Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92 results about "Solar absorptivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar Energy Absorption is the ability of an Ultra to draw upon sunlight, perhaps any bright light, to recharge themselves. Almost all Ultras gain their energy from outside sources, on their homeworld of the Ultra Star, they gain energy from the Plasma Spark. However, when away from their homeworlds, Ultras draw energy from sunlight.

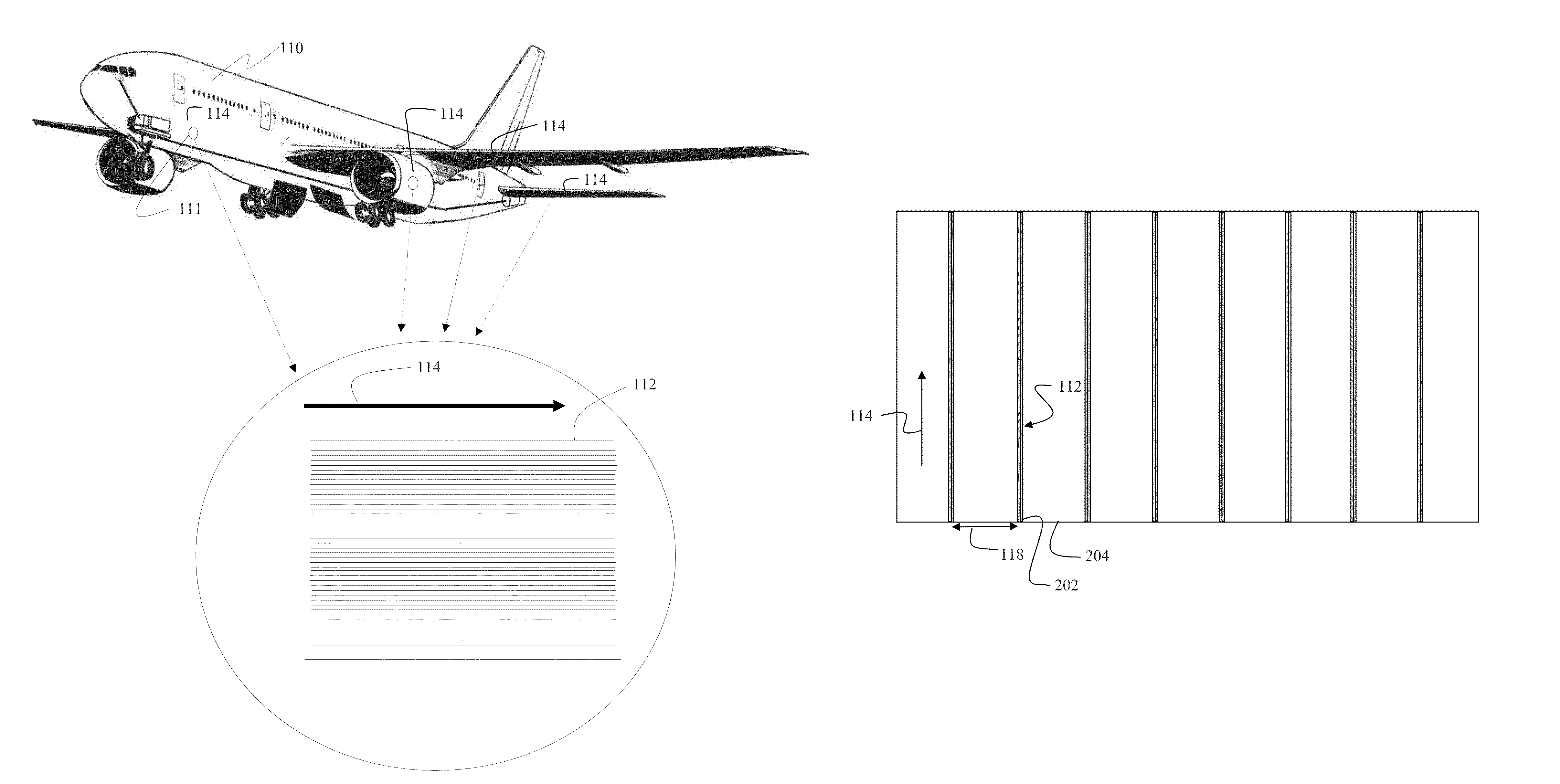

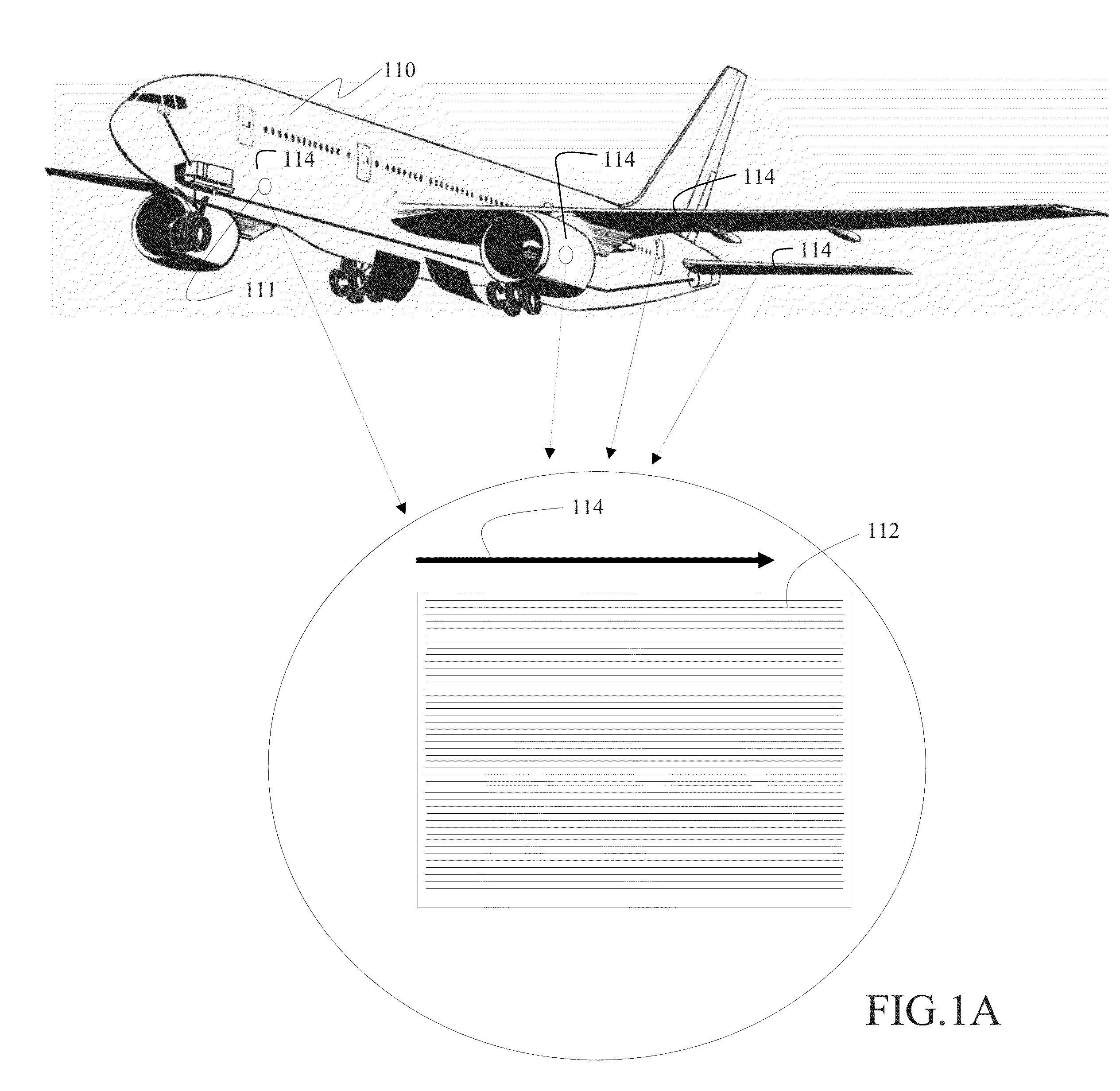

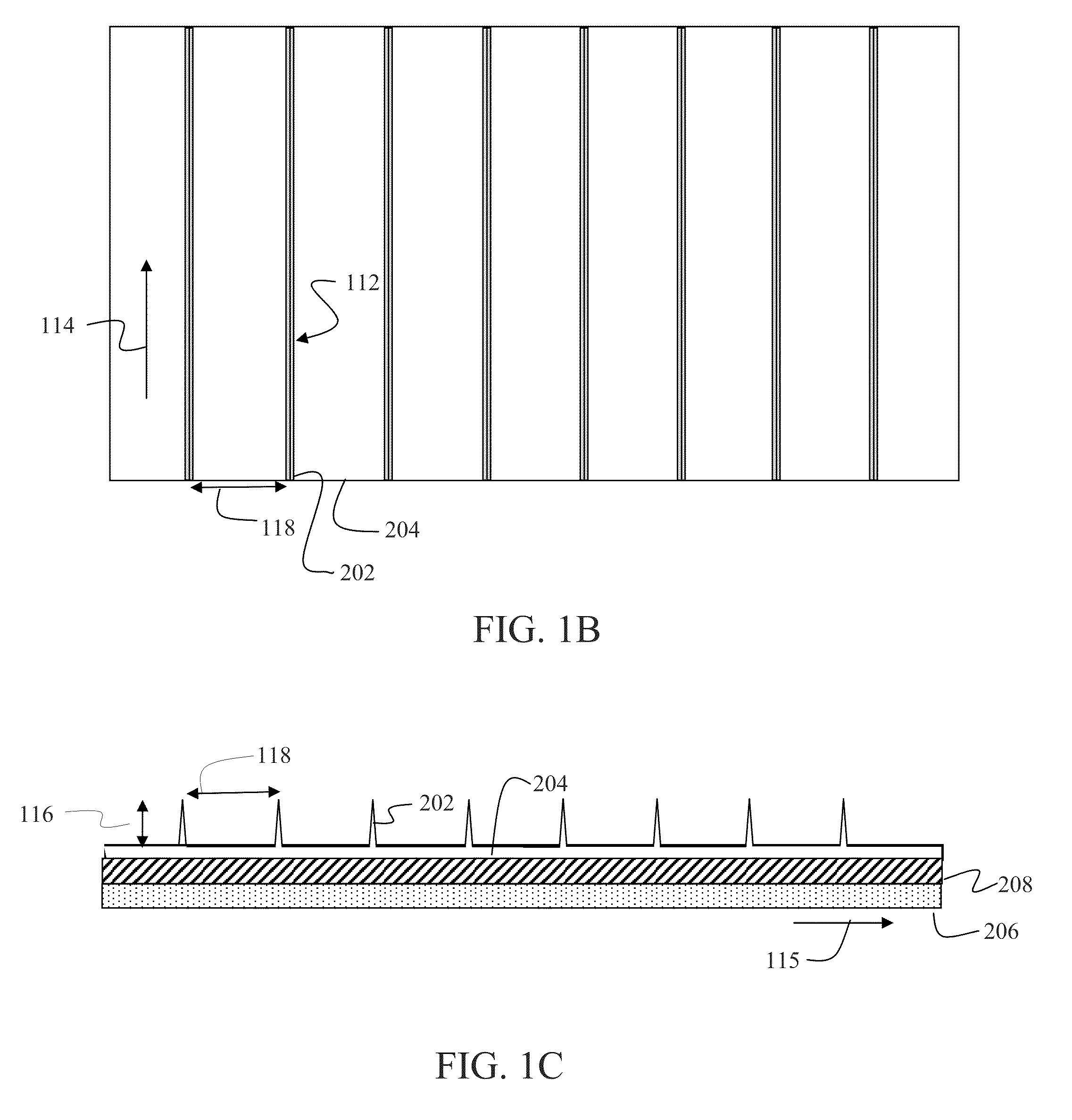

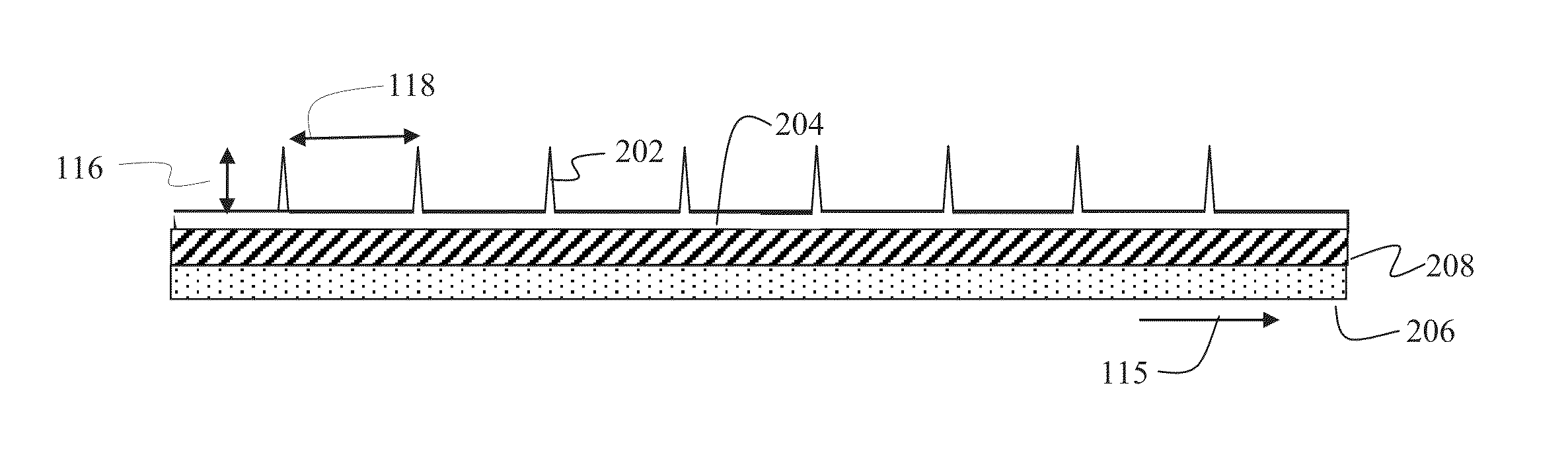

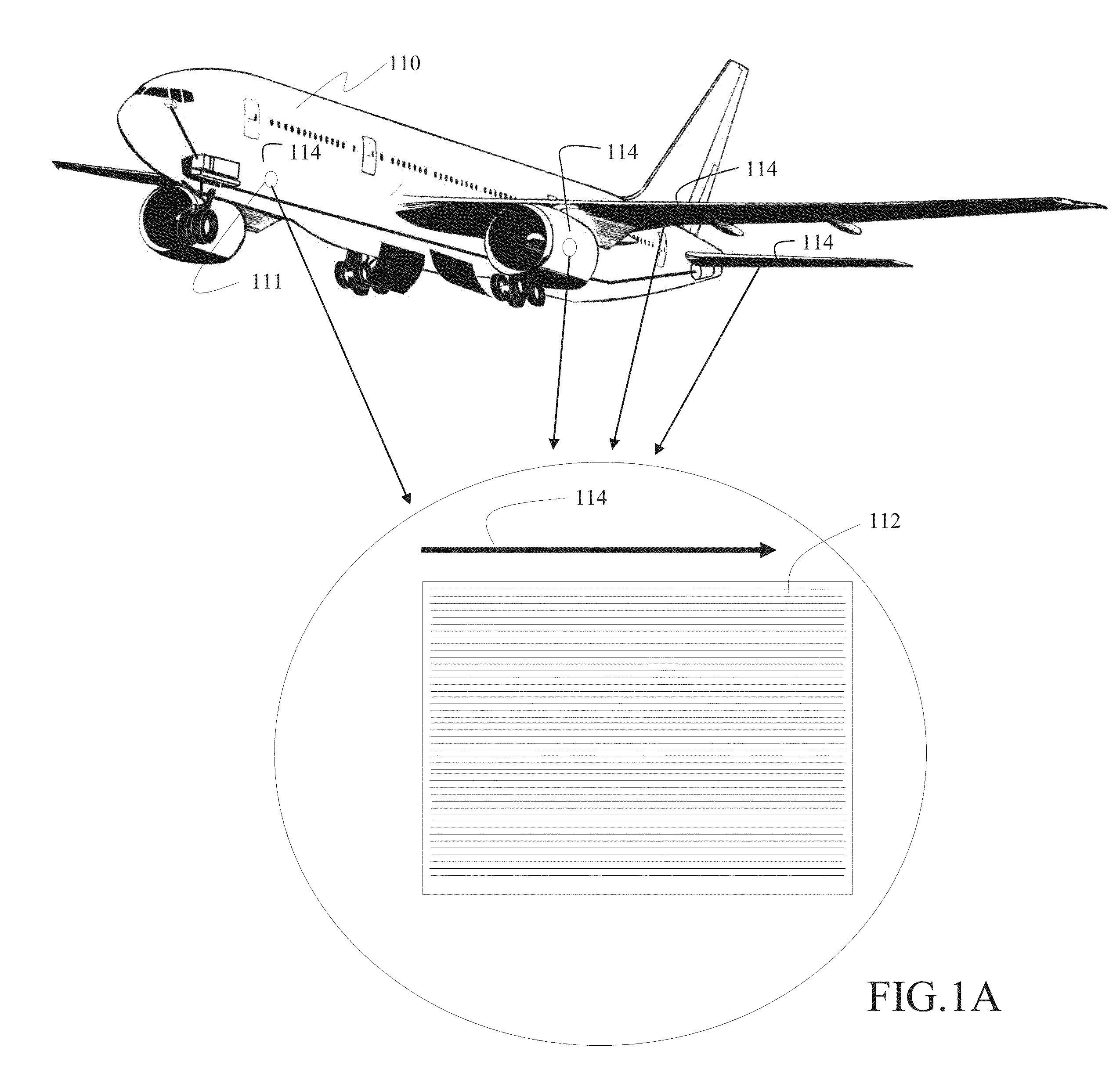

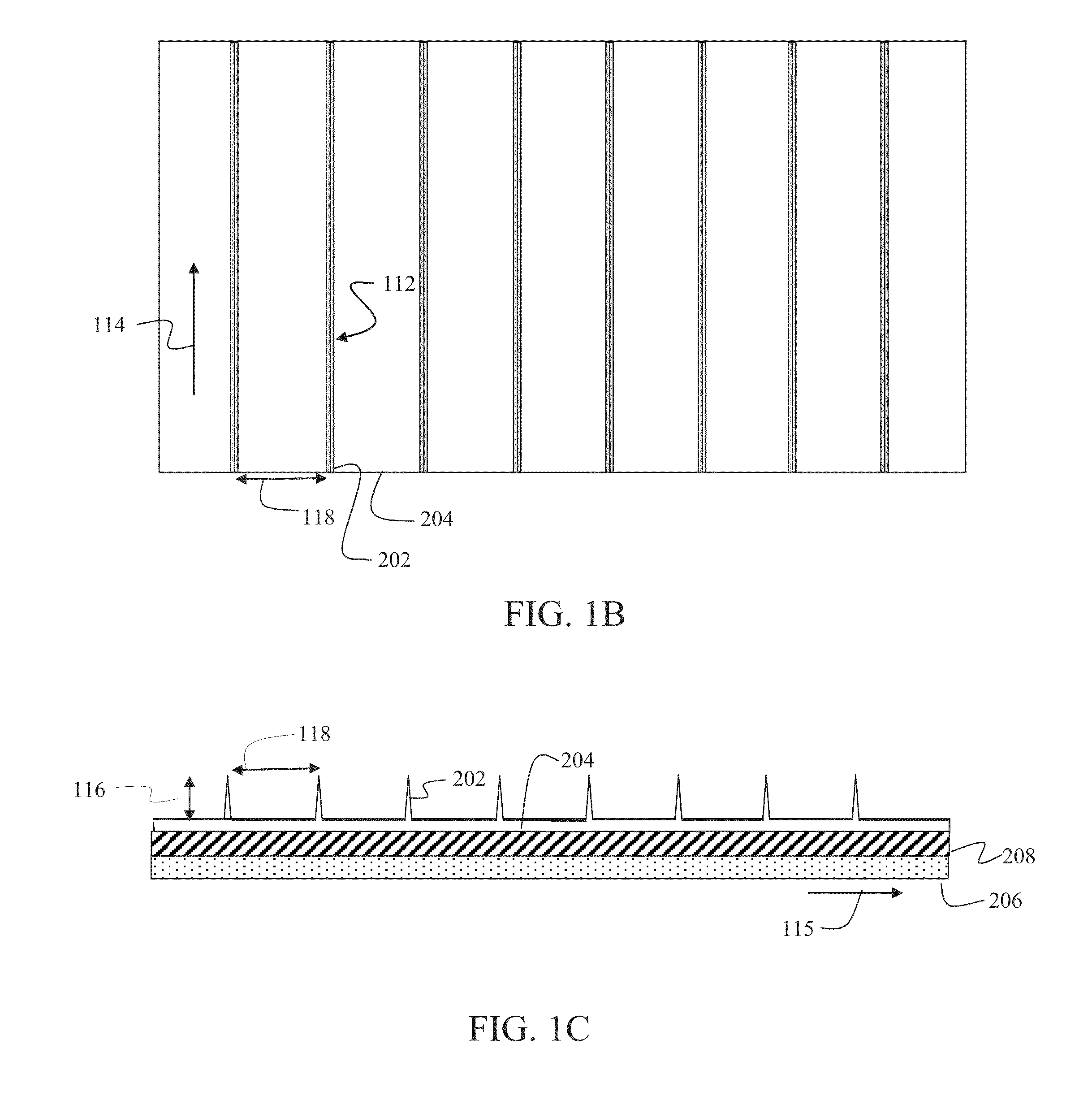

Reduced solar absorptivity applique

InactiveUS8733702B1Increased durabilityReduce decreaseLayered productsDecorative surface effectsSurface layerOptoelectronics

A reduced solar aborptivity appliqué having a surface layer for adhering to an surface and high aspect ratio microstructures extending from the surface layer having pigmentation or spectral tailoring.

Owner:THE BOEING CO

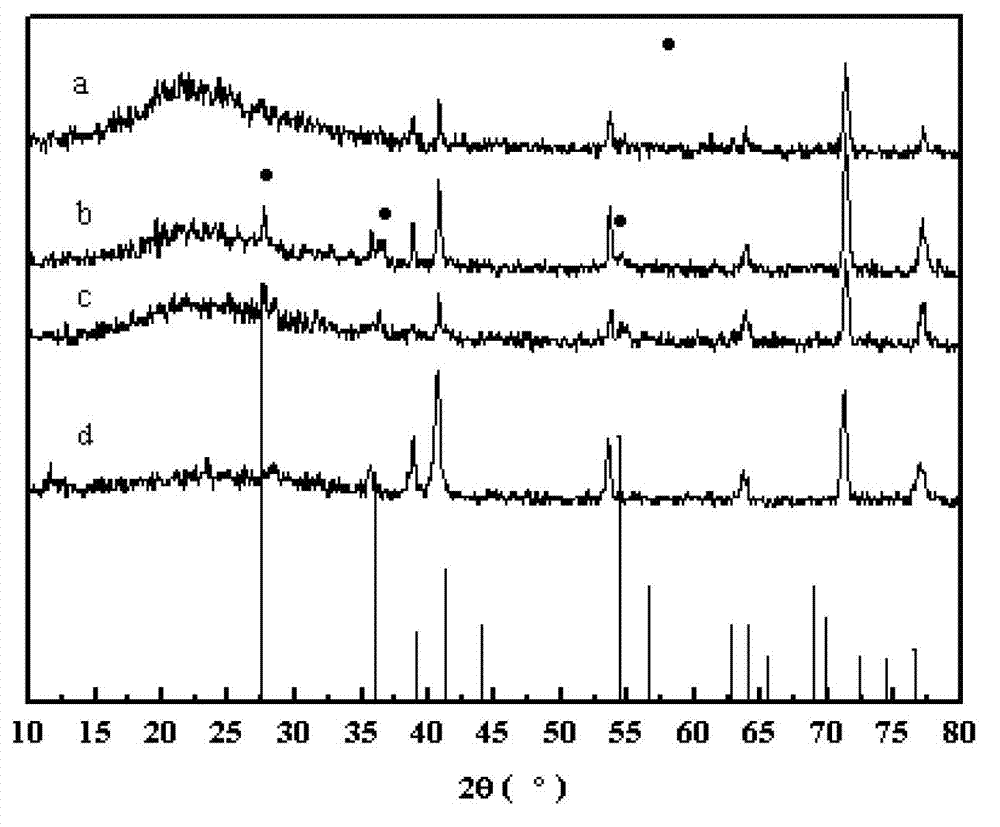

Preparation method of titanium alloy surface coating with low solar absorptivity and high emissivity

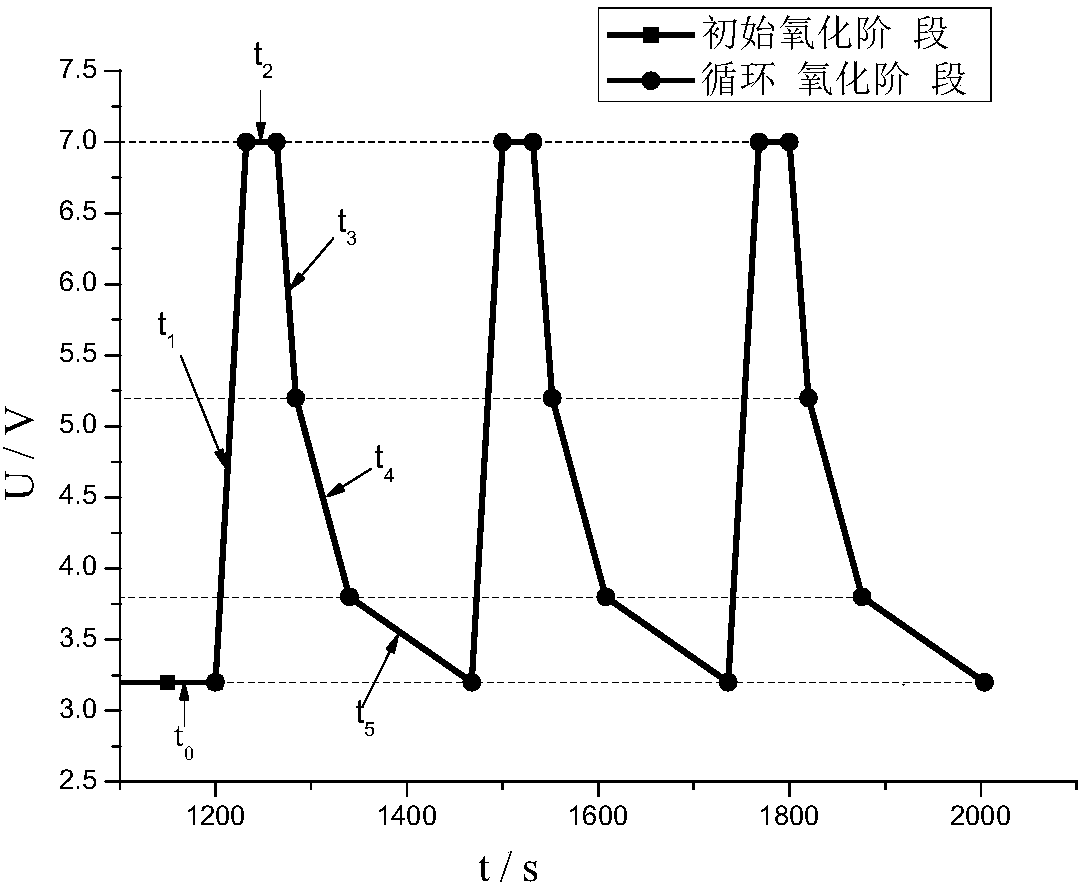

ActiveCN103194780AImprove bindingImprove thermal stabilitySurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method of a titanium alloy surface coating with low solar absorptivity and high emissivity, and relates to a preparation method of a titanium alloy surface coating. The titanium alloy surface coating provided by the invention is used for solving the problems of high solar absorptivity, low emissivity and poor binding force with a substrate and thermal stability of the titanium alloy material. The preparation method comprises the following steps of: 1, polishing and cleaning titanium alloy; and 2, carrying out micro-arc oxidation. The coating prepared by the invention is white or grey white in appearance, uniform and attractive; the thickness of the coating is up to 30-120 mu m and can be adjusted; due to in-situ growth, the coating has good binding force and thermal shock resistance; furthermore, the solar absorptivity is 0.35-0.6; the emissivity is 0.8-0.95; the coating is a thermal control coating with low solar absorptivity and high emissivity and is good in performance; and the preparation method disclosed by the invention is used for preparing the titanium alloy surface coating with low solar absorptivity and high emissivity.

Owner:HARBIN INST OF TECH

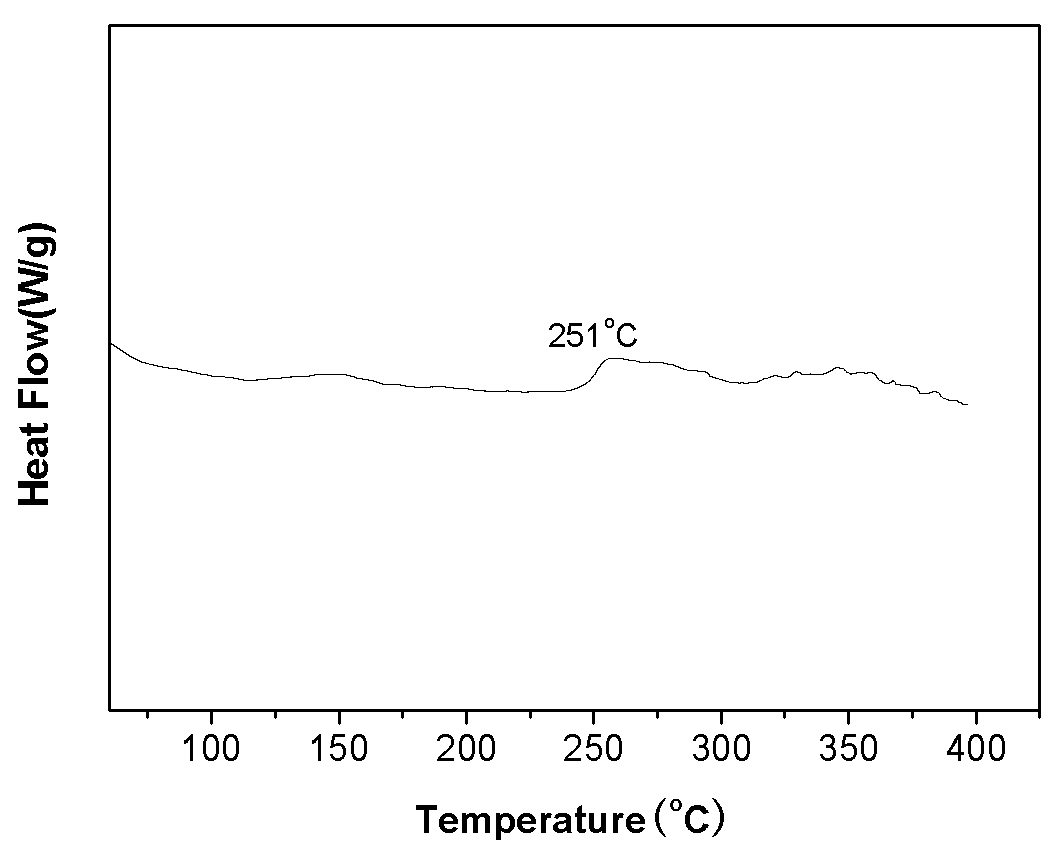

Polyimide film and preparation method and applications thereof

ActiveCN102167824AHigh transparencyReduced solar absorption and emission ratioDiphenyl etherOptical transparency

The invention discloses a polyimide film and a preparation method and applications thereof. The compound forming the polyimide film is the compound of which structural general formula is shown in the formula I. The preparation method of polyimide is as follows: aromatic dianhydride 2,3,3',4'-diphenyl ether tetracarboxylic acid dianhydride (aODPA) and a series of aromatic diamine monomers are used as raw materials to prepare polyimide resin through chemical imidization. The polyimide film prepared by the technology has good optical transparency, low solar absorptivity-emissivity ratio and good thermal stability, and can be used to prepare the thermal protection device of the spacecraft, the solar cell array substrate and the antenna reflector / collector or solar sail and have important application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing differential arc oxidation coating with high solar absorptivity and high emissivity

ActiveCN101139729AHigh hardnessImprove bindingAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a method for preparing a micro-arc oxidized coating with high solar absorptivity and high emissivity. The invention solves such a problem associated with prior Al-alloy coating that the solar-absorptivity, emissivity and bond, etc. can't meet the requirements from such fields as aerospace and decoration. The procedures are: placing a cleaned Al alloy in a stainless steel electrolytic tank as an anode, taking the stainless steel electrolytic tank as a cathode, supplying power by a pulse micro-arc oxidizing power supply, controlling the current density to be 0.5- 30A / dm<2>, positive voltage 240-1000 V, power supply frequency 50-3000 Hz, duty rate 10-50%, and controlling the electrolyte by a cooling circulating water to be no more than 30 DEG C, pH value of the electrolyte 8-12, carrying out micro-arc oxidization for 5-180 min., and then obtaining a ceramic coating. The invention reduces the cost and improves the product performance. The invention obtains a ceramic coating that has a solar absorptivity on Al alloy surface more than 0.90 and emissivity more than 0.80, in addition, the coating is of high hardness (more than 1000 Hv) and good bond with the substrate.

Owner:HARBIN INST OF TECH

Reduced solar absorptivity applique having spaced riblets with pigmented coloration

A reduced solar aborptivity appliqué having a surface layer for adhering to an surface and high aspect ratio microstructures extending from the surface layer having pigmentation or spectral tailoring.

Owner:THE BOEING CO

Ti-alloy nitride selective-absorption film system and preparation method thereof

InactiveCN103383155AHigh photothermal conversion efficiencyImprove absorption rateSolar heat devicesLayered productsLow emissivitySolar water

The invention discloses a Ti-alloy nitride selective-absorption film system. The selective-absorption film system comprises a metal substrate and further comprises a Ti-alloy nitride selective-absorption film, an anti-reflection dielectric film and an SiO2 protective film which are deposited on the metal substrate in sequence. The selective-absorption film system provided by the invention is characterized in that the solar absorptivity is greater than 97%; the solar emissivity is smaller than 3%; both the photo-thermal conversion efficiency and the heat-collecting efficiency are high. Under the premise of keeping high absorptivity and low emissivity, the selective-absorption film can meet the requirements of diversification and individuation of photo-thermal products such as solar water heaters and solar air conditioners by adjusting the components of Ti alloy. The selective-absorption film system is simple in structure and free from oxygen deposition, and has the characteristics of simple preparation technology and using less target materials, so that the production efficiency is greatly improved; the industrial large-scale production cost is lowered. Therefore, the selective-absorption film system is of great significance for the development of the field of solar selective heat absorption films.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

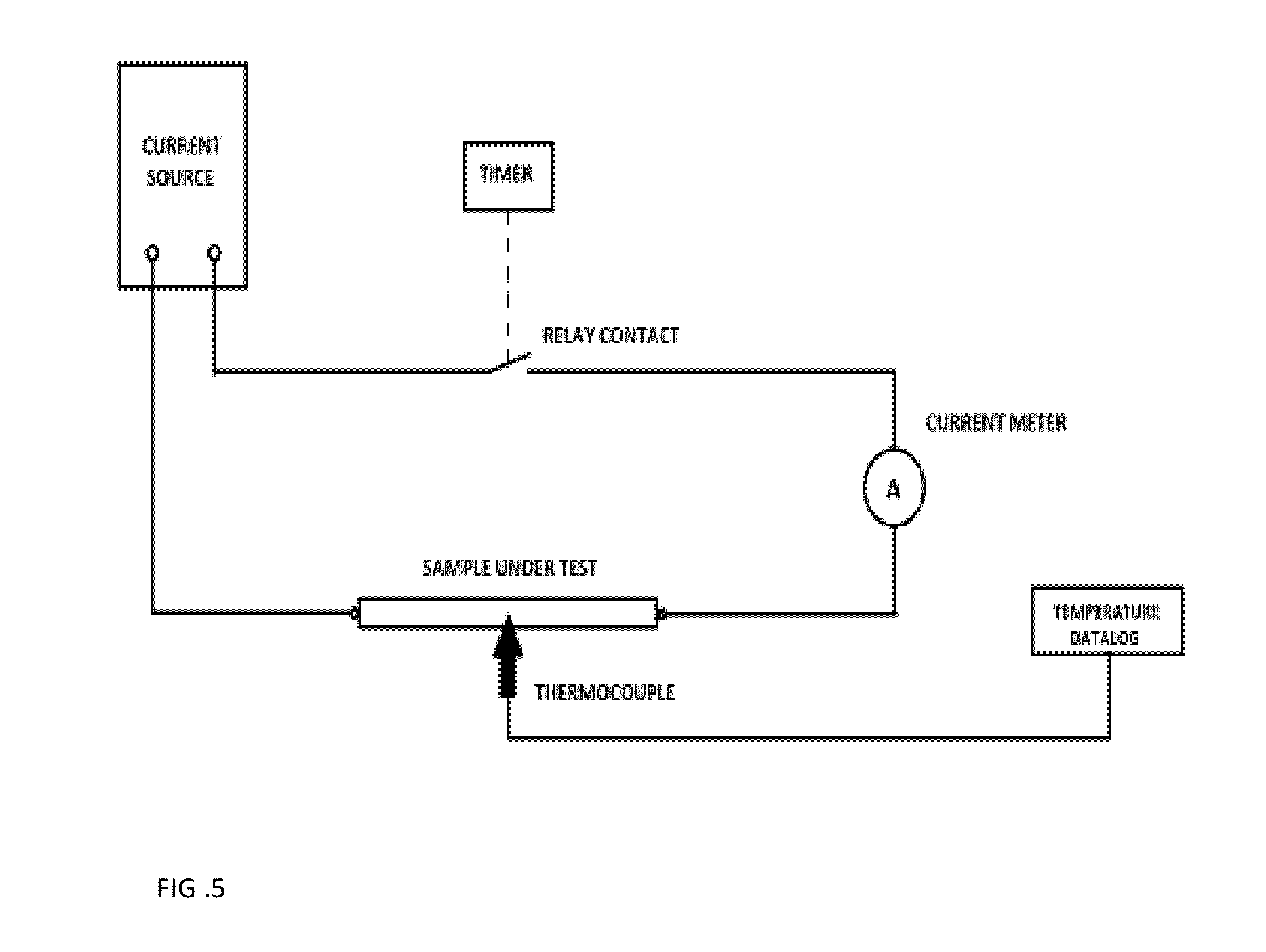

Surface modified overhead conductor

ActiveUS20150235739A1Lower operating temperaturePlastic/resin/waxes insulatorsAuxillary non-insulated conductorsElectrical conductorSolar absorptivity

The present invention relates to a surface modified overhead conductor with a coating that allows the conductor to operate at lower temperatures. The coating is an inorganic, non-white coating having durable heat and wet aging characteristics. The coating preferably contains a heat radiating agent with desirable properties, and an appropriate binder / suspension agent. In a preferred embodiment, the coating has L* value of less than 80, a heat emissivity of greater than or equal to 0.5, and / or a solar absorptivity coefficient of greater than 0.3.

Owner:GENERAL CABLE TECH CORP

Preparation method of aluminum alloy surface conductive thermal control coating with low solar absorptivity and high emissivity

ActiveCN108950549ALow solar absorptionLow emissivityAnodisationVacuum evaporation coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of an aluminum alloy surface conductive thermal control coating with low solar absorptivity and high emissivity, and relates to the preparation method of the aluminum alloy surface conductive thermal control coating. The preparation method aims at solving the technical problems that a conductive thermal control coating integrated film meeting the requirements of space ultraviolet radiation and electron radiation cannot be prepared with the existing aluminum alloy surface treatment technology. The method includes the steps of 1, surface pre-treatmentof an aluminum alloy part; 2, preparation of electrolyte; 3, pulse micro-arc oxidation; and 4, magnetron sputtering. The thickness of the prepared aluminum alloy surface conductive thermal control coating with low solar absorptivity and high emissivity is 20-100 micrometers, and the roughness of the prepared aluminum alloy surface conductive thermal control coating with low solar absorptivity andhigh emissivity is 2.0-12.0 micrometers; and the solar absorptivity is 0.35-0.42, the emissivity is 0.88-0.92, the value of alpha s / epsilon is about 0.4, the surface resistivity is 1*10<-5> Ohm.cm, the dual requirements of thermal control and static resistance of spacecrafts are met, and the conductive thermal control coating can be used for spacecraft structures.

Owner:HARBIN INST OF TECH

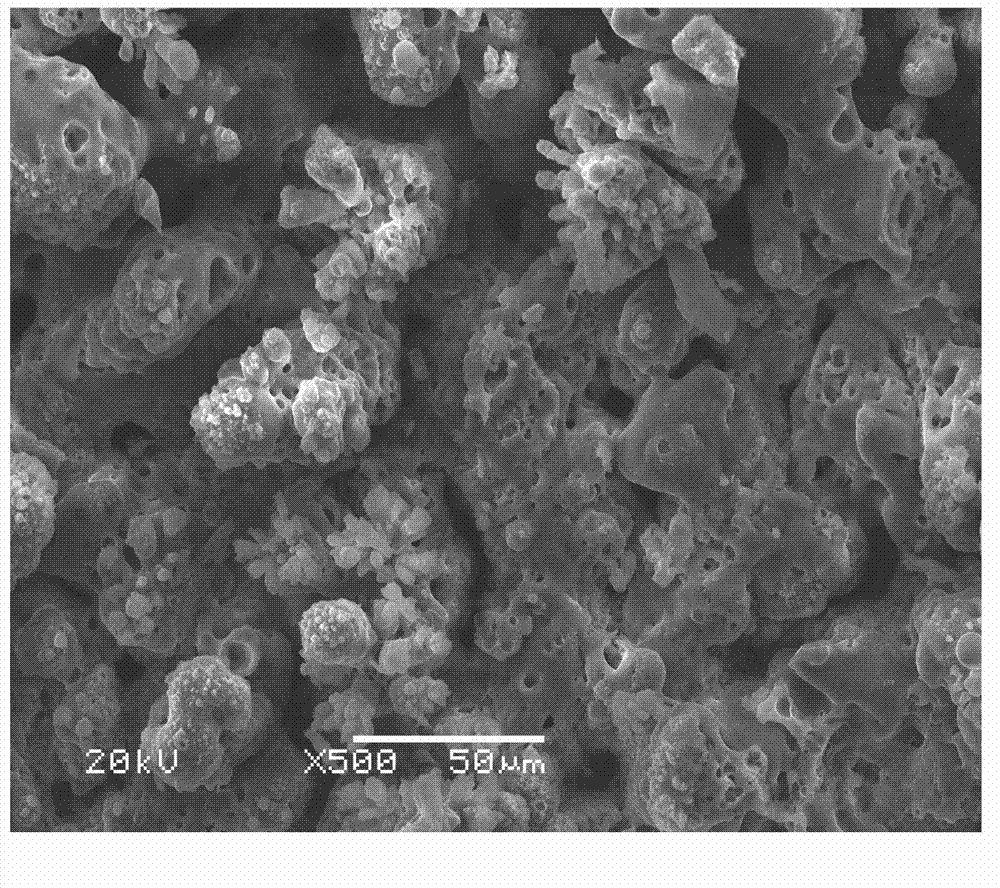

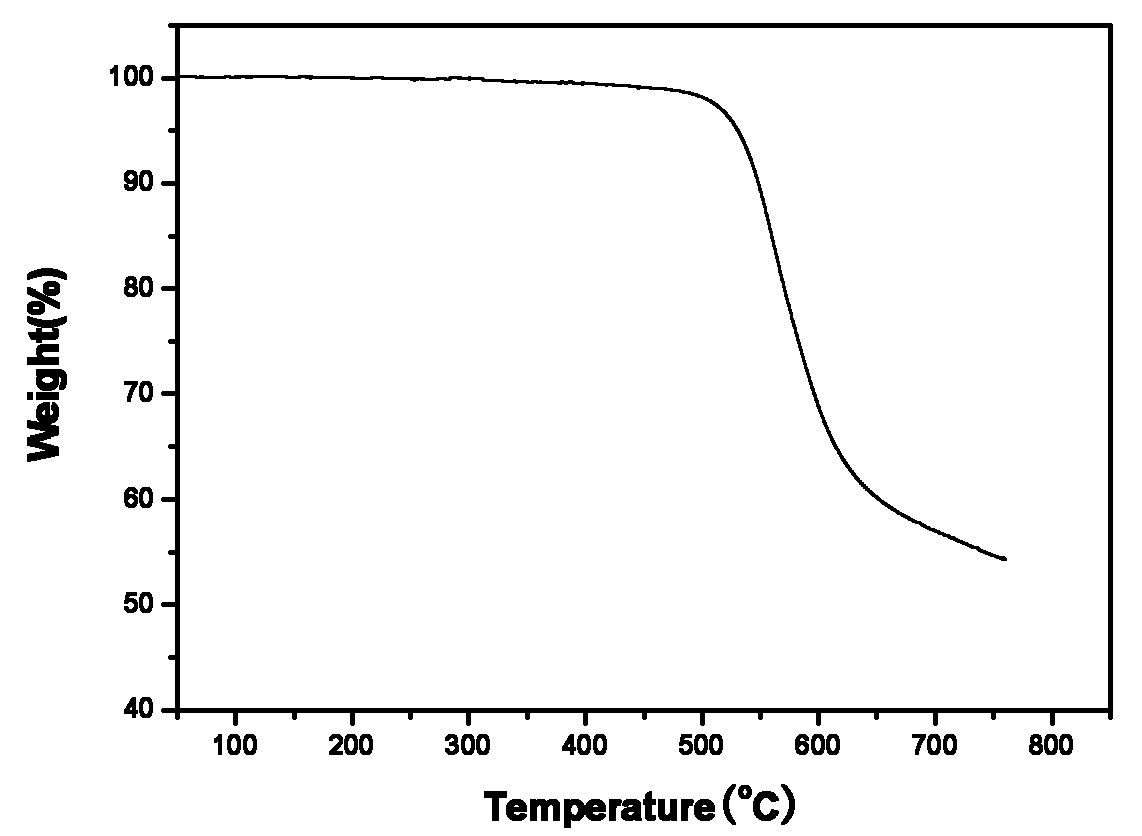

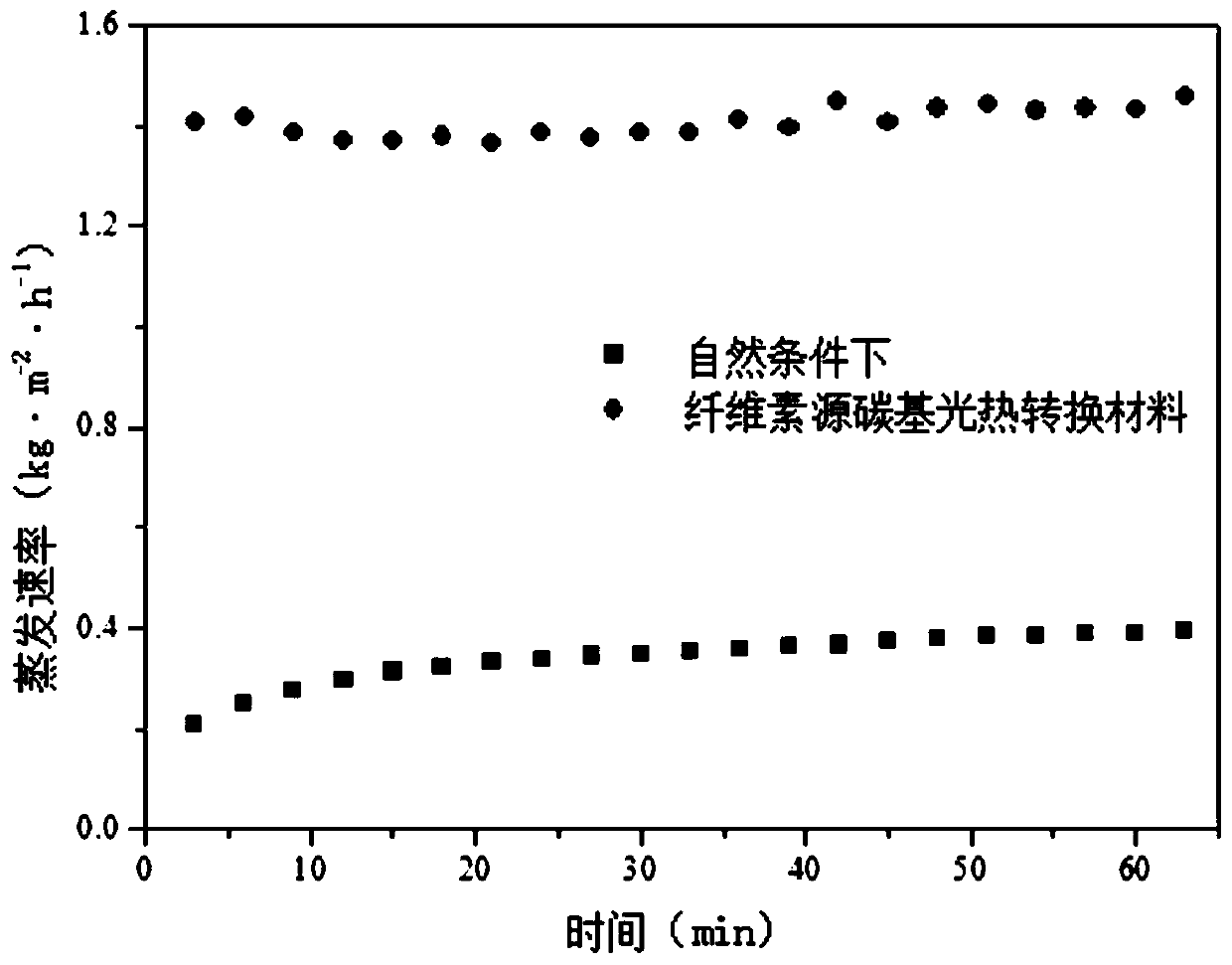

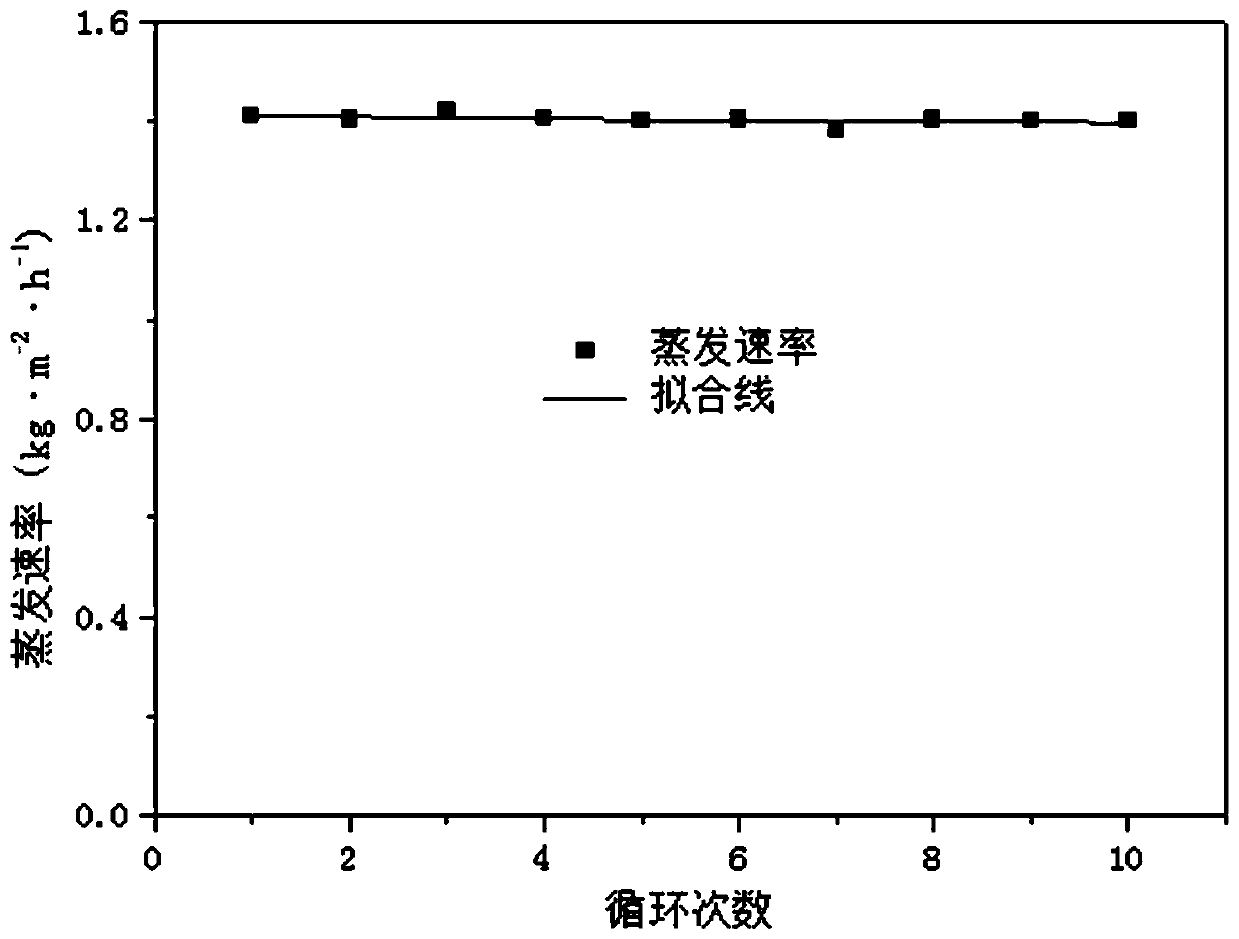

Cellulose source carbon-based photothermal conversion material for sea water desalination and preparation method thereof

ActiveCN111285704ARich porous network structureImprove controllabilityGeneral water supply conservationSeawater treatmentEpoxyFreeze-drying

The invention discloses a preparation method of a cellulose source carbon-based photothermal conversion material for sea water desalination, which comprises the following steps: mixing nanocellulose,a cell regulator, epoxy resin, polyamide resin and water, stirring to a uniform state, standing for degassing to obtain a homogeneous suspension, and carrying out directional freezing and drying to obtain a cellulose-based porous material; and performing carbonization treatment to obtain the cellulose source carbon-based photothermal conversion material for sea water desalination. According to theinvention, nanocellulose is used as a base material, epoxy resin and polyamide resin are used as adhesives, pores are generated after sublimation of ice crystals through freezing and drying, so thatthe cellulose source carbon-based photothermal conversion material has a rich porous network structure, multiple scattering of light rays in the cellulose source carbon-based photothermal conversion material is facilitated, the solar absorptivity is effectively improved, the solar seawater desalination requirement is met, the interface light-steam conversion efficiency is improved, and the seawater desalination efficiency is maximized. The raw materials are wide, the cost is low, and the biodegradability is realized.

Owner:SHAANXI UNIV OF SCI & TECH

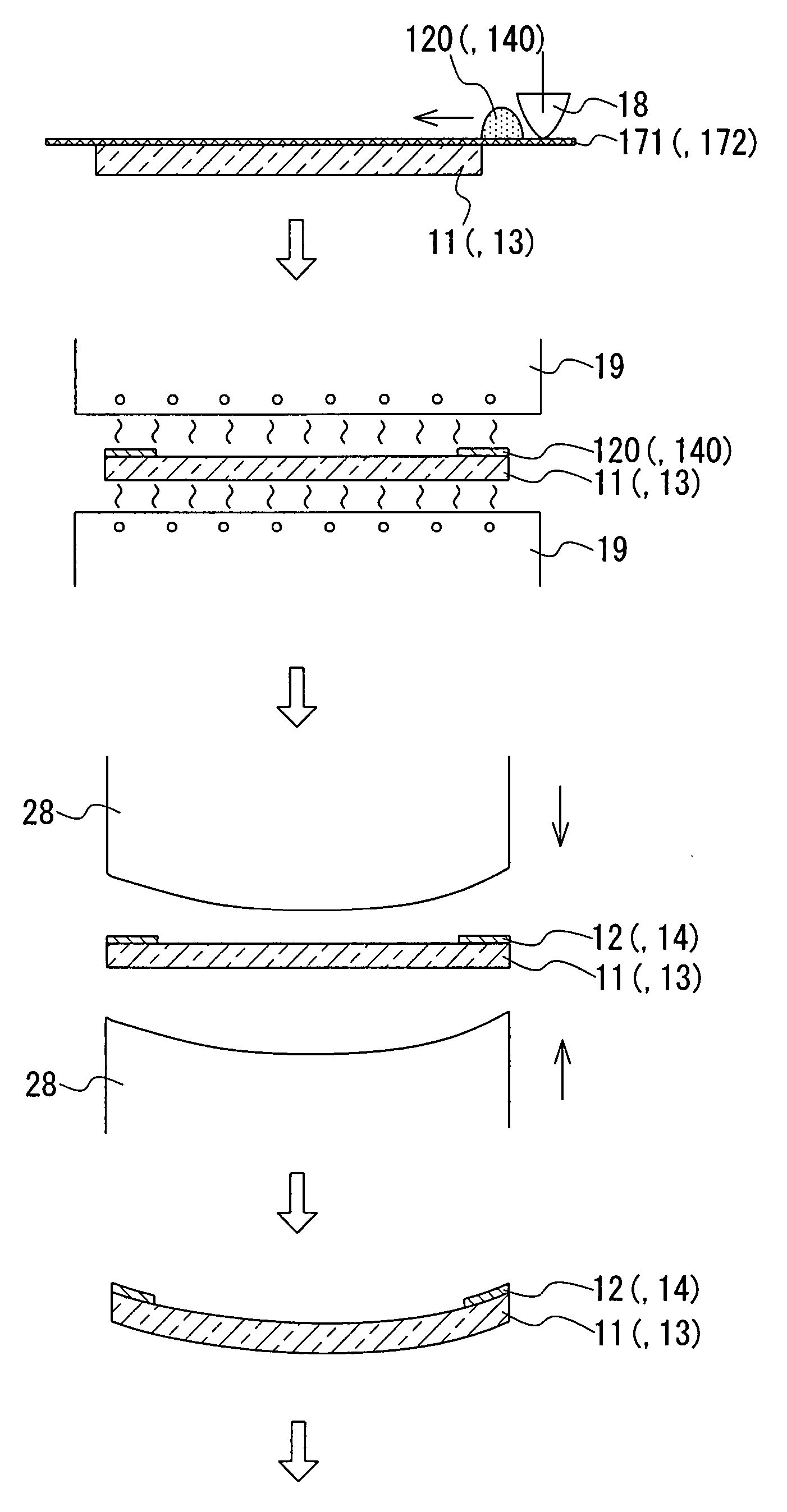

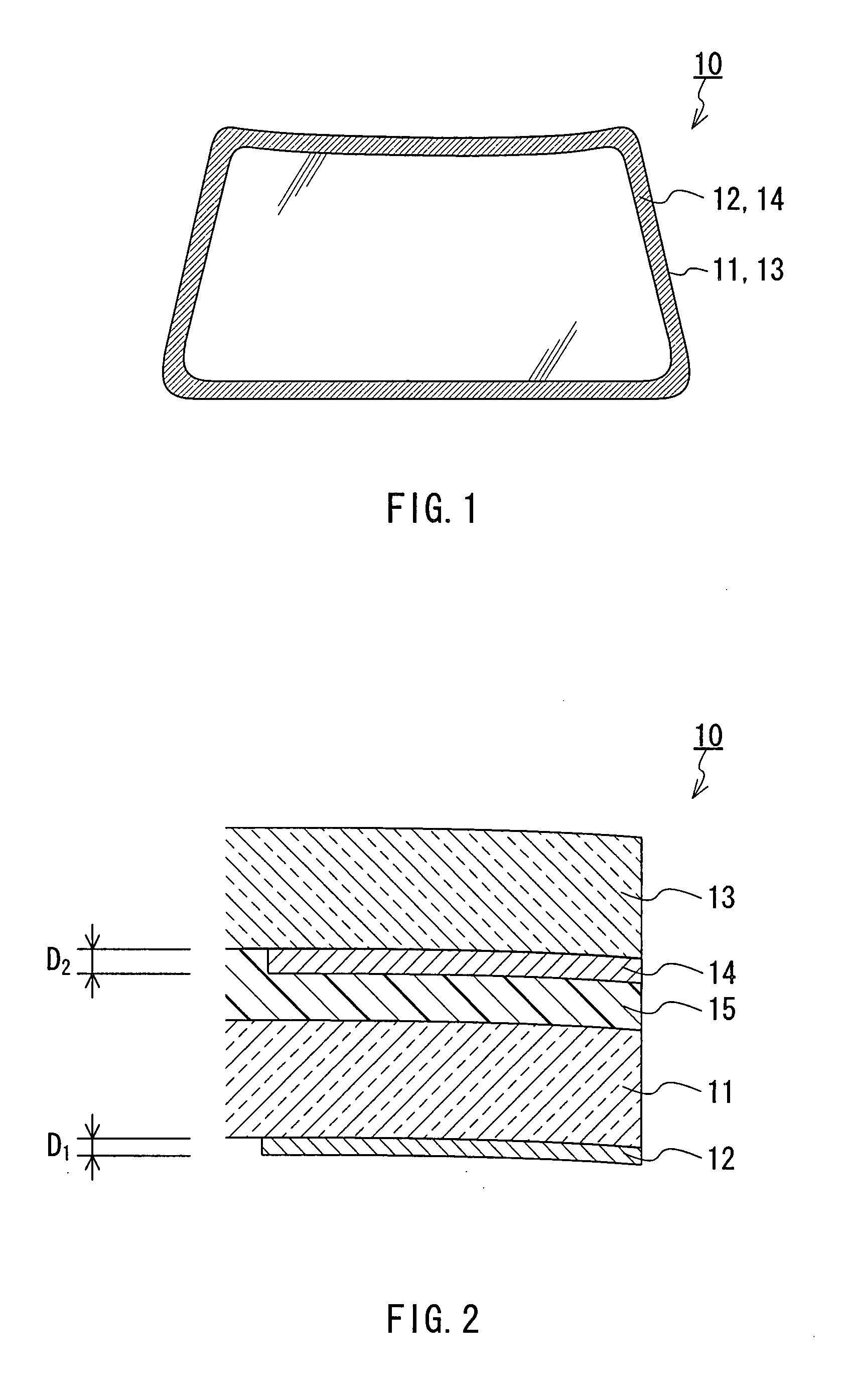

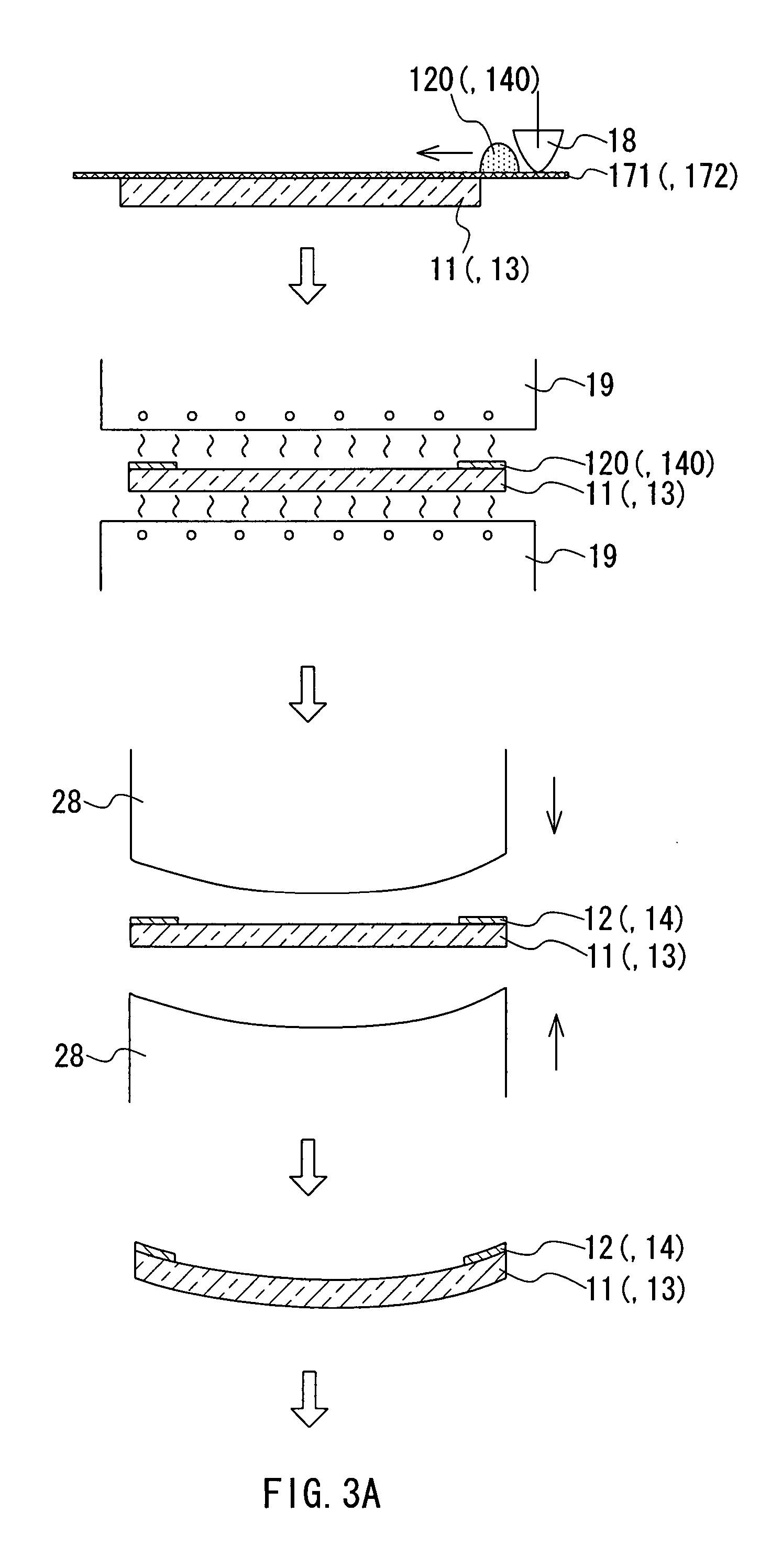

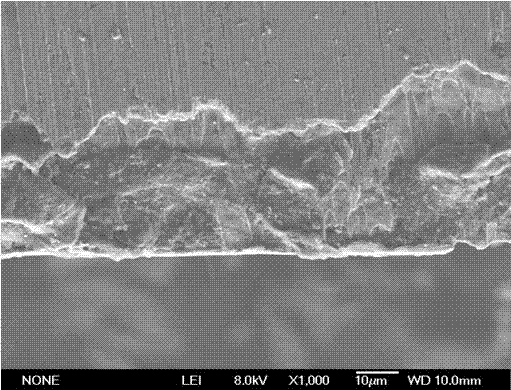

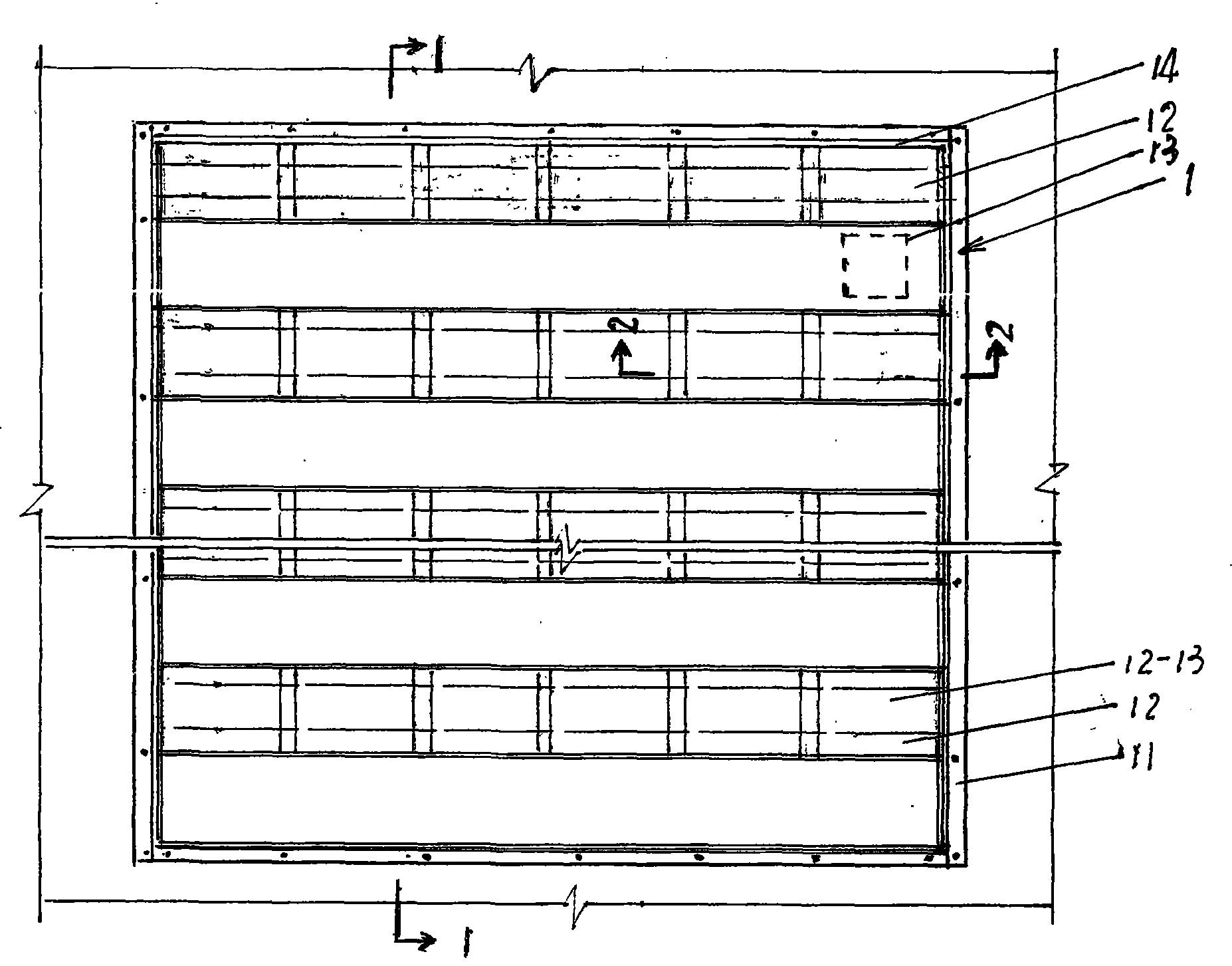

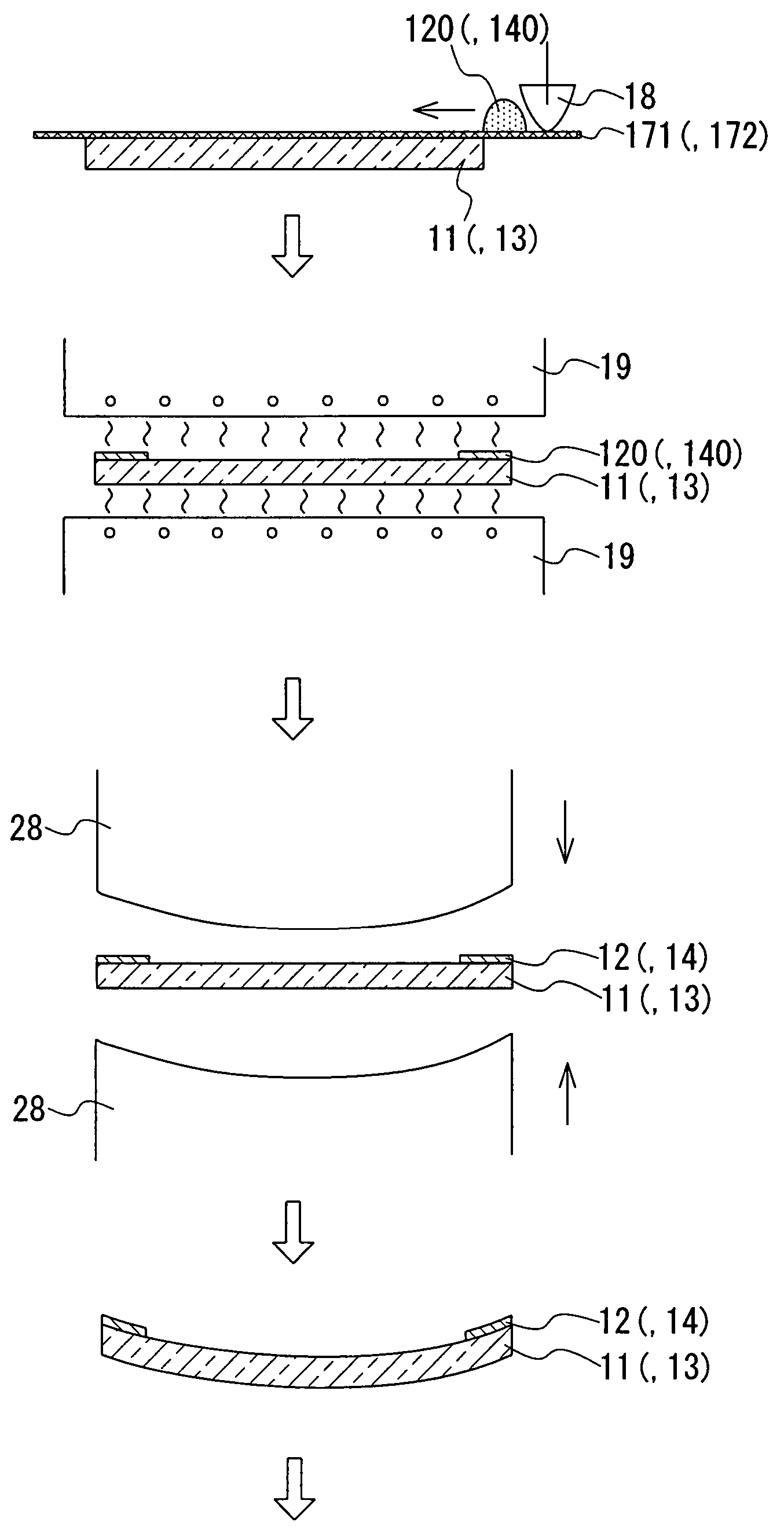

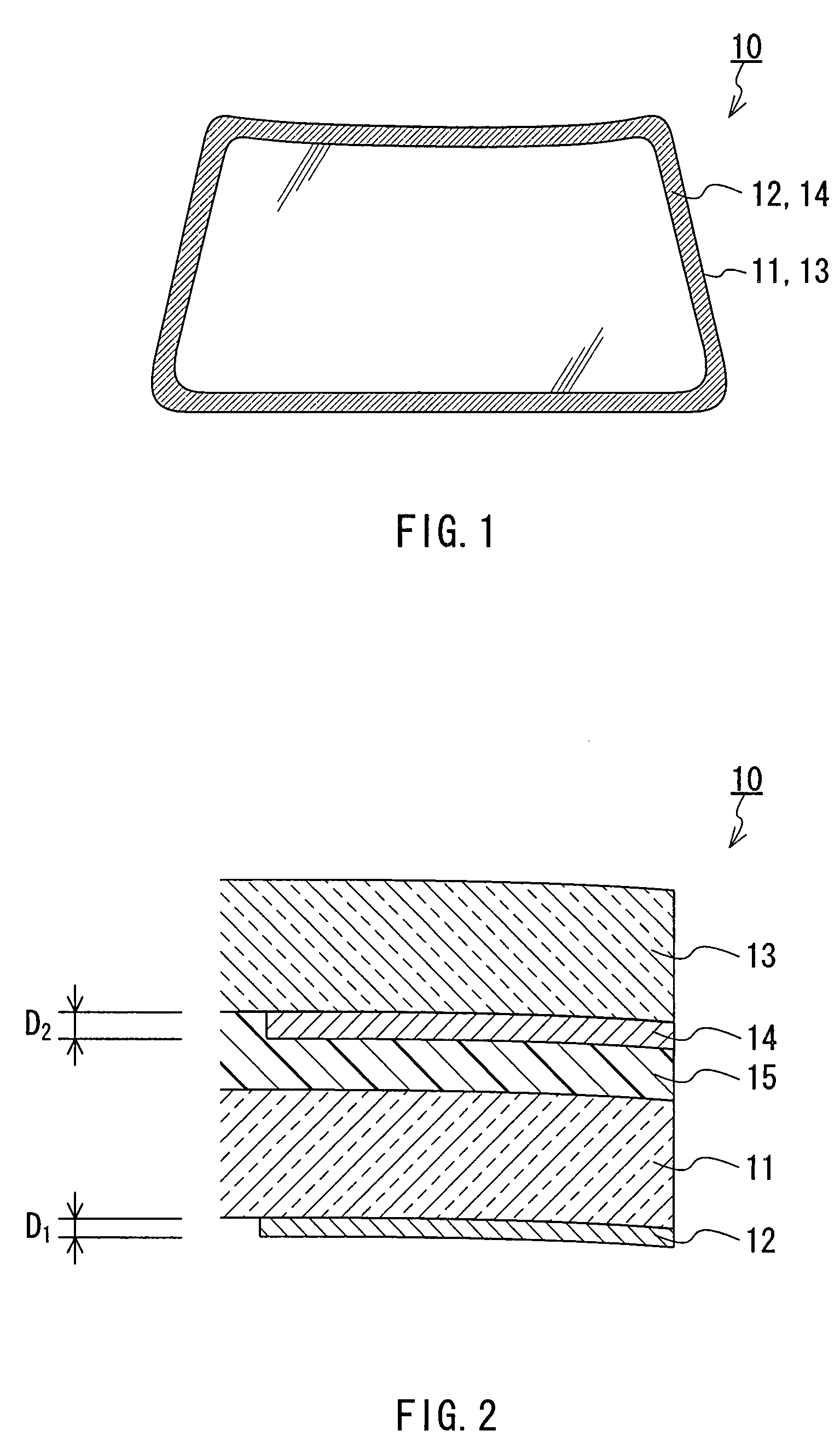

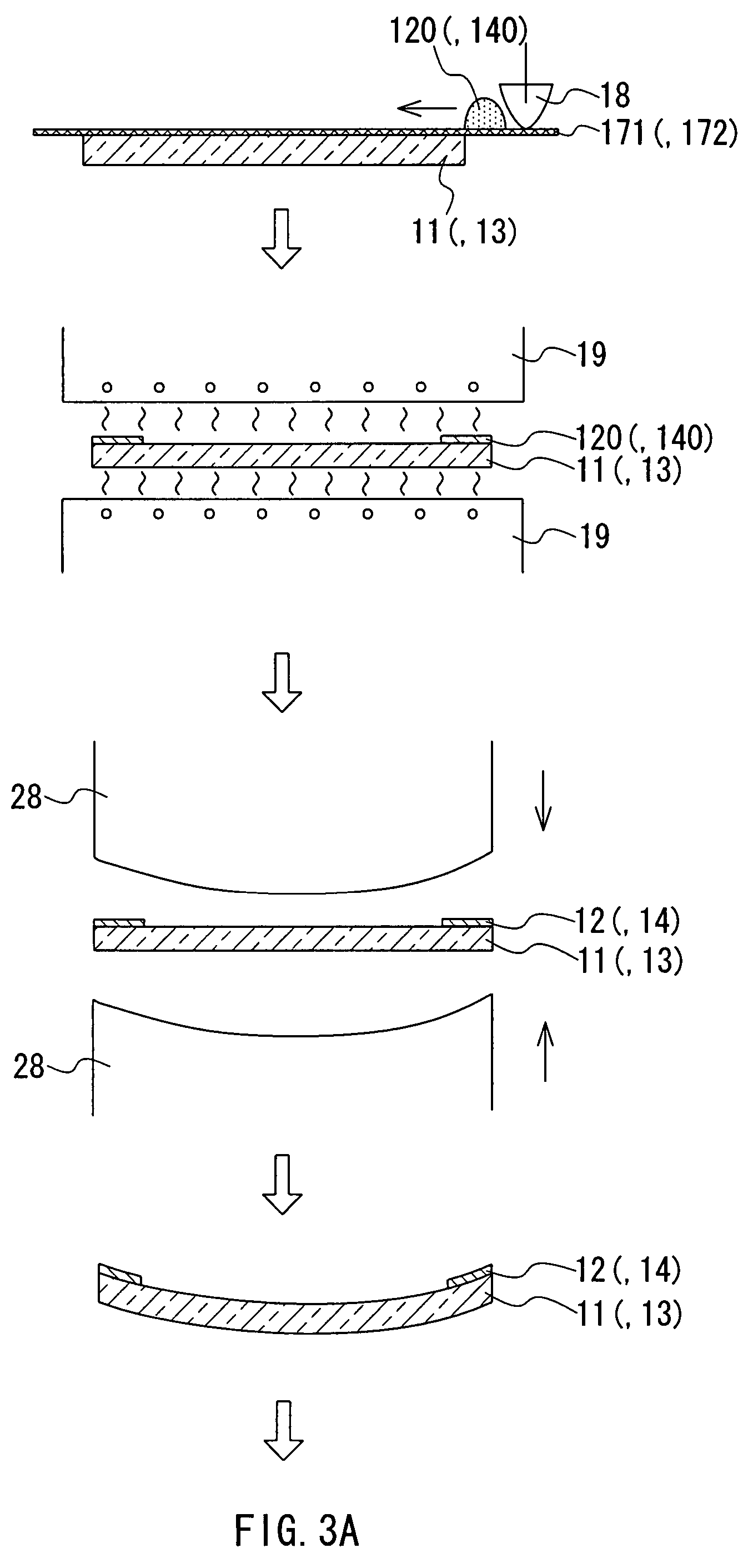

Method of manufacturing laminated glass for vehicle and laminated glass for vehicle

ActiveUS20080096026A1Edge gap can be reducedBonded firmlyLaminationLamination apparatusMetallurgySolar absorptivity

A ceramic paste is applied to a first glass sheet 11, and a ceramic paste is applied to a second glass sheet 13 with a lower solar absorptivity than that of the first glass sheet 11. In this case, the amount per unit area of the ceramic paste to be applied to the first glass sheet 11 is allowed to be smaller than that of the ceramic paste to be applied to the second glass sheet 13. Alternatively, a first ceramic paste and a second ceramic paste are allowed to have different compositions from each other. The first glass sheet 11 and the second glass sheet 13 are bent so that the surfaces onto which the ceramic pastes have been applied are shaped as concave surfaces. The applied ceramic paste is fired using the heating used for bending. Thus maskings 12 and 14 are formed. The first glass sheet 11 and the second glass sheet 13 are bonded to each other, with a resin interlayer film 15 being interposed therebetween.

Owner:NIPPON SHEET GLASS CO LTD

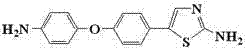

Application of diamine compound containing thiazole ring in preparing solar heat-absorbing coating

InactiveCN103788371AImprove heat stabilityImprove adhesionRadiation-absorbing paintsLow emissivitySolvent

The invention provides an application of a diamine compound containing a thiazole ring in preparing a solar heat-absorbing coating. The application comprises the following steps: under protection of argon, dissolving the diamine compound containing the thiazole ring in an organic solvent, and then adding a dianhydride monomer or a derivative thereof to carry out the polymerization reaction to obtain polyimide resin containing the thiazole ring; then, mixing the polyimide resin containing the thiazole ring with a pigment and a solvent, and then ball-milling and uniformly dispersing to obtain the coating. Test results show that the adhesive force of the coating prepared by the solar heat-absorbing coating is 4-5B, the solar absorptivity is 0.80-0.85, and the emissivity is 0.11-0.39. Therefore, the coating has higher solar absorptivity and lower emissivity, and can effectively improve the photothermal conversion efficiency of a solar heat collector. The coating has good mechanical property and strong weather resistance, and can be widely applied to the field of utilization of solar energy at medium and low temperature.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

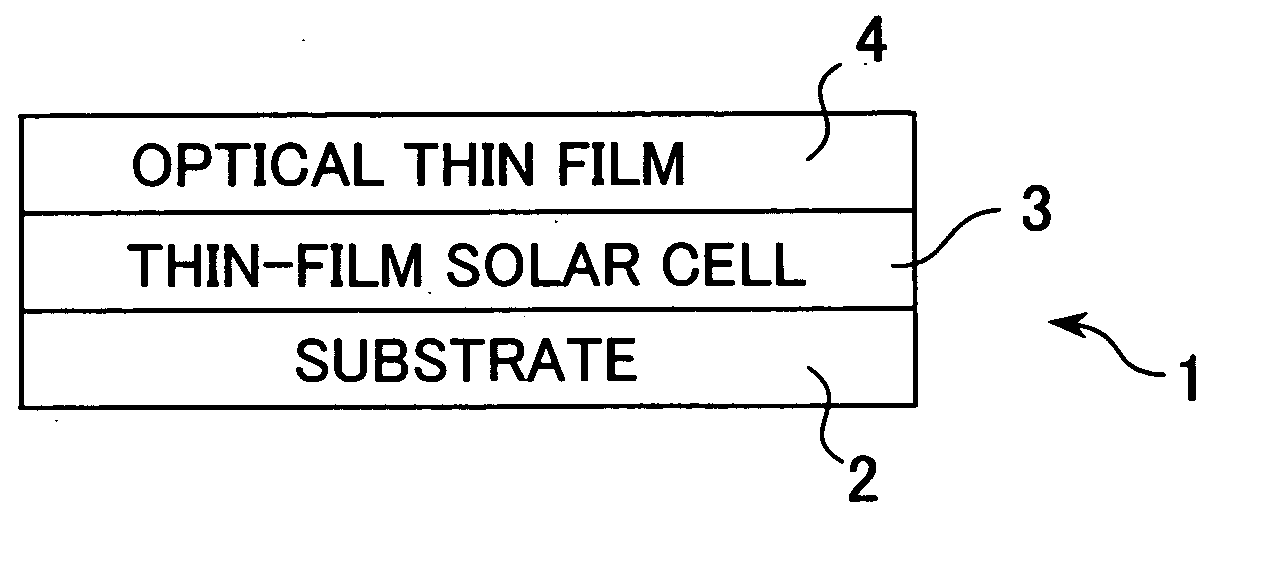

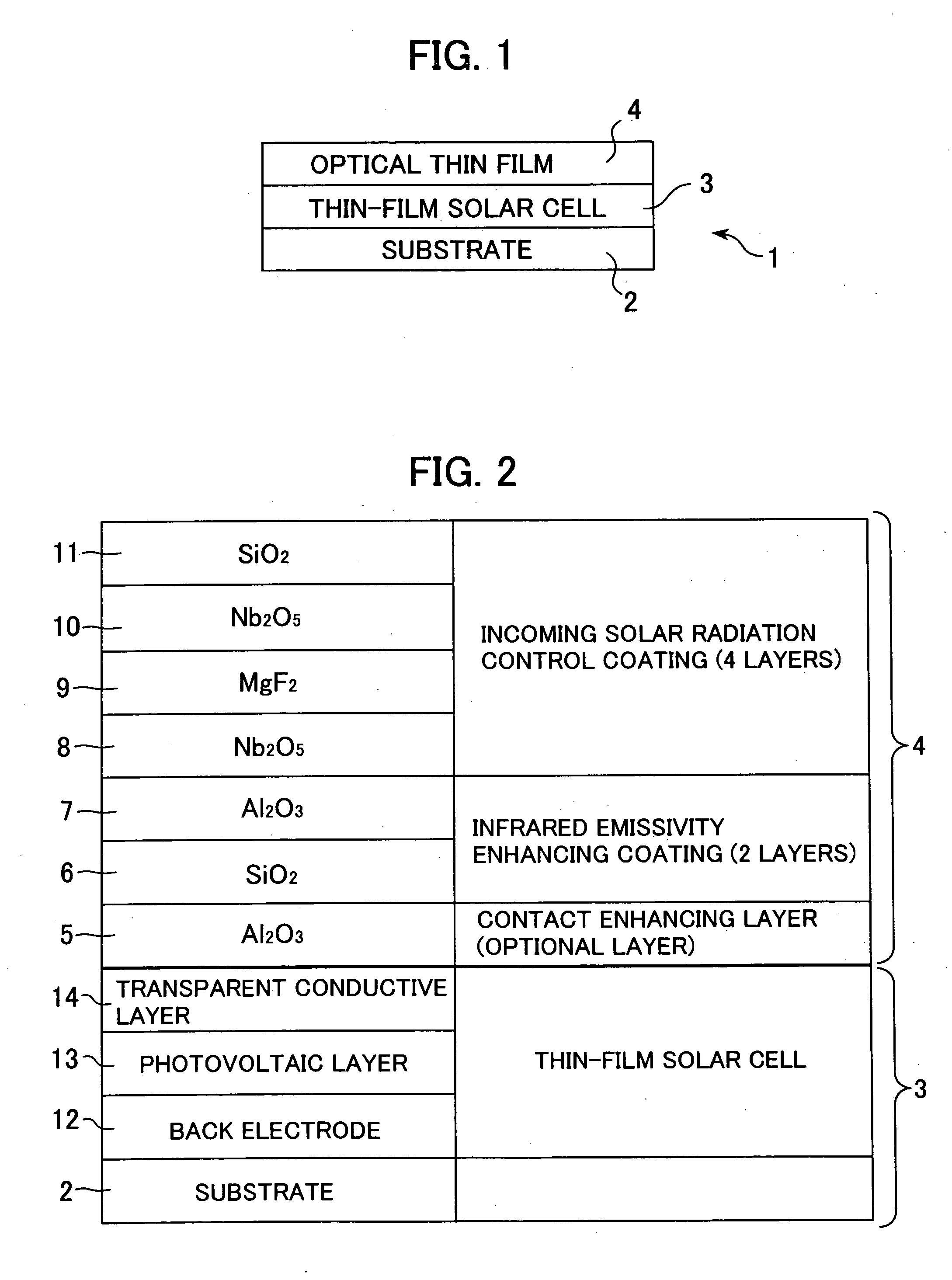

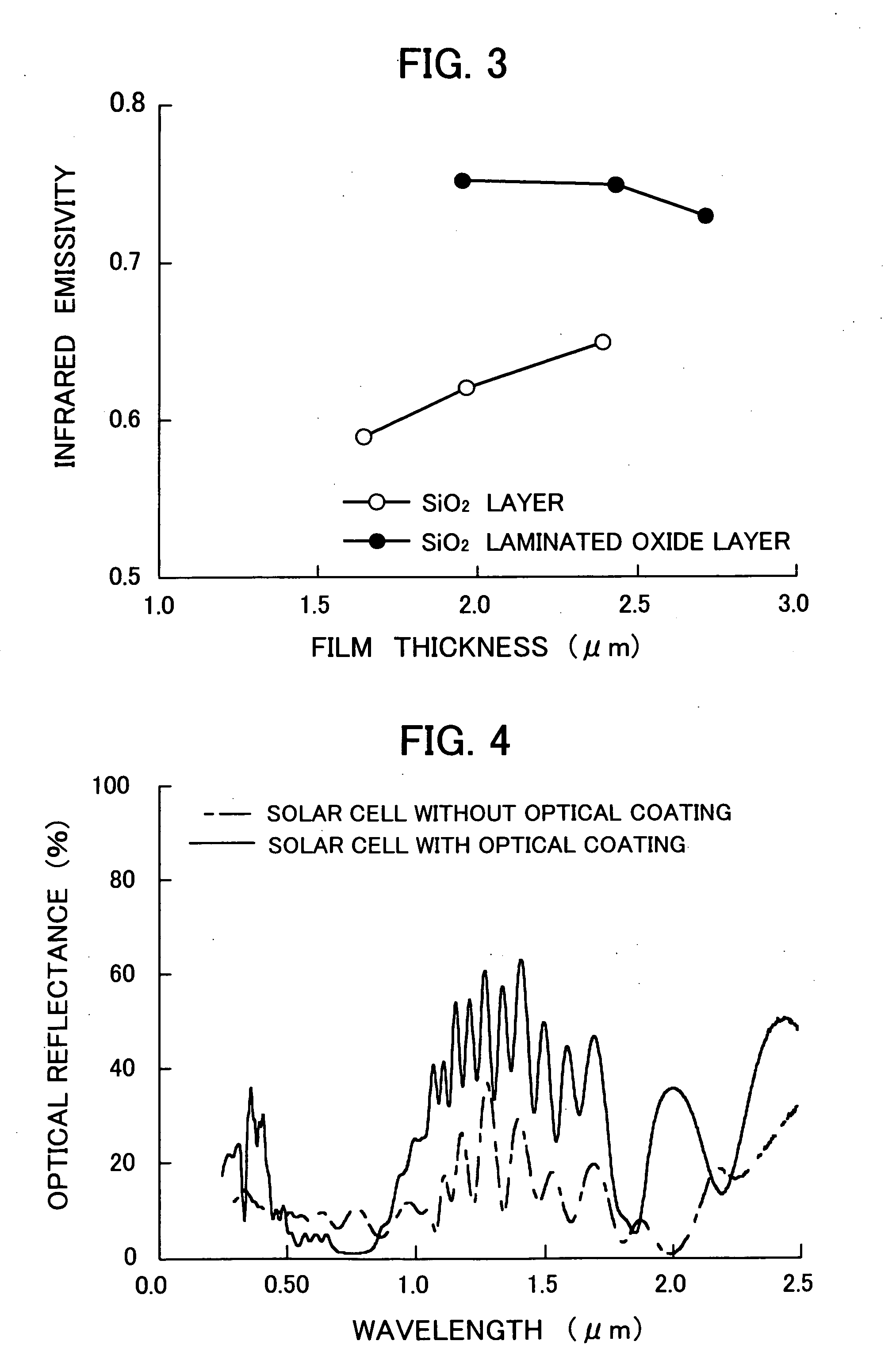

Optical thin film for solar cells and method of forming the same

InactiveUS20060243320A1Adequate thermal radiative characteristicEliminate needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSpace environmentGas phase

Disclosed is an optical thin film for a thin-film solar cell, which is formed directly on a top surface of the thin-film solar cell having a transparent conductive film layer to provide a high infrared emissivity and a lower solar absorptivity to the thin-film solar cell. The optical thin film is formed through a vacuum vapor deposition process. The thin film makes it possible to provide enhanced infrared emissivity based on its reduced thickness, while suppressing unnecessary incoming solar radiation in a simplified structure to achieve a reduced solar absorptivity so as to maintain desired cell efficiency. The optical thin film of the present invention is capable of achieving reduction in weight of a solar cell, and suitable for use, particularly, in space environments.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Black ceramic material and preparation method thereof

ActiveCN104046879ALow reduction temperatureReduce energy consumptionFluidised-bed furnacesMetallic materialsSolar absorptivity

The invention relates to a black ceramic material and a preparation method thereof and belongs to the inorganic nonmetallic material field. The black ceramic material comprises the following components in parts by weight: 1.82-3.7 parts of Gr2O3, 10.9-18.18 parts of TiO2, 1.94-4.13 parts of V2O5, 6.06-11.91 parts of MnO, 8-14 parts of Fe2O3, 0.001-0.01 part of Ni and 12-24.3 parts of SiO2. The black ceramic material is sintered by use of mill tailings and vanadium extraction tailings as the raw materials, and the solar absorptivity of the obtained black ceramic material is 0.85-0.90.

Owner:PANZHIHUA UNIV

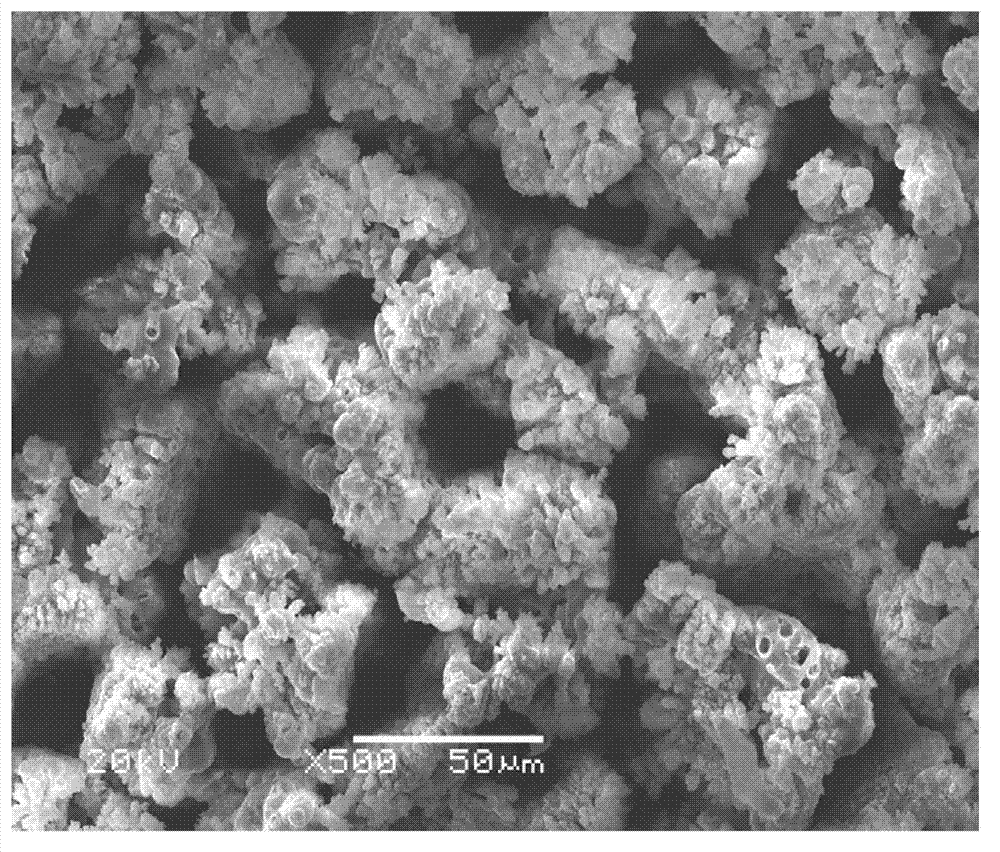

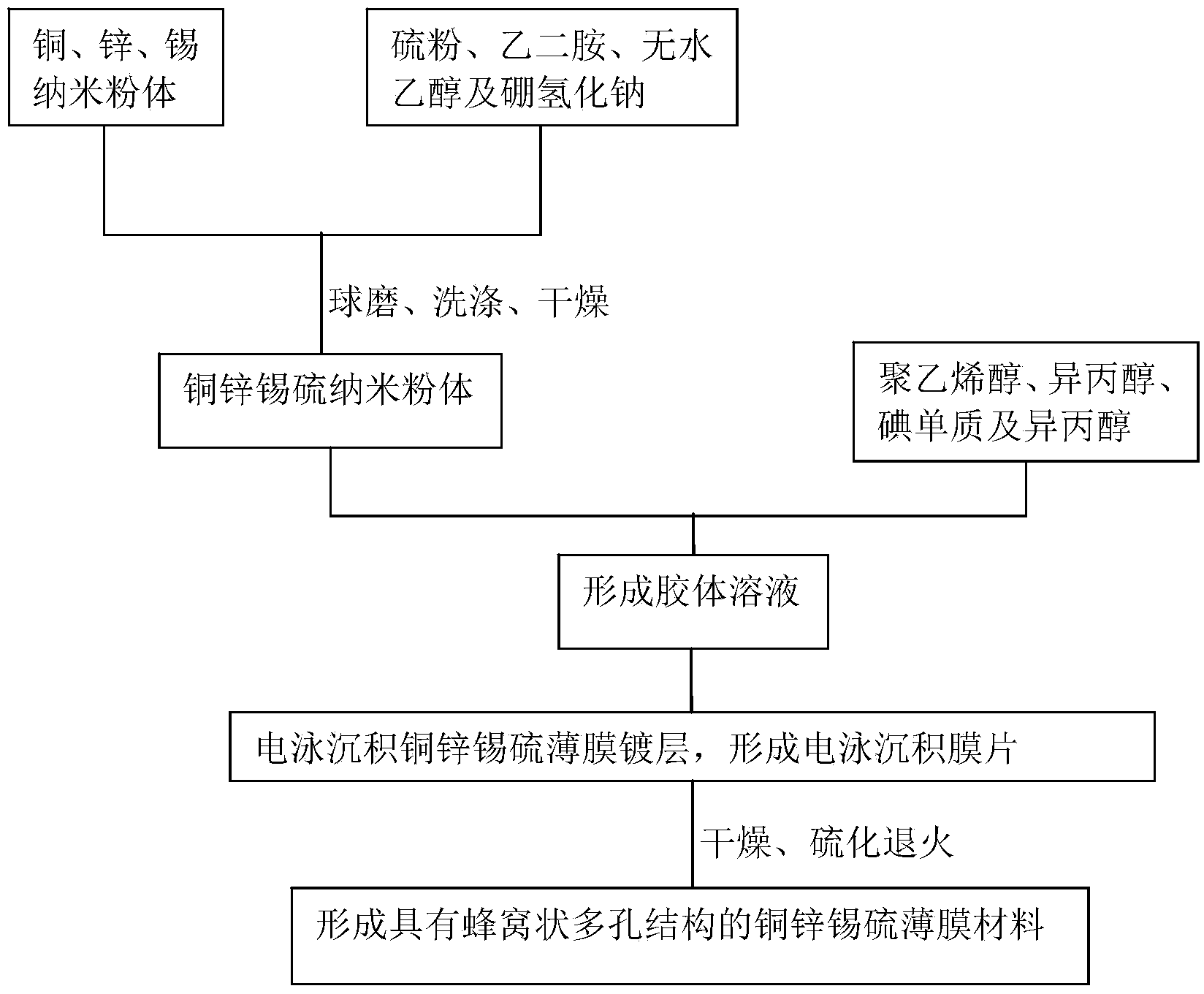

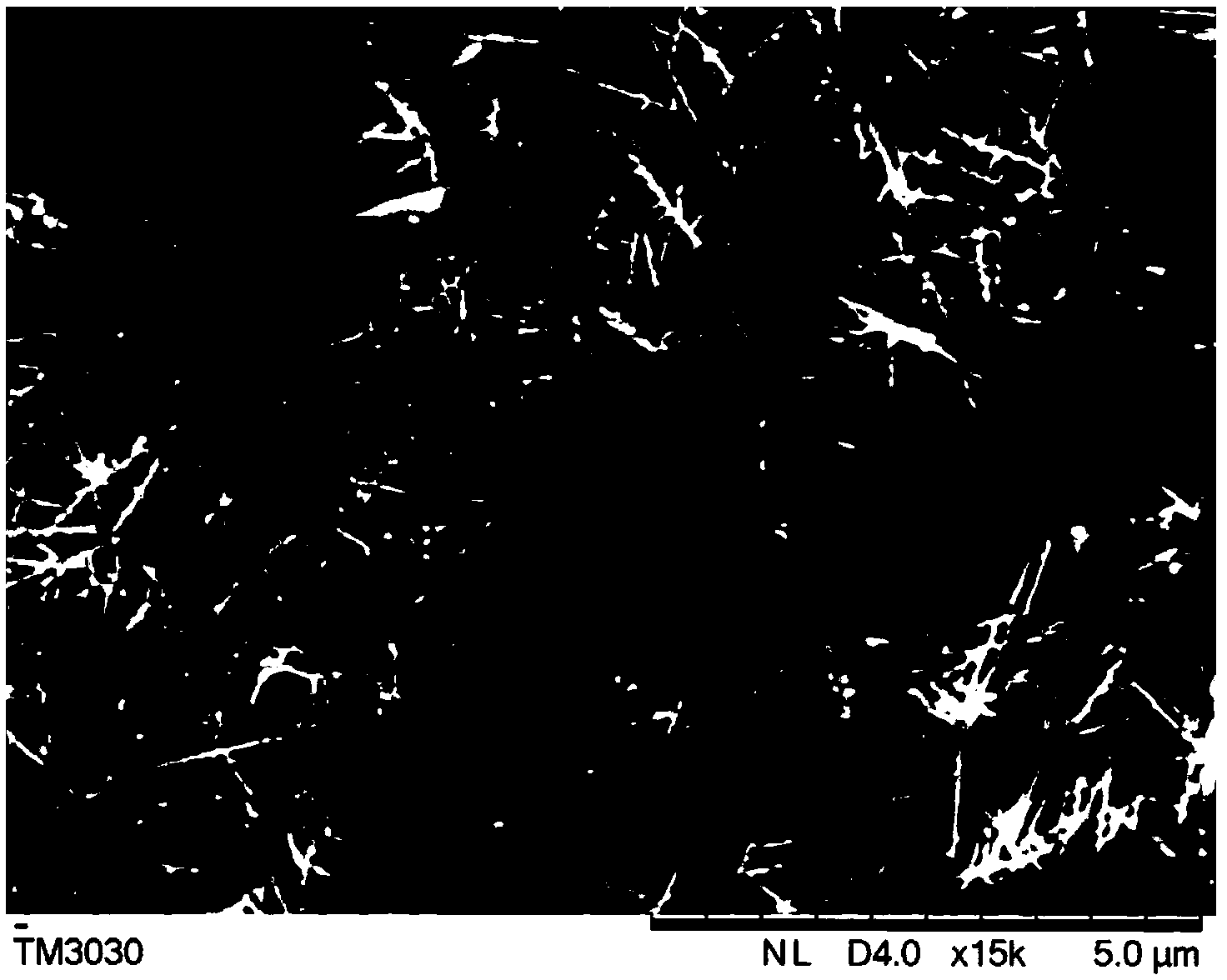

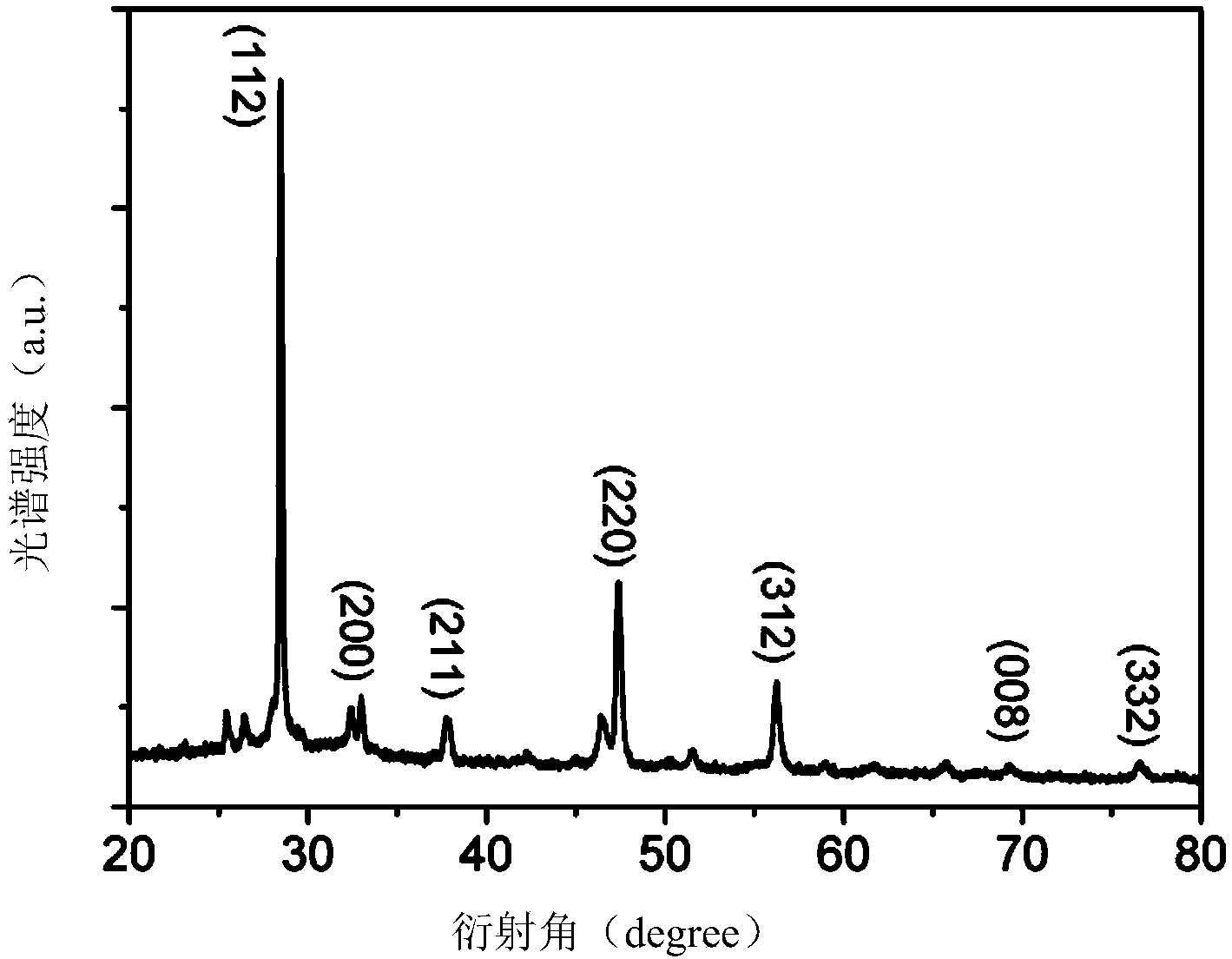

Method for preparing copper, zinc, tin and sulfur film material

InactiveCN104241447AExcellent honeycomb porous structureLarge specific surface areaFinal product manufacturePhotovoltaic energy generationVulcanizationNew energy

The invention belongs to the technical field of photoelectrical-material new energy and relates to a method for preparing a copper, zinc, tin and sulfur film material. The method comprises the following steps that copper nano-powder, zinc nano-powder, and tin nano-powder are used as raw materials and are evenly mixed with sulfur powder, quadrol, absolute ethyl alcohol and sodium borohydride, the mixture is washed and dried after ball milling, and then copper, zinc, tin and sulfur nano-powder is obtained; the nano-powder is evenly mixed with polyvinyl alcohol, isopropanol, and iodine elementary substance, so that a colloidal solution used as an electrophoretic solution is formed; a copper, zinc, tin and sulfur film coating is formed on a substrate through electrophoretic deposition with the electrophoretic deposition method, so that an electrophoretic deposition diaphragm is formed; drying, vulcanization and annealing are carried out on the electrophoretic deposition diaphragm, so that the copper, zinc, tin and sulfur film material is formed. According to the method, the copper, zinc, tin and sulfur film material with the honeycomb-shaped cellular structure is prepared according to the electrophoretic deposition technology and the reduction, vulcanization and annealing comprehensive treatment technology and is large in specific surface area, the cost is reduced, and the solar absorptivity and the efficiency of photovoltaic conversion of a film photovoltaic battery are effectively improved. The method is suitable for manufacturing of the film photovoltaic battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

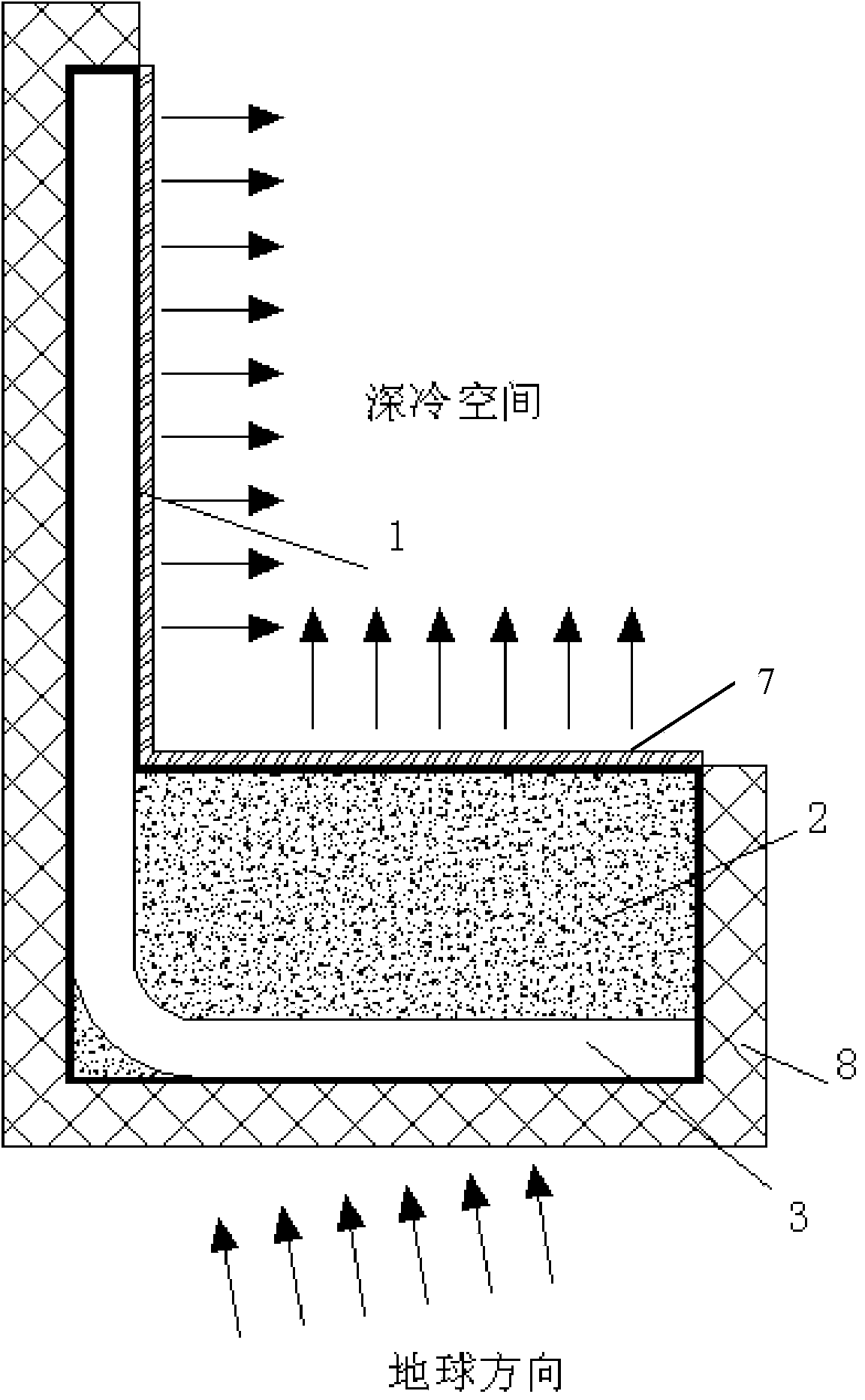

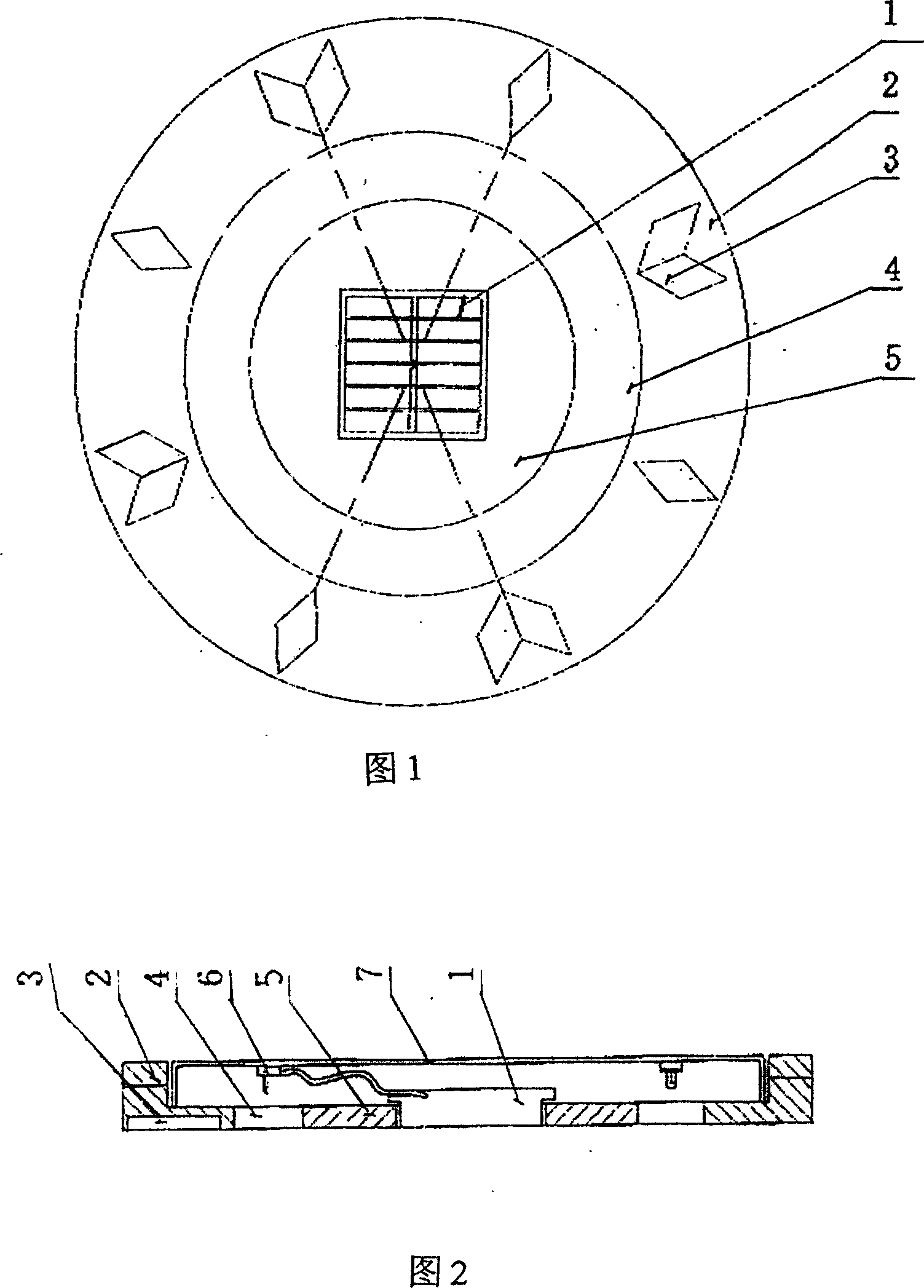

Cooling device of space optical remote sensor

ActiveCN103471634ASuppresses temperature fluctuationsMeet the requirements of temperature fluctuation controlMeasurement apparatus componentsEngineeringSolar absorptivity

The invention discloses a cooling device of a space optical remote sensor. The cooling device of the space optical remote sensor comprises a radiator (1), a heat reservoir (2), at least one L-shaped heat pipe (3) and two heat insulation plates (4), wherein thermal control coatings which are high in infrared emittance and low in solar absorptivity are arranged on the outer surfaces, facing a copious cooling space, of the radiator (1) and the heat reservoir (2), other outer surfaces of the radiator (1) and the heat reservoir (2) are respectively coated with multiple layers of heat insulation assemblies, the heat reservoir (2) and the radiator (1) are machined integrally to form a part with an L-shaped cross section, both the heat reservoir (2) and the radiator (1) are filled with phase-change materials, the bottom of the heat reservoir (2) faces the earth and prevents heat flow coming from the earth from reaching the radiator (1) together with the heat insulation plates (4), and the at least one L-shaped heat pipe (3) is installed in the radiator (1) and in the heat reservoir (2). The cooling device of the space optical remote sensor has the advantages that resources on a satellite can be saved, heat disturbance from the earth can be eliminated, and temperature of electronic equipment which emits heat intermittently and is arranged inside the space optical remote sensor is controlled.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

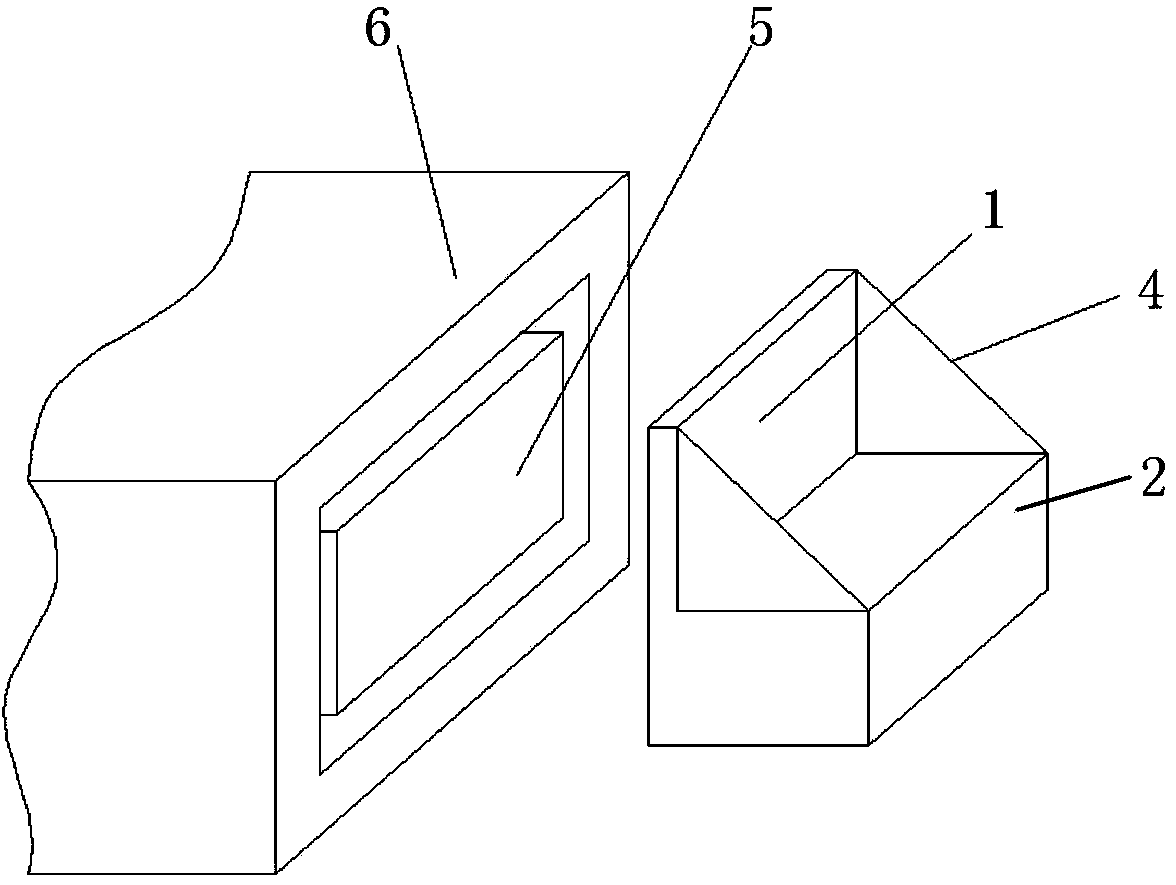

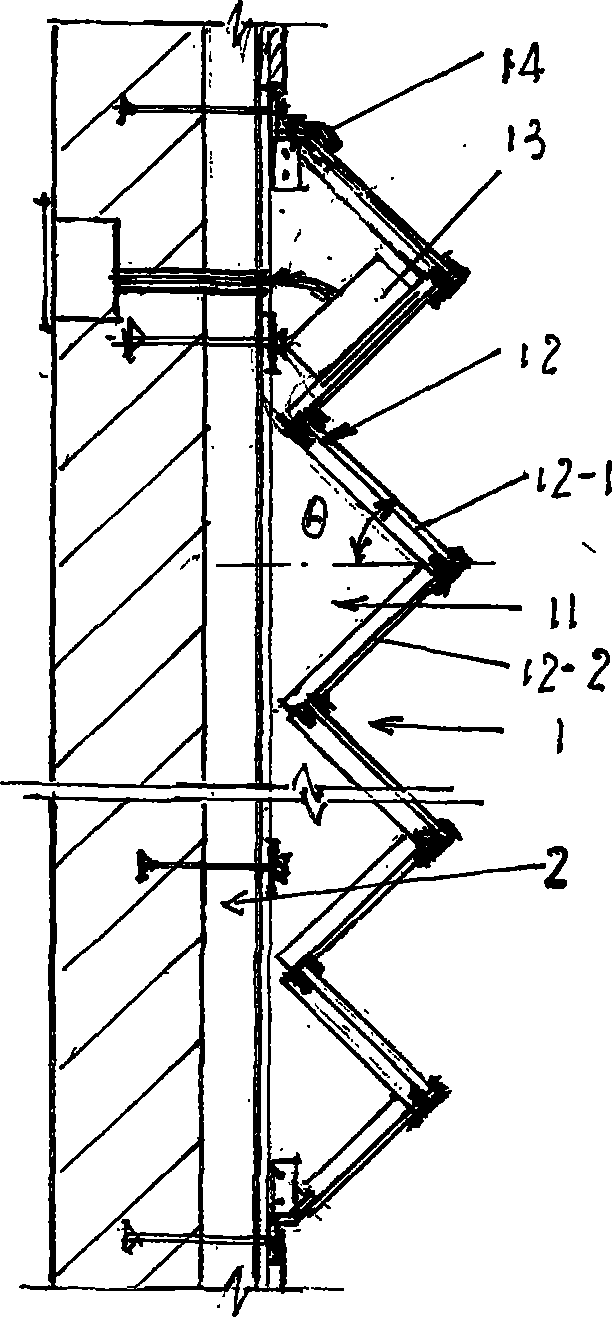

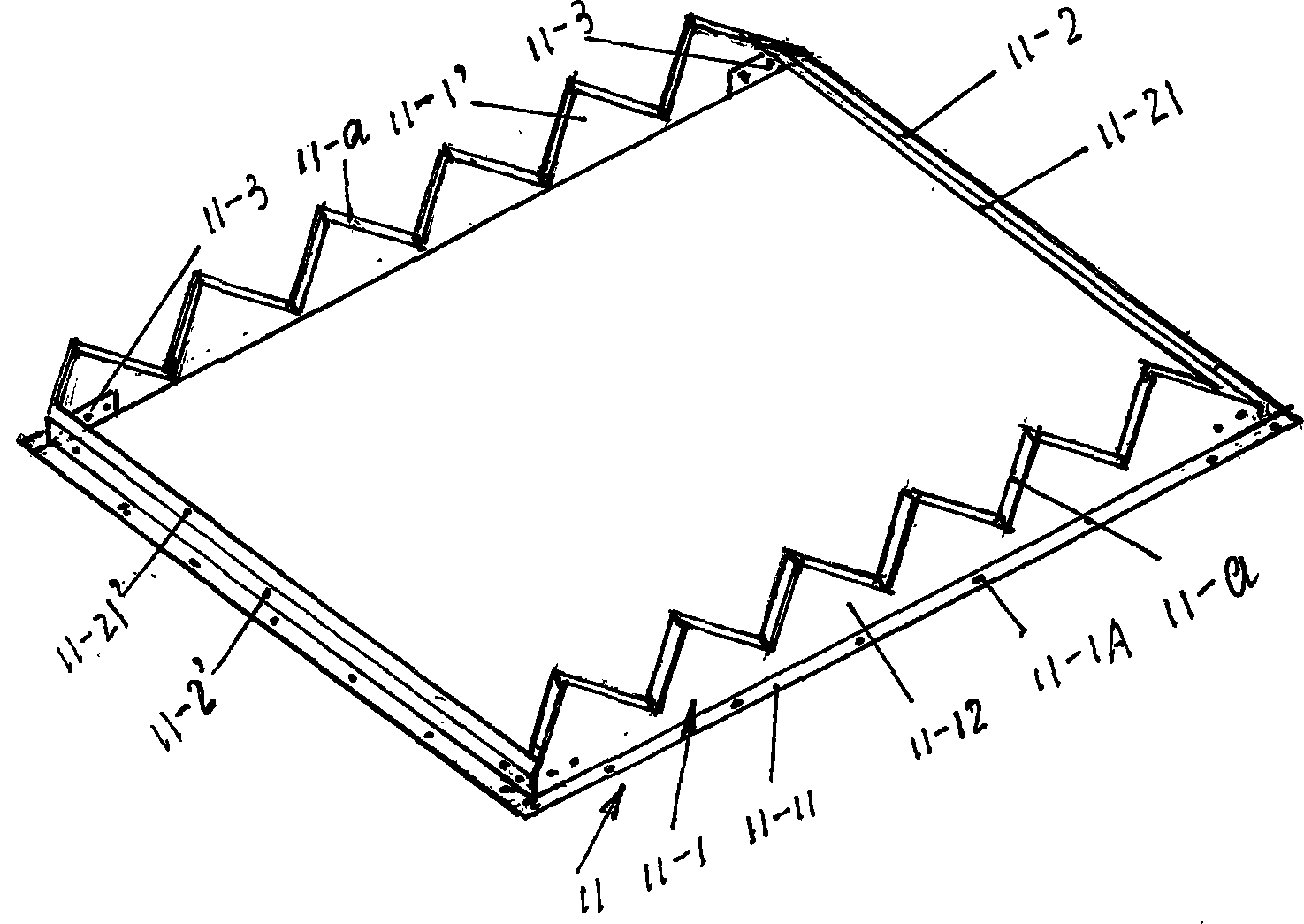

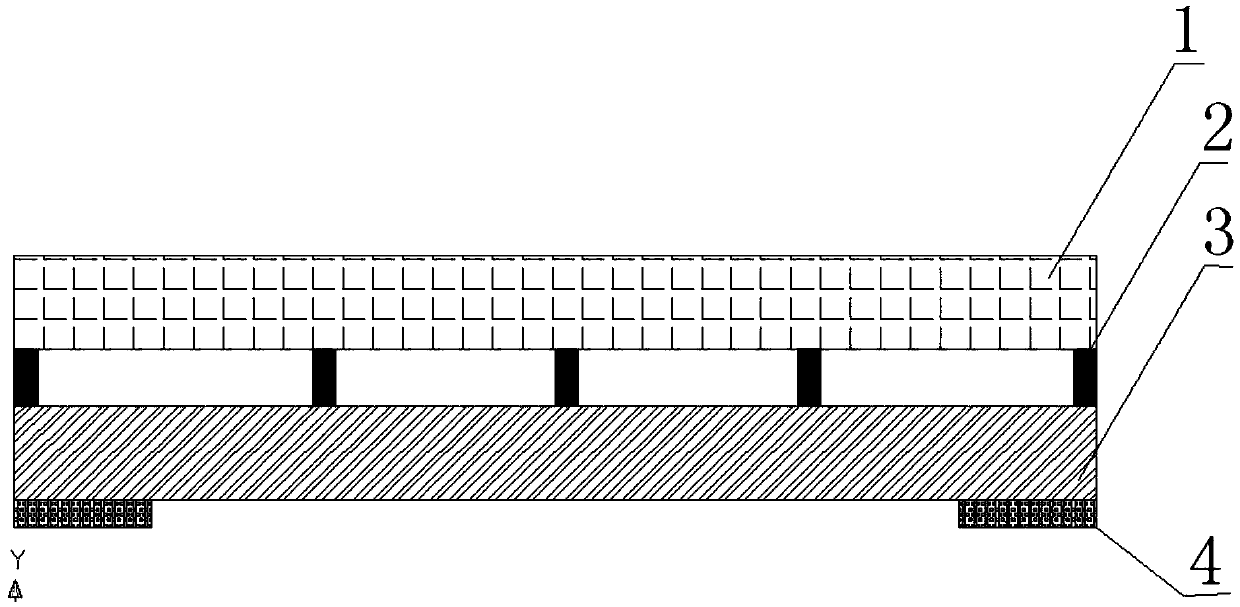

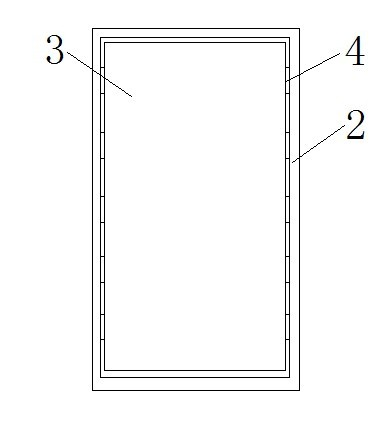

Building-integrated solar cell module curtain wall and roof

InactiveCN103806580AHigh yieldImprove photoelectric conversion efficiencyPhotovoltaic supportsRoof covering using slabs/sheetsBuilding integrationVertical edge

The invention relates to a building-integrated solar cell module curtain wall and roof which comprise included angle type solar cell module bodies 1 and wall fireproof thermal insulation boards 2 or a steel framework; the included angle type solar cell module bodies 1 are formed by right-angle vertical-edge frameworks 11, solar cell panels 12, junction boxes 13 and pressing strips 14. The slant slope theta of the solar cell panels is set as forty degrees to eighty degrees and specifically needs to be determined according to the latitude of the location where the solar cell panels are installed so as to improve the solar absorptivity and the photoelectric conversion efficiency; the problem that the solar absorptivity and the photoelectric conversion efficiency are low due to the fact that traditional solar cell modules are directly installed on outer walls is solved; the included angle type solar cell module bodies 1 are veneers of the curtain wall and the roof, the two plates are combined organically, the structure is simple, a triangle supporting frame is not needed, and the dead weight is low; the building-integrated solar cell module curtain wall and roof are completely integrated with a building, the manufacturing and installation cost is lowered, and the application range of the solar cell panels is enlarged further.

Owner:冯刚克

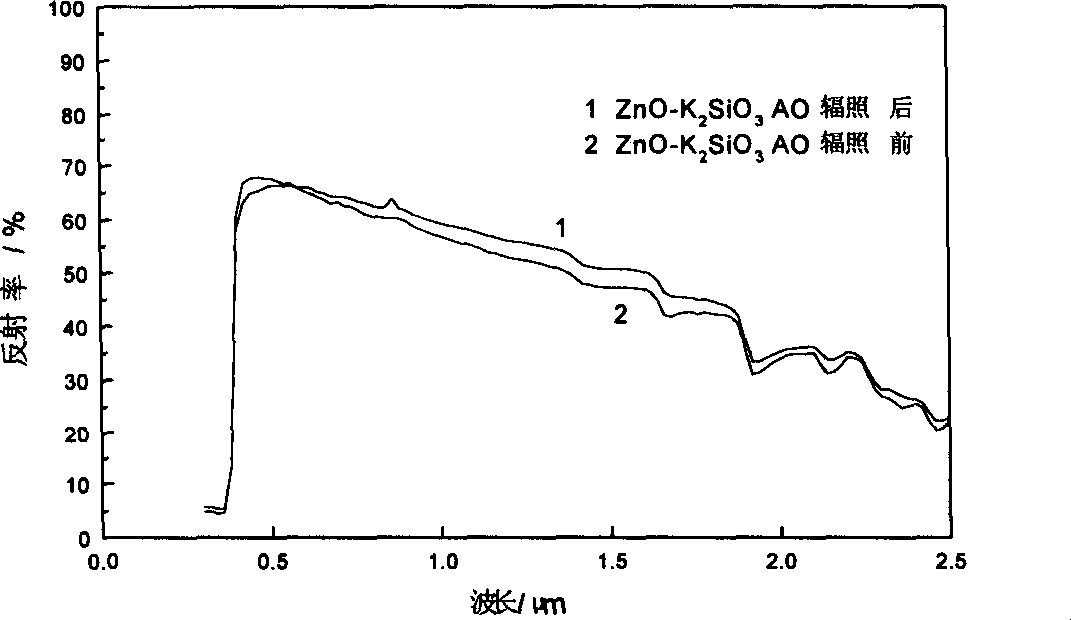

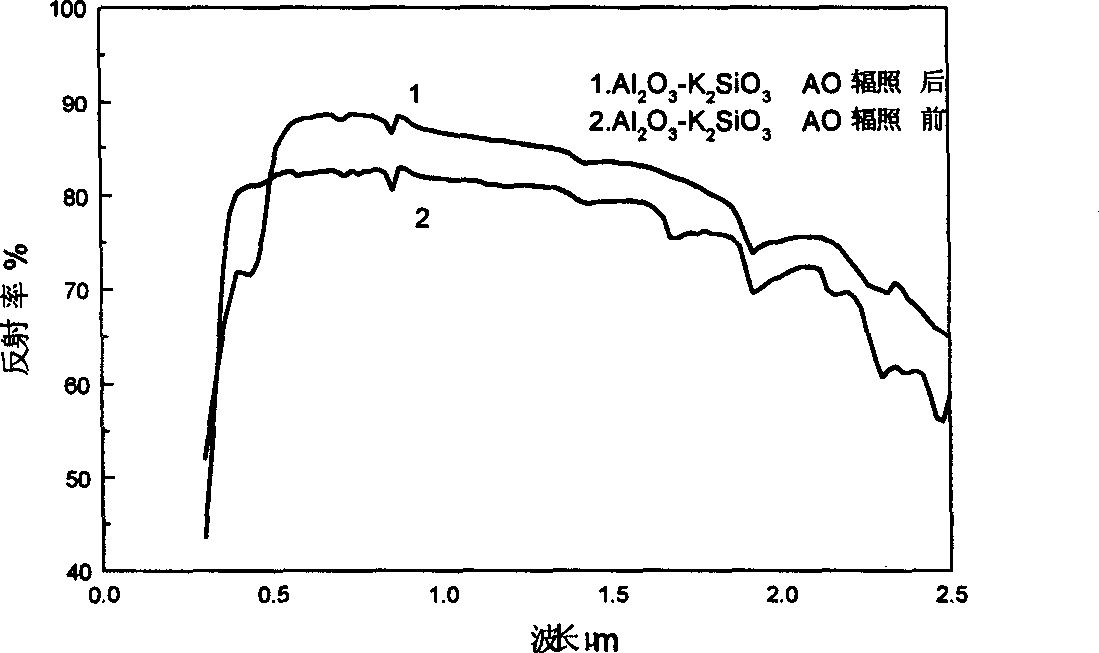

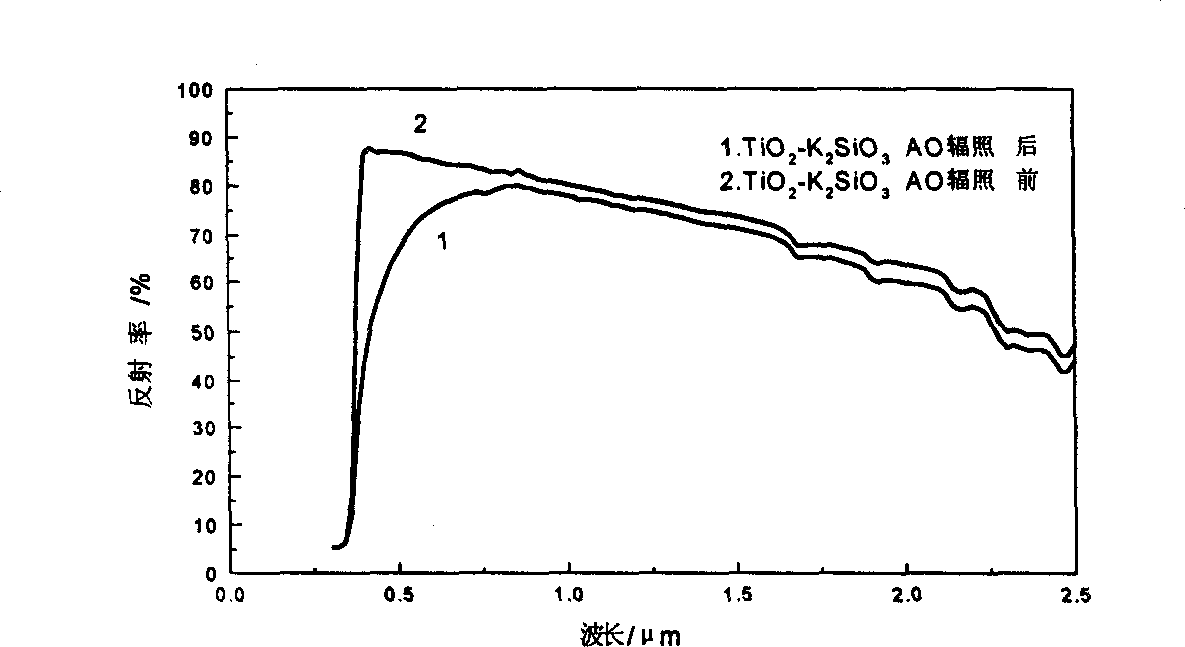

Low sunlight absorptivity alumina-potassium silicate paintcoat for heat control and its preparing method

A thermally controlled alumina-potassium silicate coating with low solar absorptivity for artificial satellite, space aircraft, etc is prepared from potassium silicate, diethanolamine, emulsifier, sodium hexametaphosphate, disperser, defoaming agent, light calcium carbonate, heavy calcium carbonate, talc power, mica powder, alumina powder and water through preparing slurry and proportionally mixing with phenylacrylic acid emulsion. Its advantages are high space stability, resistance to atomic oxygen corrosion, and thermal control effect, and low heat absorptivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

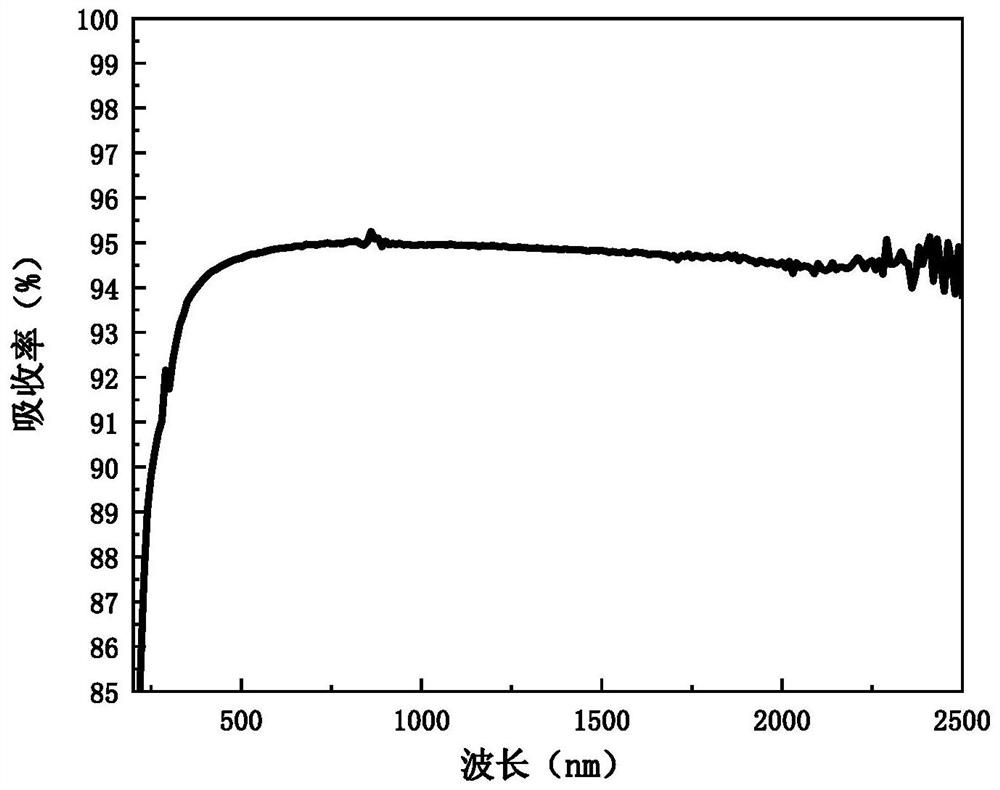

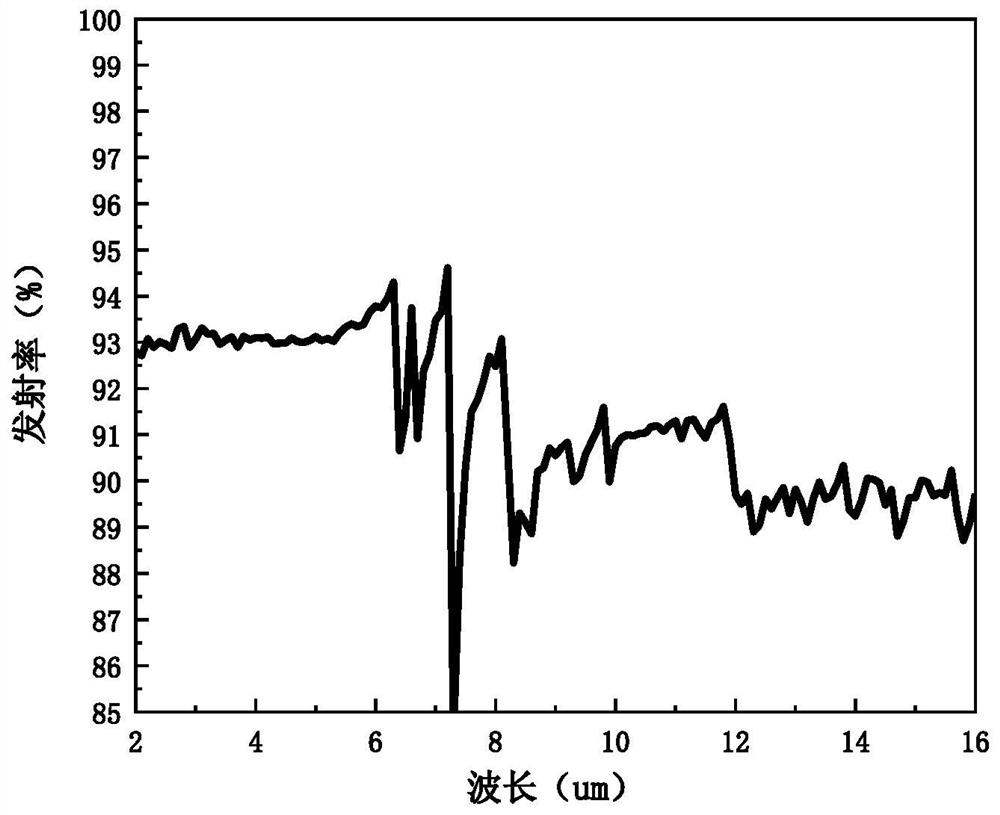

Preparation method of high-absorption high-emissivity ultra-black molecular adsorption coating

ActiveCN112675822AHigh yieldImprove featuresLiquid surface applicatorsOther chemical processesAbsorptanceMolecular adsorption

The invention discloses a preparation method of a high-absorption high-emissivity ultra-black molecular adsorption coating, belonging to the technical field of ultra-black materials. The invention aims to overcome the problems that an existing molecular pollution adsorber with a zeolite molecular sieve as a functional material is large in weight and size, inflexible in installation position and not wide enough in absorption area. According to the preparation method, carbon black and zeolite powder with large specific surface areas are taken as cores, functional powder prepared by an atomic layer deposition technology and taking an ultrathin oxide film layer as a shell is taken as filler, the filler is mixed with a low-volatility resin material, and then coating and curing are conducted so as to obtain the molecular adsorption coating. The average solar absorptivity of the coating is 95%, the hemispherical emissivity of the coating is 91%, a surface layer has the performance of eliminating stray light, and the adsorption capacity of the coating to organic gases (VOCs) such as phthalate, organosiloxane and n-butene is larger than or equal to 17.58 mg / g. The coating has excellent space environment adaptability and can meet the application requirements of spacecrafts and satellite imaging systems.

Owner:HARBIN INST OF TECH

Method of manufacturing laminated glass for vehicle and laminated glass for vehicle

ActiveUS7713631B2Reduce the differenceBonded firmlyDecorative surface effectsCeramic layered productsMetallurgySolar absorptivity

A ceramic paste is applied to a first glass sheet 11, and a ceramic paste is applied to a second glass sheet 13 with a lower solar absorptivity than that of the first glass sheet 11. In this case, the amount per unit area of the ceramic paste to be applied to the first glass sheet 11 is allowed to be smaller than that of the ceramic paste to be applied to the second glass sheet 13. Alternatively, a first ceramic paste and a second ceramic paste are allowed to have different compositions from each other. The first glass sheet 11 and the second glass sheet 13 are bent so that the surfaces onto which the ceramic pastes have been applied are shaped as concave surfaces. The applied ceramic paste is fired using the heating used for bending. Thus maskings 12 and 14 are formed. The first glass sheet 11 and the second glass sheet 13 are bonded to each other, with a resin interlayer film 15 being interposed therebetween.

Owner:NIPPON SHEET GLASS CO LTD

Thermal control film for space

InactiveCN109648971AReduce the impact of high temperatureConducive to lightweight designSynthetic resin layered productsDisturbance protectionMicrowaveHeat flow

The invention provides a thermal control film for a space. The thermal control film comprises a polyimide germanium-plated film body and a carburized polyimide film body, wherein the polyimide germanium-plated film body and the carburized polyimide film body are bonded with each other point to point locally through a polyimide double-sided pressure-sensitive adhesive. The thermal control film hasthe advantages that the polyimide double-sided pressure-sensitive adhesive is used for locally bonding the polyimide germanium-plated film body with the black carburized polyimide film body point to point, a microwave array antenna is completely coated, heat in the thermal control film is absorbed by the black carburized polyimide film body, and the high infrared emissivity of the polyimide germanium-plated film body is utilized to dissipate heat to the space. Meanwhile, the low solar absorptivity of the polyimide germanium-plated film body is utilized to reduce the high-temperature influenceof external heat flow of the space on the antenna. Since the weight of the thermal control film is much lower than that of spray paint of an antenna structure, the lightweight design of a satellite isfacilitated.

Owner:SHANGHAI SATELLITE ENG INST

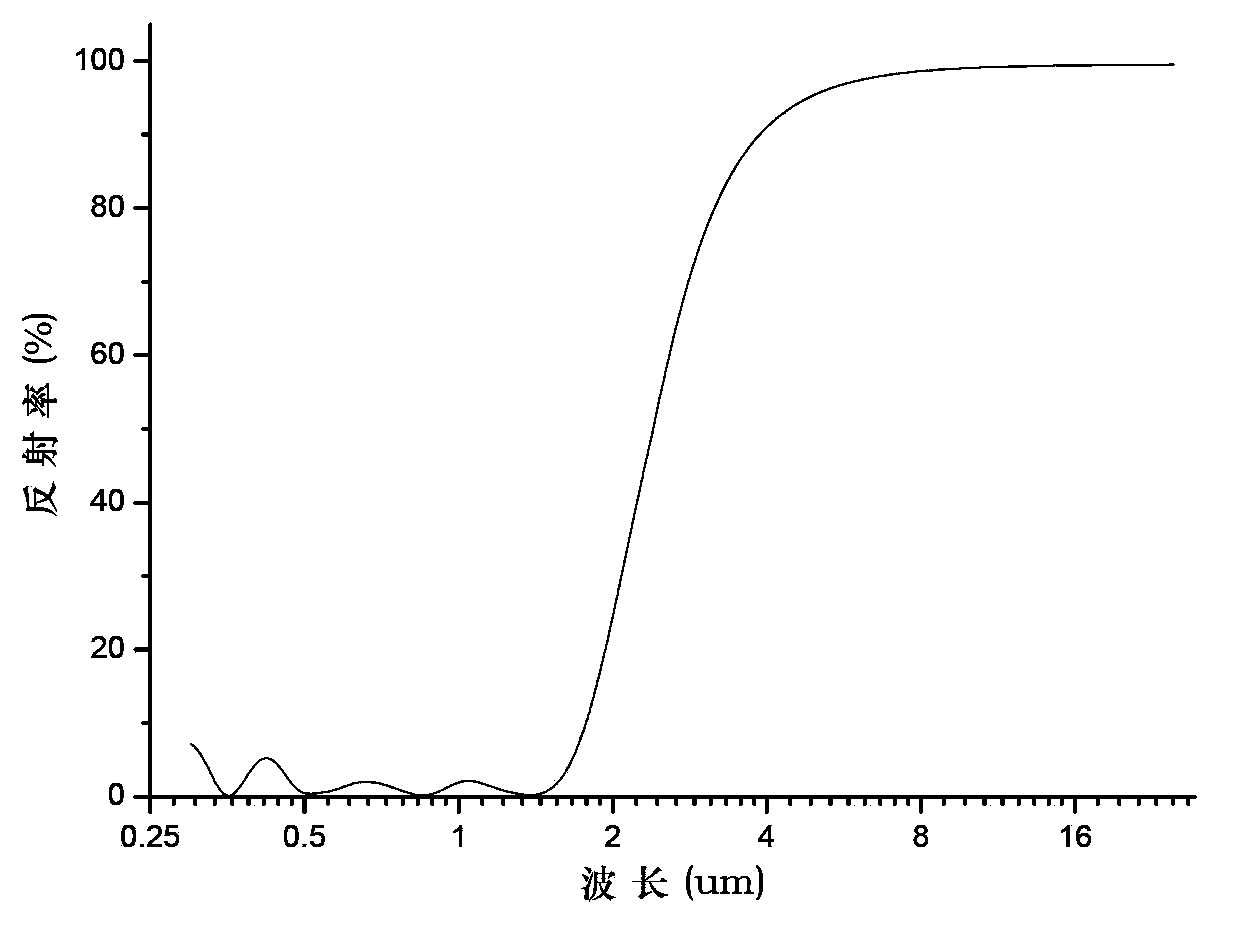

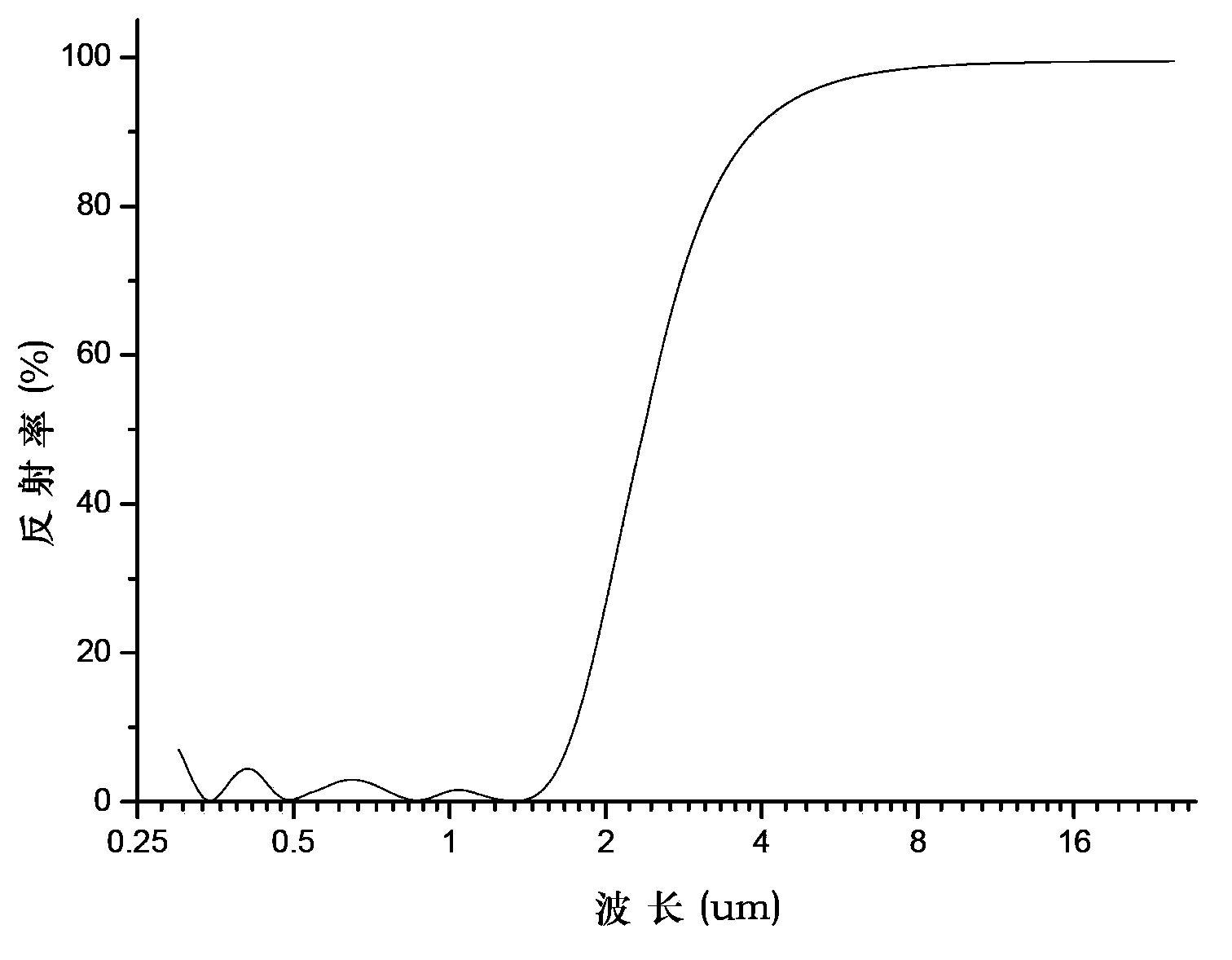

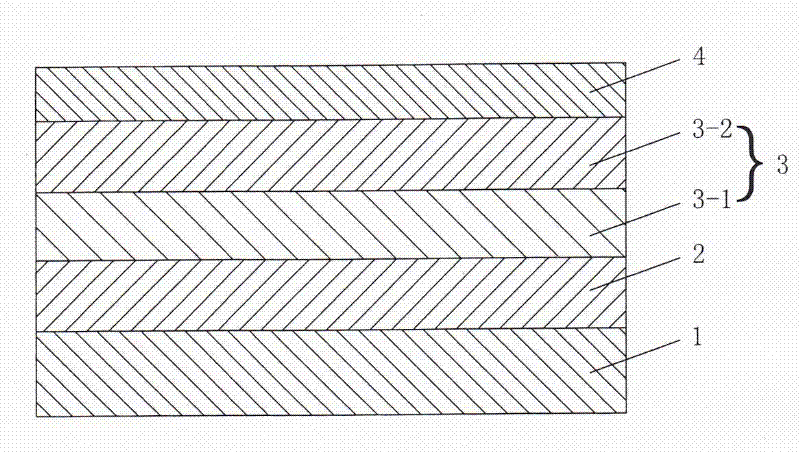

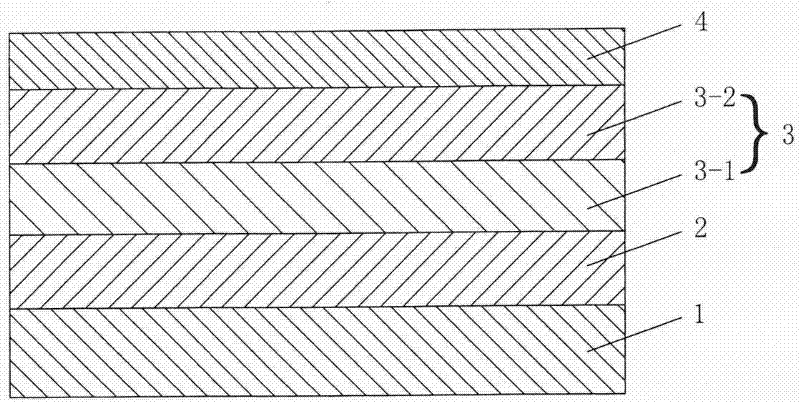

A kind of solar heat conversion absorbing film system and preparation method thereof

InactiveCN102287940ASimple manufacturing methodRaw materials are easy to getSolar heat devicesSolid/suspension decomposition chemical coatingAbsorptanceSolar absorptance

The invention relates to a solar photo-thermal transforming absorbing film system and a preparation method thereof. The transformation absorbing film system is of a three-layer structure, and composed of an absorbing bottom layer, an absorbing middle layer and an antireflective top layer, wherein the absorbing bottom layer and the absorbing middle layer are prepared from M-A12O3 mixed hydrosol which is composed of transition metal M salt and aluminium salt and has different contents of the M salt; and the antireflective top layer is prepared from A 12O3 collosol, SiO2 collosol, and A12O3-SiO2mixed collosol. The solar photo-thermal transforming absorbing film system has a low preparation cost, the preparation method is simple and feasible, and no environment pollution is caused; and the optical property of the film system can meet the practical application requirement, that is to say, the solar absorptivity is greater than 0.90, and the emissivity is less than 0.10.

Owner:FUZHOU UNIV

Preparation method of AAO photonic crystal based high-temperature-resistant ternary nano composite heat-absorbing coating

The invention discloses a preparation method of an AAO photonic crystal based high-temperature-resistant ternary nano composite heat-absorbing coating. The coating prepared by adopting the method is simple in process operation, is 0.84-0.94 in absorptivity and 0.12-0.21 in emissivity and has high solar absorptivity. After being thermally treated at 100-600 DEG C, a sample coating is comparativelytable in absorptivity and emissivity. The coating is high in solar spectrum absorptivity, low in emissivity, extensive in material source, firm in binding force and good in resistance to high temperature. The coating can be applied in the field of solar water heaters, solar cooker heat collection, high-temperature power generation and seawater desalination.

Owner:FOSHAN UNIVERSITY

Nano cermet solar heat-absorption coating material and preparation method thereof

ActiveCN106752915AImprove thermal conductivityExcellent solar absorption performanceAnti-corrosive paintsRadiation-absorbing paintsHeat conductingDistillation

The invention relates to a nano cermet solar heat-absorption coating material and a preparation method thereof. The coating material is prepared from the following components in parts by weight: 40-50 parts of organic silicon resin, 2-7 parts of curing agent, 11-12 parts of absorbent, 2-4 parts of absorbing enhancer, 33-45 parts of aid, 13-17 parts of cermet material and 7-13 parts of heat-conducting material. The absorbent is doping-modified nano titanium dioxide. The preparation method sequentially comprises the following steps: constant-temperature pressurization reaction, reflux reaction and reduced pressure distillation reaction. Compared with the prior art, the doping-modified nano titanium dioxide is used as the absorbent and matched with the absorbing enhancer, so that the coating material has excellent solar absorptivity. The cermet material and heat-conducting material with photocatalytic mobility are adopted to widen the solar absorption range and enhance the heat-conducting property of the coating material, so that the coating material has the advantages of longer service life, mild technological conditions for reaction and low production cost, and can easily implement industrial production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing low-absorptivity high-hemispherical-emissivity oxidation film on surface of aluminum through electro-deposition

ActiveCN106435685AIncreased hemispherical emissivityImprove aging resistanceAnodisationElectrolytic inorganic material coatingAnodizingDistilled water

The invention relates to a method for preparing a thermal control coating on the surface of aluminum alloy through ultrasonic pulse electro-deposition, in particular to a preparation method of preparing a composite oxidation film with the low solar absorptivity / hemispherical emissivity ratio on the surface of aluminum alloy. The preparation method comprises the following steps that 1, pretreatment is conducted on the surface of the aluminum alloy; 2, anodizing is conducted on the aluminum alloy; and 3, the oxidized aluminum alloy is subjected to ultrasonic pulse electro-deposition to prepare silicon dioxide sol, then, the surface of the aluminum alloy is cleaned with distilled water and dried, and a low-absorptivity high-emissivity thermal control coating on the surface of the aluminum alloy is obtained. The solar absorptivity of the coating is 0.10-0.20, the hemispherical emissivity of the coating is 0.80-0.95, and the thermal control coating which is low in solar absorptivity and high in hemispherical emissivity has good performance.

Owner:FOSHAN UNIVERSITY

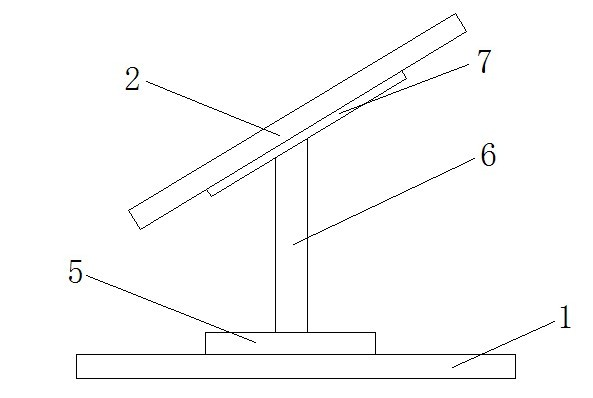

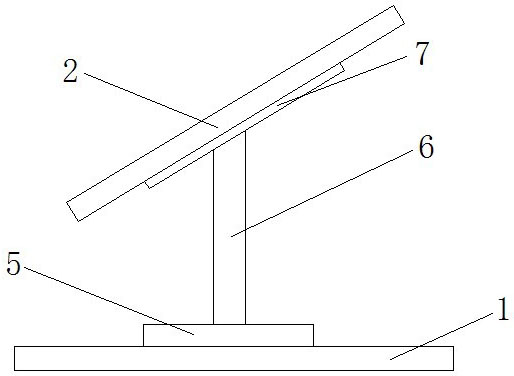

Solar energy bracket

InactiveCN102623527AEasy to installWill not cause weak connectionPhotovoltaic supportsPhotovoltaic energy generationSolar absorptivityPhotovoltaics

The invention discloses a solar energy bracket, which comprises a bottom framework, a plurality of top frameworks and the same number of solar energy photovoltaic plates. The solar energy bracket is characterized in that a strip-shaped groove is formed on the inner wall of each framework side of the top frameworks; the solar energy photovoltaic plates are mounted in the top frameworks through the strip-shaped grooves; an upright column is arranged in the bottom framework; a rotating beam capable of rotating round the upright column is arranged at the top of the upright column; a plurality of cross beams are arranged between two opposite framework sides of each top framework; and the rotating beam is arranged below the cross beams and perpendicular to the cross beams. The invention solves the problems that the solar energy photovoltaic plates have low solar absorptivity, are easy to be damaged, have short service lives and influence the use of solar energy, which are caused by the solar energy bracket placing manner in the prior art, and provides the solar energy bracket which has a simple structure, is safe and convenient to use, can fully absorb solar energy and improves the work efficiency of the solar energy photovoltaic plates.

Owner:昆山光翼光伏科技有限公司

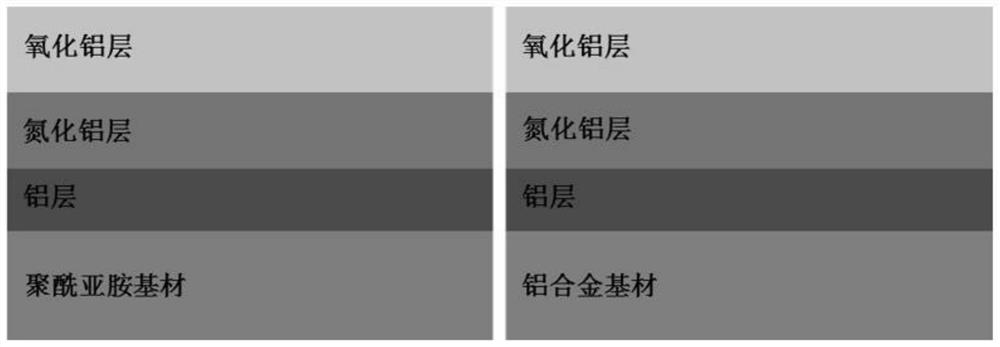

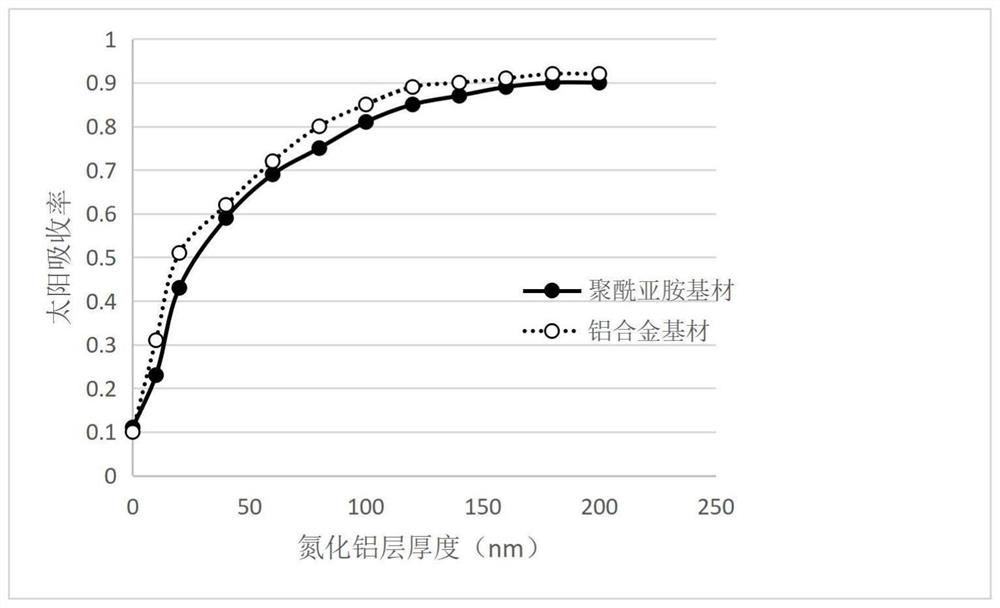

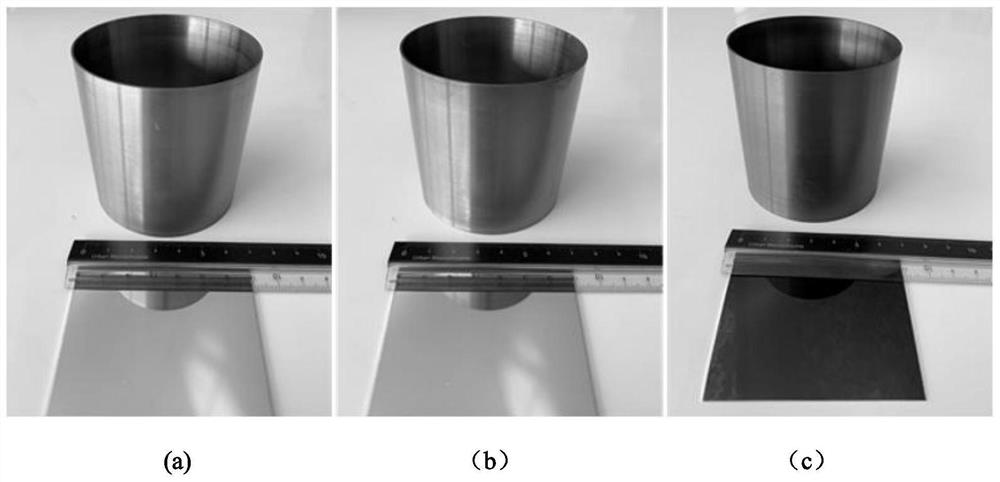

Thermal control coating with designable solar absorptivity and preparation method

InactiveCN111996491ASolar Absorption AdjustmentVacuum evaporation coatingSputtering coatingAbsorptanceAlloy substrate

The invention discloses a thermal control coating with designable solar absorptivity and a preparation method. A first clay layer, a second clay layer and a third clad layer are successively arrangedon the surface of a substrate from inside to outside. The first clad layer is a pure aluminum layer, the second clad layer is an aluminum nitride layer, and the third clad layer is an aluminum oxide layer. The thermal control coating is prepared on the surface of the aluminum alloy substrate by the preparation method. By designing thickness of a plated film, the solar absorptivity of the thermal control coating can be adjusted within a range of 0.10-0.92.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Nano black chrome highly selective endothermic film formula and preparation method thereof

InactiveCN108610662AImprove stabilityGood weather resistanceCoatingsMANGANESE ACETATEEconomic benefits

The invention discloses a nano black chrome highly selective endothermic film formula and a preparation method thereof. The raw materials consist of a base material, nano dichromium trioxide powder and ethanol; the base material includes manganese acetate, ferric chloride, nickel chloride and cupric chloride; and the mass ratio of the components which are the manganese acetate, the ferric chloride, the nickel chloride and the cupric chloride in the base material is 3-5:1-3:2-4:1. The nano material uniformly is deposited on the surface of the metal base material; and through actual measurement,solar absorptivity is greater than 93%, and infrared emissivity is less than 10%; the obtained film has excellent product stability, weatherability and optical performance; and the preparation technology is simple and feasible, and the formula and the preparation method have stronger market prospects and economic benefits prospects.

Owner:德州金奈尔新材料科技有限公司

Decoration granite using solar energy

The invention relates to decorative granite which utilizes the solar power and belongs to the technical field of the solar power application and the architectural decoration. The invention is characterized in that: the granite has a regular shape and a concave on the back, an insulating base plate is laid on the concave, a solar absorption circuit board which faces a though hole of the granite is fixed on a base plate; a pattern is designed on the front face of the granite, granites with different colors are embedded in punches, a transparent annular jade is arranged between two lighttight granites, and an LED ( light-emitting diode) which is connected with the output end of the solar absorptivity circuit board is arranged under the jade. The regular shapes are round shape, ellipse, square shape, lozenge shape, triangular shape, rectangular shape, quincunx and star. The transparent jade is made of yellow colophony. The lighttight granite is made of Cherry Blossom Red and the Imperial California. The execution of the invention has the positive effect that: the solar absorptivity circuit board is utilized to absorb the solar power in the day and stores the electricity to supply for the LED at night, as the jade is transparent, the colorful jade can give out attractive light; no extra power supply is needed and the energy can be saved.

Owner:JINBO SHANGHAI CONSTR GROUP

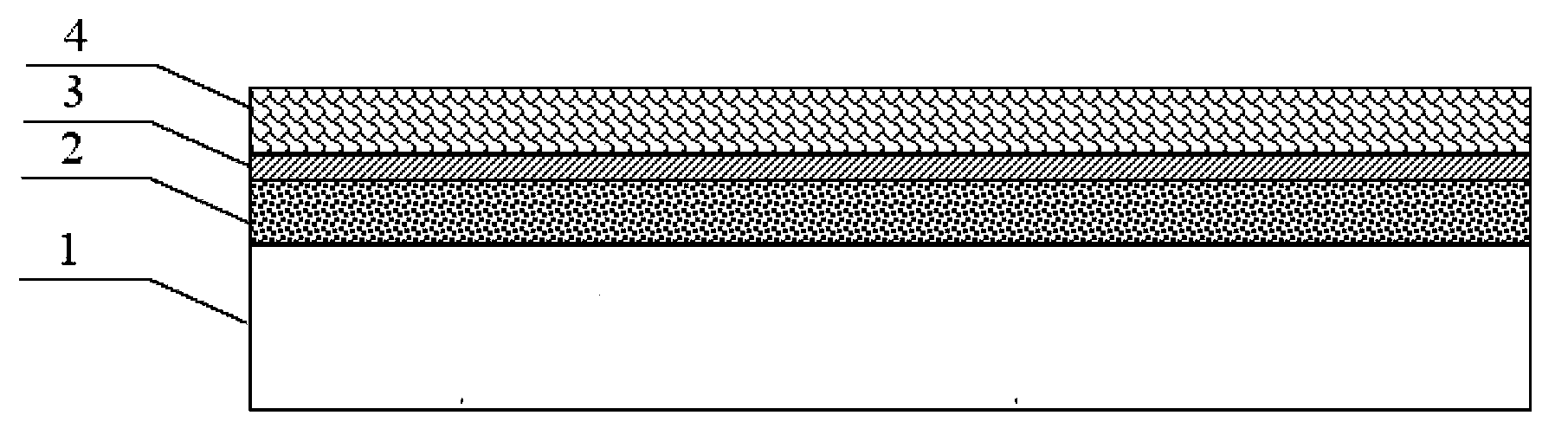

Membrane structure of high-temperature oxidation-resistant selective absorption membrane for inner pipe of condensation solar thermal power generation collector pipe

InactiveCN102226593AImprove absorption rateLow emissivitySolar heat devicesCoatingsEngineeringOxidation resistant

The invention discloses a membrane structure of a high-temperature oxidation-resistant selective absorption membrane for the inner pipe of a condensation solar thermal power generation collector pipe, which is mainly characterized by comprising a stainless steel substrate (1), wherein a Ti membrane (2), a TiAlON membrane (3) and an Al2O3 membrane (4) are sequentially arranged on the surface of the stainless steel substrate (1) from interior to exterior. The membrane structure disclosed by the invention has the characteristics of reasonable membrane structure, strong high-temperature oxidation resistance, high solar absorptivity, low reflectivity, long service life and the like.

Owner:常州龙腾光热科技股份有限公司

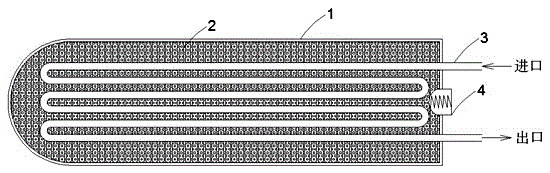

Solar instantaneous water-based phase change heat accumulator

InactiveCN105650897AReduce reflection lossEffective Thermal ProtectionSolar heating energySolar heat devicesWater basedEngineering

The invention relates to a solar instantaneous water-based phase change heat accumulator which comprises a double-layer vacuum glass jacketing, a mixture of energy storage particles and water, a heat exchange copper calandria and an anti-expansion spring plug, wherein the double-layer vacuum glass jacketing is cylindrical; an outlet and an inlet of the heat exchange copper calandria are positioned outside the double-layer vacuum glass jacketing, and are symmetrically formed in the outlet end of the double-layer vacuum glass jacketing up and down; other parts of the heat exchange copper calandria are wound inside the double-layer vacuum glass jacketing; the space between the heat exchange copper calandria in the double-layer vacuum glass jacketing and the inner wall of the double-layer vacuum glass jacketing is filled with the mixture of energy storage particles and water; and the center of the outlet of the double-layer vacuum glass jacketing is sealed with the anti-expansion spring plug. According to the solar instantaneous water-based phase change heat accumulator, the solar absorptivity can be effectively improved, the heat loss due to radiation is reduced, and a wider approach for the application of solar thermal collectors is developed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com