Environment-friendly fireproof coating and preparation method thereof

A fire-resistant coating and environmental protection technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of short fire extinguishing response time, difficulty in actively extinguishing fires, and the existence of fire extinguishing agents, and achieve the effects of improving storage stability, high practicability, and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the prior art, there is a Chinese invention patent with a publication number of CN114558268A, which discloses a perfluorohexanone microcapsule flame suppression medium and its preparation method, product and application, including by weight: 140 parts of core materials and 25-28 parts of shell materials The core material is perfluorohexanone; the shell material is formed by mixing the polymer capsule material and polyvinyl alcohol; the specific embodiment provides the explosion breaking temperature of the perfluorohexanone microcapsules obtained by the scheme If the temperature is 97°C, the effect of cooling and / or fire prevention cannot be exerted, and the early warning effect of fire is weak.

[0057] In the prior art, there is a Russian patent with an application number of RU2011125756, which discloses a microcapsule fire extinguishing agent and a preparation method thereof, a fire extinguishing composite material and a fire extinguishing coating, which can be blas...

Embodiment approach

[0065] Various embodiments are described where the fire suppressant microcapsules include:

[0066] A core material that vaporizes and absorbs heat when released by heat;

[0067] at least two layers of wall material containing polymeric material; and

[0068] The wall material can be broken when not lower than 75°C.

[0069] Various embodiments are described where the wall is not lower than 80°C, not lower than 85°C, not lower than 90°C, not lower than 95°C, not lower than 100°C, not lower than It can be broken at 120°C and not lower than 150°C.

[0070] Various embodiments are described where the fire extinguishing agent microcapsules are exposed to a temperature of not lower than 80°C, not lower than 85°C, not lower than 90°C, not lower than 95°C, not lower than 100°C , Not lower than 120 ℃, not lower than 150 ℃ environment after rupture and can vaporize and release fire extinguishing material to achieve the purpose of cooling and / or fire prevention and / or fire extinguis...

Embodiment 1

[0234] An environmental protection fireproof coating, the preparation method of which comprises the following steps.

[0235] 100 g of a gelatin aqueous solution with a mass fraction of 10% was prepared as a wall material solution, 0.002 g of nano-silica powder and 0.01 g of nano-titanium dioxide powder were added, and the mixture was stirred at 60° C. to mix and disperse. Add 80 g of perfluorohexanone, stir at 450 r / min for 40 min at 25 °C, slowly add 3 mL of glutaraldehyde solution with a mass fraction of 10%, stir and crosslink for 30 min, filter, wash and separate to obtain about 80 g of preliminarily solidified microcapsules.

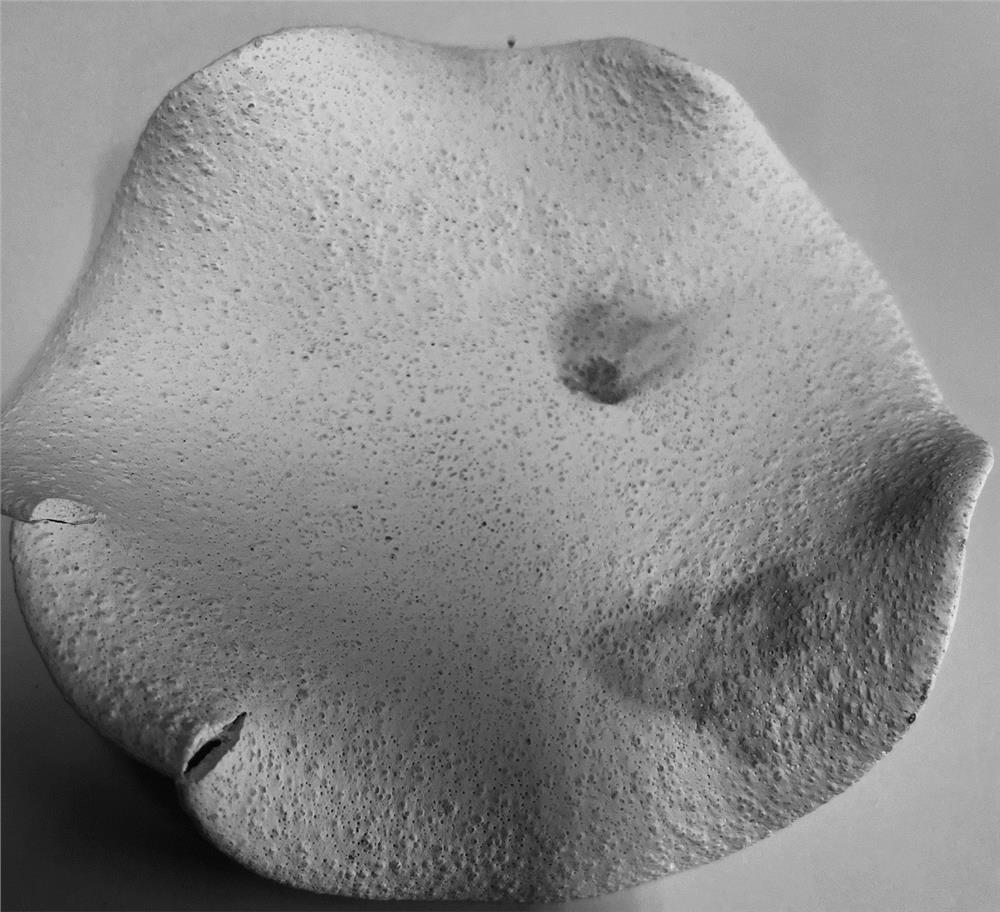

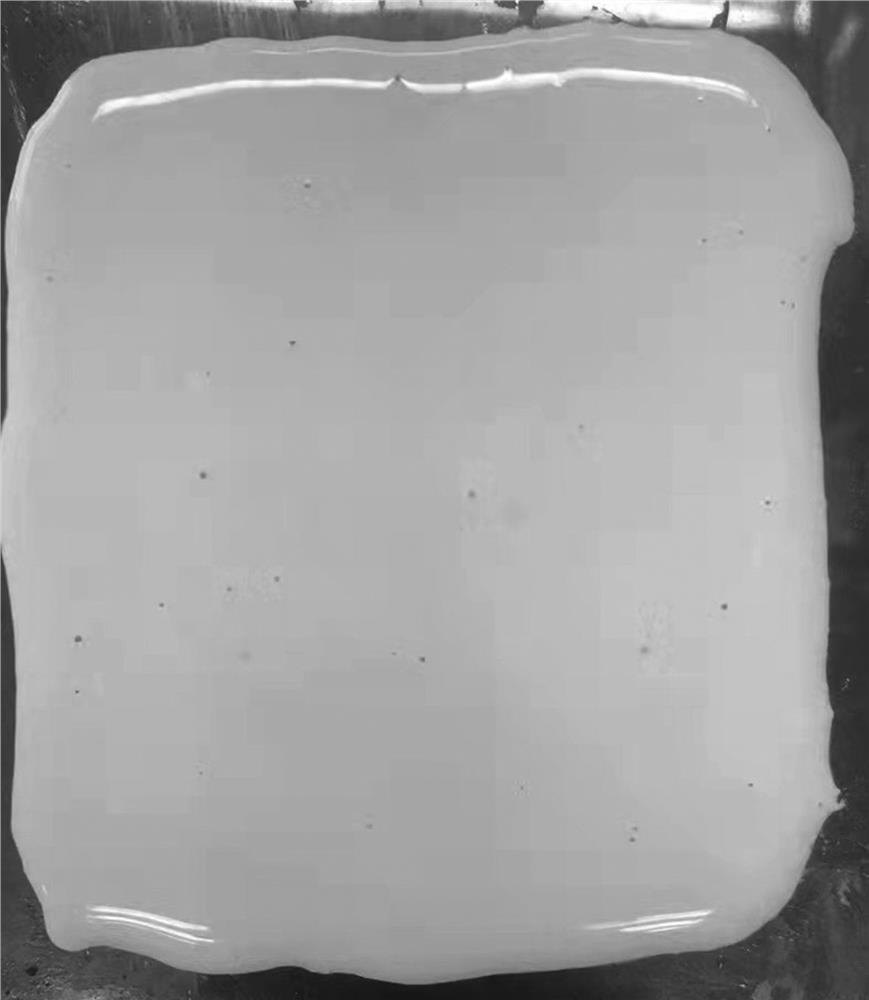

[0236] Add 80g of preliminarily solidified microcapsules to 60g of melamine-formaldehyde prepolymer solution, stir for 1 hour, filter, wash, and dry at low temperature to obtain fire extinguishing agent microcapsule powder. The microscopic image is as follows: figure 1 As shown, the microscopic image after high temperature rupture is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com