Ti-alloy nitride selective-absorption film system and preparation method thereof

A nitride and selective technology, applied in the direction of climate sustainability, metal material coating technology, sustainable manufacturing/processing, etc., can solve the problems of very strict equipment sealing requirements, difficult control of process parameters, and environmental pollution, etc., to achieve High photothermal conversion efficiency, improved industrial production efficiency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

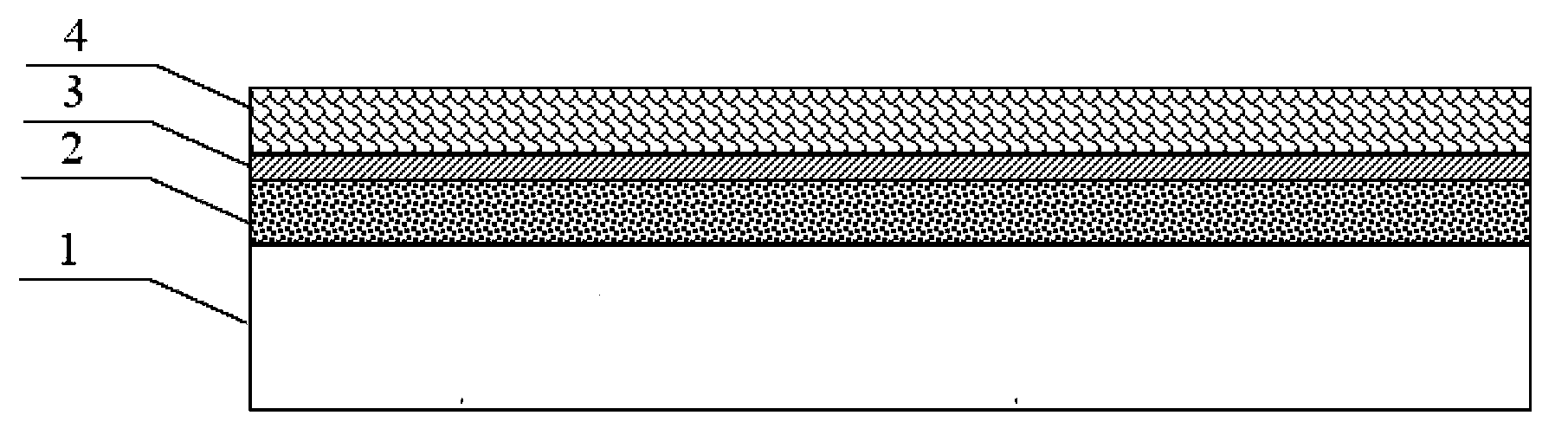

[0032] Cu substrate / TiAlN / Si 3 N 4 / SiO 2 Absorbent film system and its preparation method.

[0033] The absorption film system is specifically: Cu foil substrate / Ti 0.38 Al 0.62 N thin film (103nm) / Si 3 N 4 Thin film (27nm) / SiO 2 Thin film (80nm).

[0034] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the specific preparation conditions of each layer of the absorbing film system are as follows:

[0035] (1) First, using Cu foil as the substrate, using TiAlN ceramics sintered according to the preset atomic ratio of Ti, Al, and N as the target, deposit a layer on the Cu film in a pure argon atmosphere. The TiAlN thin film is grown to a thickness of 103nm by controlling the reactive sputtering time. The atomic ratio of the three elements in the target used in this embodiment is Ti:Al:N=0.38:0.62:1.00, the sputtering power is 1kW, the intermediate frequency frequency is 30kHz, and the Ar gas flow rate is 35sccm...

Embodiment 2

[0042] Cu substrate / TiSiN / Si 3 N 4 / SiO 2 Absorbent film system and its preparation method.

[0043] The absorption film system is specifically: Cu foil substrate / Ti 0.4 Si 0.6 N thin film (96nm) / Si 3 N 4 Thin film (30nm) / SiO 2 Thin film (88nm).

[0044] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the specific preparation conditions of each layer of the absorbing film system are as follows:

[0045] (1) First, Cu foil was used as the substrate, TiN ceramic target and Si were used as targets, and co-sputtering was carried out under a mixed atmosphere of nitrogen and argon. The sputtering power used in this embodiment is 1 kW, the intermediate frequency is 30 kHz, the Ar gas flow is 60 sccm, and the N gas flow is 35 sccm. The film thickness was grown to 96nm by controlling the reactive sputtering time.

[0046] (2) At Ti 0.4 Si 0.6 On the N selective absorption film layer, grow Si 3 N 4 Anti-reflection ...

Embodiment 3

[0052] Cu substrate / Ag / TiAlN / AlN / SiO 2 Absorbent film system and its preparation method.

[0053] The absorption film system is specifically: Cu foil substrate / Ag thin film (10nm) / Ti 0.38 Al 0.62 N film (98nm) / AlN film (36nm) / SiO 2 Thin film (54nm).

[0054] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the specific preparation conditions of each layer of the absorbing film system are as follows:

[0055] (1) First, a 10nm infrared highly reflective Ag film was coated on the Cu foil substrate with metal Ag as the target;

[0056] (2) On the Ag film, use the TiAlN ceramics sintered according to the preset atomic ratio of Ti, Al, and N as the target material, deposit a layer of TiAlN film in a pure argon atmosphere, and control the reactive sputtering time to grow the film thickness to 98nm. The atomic ratio of the three elements in the target used in this embodiment is Ti:Al:N=0.38:0.62:1.00, the sputtering powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com