Non-destructive testing device for circular saw blade based on acoustic resonance spectrum

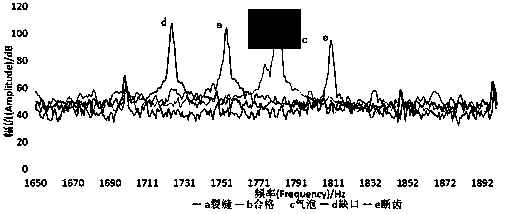

An acoustic resonance, non-destructive testing technology, used in the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves, and can solve problems such as weak welding, cracked saw blades, and broken saw blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, realization method and advantages of the present invention clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

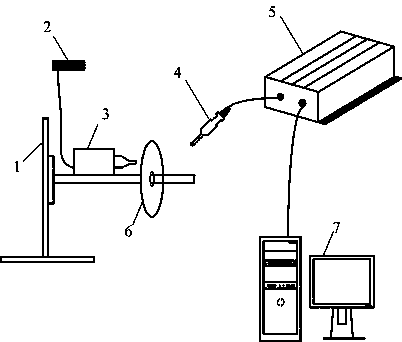

[0012] like figure 1 As shown, a circular saw blade non-destructive testing device based on acoustic resonance spectrum is characterized in that it includes a bracket 1, a microcontroller 2, an electric hammer 3, an audio collector 4, an intelligent controller 5 for signal acquisition and data processing, Circular saw blade 6 and PC 7 to be detected. The microcontroller 2 is connected with the electric hammer 3 through a data line, the audio collector 4 is connected with an intelligent controller 5 for signal acquisition and data processing through a data line, and the intelligent controller for signal acquisition and data processing 5 is connected with the PC 7, and the circular saw blade 6 to be detected and the electric hammer 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com