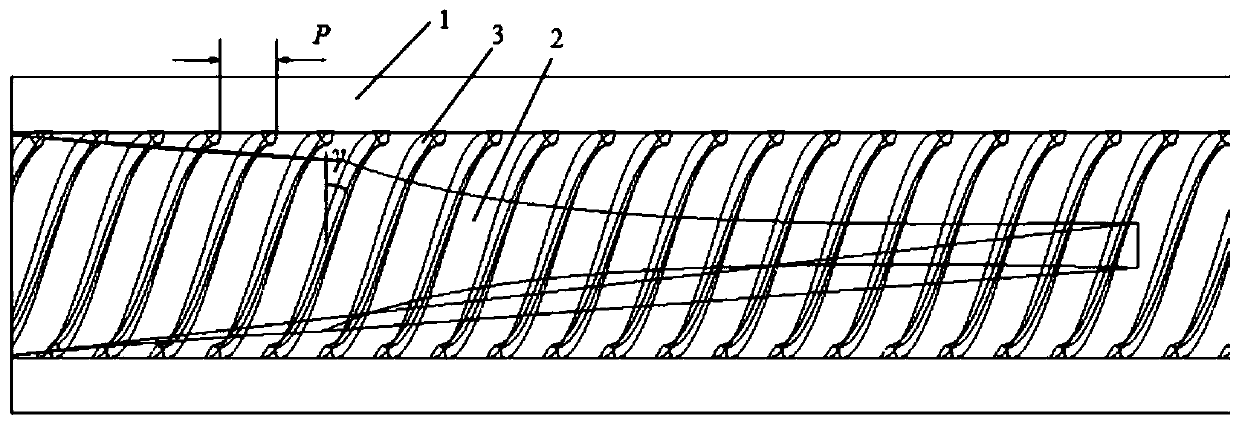

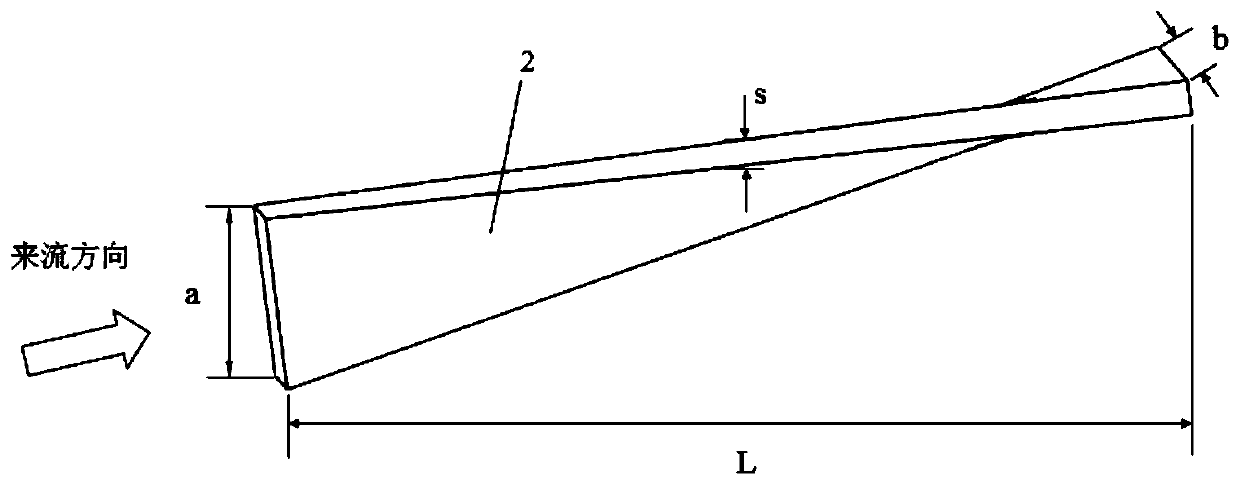

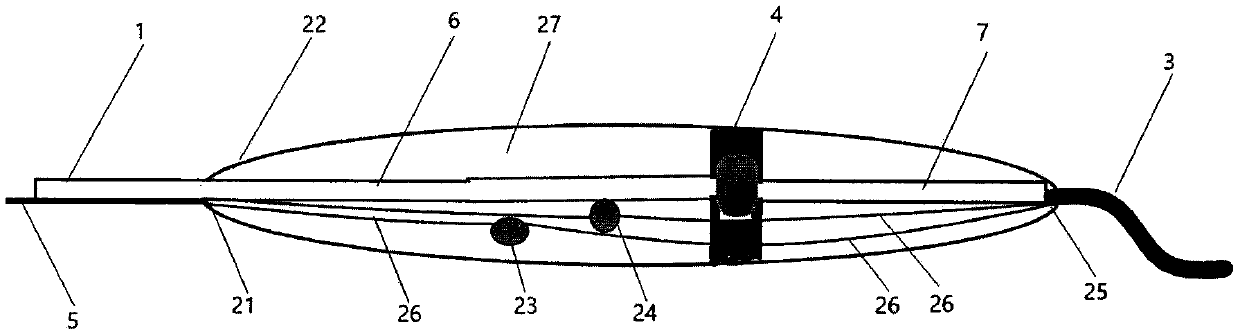

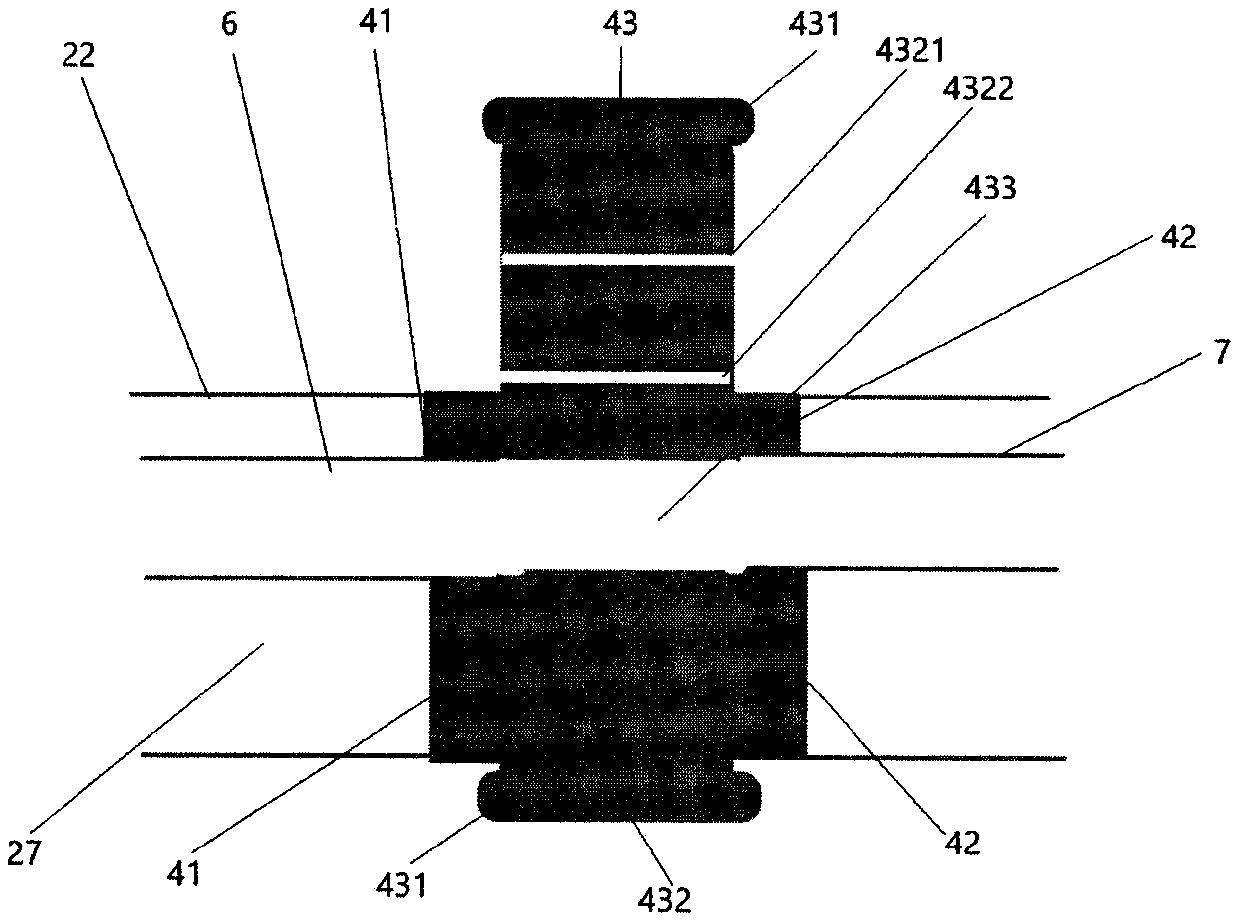

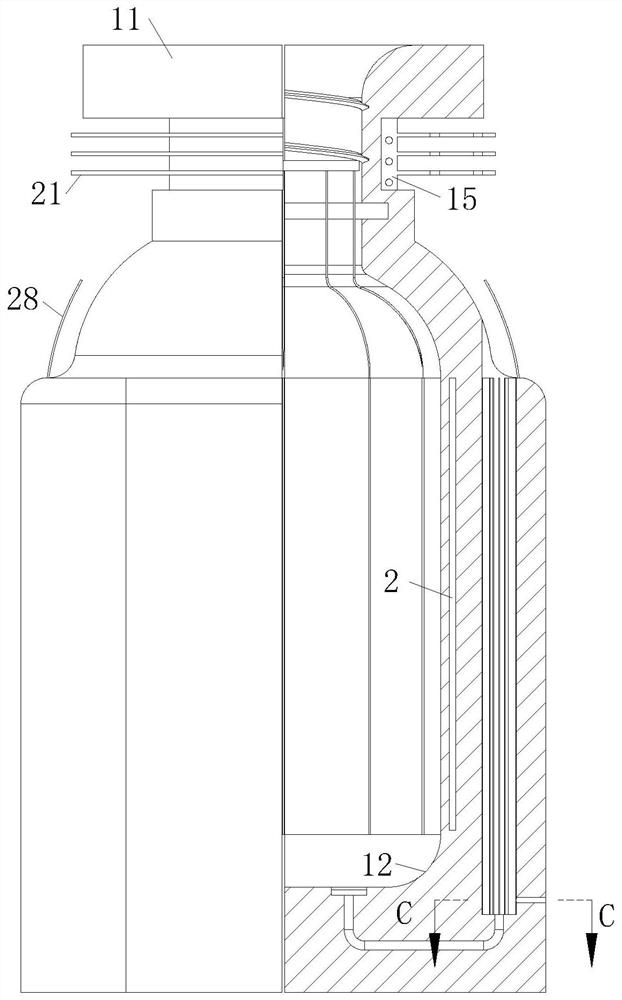

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

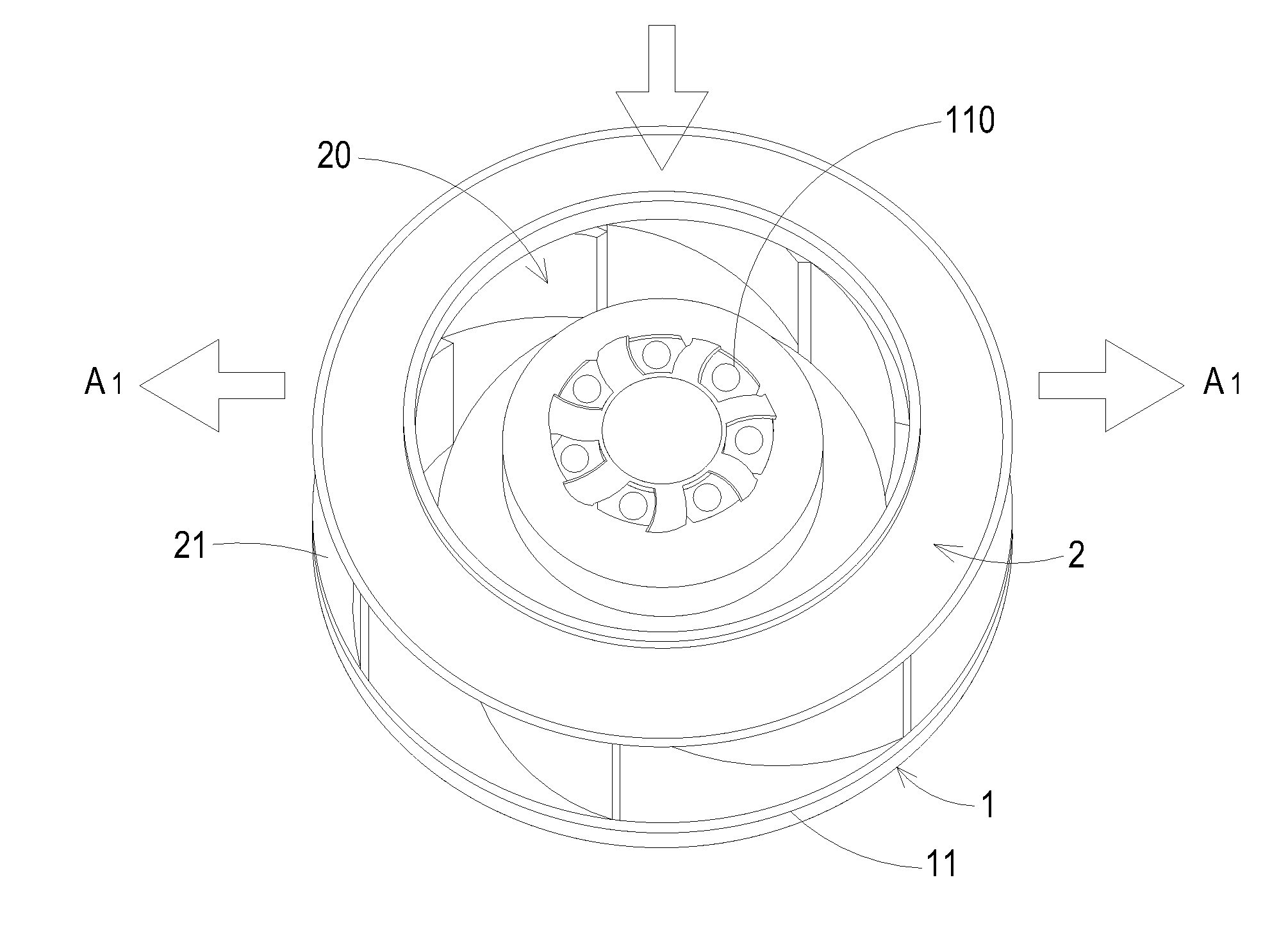

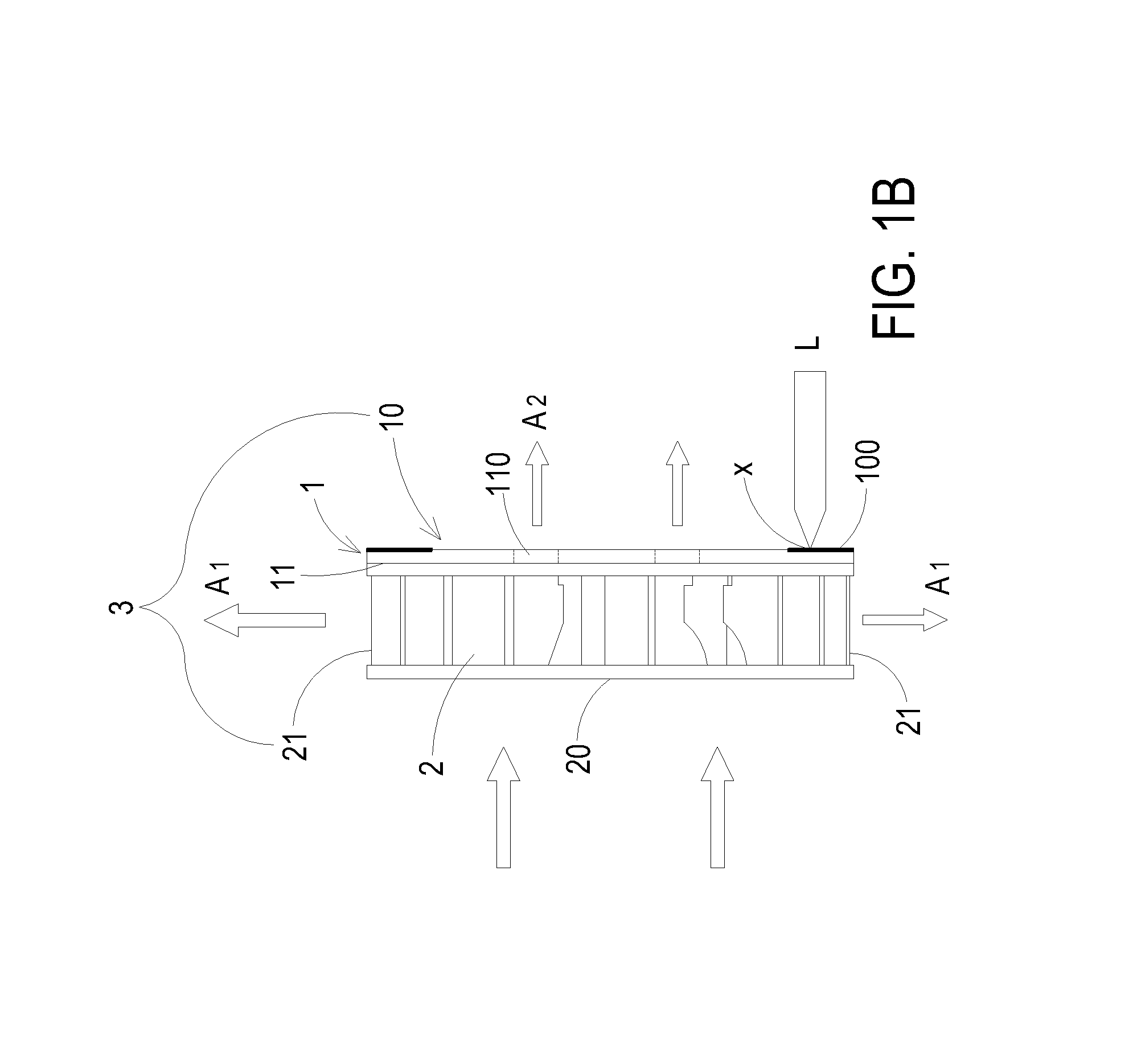

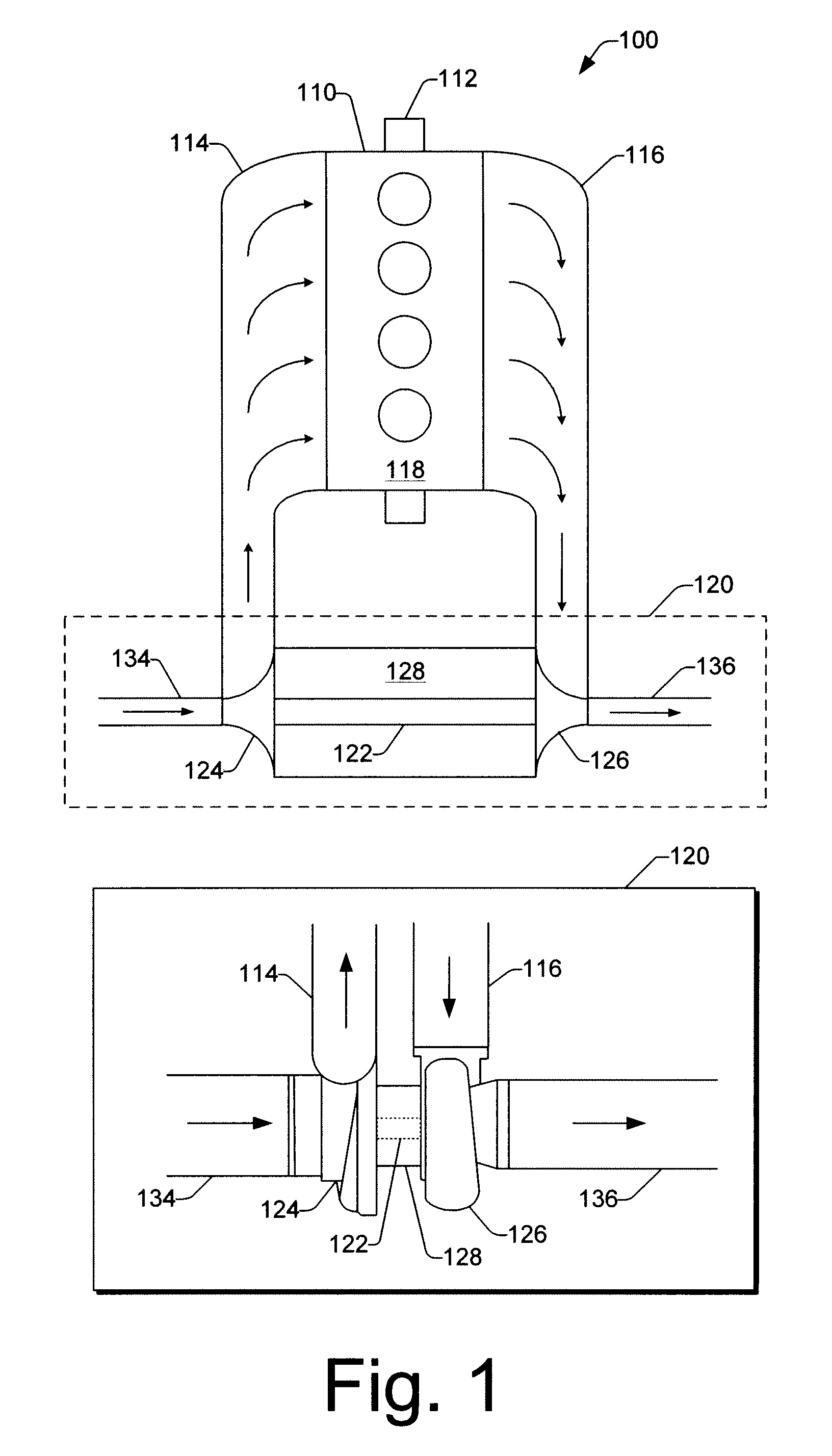

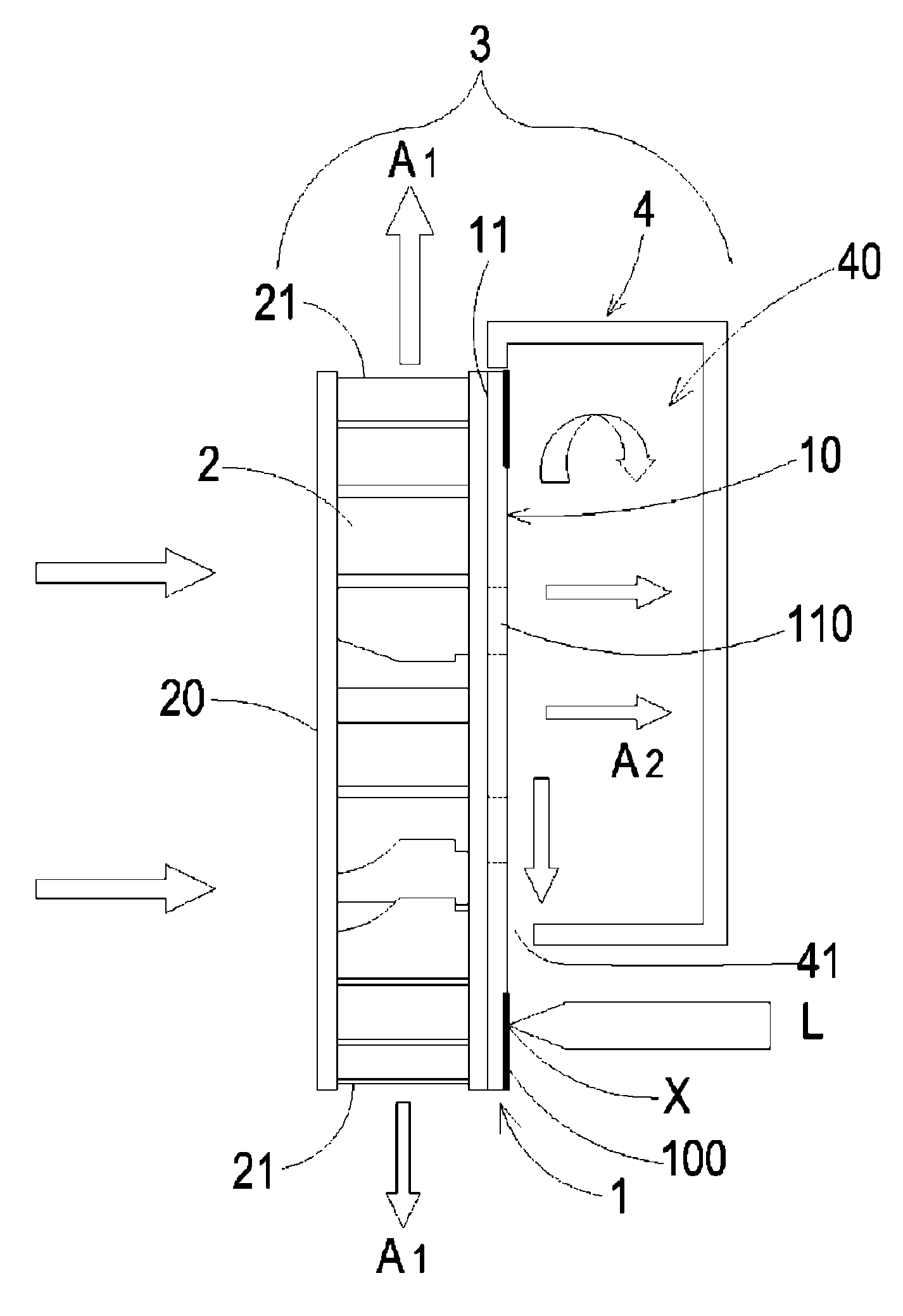

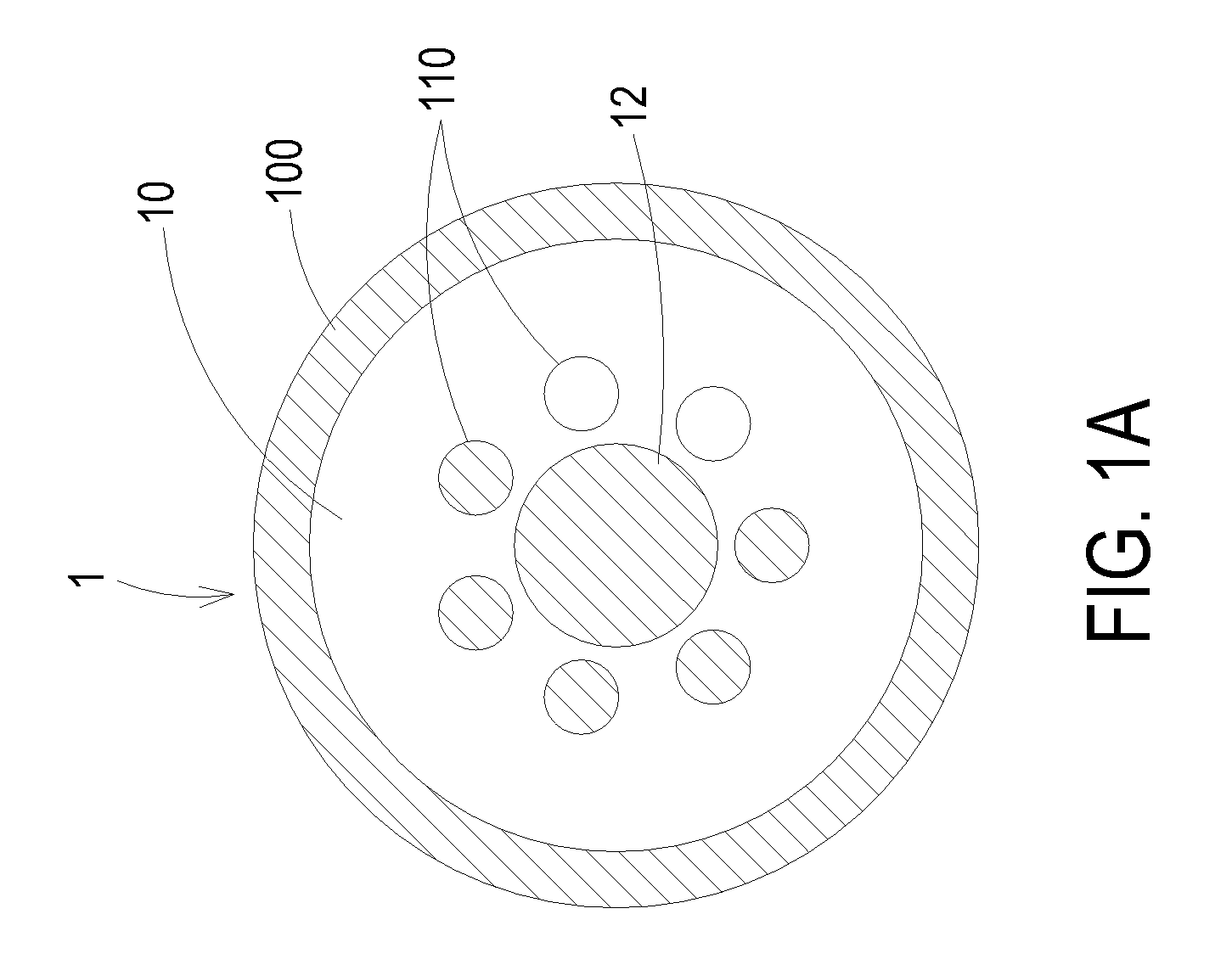

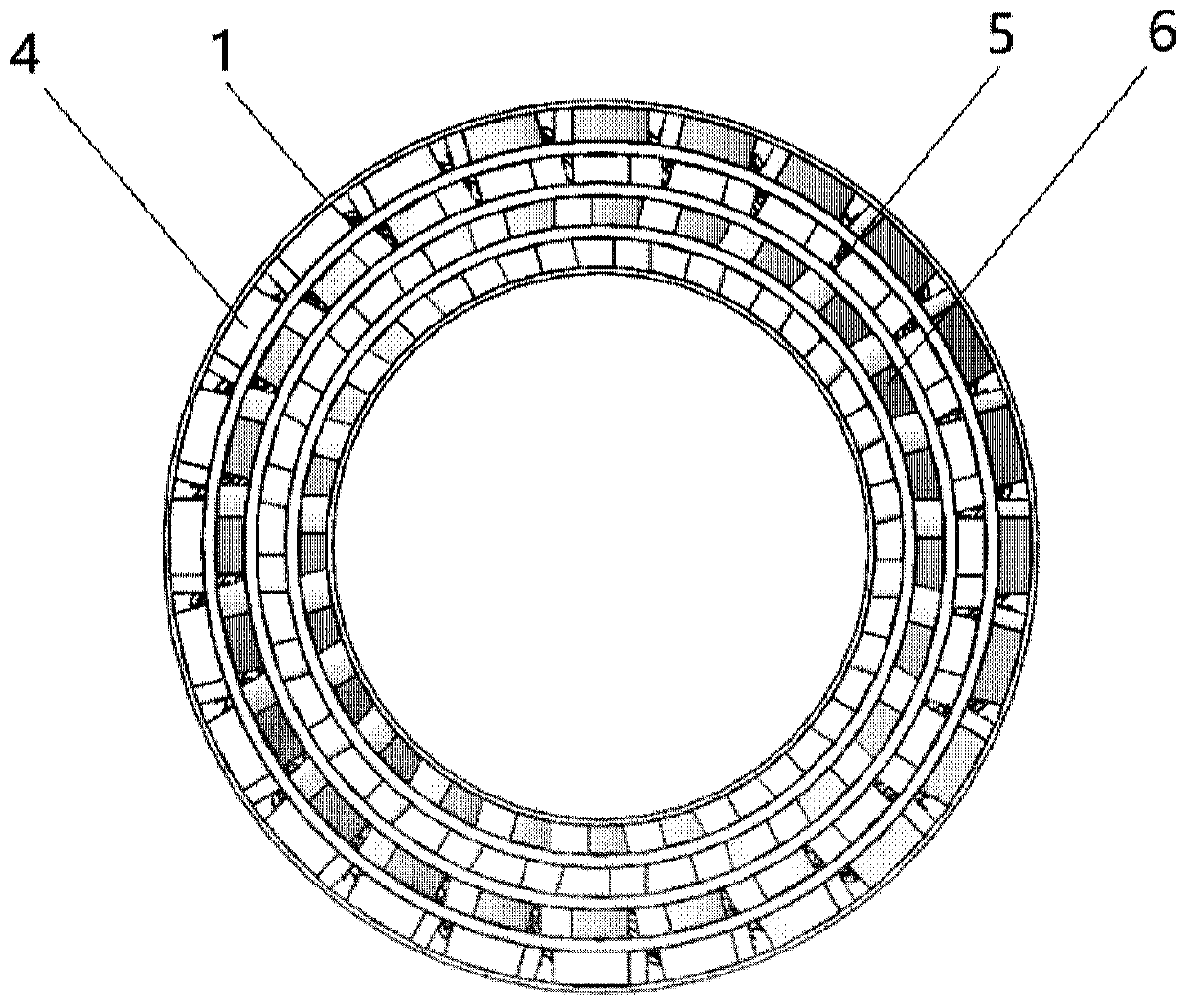

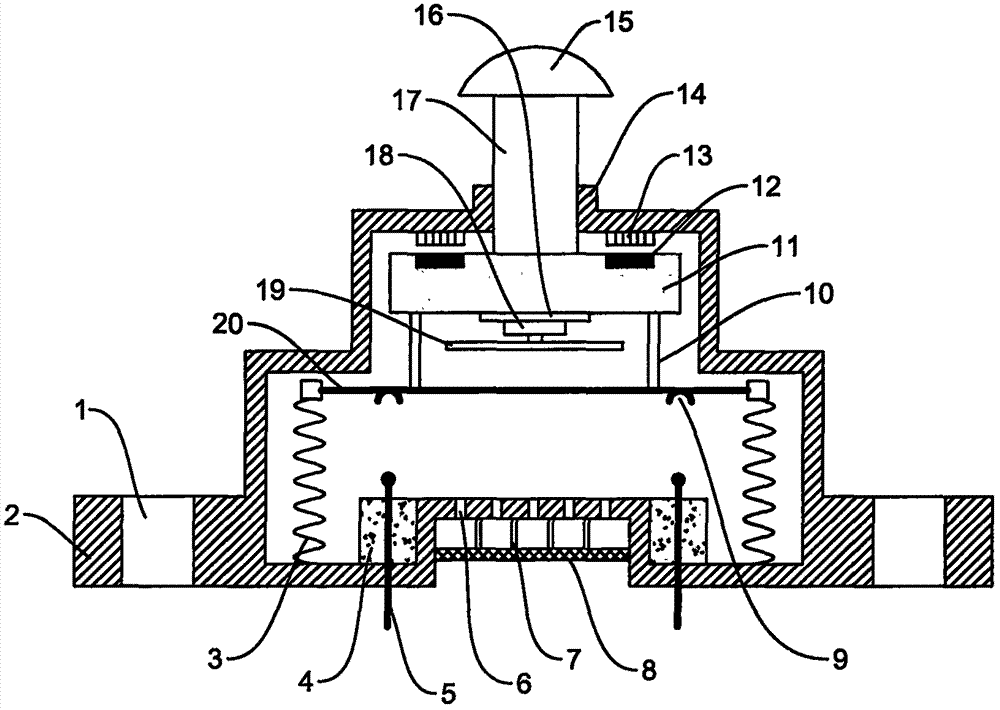

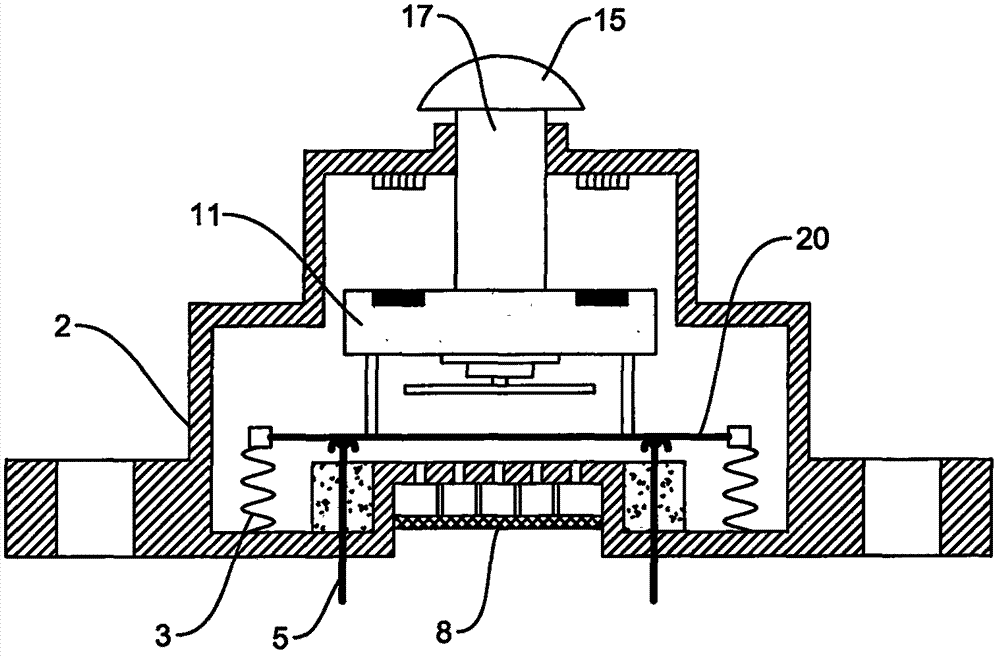

Phosphor wheel heat-dissipating module for laser projection system

A phosphor wheel heat-dissipating module for a laser projection system is provided. The phosphor wheel heat-dissipating module includes a phosphor wheel, a plurality of air vents and an impeller. At least one phosphor agent is coated on an outer-ring portion of a first surface of the phosphor wheel. The air vents run through the phosphor wheel. The impeller is disposed on a second surface of the phosphor wheel, and includes an inlet and a first outlet. A laser beam is projected on the outer-ring portion of the phosphor wheel. When the phosphor wheel is rotated at a high rotating speed, an airflow is inhaled into the impeller through the inlet. A first portion of the airflow is blown out through the first outlet, and a second portion of the airflow is transferred to the first surface of the phosphor wheel through the air vents.

Owner:DELTA ELECTRONICS INC

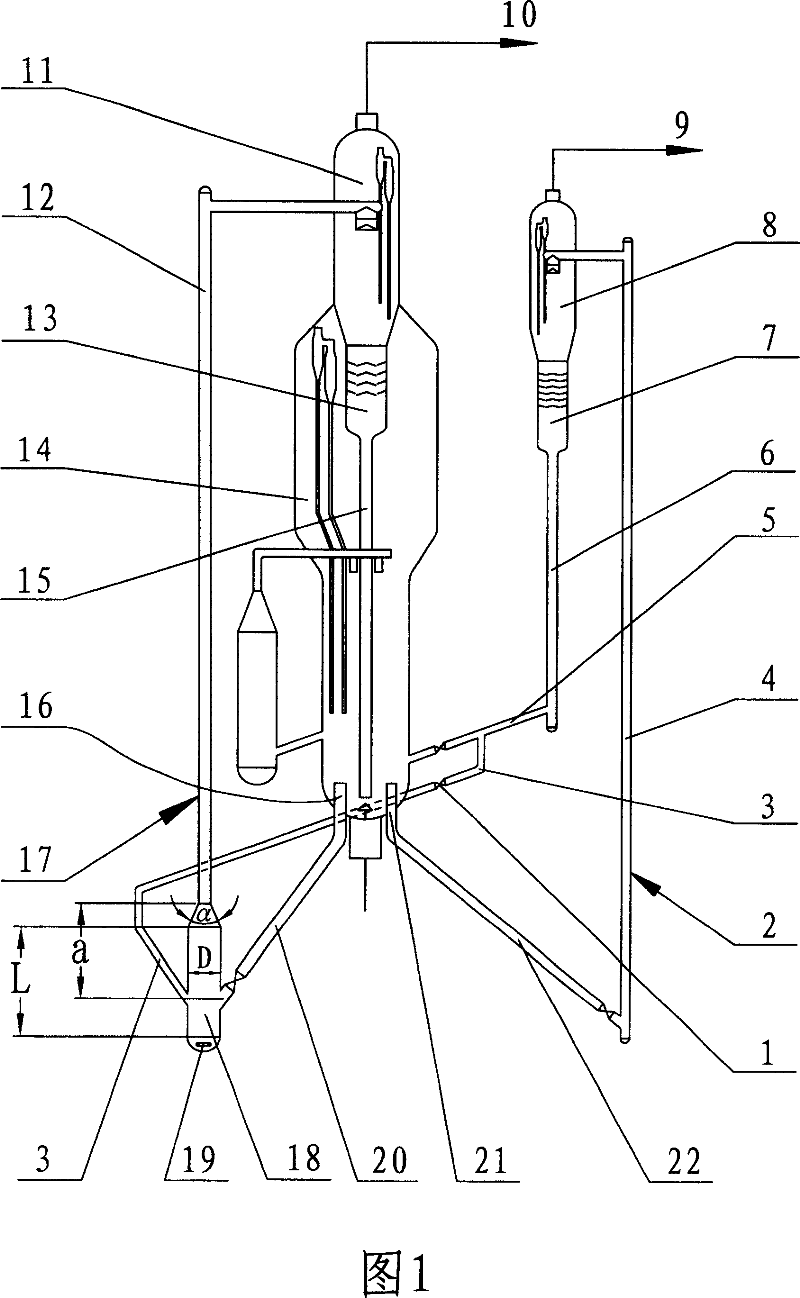

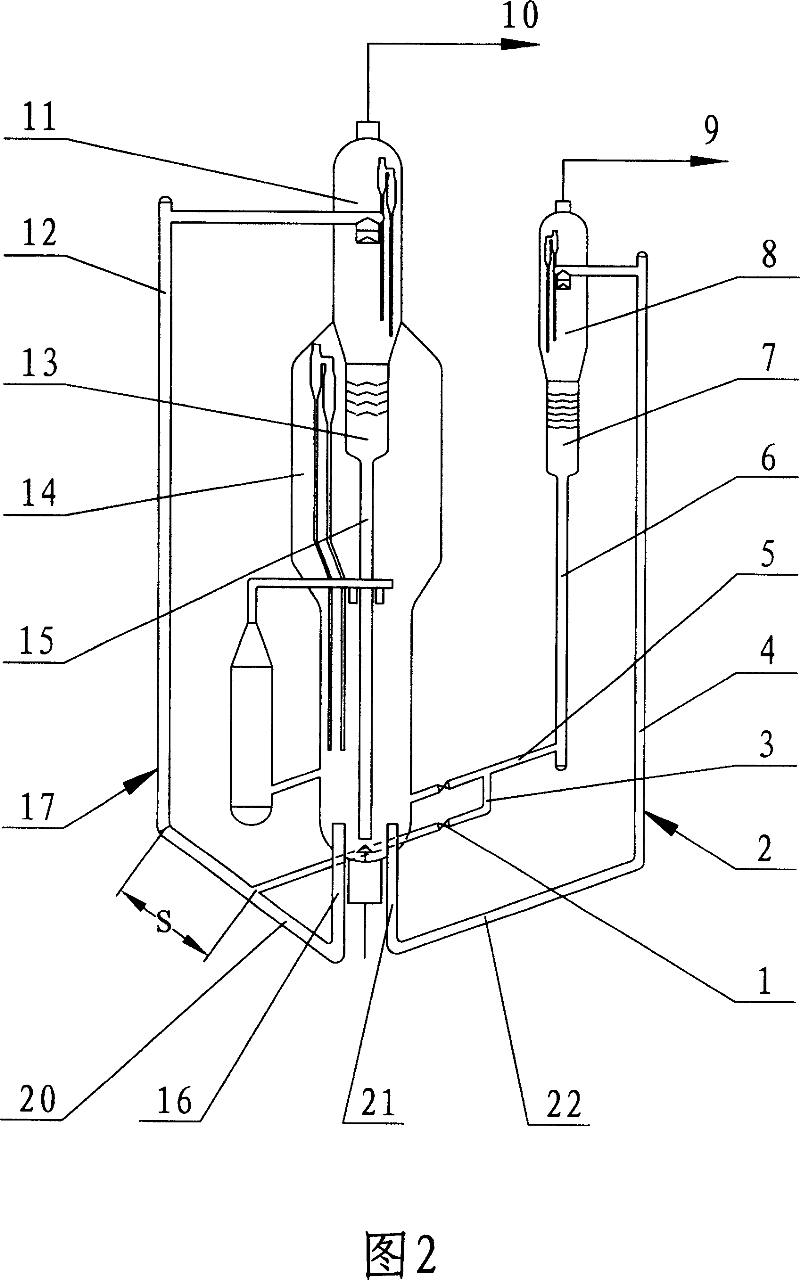

Catalytic cracking method and apparatus

ActiveCN100338185CReduce carbon contentHigh activityCatalytic crackingChemical industryControl valves

The invention discloses a kind of catalysis crack method and its device in petroleum chemical industry, to solve the problems as the whole activeness reduction of mixed catalysts and the flexibility lack of adjusting the agent-oil proportion of heavy oil riser reactor caused by the mixing wise of the spend catalyst and regenerating catalyst of the present two-riser catalysis crack device. The main characteristics of the invention method are: part of the spent catalyst from the light hydrocarbon riser reactor (4) gets into catalyst mixer through the spent catalyst duct (3) set flow control valve (1) after water vapour stripped in the stripping section (7) of the second settler, and gets into heavy oil riser reactor (12) to react after mixed by the effect of water vapour with the regenerating catalyst form regenerator (14) in catalyst mixer. The method of the invention is suitable to be used in the two-riser catalysis crack craft and the three-riser catalyst crack craft set heavy oil riser reactor; the invention has disclosed related devices.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

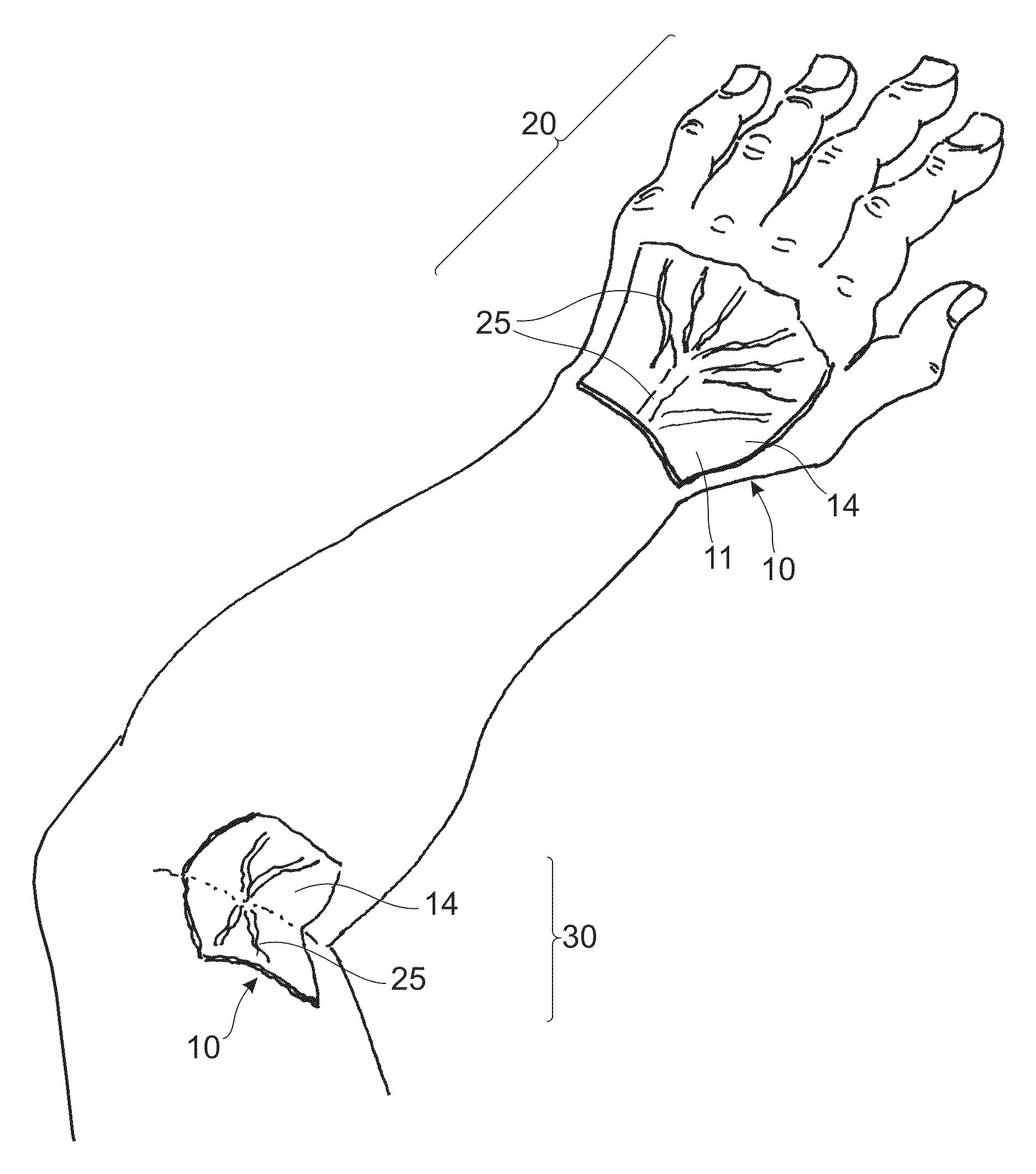

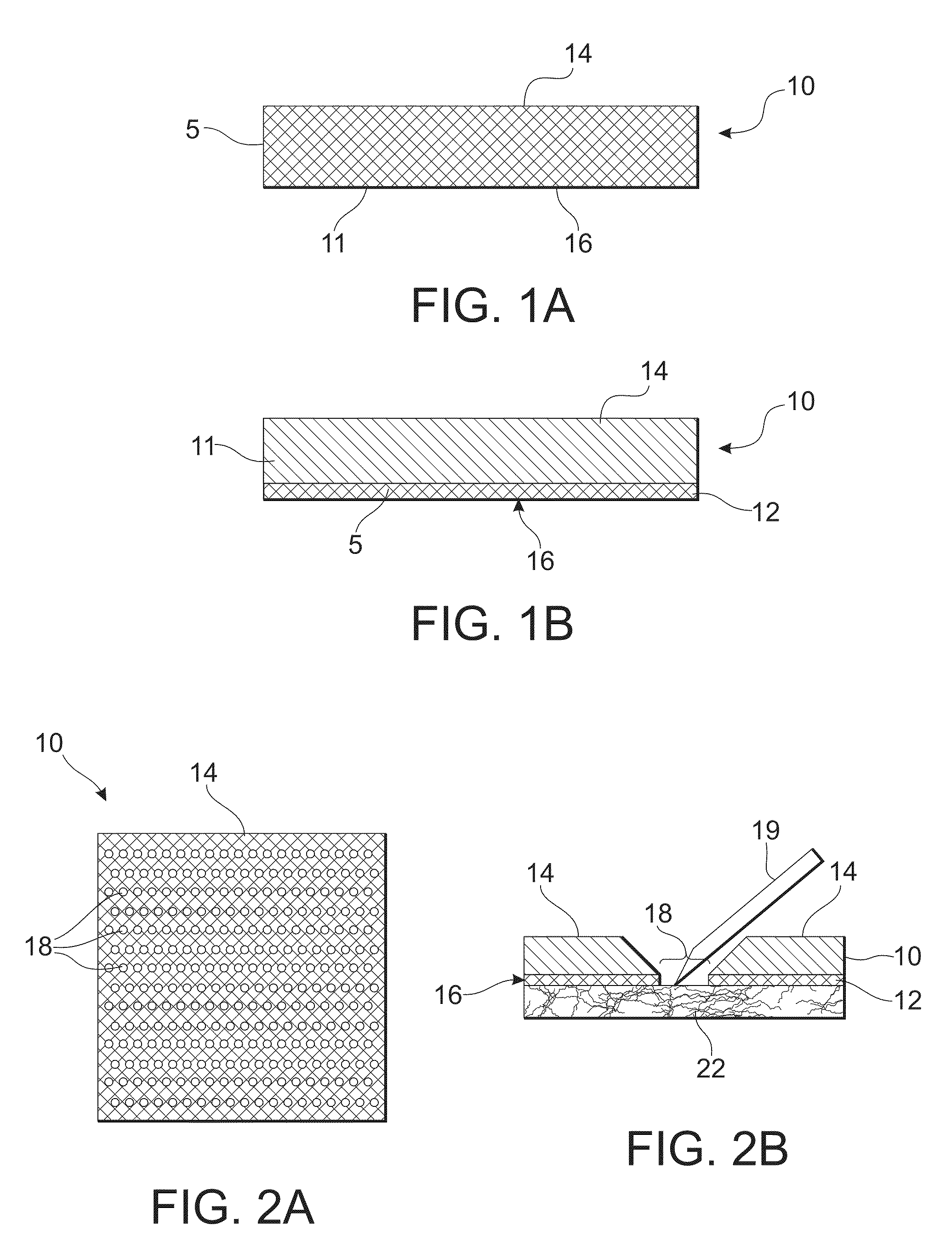

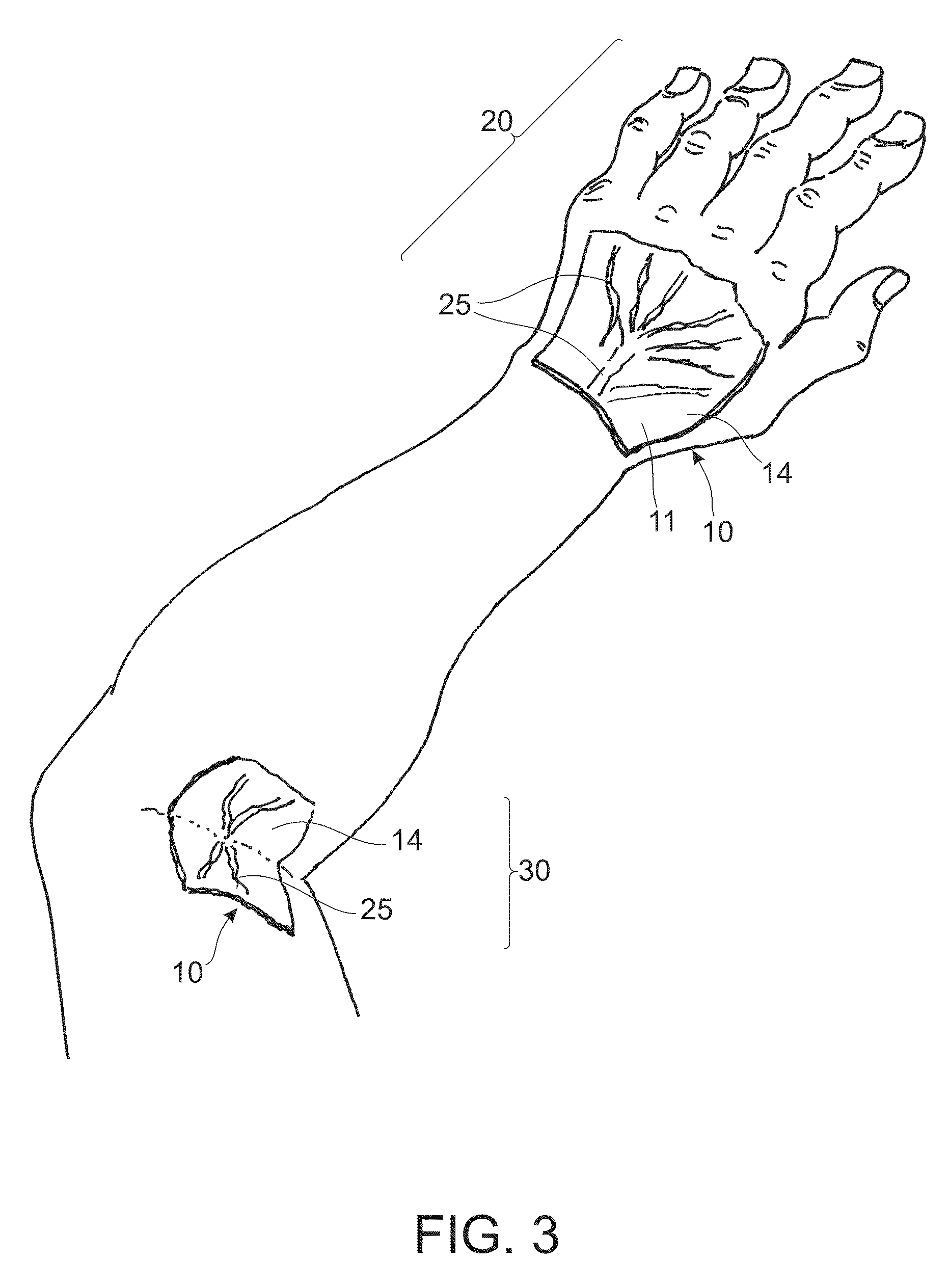

Self-cooling gel substrate for temperature differentiated imaging

InactiveUS20110077527A1Improve visualizationEasy to detectCompounds screening/testingLuminescence/biological staining preparationCooling gelBiomedical engineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

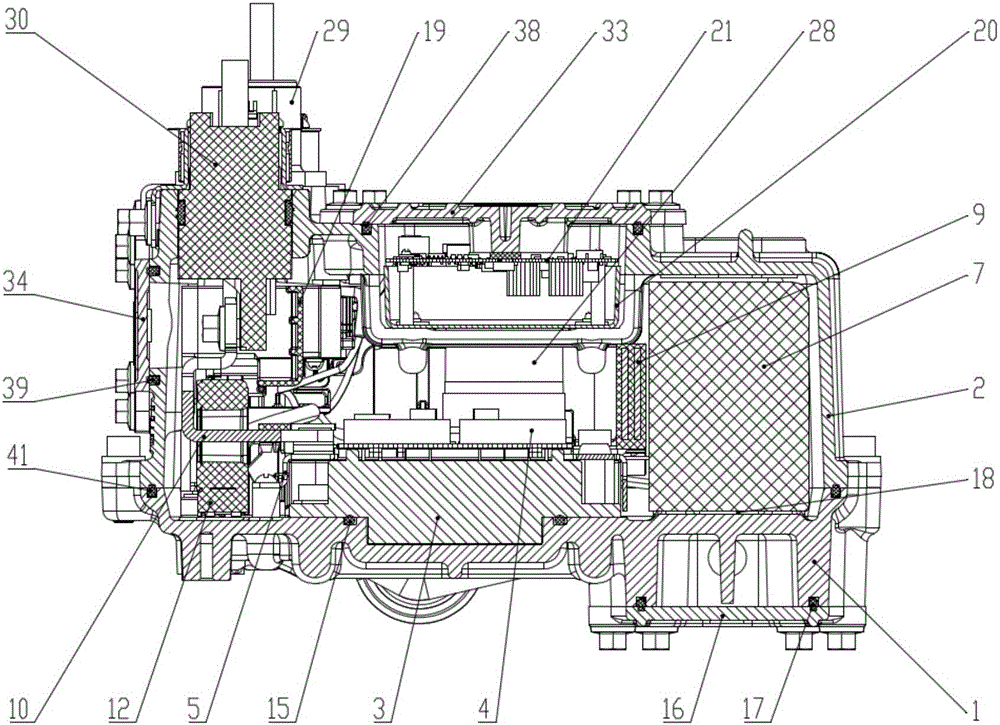

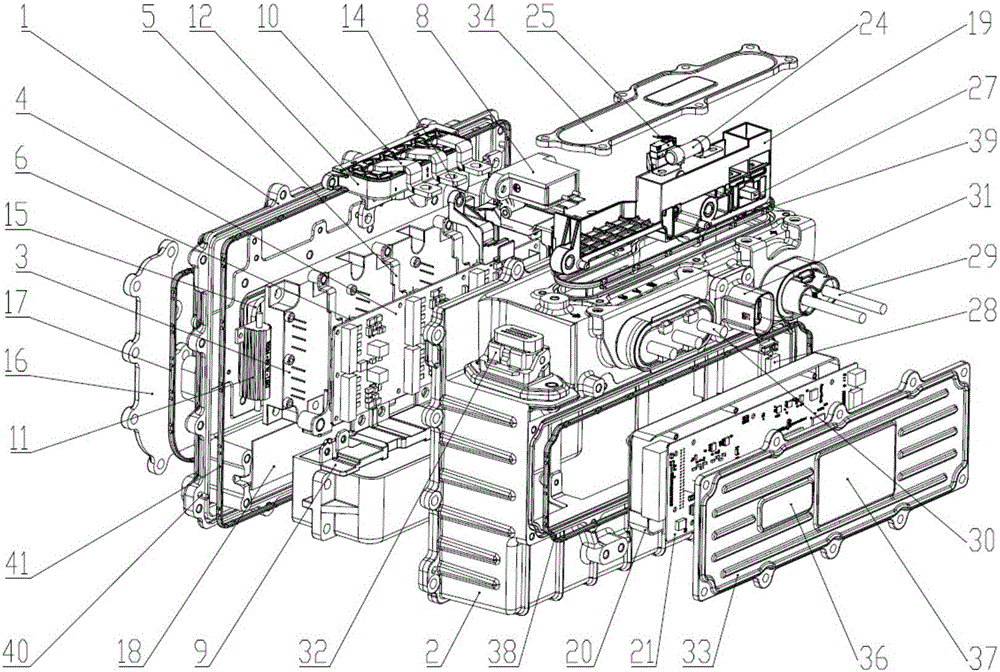

Electric car motor controller

ActiveCN105846750AReduce volumeAchieve mutual complementarityAC motor controlCooling/ventilation/heating modificationsCapacitanceLow voltage

The invention relates to an electric car motor controller. The controller comprises a direct current bus capacitor, an IGBT module, a metal support, a driving board, a current sensor, an AC busbar, a DC busbar assembly and a Y capacitor which are arranged in a main box body. An upper box body is also included. An internal portion of the upper box body is provided with a wire connection seat assembly, a shielding board, a control board, a cathode change over busbar, an anode change over busbar, an air conditioning connector, a microswitch, an air conditioning insurance and a direct-current high-voltage interlock connector. A direct current connector, an alternating current connector, an air conditioning connector, a low voltage connector, a control board cover and a junction box cover are fixed to an external portion of the upper box body. When the motor controller provided in the invention works, an IGBT and the direct current bus capacitor are vertically placed so that the controller can flexibly adapt to whole car arrangement. And simultaneously the controller possesses advantages that the structure is compact; power density is high; a heat dissipation effect is good; electromagnetic compatibility is good; operation safety is high and so on.

Owner:CHINA FIRST AUTOMOBILE

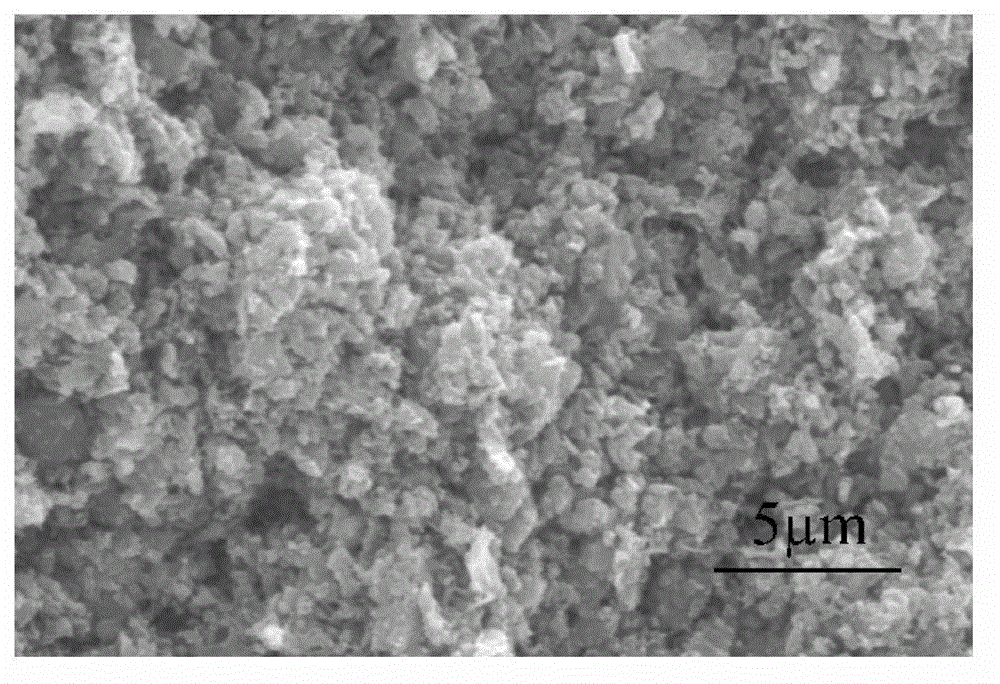

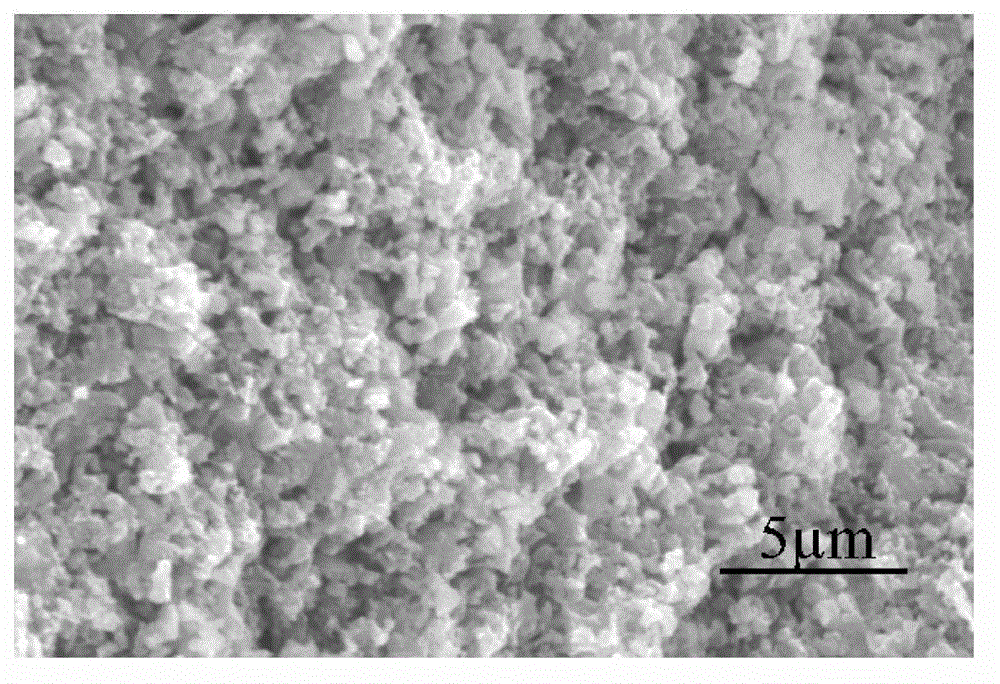

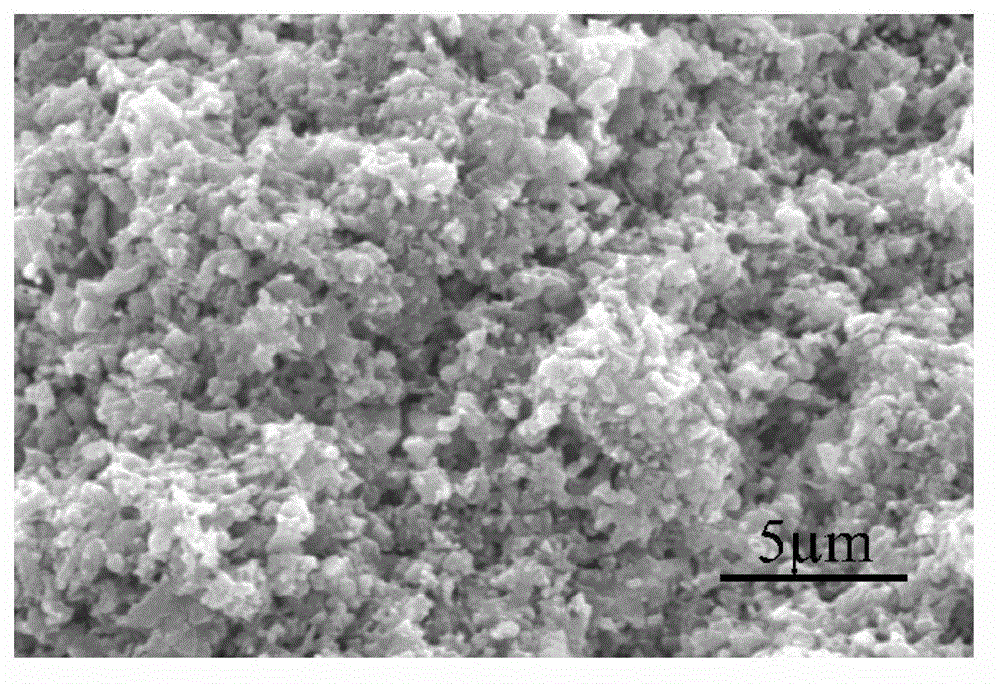

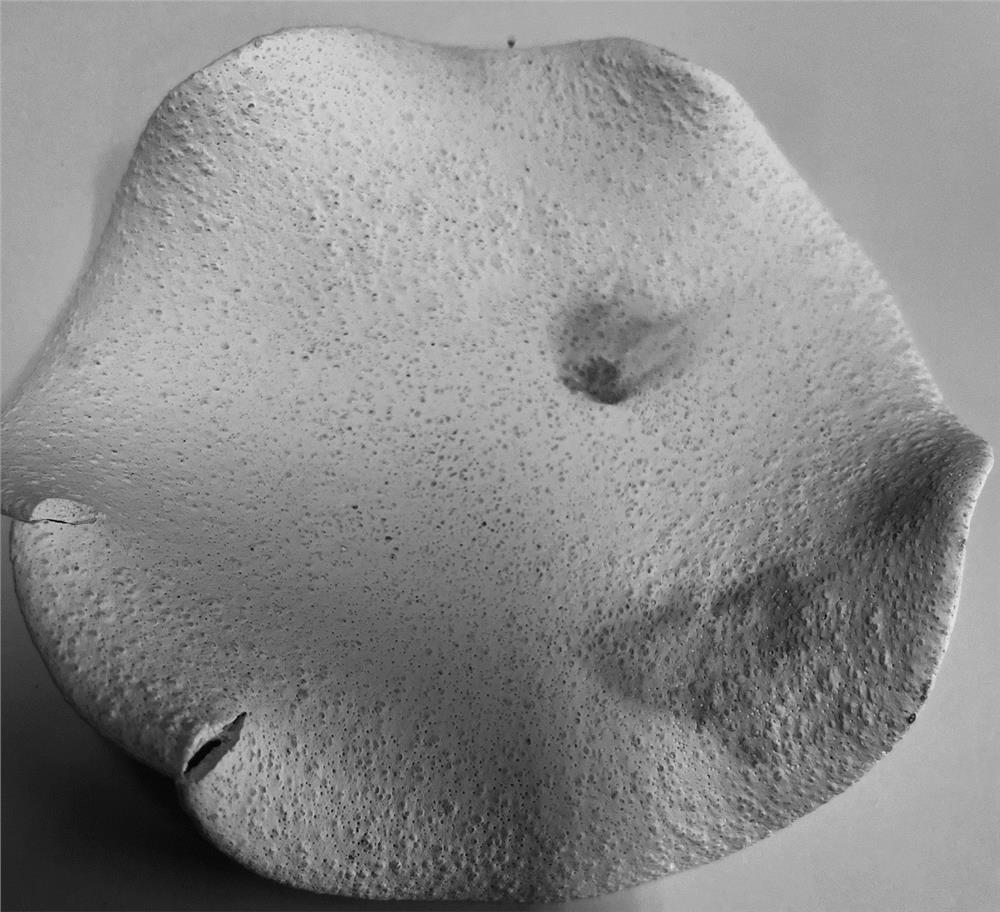

Silicon nitride/silicon carbide complex phase porous ceramic and preparation method thereof

The invention discloses a Si3N4 / SiC complex phase porous ceramic of which the nitriding ratio is higher than 85% and the porosity is 30-60%. The preparation method comprises the following steps: (1) by using Si and SiC as raw materials, adding a sintering assistant, and uniformly mixing by ball milling to obtain a slurry; (2) drying the slurry, screening, carrying out dry pressing, and carrying out cold isostatic pressing treatment to form a biscuit; and (3) putting the biscuit in a sintering furnace, heating to 900-1200 DEG C and then to 1300-1500 DEG C in a high-purity nitrogen atmosphere, sintering by nitriding reaction, cooling, and finally carrying out furnace cooling. The sintering method has the characteristics of short sintering time, simple technique, low energy consumption and the like, can easily obtain the Si3N4 / SiC complex phase porous ceramic material with net size molding, complicated shape, high porosity, controllable gap and oriented and interconnected gap structure, and is simple for molding; and the maximum bending strength can reach 150 MPa.

Owner:江西中科上宇科技有限公司

Helical inner diameter groove journal bearing

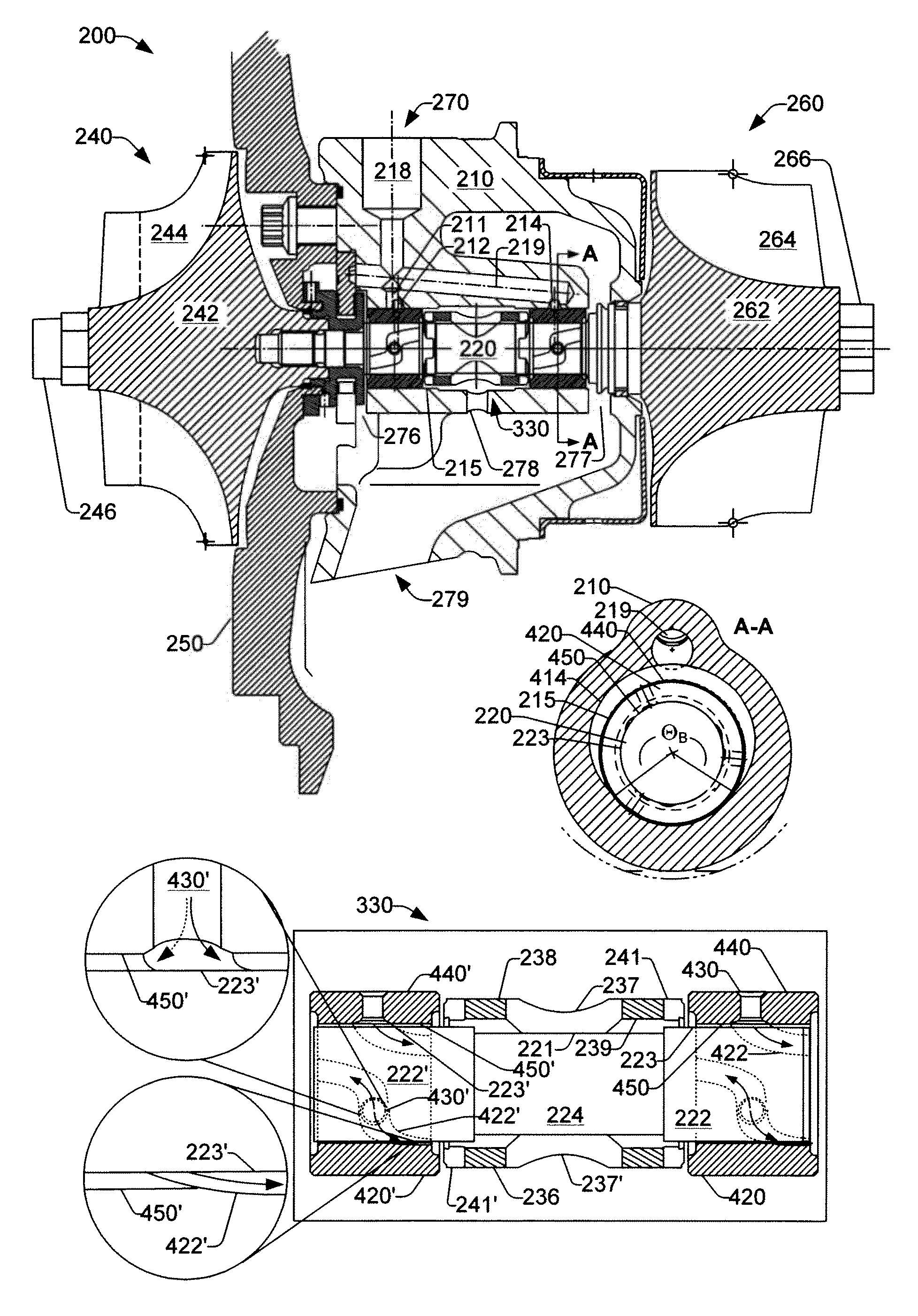

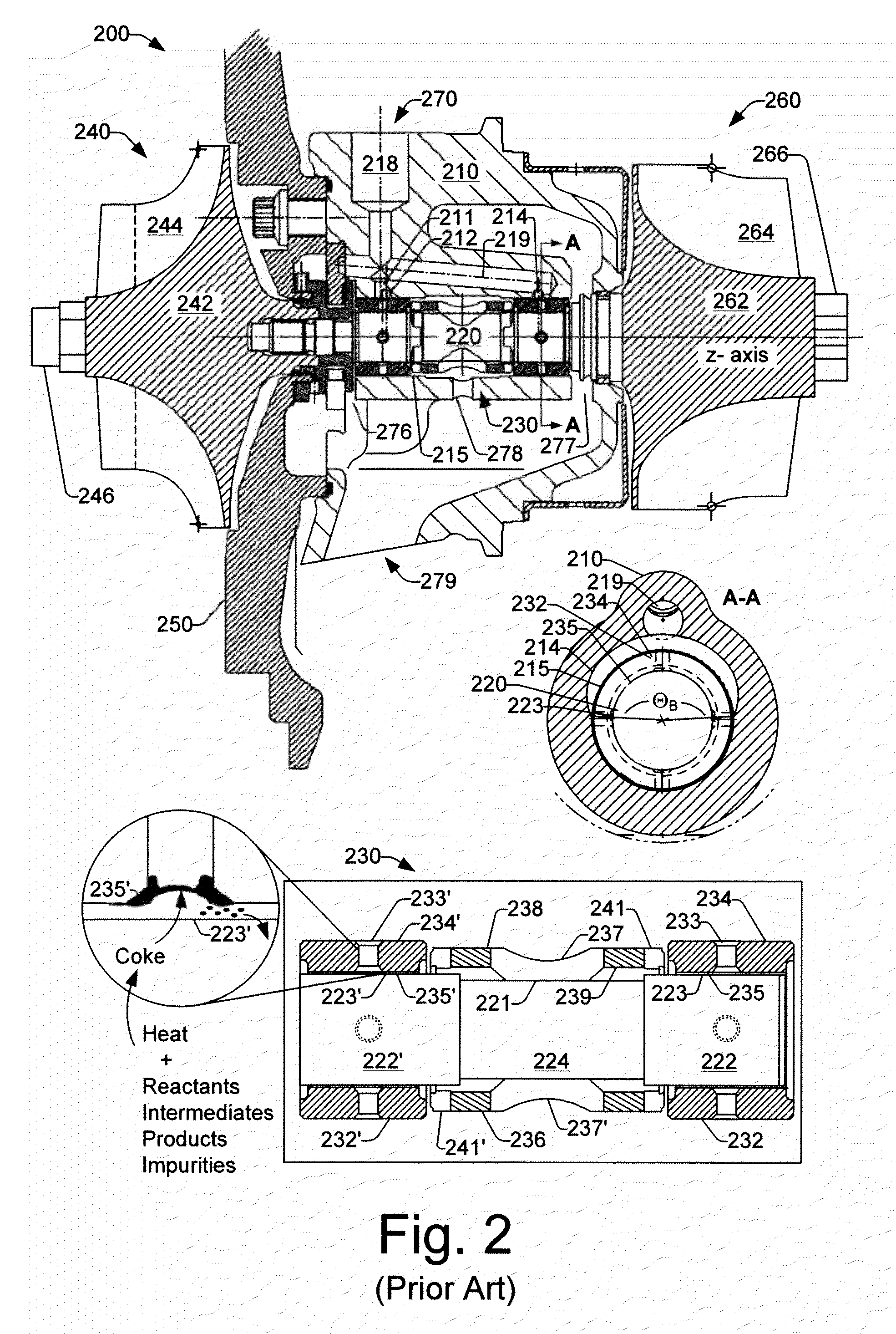

ActiveUS8075191B2Reduce local temperatureHigh viscosityEngine manufactureEngine fuctionsEngineeringTurbine

An exemplary bearing assembly includes a turbine side journal bearing with helical grooves along an inner journal surface where each helical groove includes a lubricant opening and opposing arms where each arm terminates at a respective axial surface of the journal bearing; a compressor side journal bearing with helical grooves along an inner journal surface where each helical groove includes a lubricant opening and opposing arms where each arm terminates at a respective axial surface of the journal bearing; and a spacer to space the turbine side journal bearing and the compressor side journal bearing along an axis. Various other exemplary devices, systems, methods, etc., are also disclosed.

Owner:GARRETT TRANSPORATION I INC

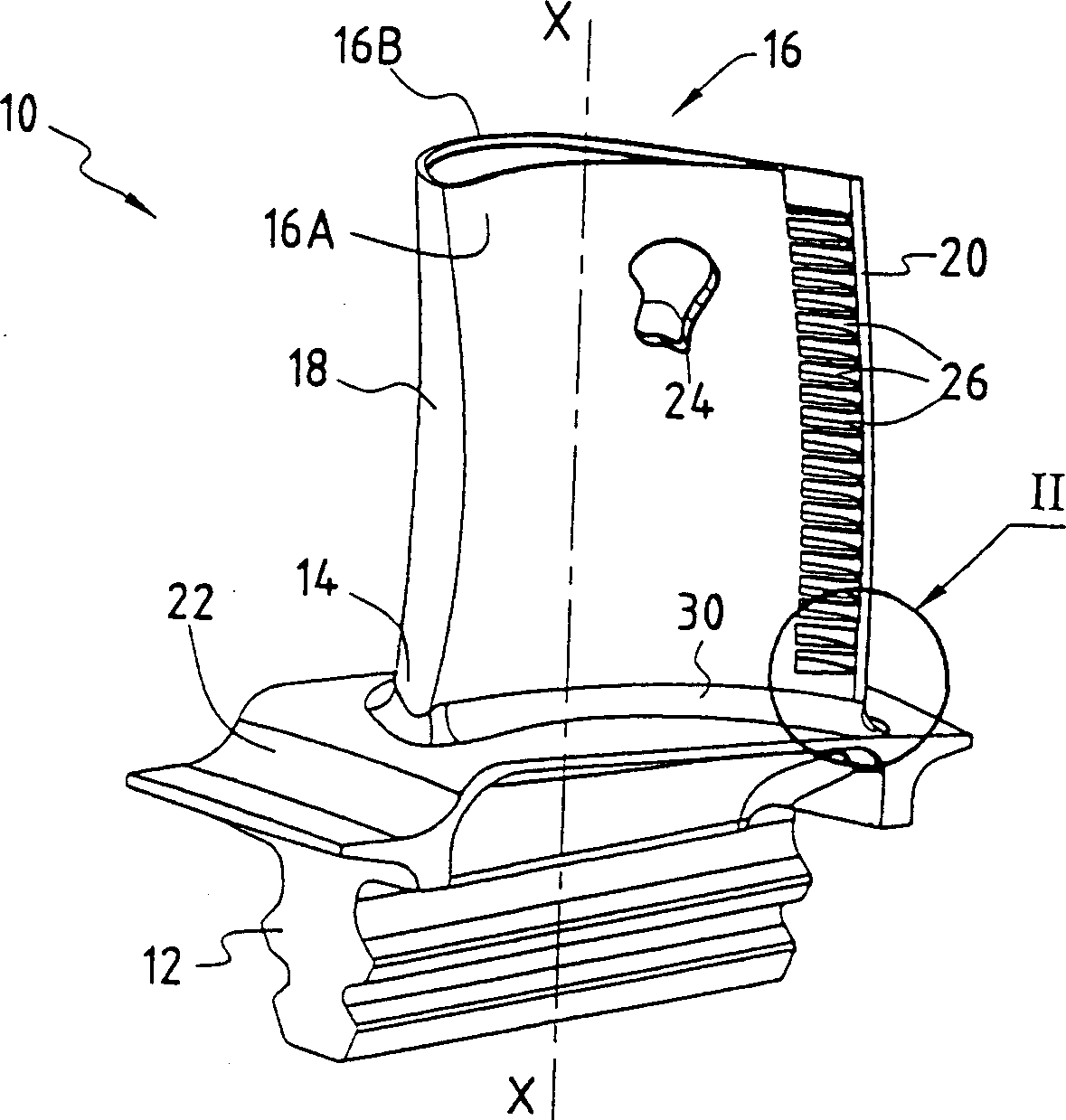

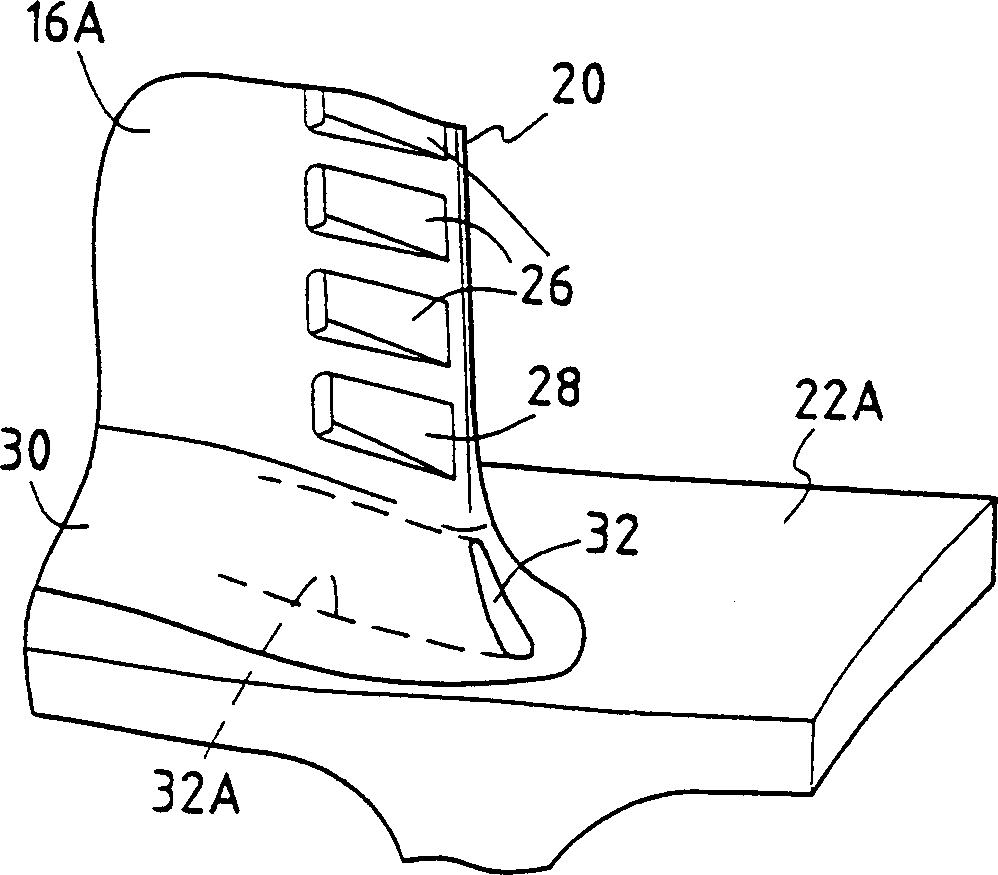

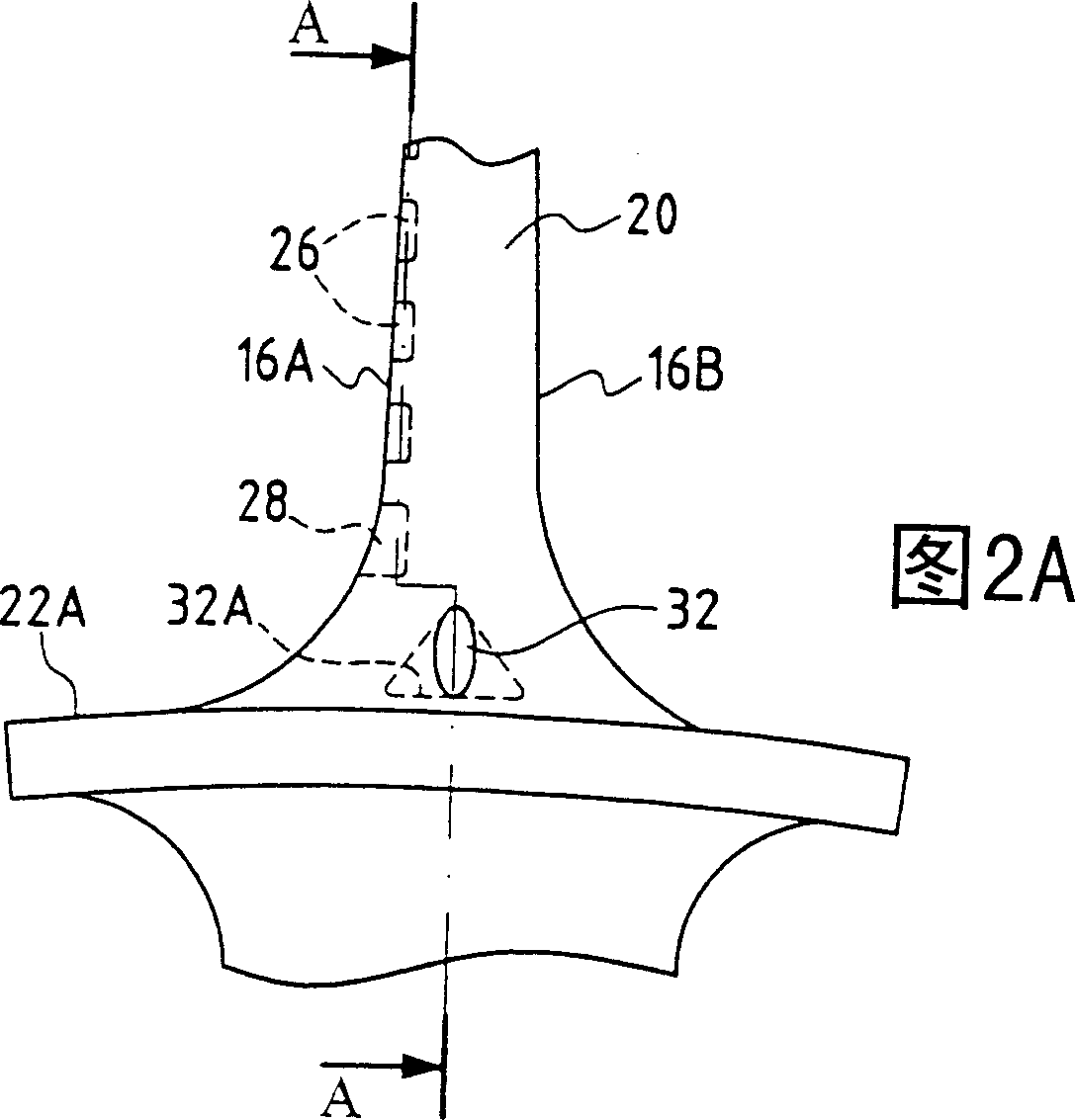

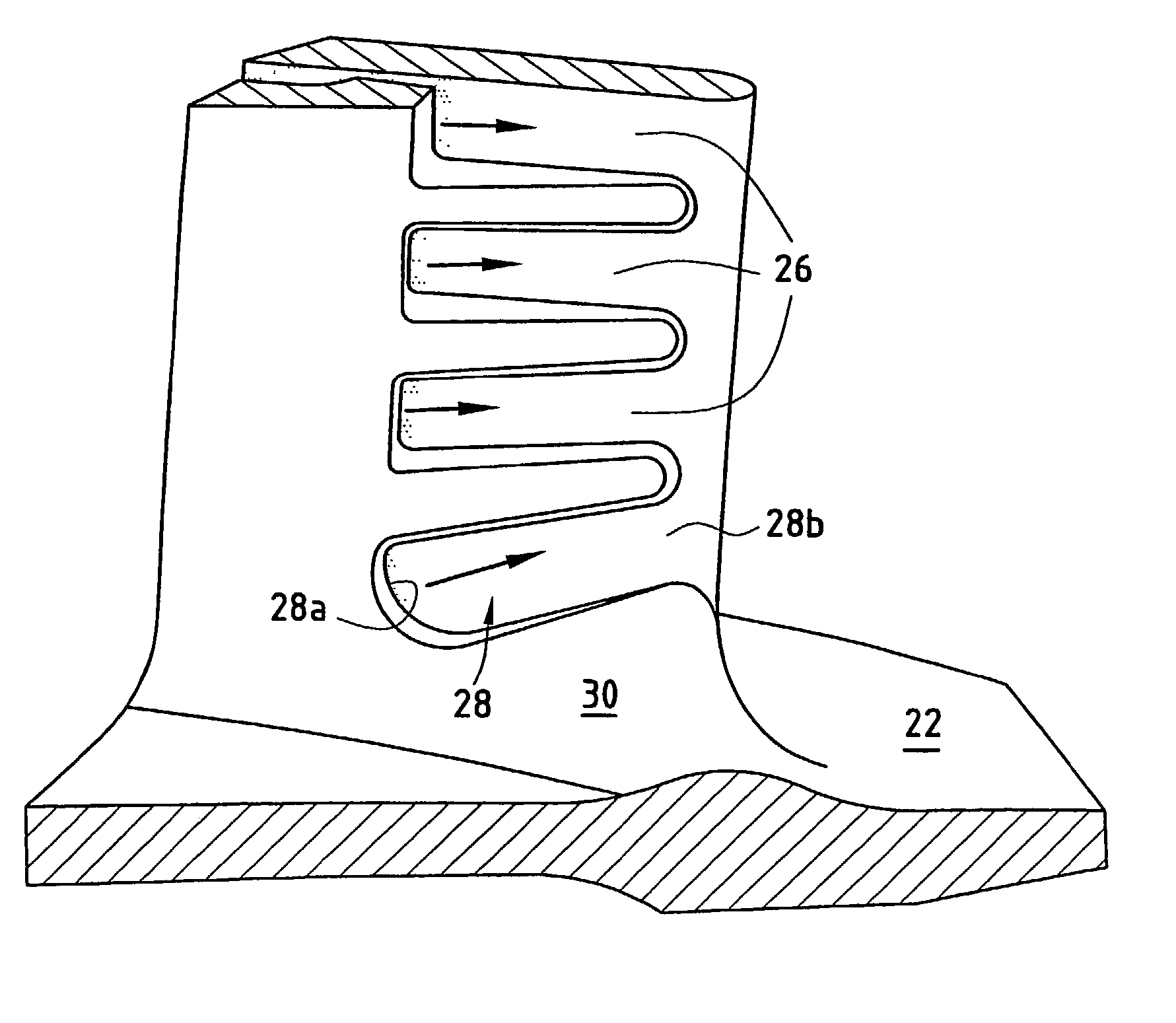

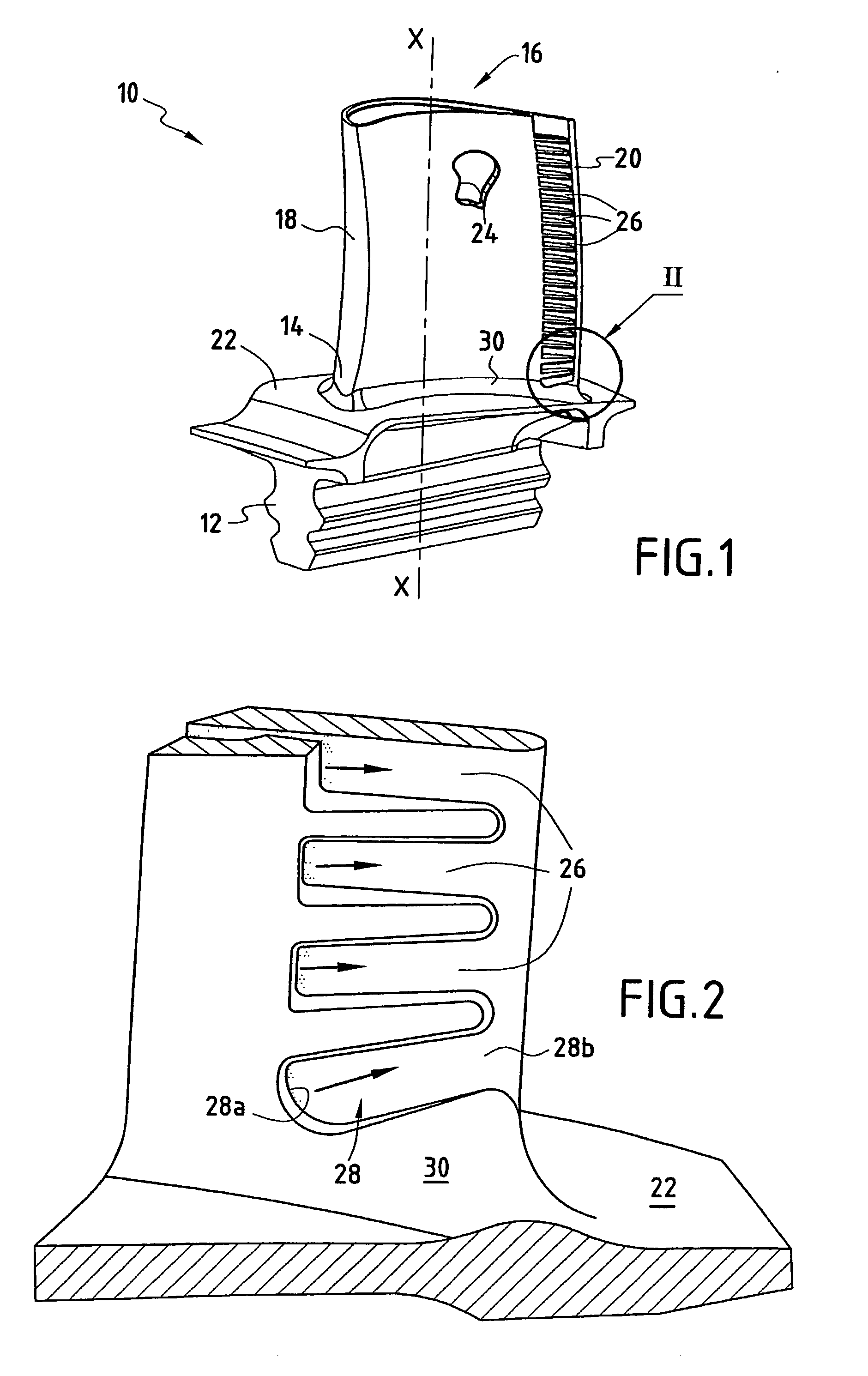

Moving vane with trailing edge for improving thermal behaviour used for high pressure turbine

InactiveCN1436919AAvoid crackingReduce local temperatureBlade accessoriesMachines/enginesEngineeringHigh pressure

The blade (10) has at least one cavity (24) radially extending between its tip and its base to form at least one cooling circuit. Air is discharged from the cavity through exhaust slots (26) opened to the blade trailing edge (20). A connection zone (30) is formed between the blade base and the platform (22) top surface. An auxiliary exhaust slot leads air from the cavity to the discharge side of the zone. An Independent claim is also included for a high-pressure turbine.

Owner:SNECMA MOTEURS (FR)

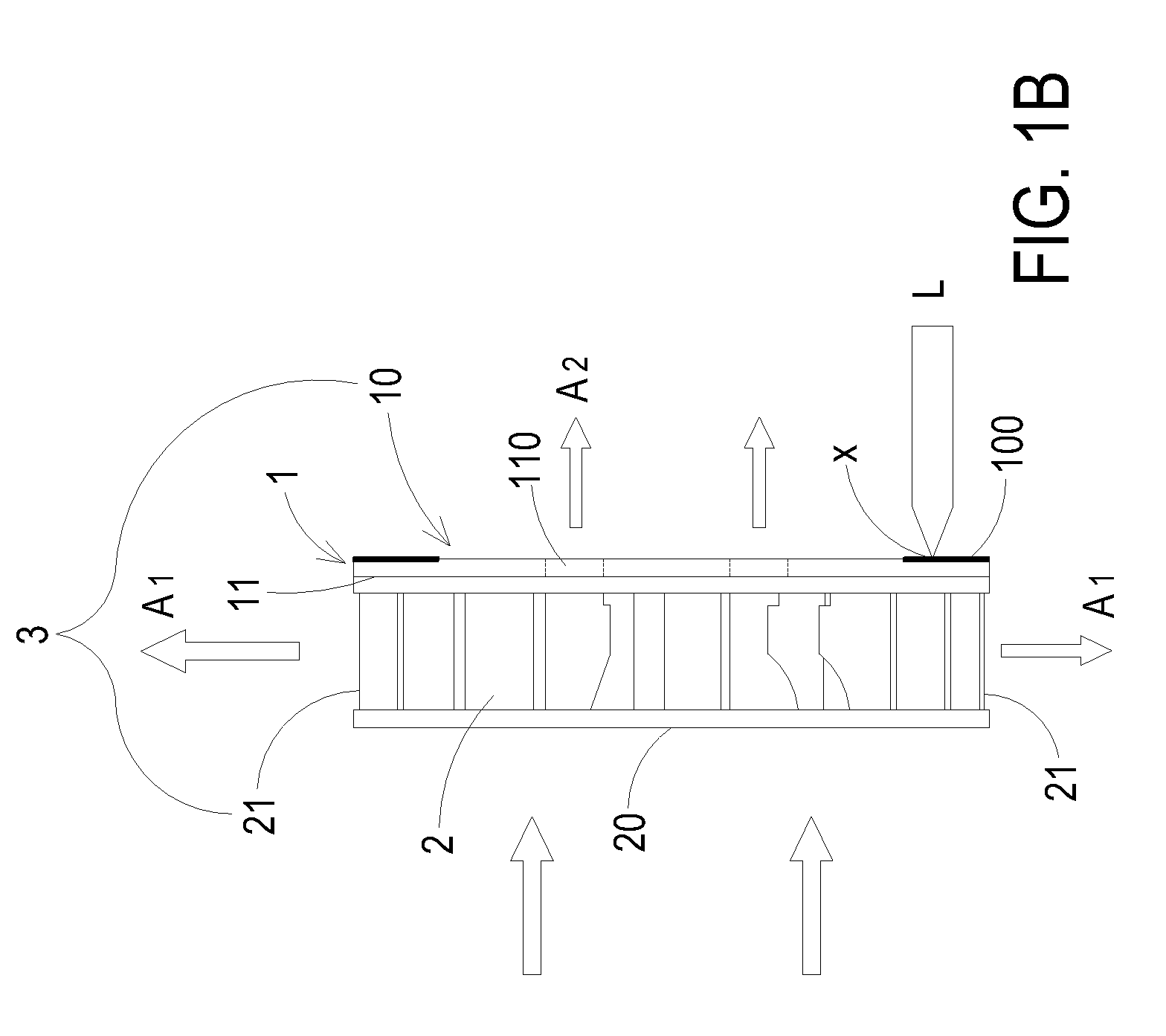

Phosphor wheel heat-dissipating module for laser projection system

ActiveUS9010971B2Effective coolingReduce areaLighting heating/cooling arrangementsProjectorsImpellerPhosphor

A phosphor wheel heat-dissipating module for a laser projection system is provided. The phosphor wheel heat-dissipating module includes a phosphor wheel, a plurality of air vents and an impeller. At least one phosphor agent is coated on an outer-ring portion of a first surface of the phosphor wheel. The air vents run through the phosphor wheel. The impeller is disposed on a second surface of the phosphor wheel, and includes an inlet and a first outlet. A laser beam is projected on the outer-ring portion of the phosphor wheel. When the phosphor wheel is rotated at a high rotating speed, an airflow is inhaled into the impeller through the inlet. A first portion of the airflow is blown out through the first outlet, and a second portion of the airflow is transferred to the first surface of the phosphor wheel through the air vents.

Owner:DELTA ELECTRONICS INC

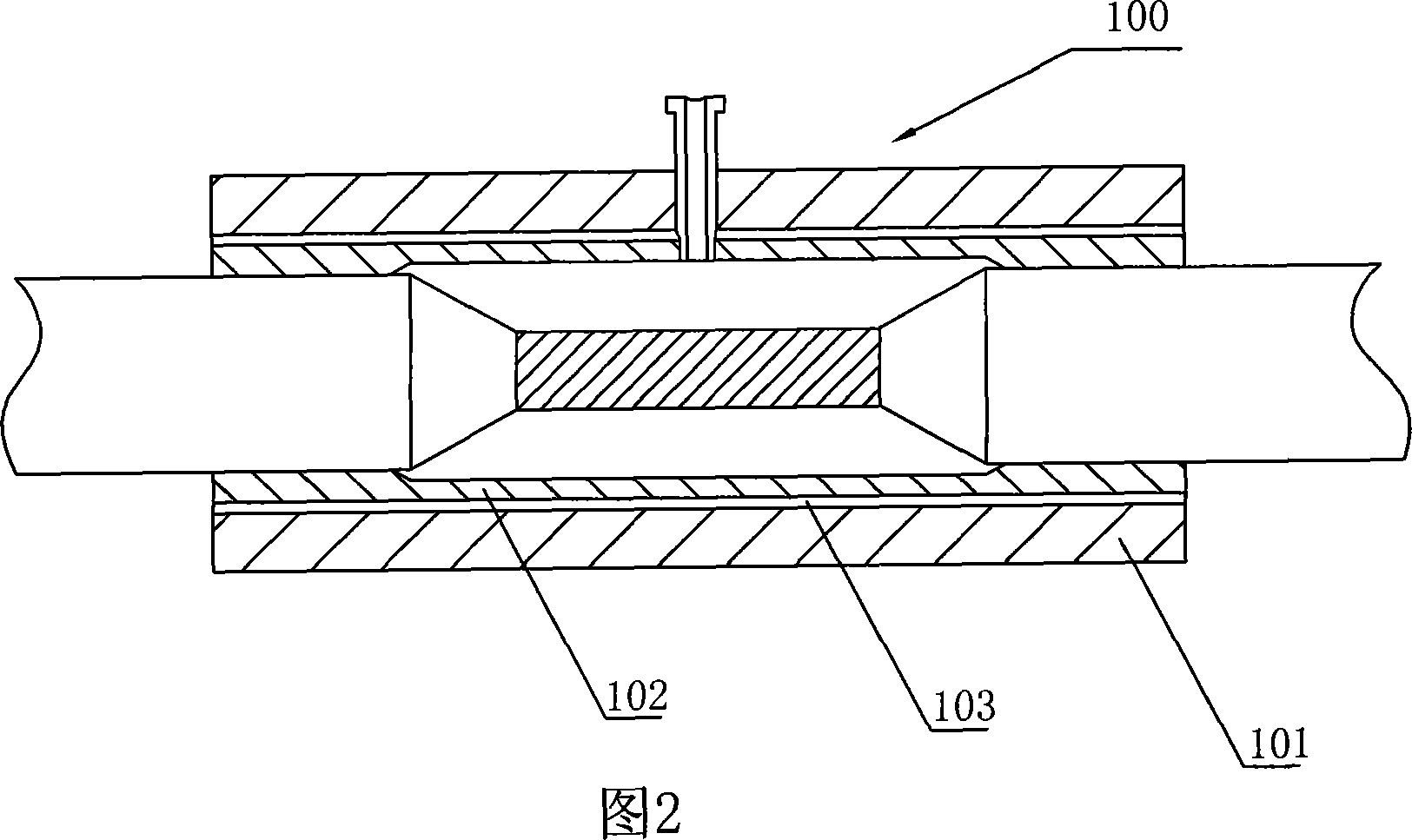

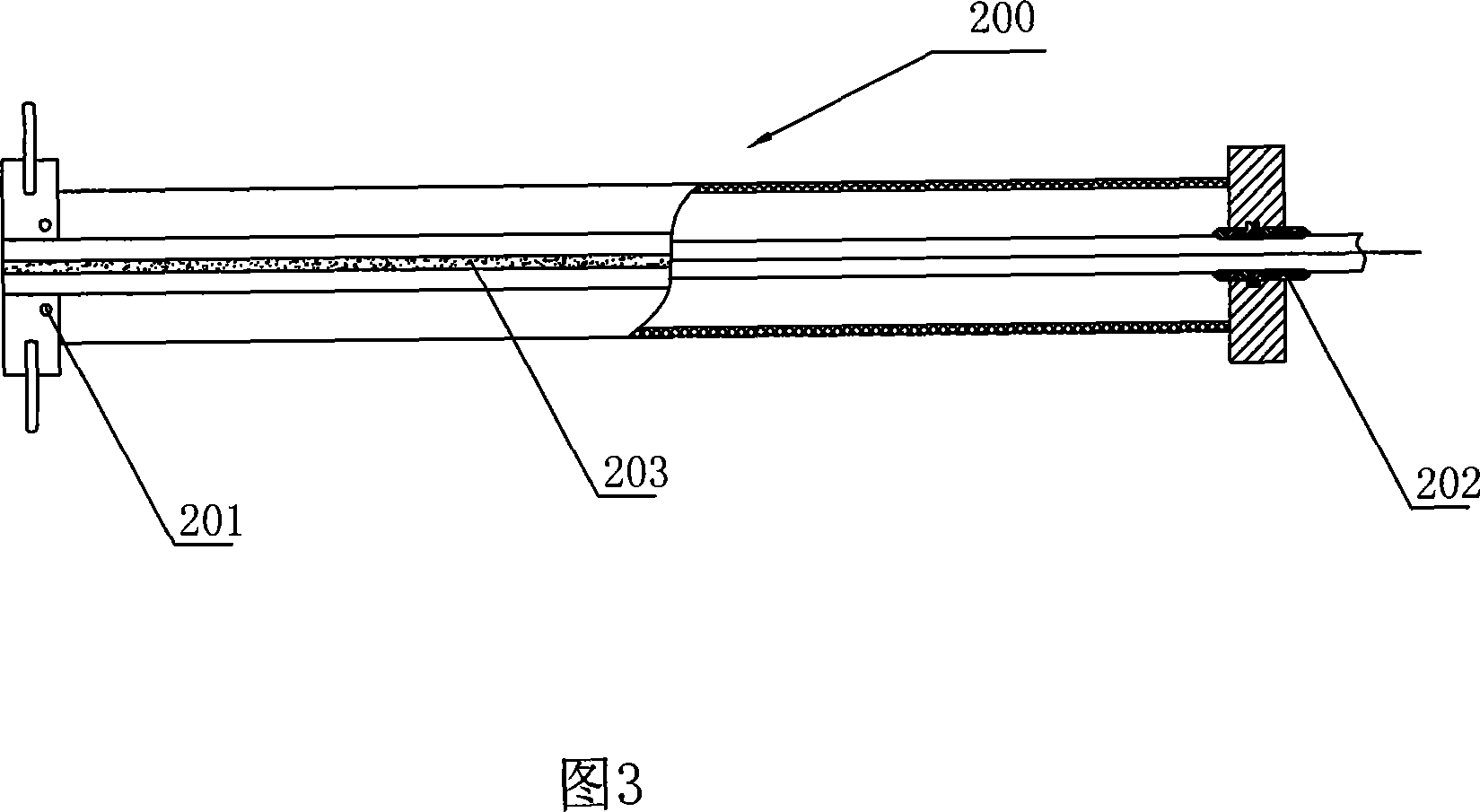

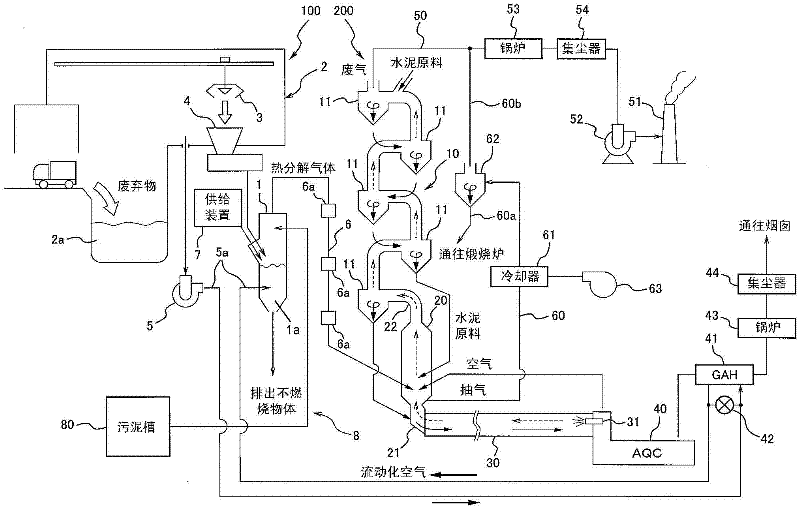

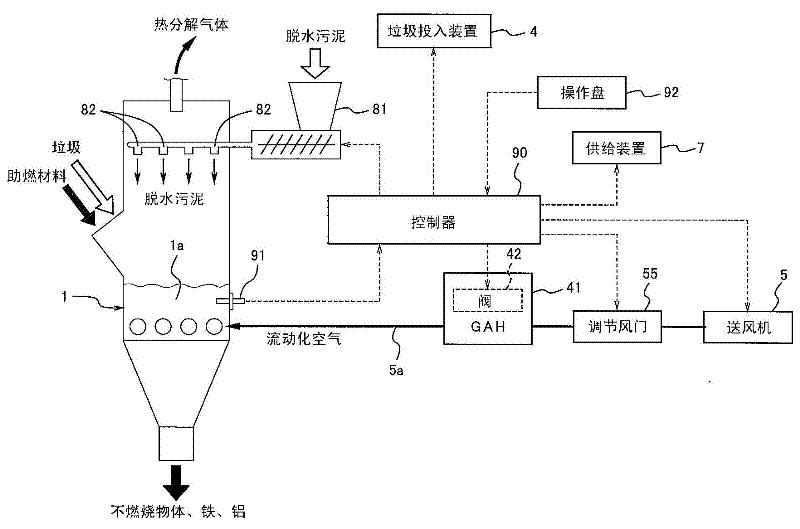

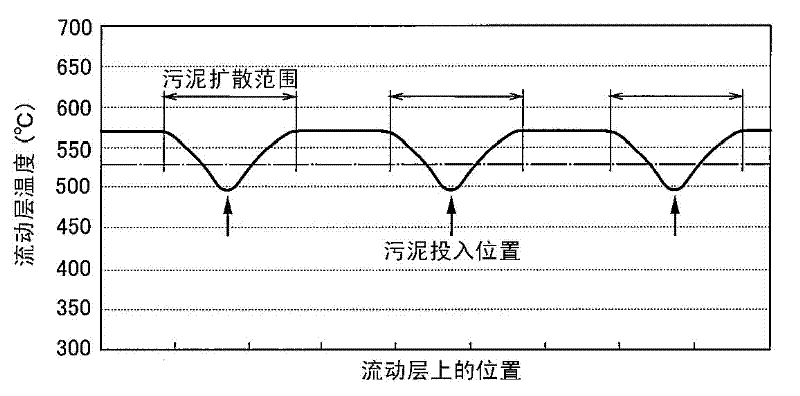

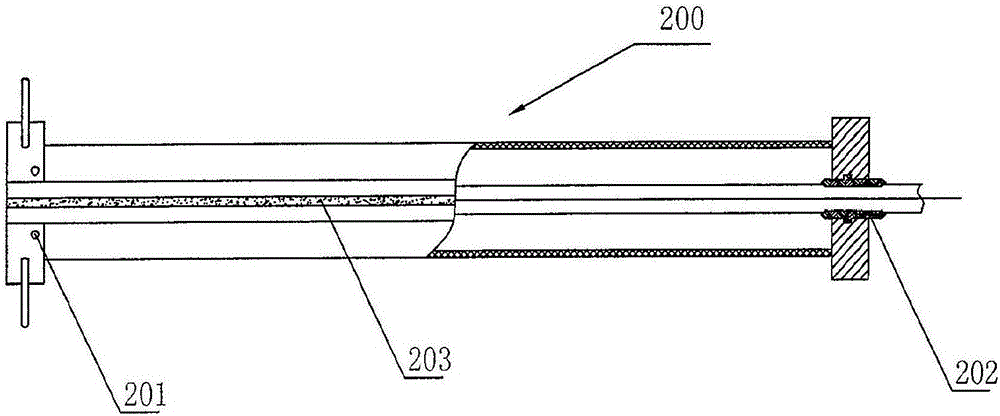

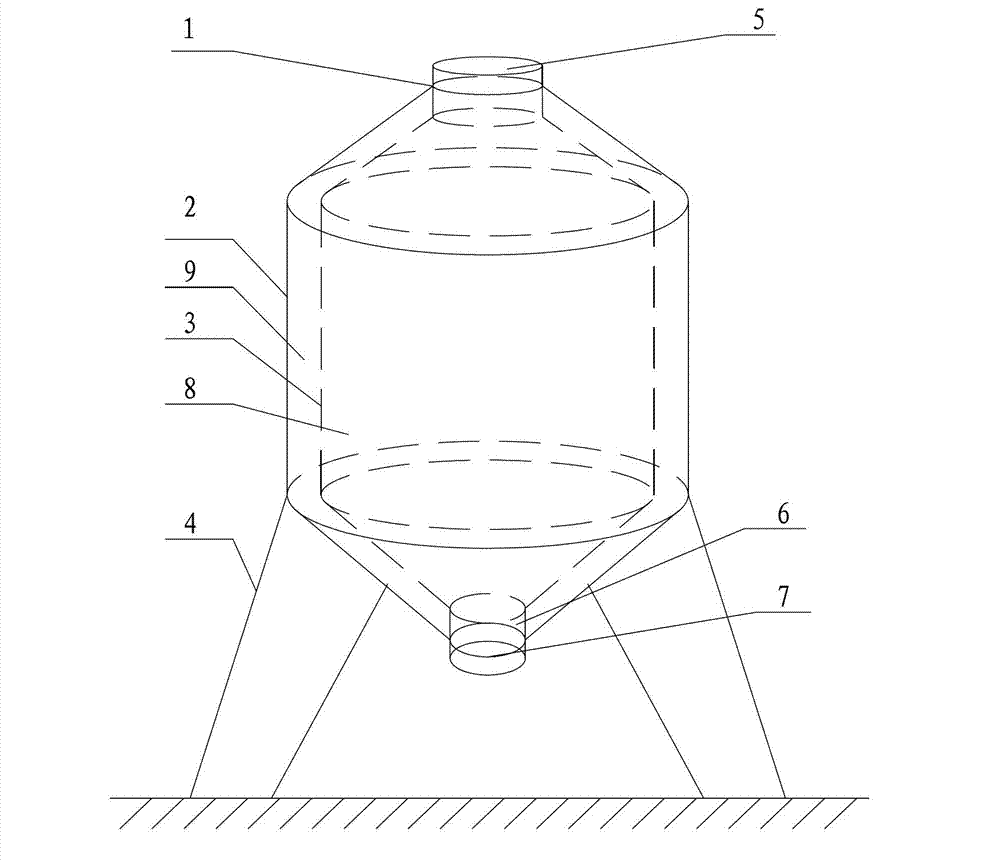

Treating equipment for waste containing sludge

ActiveCN102452802AEfficient use ofHigh calorific valueWater treatment parameter controlWaste water treatment from ceramic industriesSludgeProduct gas

The invention provides treating equipment for waste containing sludge. The objective of the invention is that the temperature of a fluid bed (1a) in a fluid bed gasification furnace (1) used for thermal decomposition of waste can be maintained in a proper range even when considerable waste containing high water content dehydrated sludge is treated. To realize the objective, treating equipment (100) for waste containing sludge is constructed beside cement manufacturing equipment (200). The treating equipment for waste comprises the fluid bed gasification furnace (1) which enables waste to be gasified for production of thermal decomposition gas, a gas delivery line (6) which delivers the produced thermal decomposition gas together with charcoal and ash to between a cement preheater (10) anda decomposing furnace (20), and heating devices like a waste gas air heater (41) which enables the temperature of fluidized air supplied to the gasification furnace (1) to rise by using waste heat ofthe cement manufacturing equipment (200).

Owner:KAWASAKI HEAVY IND LTD +4

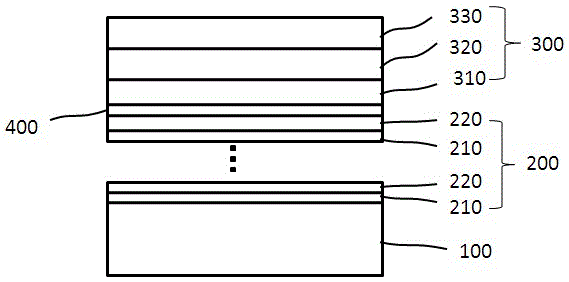

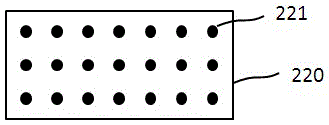

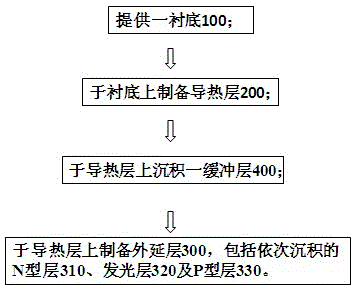

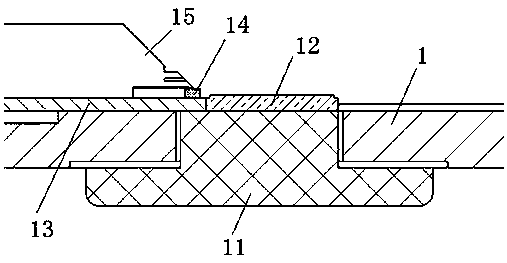

Light-emitting diode having heat conducting layer and preparation method thereof

ActiveCN105762266AImprove uniformityInstantaneous local temperature dropSemiconductor devicesPower flowHeat conducting

The invention, which belongs to the field of the semiconductor technology, especially relates to a light-emitting diode having a heat conducting layer and a preparation method thereof. The light-emitting diode at least comprises a substrate, an N type layer, a light emitting layer and a P type layer, wherein the N type layer, the light emitting layer and the P type layer are arranged on the substrate successively. And a heat conducting layer formed by alternate lamination of aluminium nitride layers and graphene particle layers is inserted between the substrate and an epitaxial layer. Therefore, problems that heat dissipation can not be carried out uniformly during current injection into the existing light-emitting diode and a warping phenomenon occurs due to uniform heat dissipation during large-size epitaxial wafer growth can be solved.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

Preparation method of crosslinked polyethylene cable connector

InactiveCN106374397AElectrical performance improvements and enhancementsEliminate void defectsApparatus for joining/termination cablesAnti stressEngineering

The invention relates to a cable connector, in particular to a preparation method of a crosslinked polyethylene cable connector. The preparation method comprises the following steps: firstly, peeling and cutting insulating layers at two ends of a cable so that a core of the cable is exposed; secondly, cutting the crosslinked insulating layers on two sides of the connector to be conical; thirdly, setting an anti-stress cone at the end of the cable, and fixing the treated cable to two ends of an insulating forming die, wherein the insulating forming die comprises a metal outer die and an elastic lining die, an elastic die expansion gap is formed between the metal outer die and the elastic lining die, and the temperature of an inner cavity of the insulating forming die is raised to be 120 DEG C; fourthly, after performing cleaning drying treatment on the surface of the insulating layer, setting an outer semi-conducting layer in combination with an outer shielding layer reserved section of the cable; and fifthly, wrapping a metal belt on the surface of the outer semi-conducting layer in a gap manner, using an oxyhydrogen flame to firmly weld two ends of the metal belt and the outer surface of a lead protective tube so as to form a metal projective sleeve tube, and then using the oxyhydrogen flame to trim welding surfaces at two ends of the metal protective sleeve tube so as to form a slope connecting section.

Owner:重庆三峡电线电缆科技股份有限公司

Radiator with folding fins and preparation method of radiator

PendingCN111163622ASave internal support areaIncreased internal support areaCooling/ventilation/heating modificationsEngineeringCold area

The invention relates to a radiator with folding fins. The radiator comprises a radiating substrate, the radiating substrate comprises a base and an upper plate, the base is provided with a concave cavity with an upward opening, the upper plate is used for covering the base and sealing the opening, a vacuum cavity is formed between the upper plate and the base, and the folding fins are arranged inthe vacuum cavity. The folding fins form a plurality of directional airflow channels; the heated airflow flows into the cold area from the hot area according to the directional airflow channels, so agood airflow guide effect is achieved; the problem of airflow turbulence is avoided, the problem that the heat dissipation efficiency is reduced due to airflow turbulence is avoided, the folding finshave good airflow guiding performance and flow towards all the folding cavities under the action of the airflow channels, and therefore airflow can fully circulate and evenly flow in the vacuum cavity and fully exchange heat with air in a cold area. Compared with an existing radiator with a copper column as a supporting structural part, the heat dissipation effect of the radiator is remarkably improved.

Owner:DONGGUAN ZHENGKANG ELECTRONICS

Nano cermet solar heat-absorption coating material and preparation method thereof

ActiveCN106752915AImprove thermal conductivityExcellent solar absorption performanceAnti-corrosive paintsRadiation-absorbing paintsHeat conductingDistillation

The invention relates to a nano cermet solar heat-absorption coating material and a preparation method thereof. The coating material is prepared from the following components in parts by weight: 40-50 parts of organic silicon resin, 2-7 parts of curing agent, 11-12 parts of absorbent, 2-4 parts of absorbing enhancer, 33-45 parts of aid, 13-17 parts of cermet material and 7-13 parts of heat-conducting material. The absorbent is doping-modified nano titanium dioxide. The preparation method sequentially comprises the following steps: constant-temperature pressurization reaction, reflux reaction and reduced pressure distillation reaction. Compared with the prior art, the doping-modified nano titanium dioxide is used as the absorbent and matched with the absorbing enhancer, so that the coating material has excellent solar absorptivity. The cermet material and heat-conducting material with photocatalytic mobility are adopted to widen the solar absorption range and enhance the heat-conducting property of the coating material, so that the coating material has the advantages of longer service life, mild technological conditions for reaction and low production cost, and can easily implement industrial production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

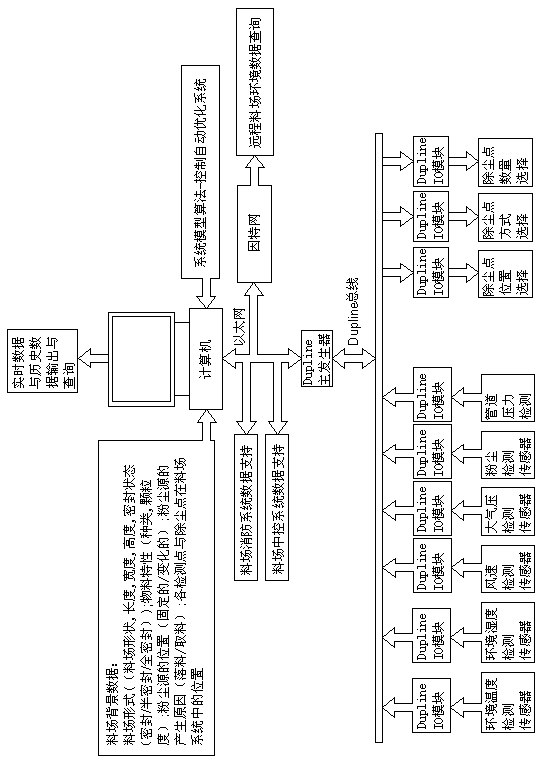

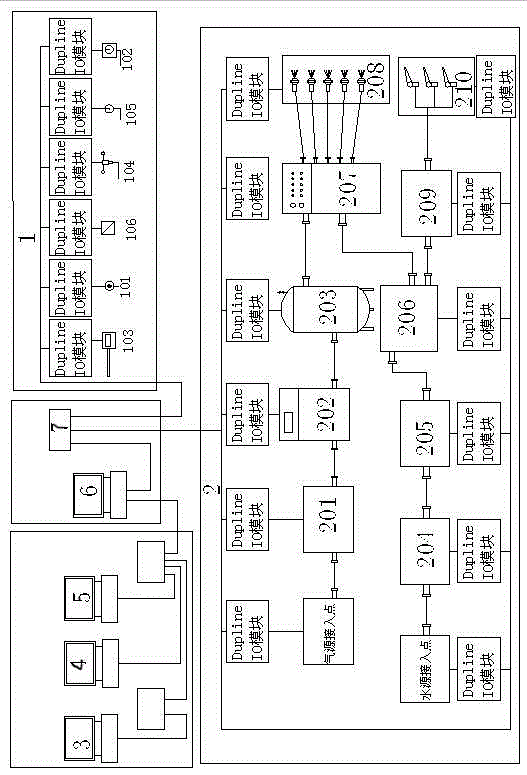

Environment-friendly material yard dust removal control system

ActiveCN105259877ADisplayFunctionalCombination devicesProgramme total factory controlFire-control systemReal-time data

An environment-friendly material yard dust removal control system comprises a material yard detection system, a material yard dust removal system, a dust removal electric control system, a remote environment monitoring system, a material yard central control system, a material yard fire control system, a control host, and a Dupline bus system. The control host is responsible for carrying out material yard model data calculation and optimizing selection, processing the data of the material yard detection system in real time, controlling and monitoring the dust removal electric control system in real time, exchanging data with the material yard central control system and the material yard fire control system in real time, providing real-time online data service for the remote environment monitoring system, and displaying the material yard dust environment parameters, the running state of the material yard dust removal system and the fault record in real time. The Dupline bus system connects the control host with the material yard detection system and the dust removal electric control system. The remote environment monitoring system is remotely connected to the database of the control host through the network, and is used for querying environment data of the material yard in real time and calling historical data, grasping the environment situation of the material yard in real time and checking whether the environmental protection of the material yard reaches the standard in real time.

Owner:TIDFORE INT ENG

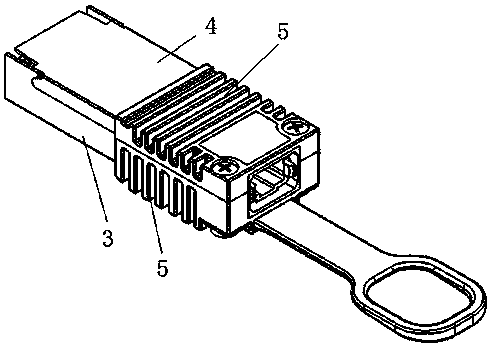

CXP modular structure

InactiveCN107907947AImprove working environment temperatureIncrease cooling areaCoupling light guidesAudio power amplifierLaser array

The invention relates to a CXP modular structure comprising an upper casing and a lower casing. The lower casing is provided therein with a transmitting end printed circuit board in which a transmitting end metal block is disposed. A driver chip is pasted on the surface of the transmitting end metal block by a thermally conductive adhesive. A transmitting end ceramic spacer is pasted on the surface of the transmitting end printed circuit board. A laser array chip is pasted on the surface of the transmitting end ceramic spacer. A gap between the transmitting end metal block and the lower casingis filled with the thermally conductive adhesive. A receiving end printed circuit board is arranged in the upper casing, and a receiving end metal block is arranged in the receiving end printed circuit board. An amplifier chip is pasted on the surface of the receiving end metal block by the thermal conductive adhesive. A receiving end ceramic spacer is pasted on the surface of the receiving end printed circuit board. A detector array chip is pasted on the surface of the receiving end ceramic spacer. A gap between the receiving end metal block and the upper casing is filled with the thermallyconductive adhesive. The CXP modular structure has a good heat dissipation effect and can increase the working environment temperature of an optical device by more than 10 degrees centigrade.

Owner:JIANGSU ALLRAY

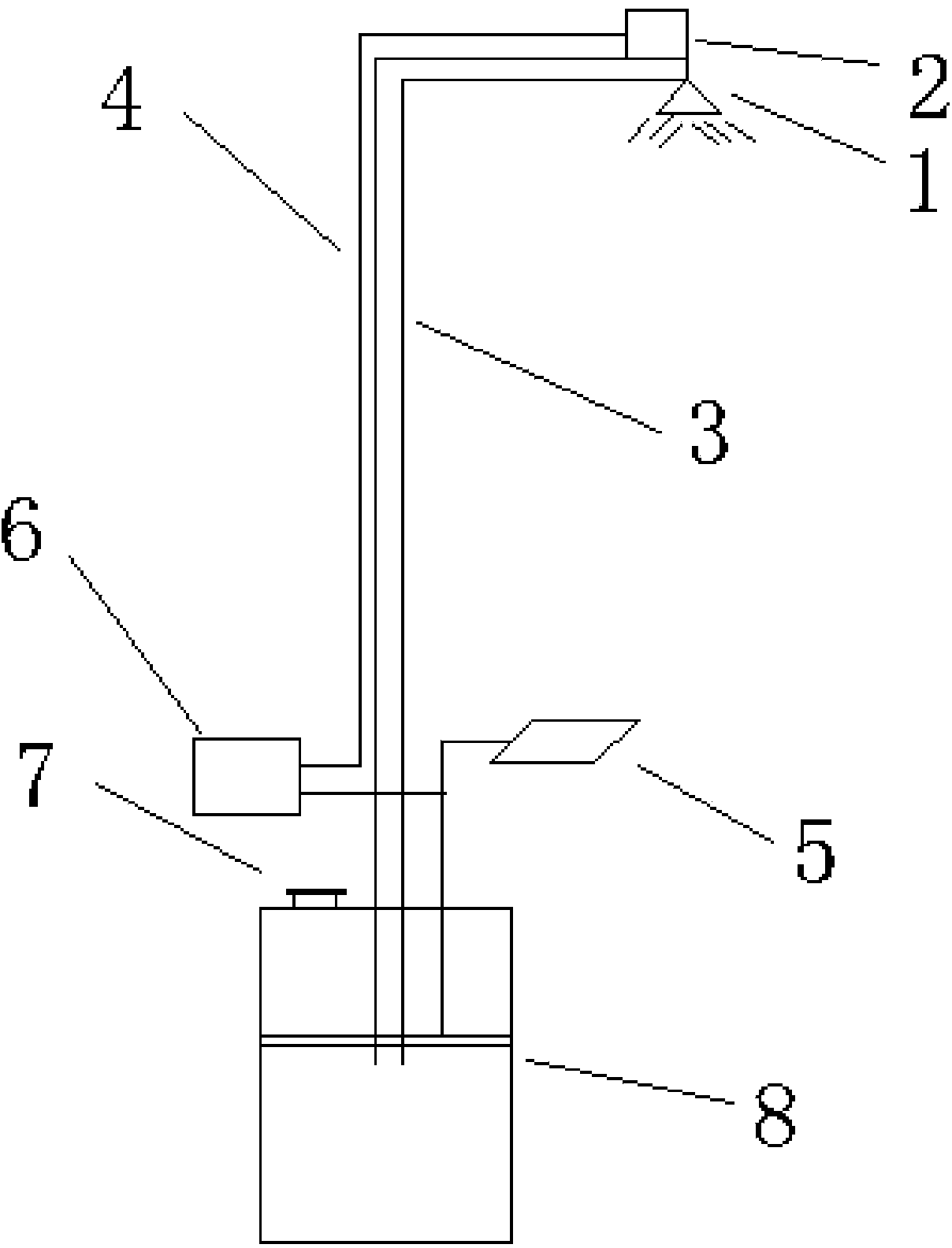

Method for cooling and purifying bus stop through electrostatic spraying

InactiveCN103940017AMeet health needsMeeting comfort needsLighting and heating apparatusElectrostatic separationSpray nozzleLiquid storage tank

A method for cooling and purifying a bus stop through electrostatic spraying is used for conducting local cooling and local dust removal on the bus stop and is characterized in that the method is applied to an electrostatic spraying dust removal system; the electrostatic spraying dust removal system is installed on the bus stop and composed of a nozzle, an electrostatic device, a liquid conveying pipeline, a pressurizing device, an electric device and a liquid storage tank; the liquid storage tank is connected with the nozzle through the liquid conveying pipeline; water is stored in the liquid storage tank; the pressurizing device is arranged in the position, close to the ground, of an upright of the bus stop and connected with the electrostatic device and the electric device; when external pressure is received by the pressurizing device, starting signals are sent to the electrostatic device and the electric device by the pressurizing device; the electrostatic device is started to conduct local dust removal and the electric device is started at the same time, so that the water in the liquid storage tank is driven to enter the nozzle through the liquid conveying pipeline and water mist is sprayed from the nozzle to conduct local cooling. According to the method for cooling and purifying the bus stop through electrostatic spraying, the requirements for health and the comfort level of people can be satisfied when people are waiting for buses at the bus stop.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

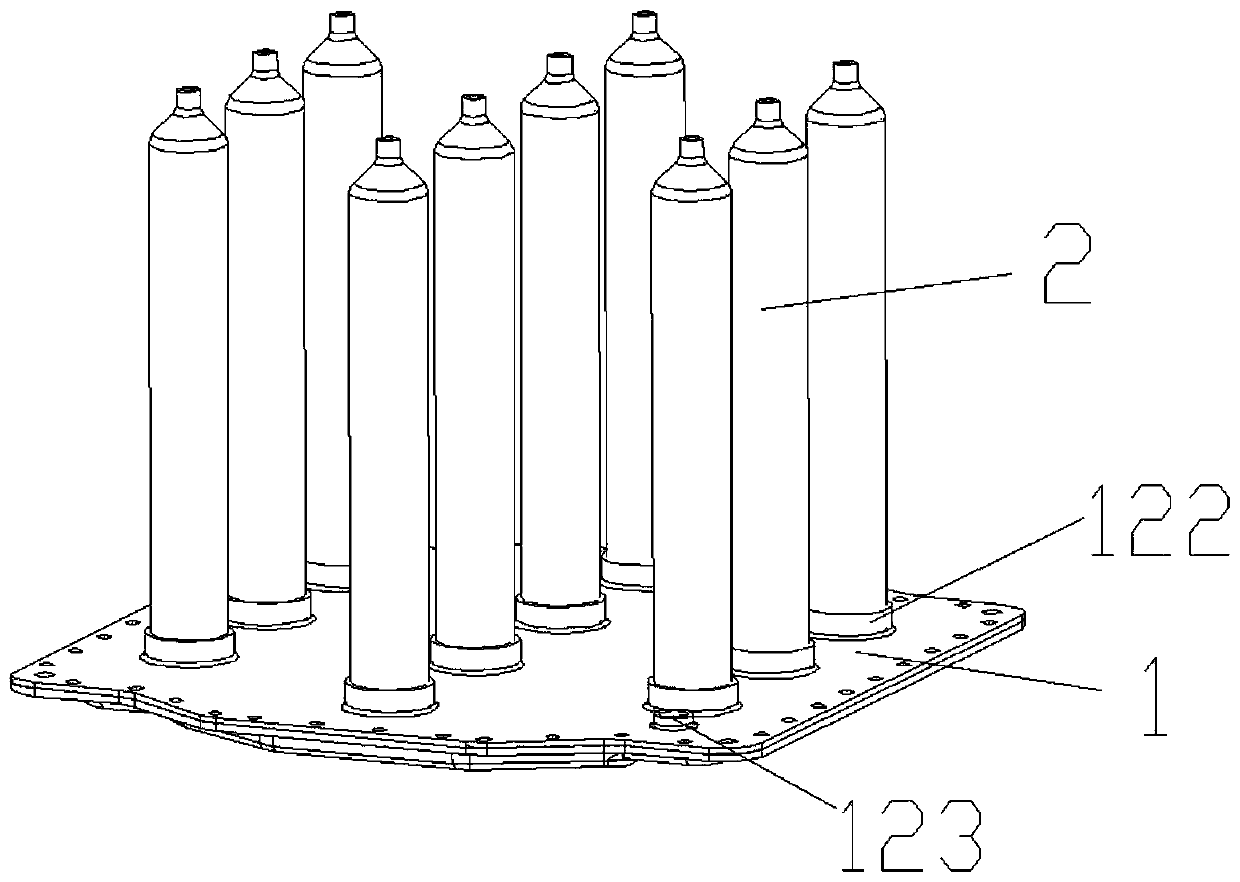

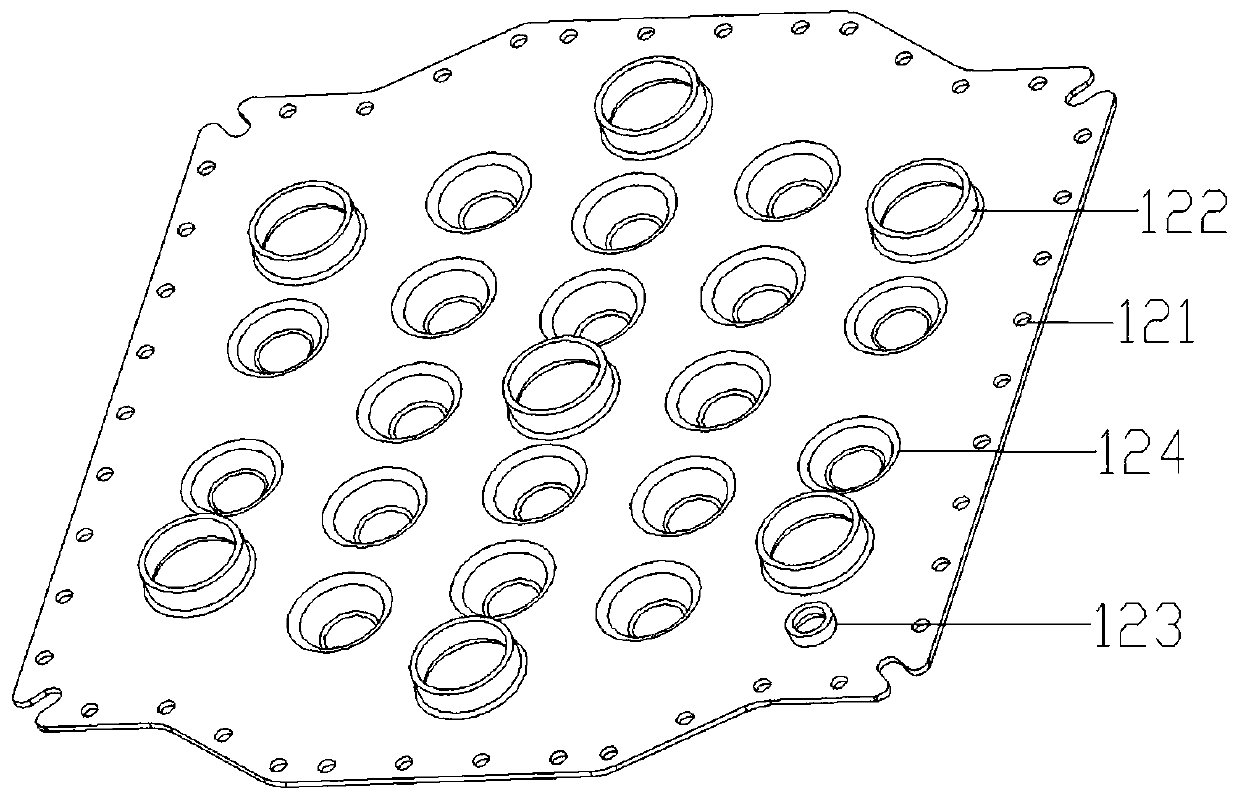

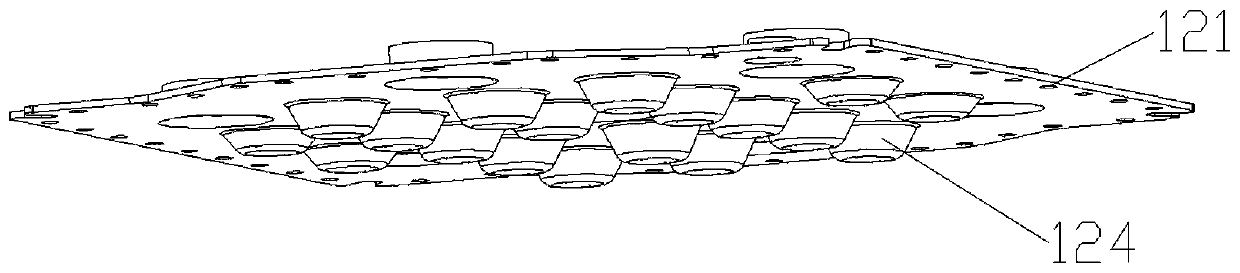

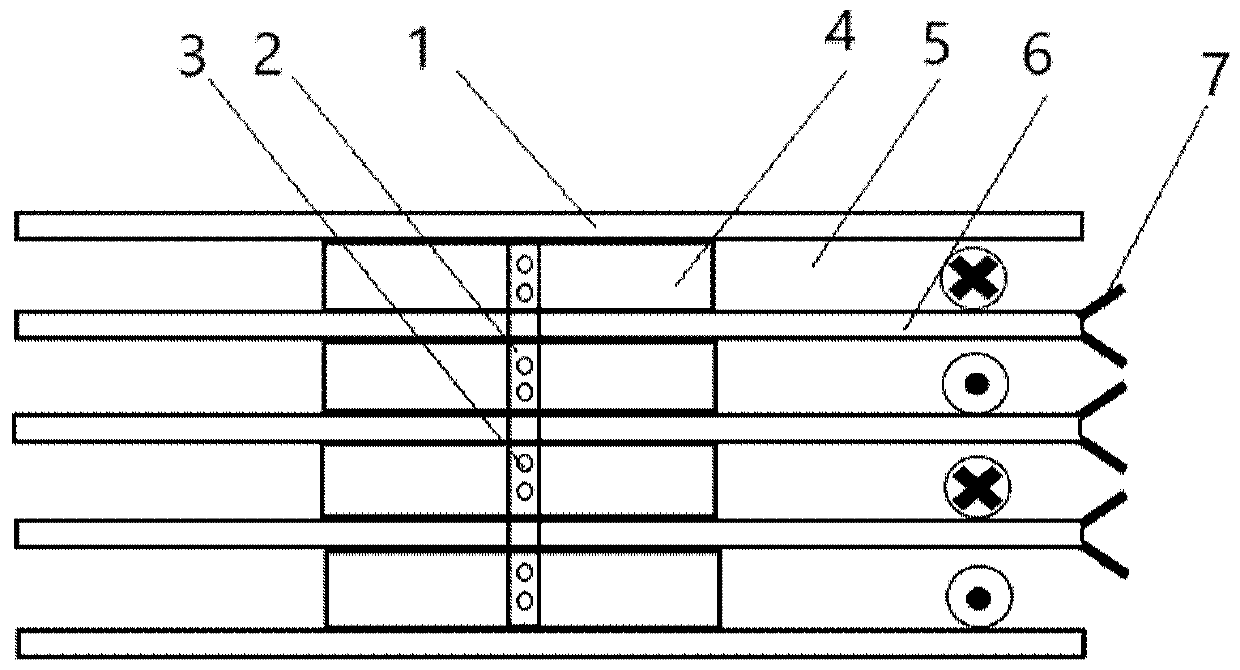

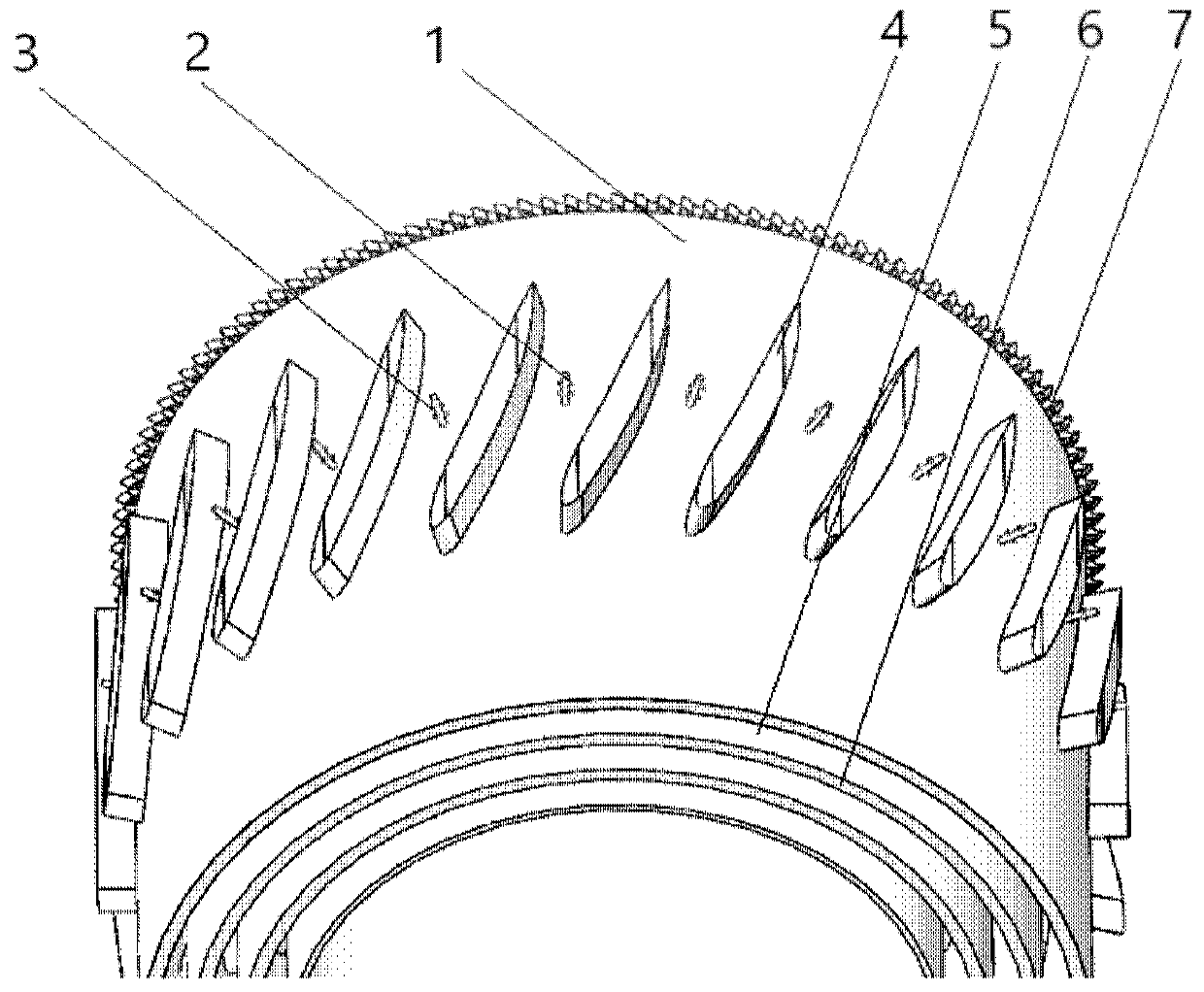

Two-dimensional array low-pollution combustion device without traditional cyclone

ActiveCN111396927AEmission reductionRealize multi-point injectionContinuous combustion chamberCombustion chamberEngineering

The invention discloses a two-dimensional array low-pollution combustion device without a traditional cyclone. The two-dimensional array low-pollution combustion device without the traditional cyclonecomprises a ring combustion chamber head, the ring combustion chamber head is separated into a plurality of ring air flow channels, and flame-stabilizing structures are aranged on outlets of the ringair flow channels; a plurality of guide blades are arranged in each ring air flow channel in the circumferential direction; and fuel pipelines are arranged between the guide blades. The two-dimensional array low-pollution combustion device without the traditional cyclone makes full use of the head space of the combustion chamber to form a uniform premixed combustion mode, at the same time, by increasing the number of fuel nozzles, the multi-point injection is realized, the local high temperature is avoided, and the emission of thermal NOx pollutants is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Anti-condensation steel silo for grain storage

InactiveCN102783320AUniform temperatureKeep in storageAgriculture tools and machinesHarvested fruit hanging devicesSheet steelIsolation layer

An anti-condensation steel silo for grain storage comprises a steel silo body and a support. The steel silo body is provided with a top opening at the top end and a discharge opening at the bottom end. A top cover is disposed at the top opening. A discharge opening seal cover is disposed at the discharge opening. The steel silo body is in a hollow rotary structure made up of steel plates. The anti-condensation steel silo is characterized in that an inner barrier layer made of an enclosing lining net is also in a hollow rotary structure and is fixed in the steel silo body, an area surrounded by the inner barrier layer serves as a grain storage area, and an area between the inner barrier layer and the inner wall of the steel silo body is an air area. Direct contact of grain with the steel plates is isolated by the lining net, voids between meshes of the lining net and the steel plates rapidly exchange external high heat to lower interior local temperature, and accordingly condensate of the grain is avoided dispersing. Therefore, storage state of the grain is maintained.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

High-temperature behavior of the trailing edge of a high pressure turbine blade

InactiveUS20030108425A1Reduce the temperatureAvoid degrading general mechanical strengthPump componentsBlade accessoriesTurbine bladeTrailing edge

A moving blade for a high pressure turbine of a turbomachine, the blade having at least one cooling circuit comprising at least one cavity extending radially between a tip and a root of the blade, at least one air admission opening at one of the radial ends of the cavity(ies) to feed the cooling circuit(s) with cooling air, and a plurality of slots opening out from the cavity(ies) and into the trailing edge of the blade, the slots being arranged along the trailing edge between the root and the tip of the blade in a manner that is substantially perpendicular to a longitudinal axis of the blade, at least the slot closest to the root of the blade presenting an inclination towards the tip of the blade lying in the range 10° to 30° relative to an axis of rotation of the blade.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

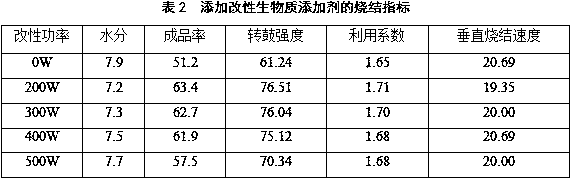

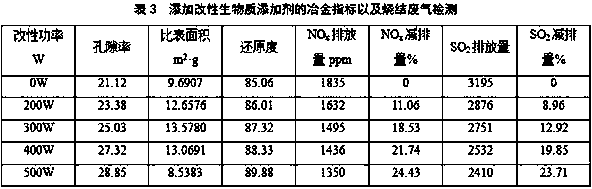

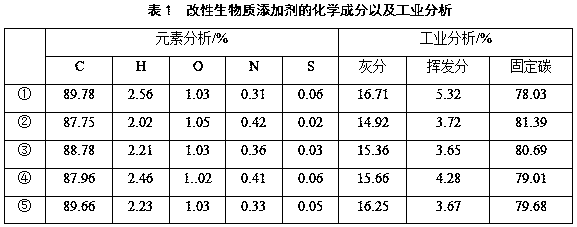

Preparation method of modified biomass iron ore sintering additive

The invention belongs to the field of additive preparation and particularly relates to a preparation method of a modified biomass iron ore sintering additive, in particular to a preparation method ofa modified biomass additive capable of lowering exhaust emission in production of iron ores and improving the iron ore sintering quality. The preparation method comprises the following steps of step 1, crushing a biomass material, and putting the crushed biomass material in an industrial microwave oven for modification treatment; step 2, spraying the treated biomass material with a Ca2+ mother liquor; and step 3, fully and uniformly mixing the materials, performing continuous pressing for 1-2mins under the effect of pressure of 20Mpa, and preparing massive particles with the particle size being 8-12mm to obtain the modified biomass additive. The technical scheme of the invention has important significance of reasonably utilizing clean energy, increasing the utilization ratio of resources and promoting emission reduction and benefit increase of the sintering industry.

Owner:UNIV OF SCI & TECH LIAONING

Boiler water cooling wall heat transfer enhancement tube with spoilers

PendingCN110260292AImprove heat transfer efficiencyReduce swirlBoiler water tubesHeat exchanger casingsIsosceles trapezoidHeat transfer efficiency

The invention discloses a boiler water cooling wall heat transfer enhancement tube with spoilers. The boiler water cooling wall heat transfer enhancement tube with the spoilers comprises a tube body, the spoilers arranged along the axial direction of the tube body and an inner fin arranged in spiral mode along the axial direction of the tube body, wherein each spoiler is formed by twisting a stainless steel sheet, the twisting angle of each stainless steel sheet is 90 degrees, the windward sides of the spoilers are welded on the inner wall of the tube body, the spoilers are arranged at intervals from 1000mm to 1300mm along the axial direction in the tube body, the section of the inner fin is in non-isosceles trapezoid shape, the lower bottom face of the inner fin is smoothly connected with the inner wall surface of the tube body, an included angle Alpha between the side face of the inner fin and the lower bottom face of the inner fin is 60-70 degrees, and the other included angle Beta between the side face of the inner fin and the lower bottom face of the inner fin is 20-30 degrees. The boiler water cooling wall heat transfer enhancement tube with the spoilers adopts a cooperation mode of the spoilers and the inner fin with the section in non-isosceles trapezoid shape, improves heat transfer efficiency between near wall fluid and mainstream fluid, reduces occurrence rate of rotational flow of the fluid on the leeward side of the inner fin, thereby reducing local temperature, improving heat transfer performance of an inner spiral tube overall, and ensuring safe operation of a boiler water cooling wall.

Owner:SHANGHAI BOILER WORKS +1

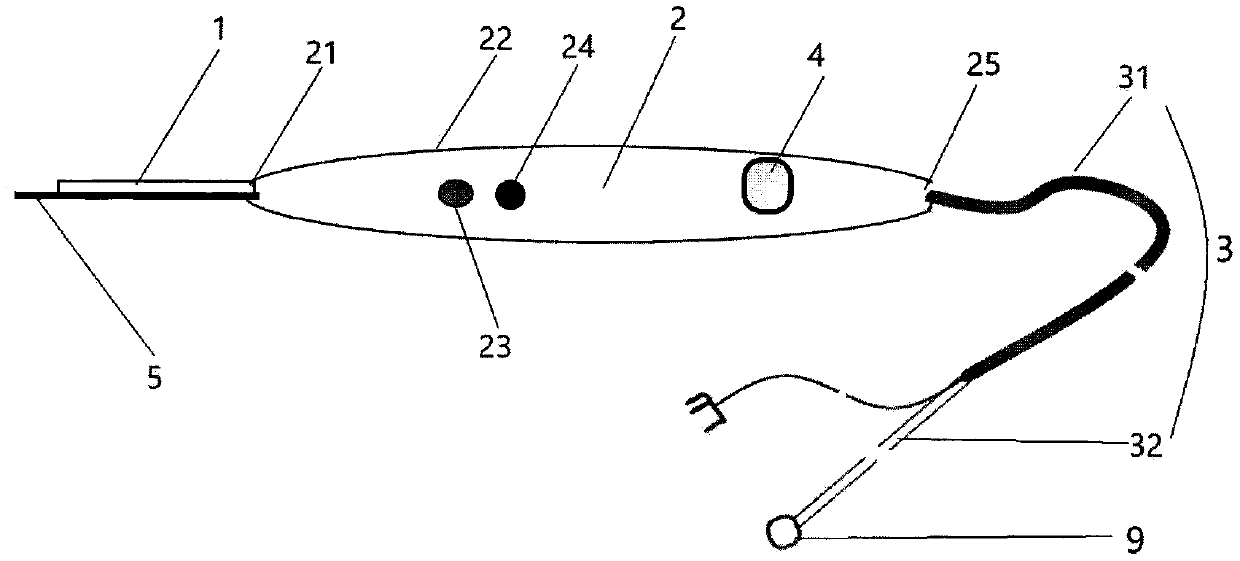

Vacuum suction monopolar electrocoagulation and electro-excision pen

InactiveCN110123441AReduce local temperatureIncrease the efficiency of attracting smokeSurgical instruments for heatingSurgical instruments for aspiration of substancesElectricityElectrocoagulation

A vacuum suction monopolar electrocoagulation and electro-excision pen comprises a monopolar electrocoagulation and electro-excision pen body and a vacuum suction duct system, wherein the monopolar electrocoagulation and electro-excision pen body comprises an electrode head, a handle, and a connection wire; the vacuum suction duct system comprises a hollow duct and a control device. The vacuum suction monopolar electrocoagulation and electro-excision pen allows a user to perform electrocoagulation and electro-excision, suck off smoke and suck away oozing blood and liquid by one hand; occupational injury is avoided, personnel is reduced, and efficiency is improved.

Owner:XIAMEN BONAI MOLD DESIGN CO LTD

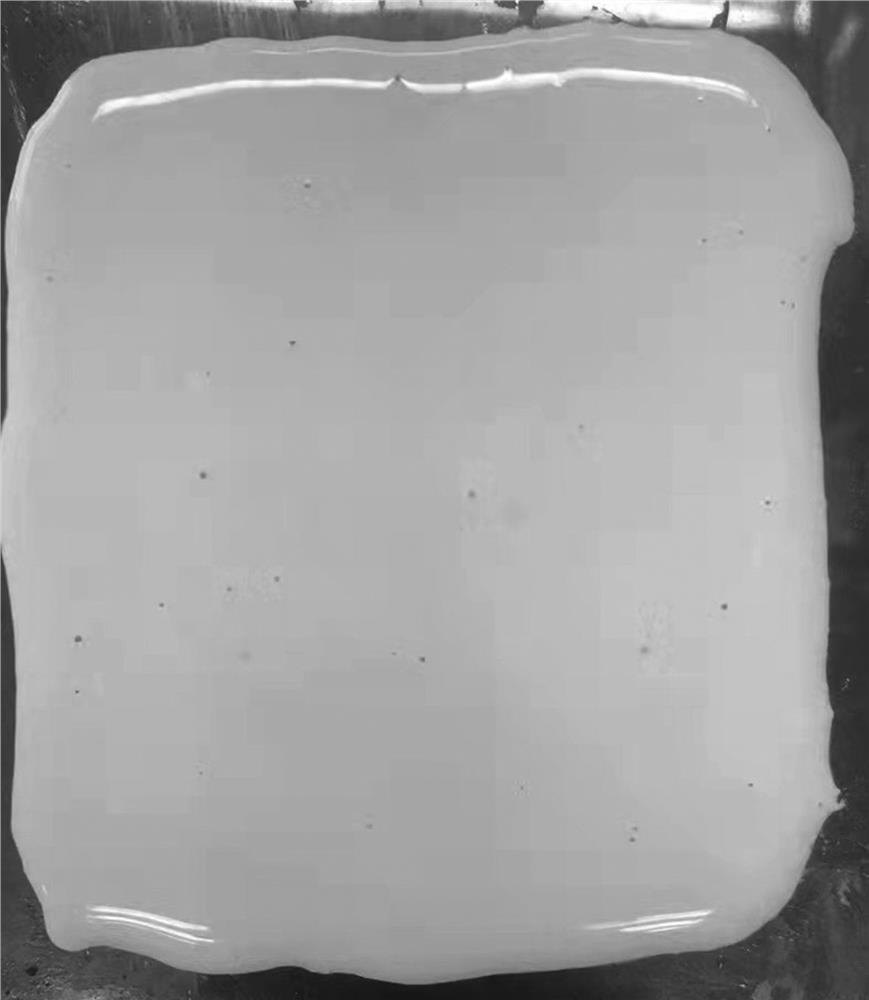

Medical cold compress adhesive film with long-acting moisture retention function

InactiveCN109820637AReduce local temperatureReduce burning sensationTherapeutic coolingTherapeutic heatingMETHYLPROPANEDIOLGentiana lutea Root Extract

The invention provides a medical cold compress adhesive film with long-acting moisture retention. The adhesive film is composed of the following raw materials: one components: water, glycerol, methylpropylene glycol, trehalose, PEG / PPG-17 / 6 copolymer,1,2-hexanediol, p-hydroxyacetophenone, acryloyl dimethyl taurine ammonium / VP copolymer; two components: water, phenoxyethanol, biological sugar gum-1; three components: water, propylene glycol, liquorice root extract, gentian root extract, radix sophoraeflavescentis root extract, snake bed fruit extract and sweet wormwood extract; four components: allantoin, sodium hyaluronate and daily essence; five components: water, propylene glycol, nonylphenol polyether-14, PEG-50 castor oil. Compared with the prior art, the medical cold compress adhesive film with long-acting moisture retention has the following advantages: the burning sensation, the pain sensation and the sensitivity of local skin can be reduced, and the long-acting moisturizing can be maintained.

Owner:GUANGZHOU HWASUEN HEALTH IND CO LTD

Environment-friendly fireproof coating and preparation method thereof

The invention mainly relates to the technical field of fireproof coatings, in particular to an environment-friendly fireproof coating and a preparation method thereof.The environment-friendly fireproof coating comprises a coating base material and a fire extinguishing agent microcapsule, and the fire extinguishing agent microcapsule is broken after being exposed to the temperature not lower than 75 DEG C and / or an open fire environment and can be vaporized to release a fire extinguishing material to achieve the purposes of cooling and / or fire prevention and / or fire extinguishment. In order to break through the current situation that the traditional fireproof, fire-extinguishing and flame-retardant coating can only prevent spreading of an ignition area but is difficult to sensitively and actively extinguish fire in a short time, the invention provides a plurality of coatings and / or coating films which can actively cool, prevent fire and extinguish fire, have short response time, stably exist fire-extinguishing components in the coatings and / or coating films and can be repeatedly triggered to extinguish fire.

Owner:浙江铭诺新材料科技有限公司

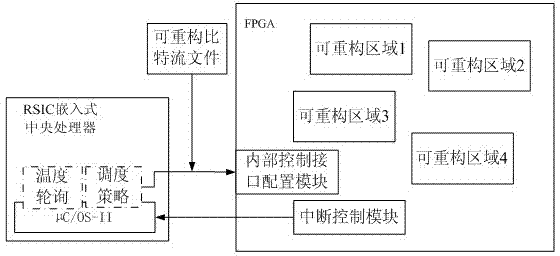

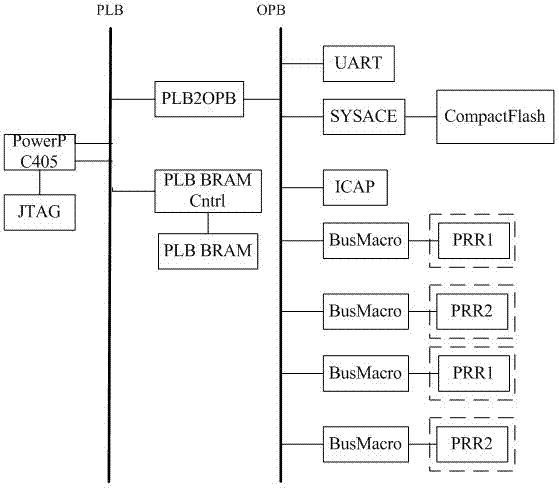

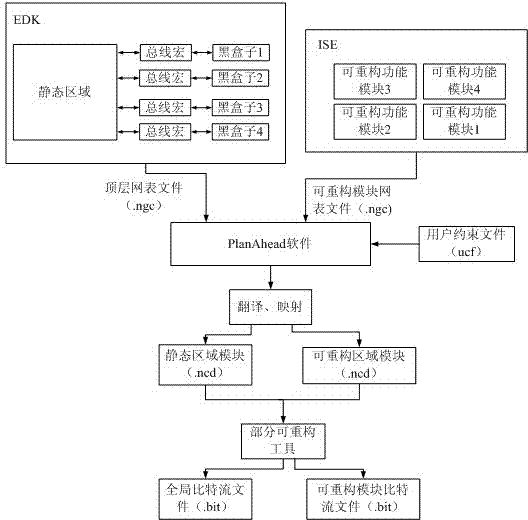

Local hot point mitigating system based on FPGA dynamic partially reconfigurable technology

InactiveCN102298344BExtend the life cycleImprove real-time performanceProgramme controlComputer controlComputer moduleFpga chip

The invention relates to a local hot point mitigating system based on FPGA (Field Programmable Gate Array) dynamic partially reconfigurable technology. In engineering applications, continuous high-temperature operation may cause damage on local functional regions of a FPGA embedded system and further cause system crash. In the system provided by the invention, a real-time operating system schedules tasks operating in the regions with excessive temperature to a reconfigurable region wither lower temperature in real time, a ring oscillator implements that each module in the embedded system detects own temperature, when the embedded system detects that own task operating modules have excessive temperature, the embedded system transmits excessive temperature interruption to an operating system via an interruption control module, and then, the operating system schedules a scheduling strategy task operating thereon to find the reconfigurable region matched with the regions with excessive temperature in size and schedule the reconfigurable tasks in the regions with excessive temperature to the reconfigurable regions with lower temperature. With the system provided by the invention, the problem of local excessive temperature in a FPGA embedded system is mitigated, power consumption of a FPGA chip is reduced and hardware life cycle of the FPGA chip is improved.

Owner:HANGZHOU DIANZI UNIV

Water-soluble trichloroisocyanuric acid smoking disinfectant

InactiveCN105409968AAvoid decompositionIncrease surface areaBiocideDead animal preservationDisinfectantWater disinfection

The invention relates to a formula and a preparation method for a water-soluble trichloroisocyanuric acid smoking disinfectant. The disinfectant comprises the following components by weight: 30 to 80 parts of trichloroisocyanuric acid, 20 to 40 parts of glucose, 5 to 15 parts of ammonium chloride and 5 to 30 parts of anhydrous sodium sulfate. The preparation method comprises the following steps: subjecting glucose and anhydrous sodium sulfate to mixing and crushing, and carrying out screening with a 200-mesh spin-vibrating sieve for subsequent usage; and mixing trichloroisocyanuric acid and ammonium chloride, carrying out screening with a 80-mesh spin-vibrating sieve, pouring obtained mixed powder into a stirring mixer and then carrying out uniform mixing, carrying out subpackaging with polyethylene plastic bags, and carrying out sealing so as to obtain the disinfectant. The disinfectant can be dissolved by adding water for sprinkling, spraying and drinking water disinfection, also can be ignited to form smoke for fumigation disinfection, and has the characteristics of safety, convenience, high efficiency, etc.

Owner:青岛汉河动植物药业有限公司

High-temperature fire extinguishing device for high-voltage cable trench

ActiveCN111437546AReduce local temperatureLower oxygen levelsCable installations on groundFire rescueStructural engineeringElectric cables

The invention relates to a high-temperature fire extinguishing device for a high-voltage cable trench. The high-temperature fire extinguishing device comprises a guide rail system and an inspection device. The guide rail system comprises a left guide rail and a right guide rail which are fixed on the left side wall and the right side wall of the cable trench respectively, and the inspection deviceis arranged between the left guide rail and the right guide rail in a sliding mode. A fire extinguishing device is arranged in the inspection device and can perform fire extinguishing operation on afire source of the cable trench. The temperature inside the cable trench can be monitored in real time, and the cable can be automatically extinguished through a sandbox and the inspection device in time after being on fire.

Owner:山东和兑智能科技有限公司

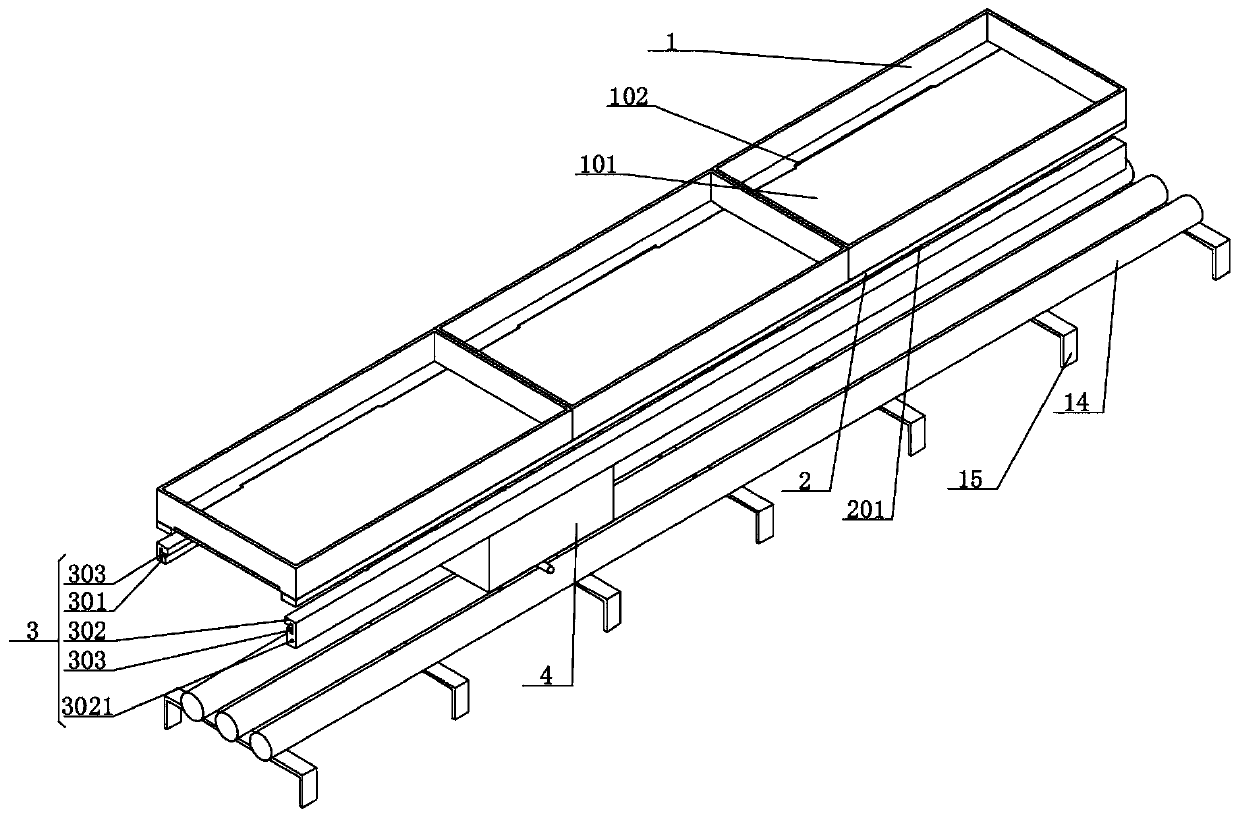

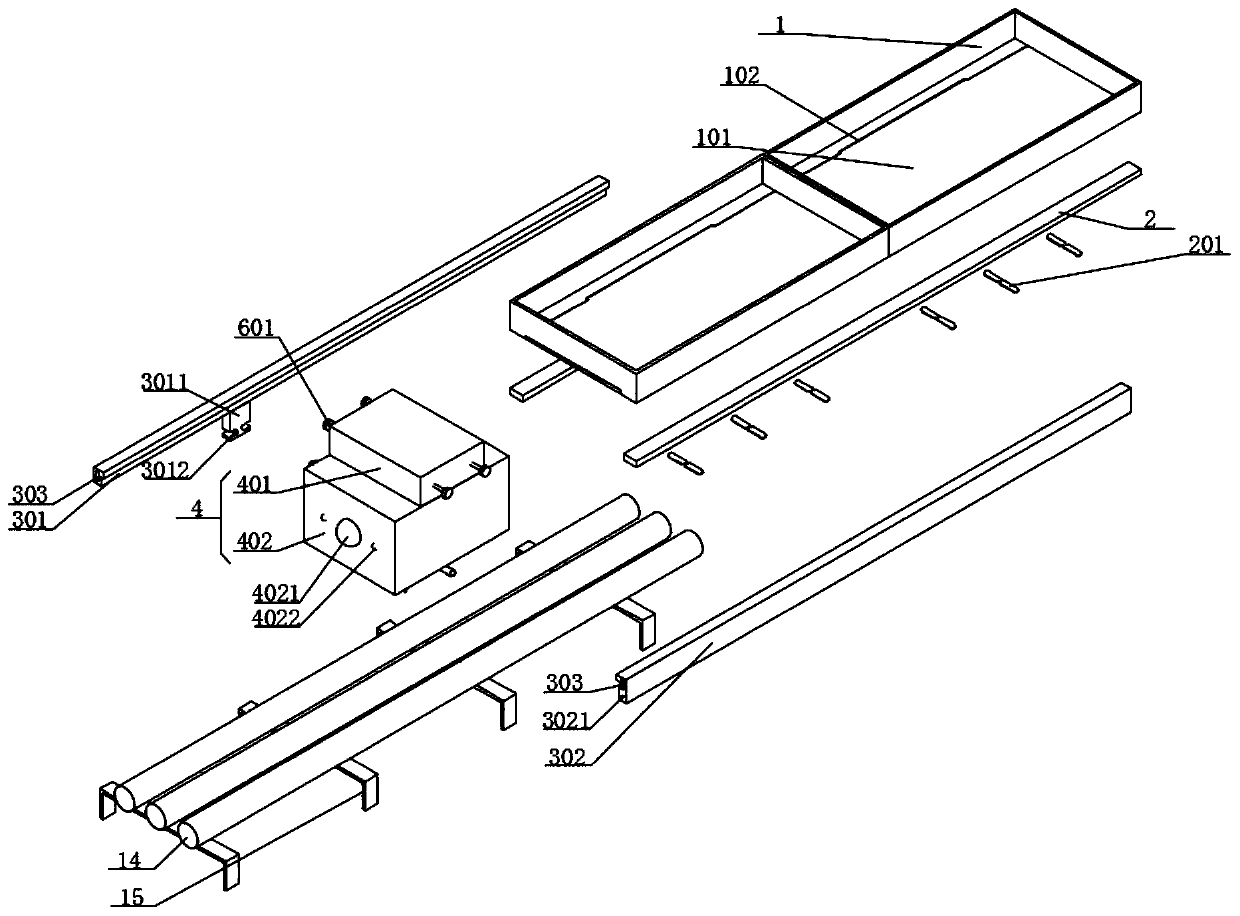

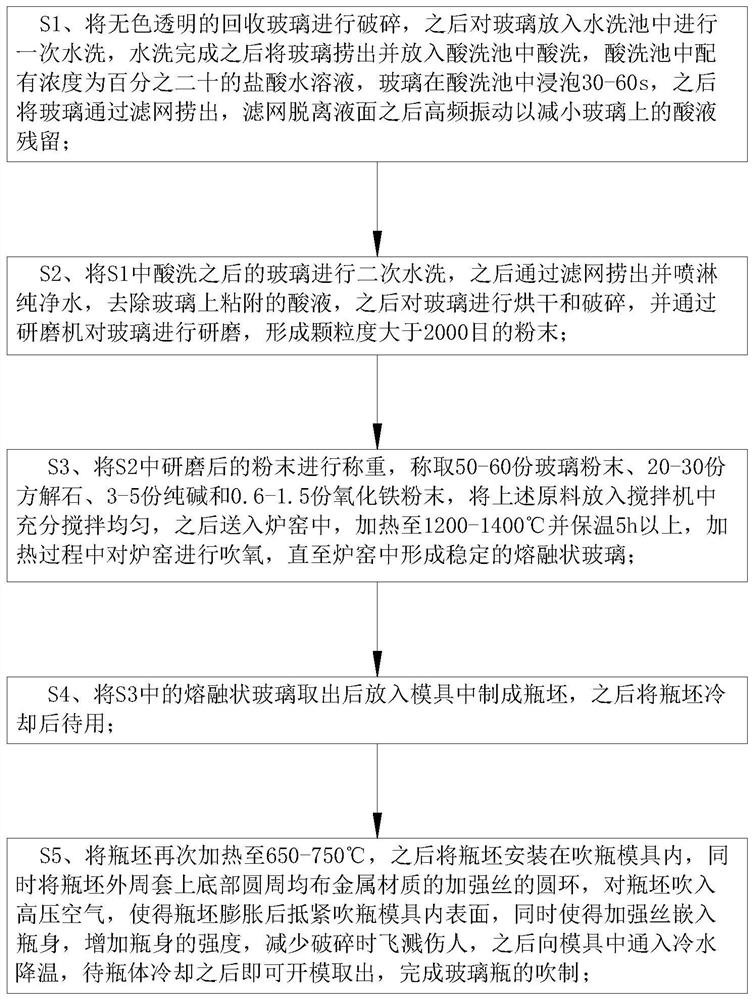

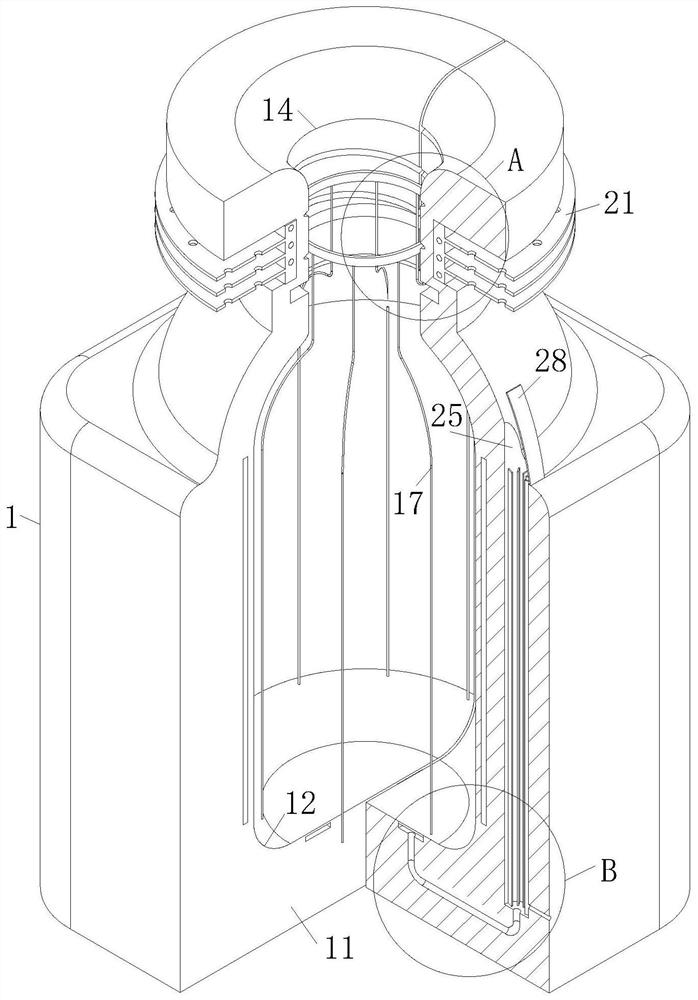

Efficient environment-friendly glass bottle blowing process

InactiveCN111777328AImprove securityReduce CooldownGlass furnace apparatusBlowing mouldsBilateral symmetryMaterials science

The invention belongs to the technical field of glass bottles, and specifically relates to an efficient environment-friendly glass bottle blowing process. A bottle blowing mold used in the process comprises a body, the body is composed of two split bodies, which are arranged in a bilateral symmetry mode, cavities used for controlling the forming of a glass bottle are formed in the adjacent sides of the split bodies, annular grooves used for fixing a bottle blank are formed in the tops of the cavities, bottle opening holes are formed in the upper portions of the annular grooves, and spiral bottle opening threaded grooves are formed in the bottle opening holes. A thin-wall heating ring is arranged at each bottle opening hole, an circular ring is arranged in the bottle opening hole and corresponds to a heating ring; the inner diameter of the circular ring is slightly greater than the outer diameter of the bottle blank, the circular ring is made of iron; the heating ring is connected witha power source through a controller, the heating ring heats the circular ring through high frequency, the fusion efficiency of the circular ring, reinforcing wires and a bottle blank is improved, andthe glass bottle strength is improved.

Owner:FUJIAN GREAT WALL HUAXING GLASS CO LTD

Magnetic electric power control switch with high heat dissipation

InactiveCN107369577AUniform temperatureImprove securityElectric switchesArchitectural engineeringControl switch

The invention discloses a magnetic electric power control switch with high heat dissipation, which comprises a shell, and is characterized in that a groove at the middle of the bottom of the shell is provided with a dust screen in a matched manner, both the left and the right of the groove are provided with a static contact, the middle of each static contact is provided with an insulation box at the inner side of the shell, the top of the shell is vertically provided with a push rod in a sliding and sealing manner at the middle position, the top end of the push rod is provided with a limiting cap, the bottom end of the push rod is provided with a pressing plate inside the shell, the outer ring of the top of the pressing plate is provided with an iron block, the top of the iron block is provided with a magnetic coil on the top inner wall of the shell, a motor mounting base at the middle of the bottom of the pressing plate is provided with a motor, an output shaft of the motor is provided with fan blades, both the left and the right of the bottom of the pressing plate are provided with a support rod, the bottom ends of the two support rods are provided with a metal grid piece in a bridging manner, both the left side and the right side of the bottom of the metal grid piece are provided with a moving contact, and both the left end and the right end of the metal grid piece are provided with a spring. The magnetic electric power control switch with high heat dissipation is safe, reliable, good in heat dissipation performance and capable of effectively prolong the service life of the switch.

Owner:DEZHOU LINGCHENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com