Preparation method of high-temperature-resistant low-resistivity lithium ion battery diaphragm

A lithium-ion battery, low resistivity technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of lack of mature preparation, high temperature resistance can not meet the requirements, etc., to achieve the best dispersion effect , Moderate viscosity, prevent further reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

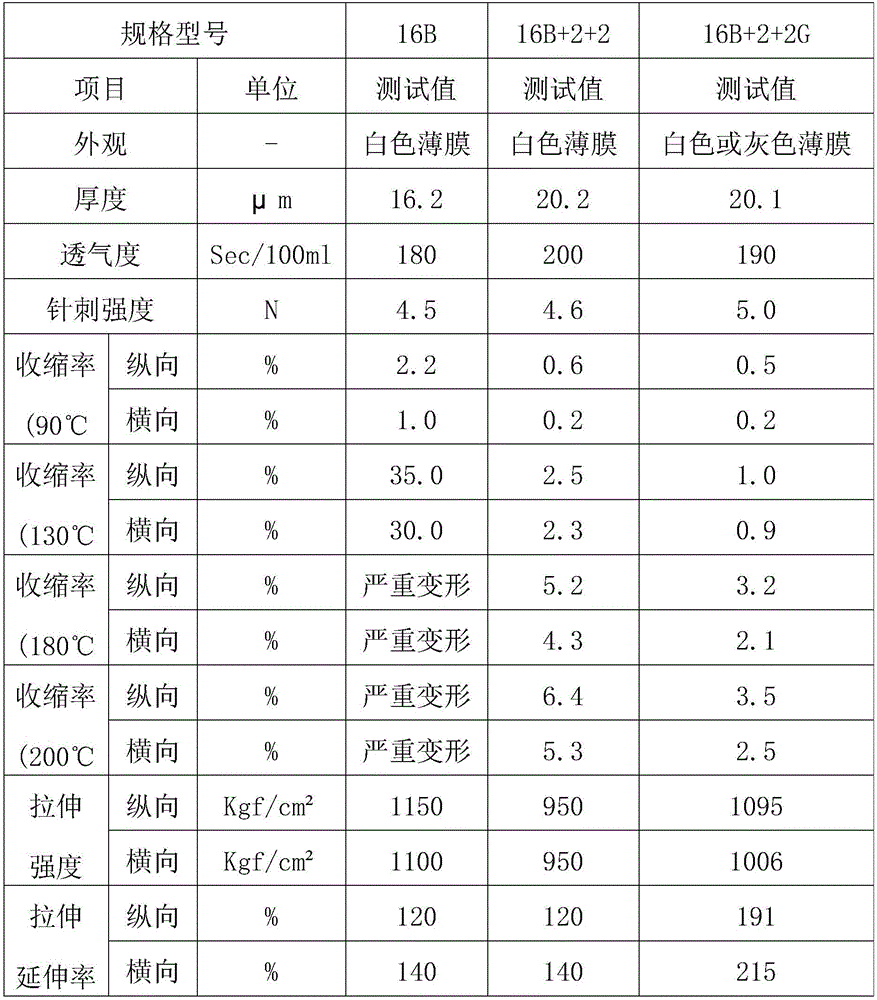

Image

Examples

specific Embodiment

[0028] In a specific embodiment, the preparation method for preparing a high-temperature-resistant and low-resistivity lithium-ion battery separator includes the following specific steps:

[0029] A. Preparation of graphene modified ceramic slurry

[0030]Add deionized water and aluminum oxide powder with a particle size of 0.5 μm to the planetary mixer, and the weight ratio is 1:4. The tank of the planetary mixer is a multi-blade stirring paddle, which also rotates while revolving, so that the material It flows up and down and around, so that the mixing effect can be achieved in a short time. The inner wall of the tank is finished by a large vertical lathe, and then automatically polished by a large polishing machine to ensure that the movable scraper on the planetary frame rotates. The material is completely scraped off. The planetary mixer is equipped with a drop-in ultrasonic vibration plate. The position of the drop-in ultrasonic vibration plate is selected and fixed acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com