Application of diamine compound containing thiazole ring in preparing solar heat-absorbing coating

A technology of solar energy absorption and amine compounds, applied in the field of solar energy, can solve problems such as poor solubility, influence of polyimide performance, optical performance attenuation, etc., and achieve improved weather resistance and adhesion, good mechanical properties and weather resistance, high Effect of light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

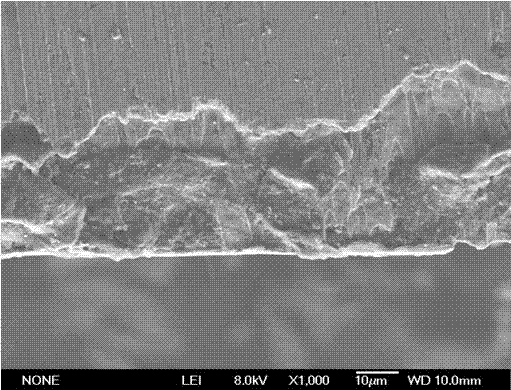

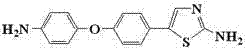

[0029] 1. Preparation of polyimide resin: under the protection of Ar gas, weigh 10 mmol of thiazole ring-containing diamine monomer 2-amino-5-[4-(4'-aminophenoxy)phenyl] -Thiazole and commercially available dianhydride monomer 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride (ODPA) 10 mmol were added to a 250mL three-necked reaction flask, and NMP (N-methylpyrrolidone) was added to make The solid content of the reaction system is between 10% and 15%. After reacting for 24 hours, a polyamic acid solution was obtained. Then add a mixed solution of 7 mmol acetic anhydride and 7 mmol pyridine, stir at room temperature for 0.8 h, and react at 100°C for 3 h. The solution was poured into excess methanol to obtain a white resin precipitate, which was washed several times with methanol and hot water, then put into a vacuum drying oven at 40° C. and dried overnight to obtain a polyimide resin.

[0030] 2. Preparation of coating: 15 parts of CuCr 2 o 4 Powder, 5 parts of thiazole...

Embodiment 2

[0033] 1.1. Preparation of thiazole ring-containing polyimide resin: under the protection of Ar gas, weigh 6 mmol of thiazole ring-containing diamine monomer 2-amino-5-[4-(4'-aminophenoxy Base) phenyl]-thiazole and commercially available dianhydride monomer pyromellitic dianhydride (PMDA) 6 mmol in a 250mL three-necked reaction flask, add DMAc (N, N - dimethylacetamide) to make the reaction system The solid content is between 10 and 15%. After reacting for 24 hours, a polyamic acid solution was obtained. Then add a mixed solution of 6.3 mmol acetic anhydride and 6.3 mmol pyridine, stir at room temperature for 1 h, then 150 o C reacted for 3h. Pour the solution into excess methanol to obtain a white resin precipitate, wash it with methanol and hot water several times, and put it in a vacuum oven for 40 o C was dried overnight to obtain a polyimide resin.

[0034] 2. Preparation of coating: 40 parts of CoMnCuO x The powder, 10 parts of thiazole ring-containing polyimide res...

Embodiment 3

[0037] 1. Preparation of thiazole ring-containing polyimide resin: under the protection of Ar gas, weigh 15 mmol of thiazole ring-containing diamine monomer 2-amino-5-[4-(4'-aminophenoxy )phenyl]-thiazole and commercially available dianhydride monomer 3,3',4,4'-benzophenone tetracarboxylic dianhydride (BTDA) 15 mmol in a 250 mL three-necked reaction flask, add DMAc (N, N-dimethylacetamide), so that the solid content of the reaction system is between 10% and 15%. After reacting for 24 hours, a polyamic acid solution was obtained. Then add 20 mmol of acetic anhydride and 20 mmol of pyridine mixture (acetic anhydride as dehydrating agent, pyridine as catalyst), stir at room temperature for 0.5 h, then react at 50°C for 10 h. The solution was poured into excess methanol to obtain a white resin precipitate, which was washed several times with methanol and hot water, then put into a vacuum drying oven at 40° C. and dried overnight to obtain a polyimide resin.

[0038] 2. Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com