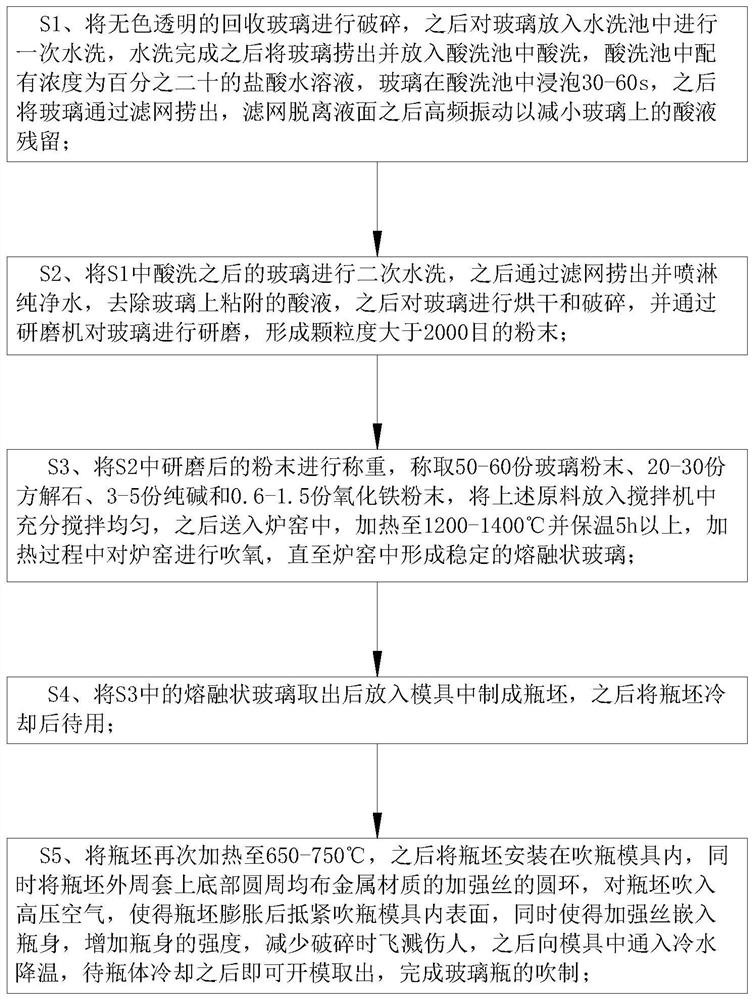

Efficient environment-friendly glass bottle blowing process

A glass bottle and glass technology, used in glass blowing molds, glass manufacturing equipment, glass blowing, etc., can solve the problems of uneven cooling speed of the bottle body, uneven distribution of cooling water channels, affecting the production efficiency of glass bottles, etc. Increase blowing efficiency, increase strength, reduce attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

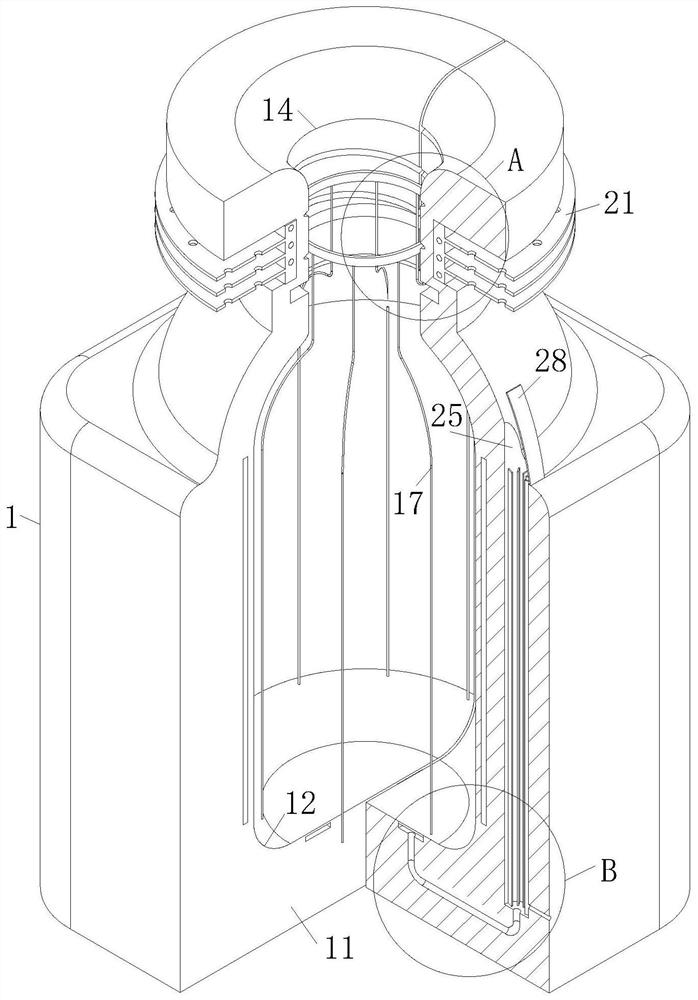

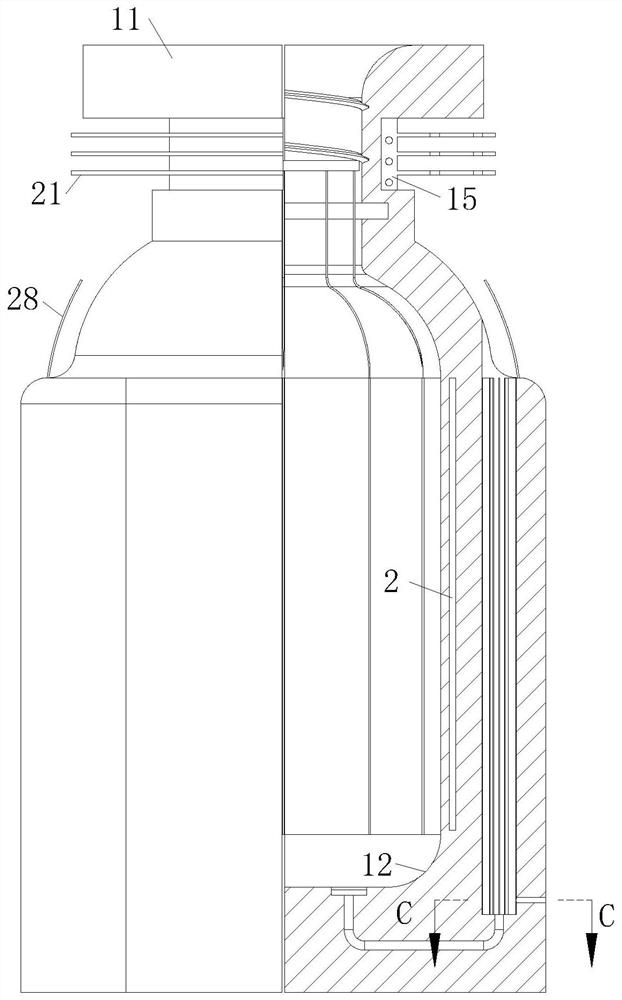

[0041] As an embodiment of the present invention, the bottom of the cavity 12 is provided with an annular groove 23, and the top of the groove 23 is fixed with a breathable membrane 24; the circumference of the first hole 25 opened in the split body 11 is evenly distributed One set of fins 26, one side of the bottom of the No. 1 hole 25 communicates with the high-pressure water through the water inlet 27; the No. 1 hole 25 at the bottom of the water inlet 27 communicates with the bottom of the groove 23 through the No. 2 hole 30; The No. 25 hole 25 sprays water and atomizes to increase the cooling efficiency of the split body 11; the side of the No. 1 hole 25 top away from the bottle mouth is provided with an arc-shaped baffle 28, and the baffle 28 is used to guide the water mist to the fin. sheet 21; a group of No. 3 holes 29 are evenly distributed on the circumference of the fins 21, and the water mist flows through the No. 3 holes 29 to further increase the cooling efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com