Efficient and long-service-life blowing method and system of vanadium extraction-decarburization dual converter

A decarburization converter and converter technology, applied in the field of vanadium-containing molten iron steelmaking, can solve the problems of short life of oxygen lance, poor stirring of vanadium extracting converter, low vanadium oxidation rate, etc., and achieve the effect of reducing acquisition cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

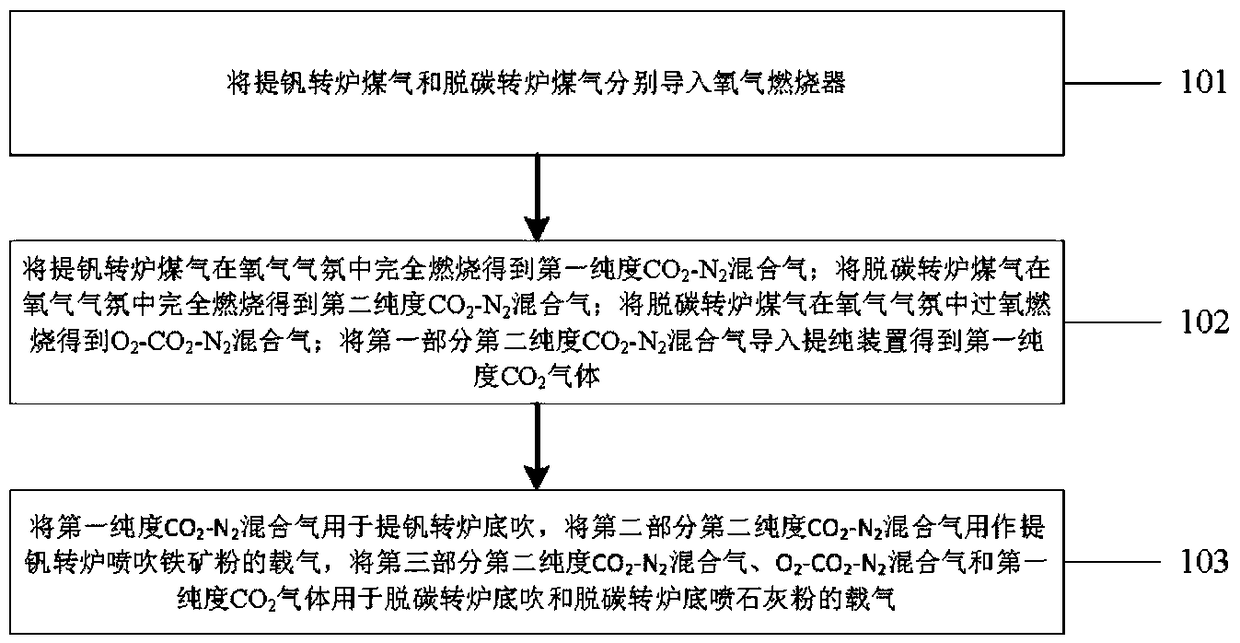

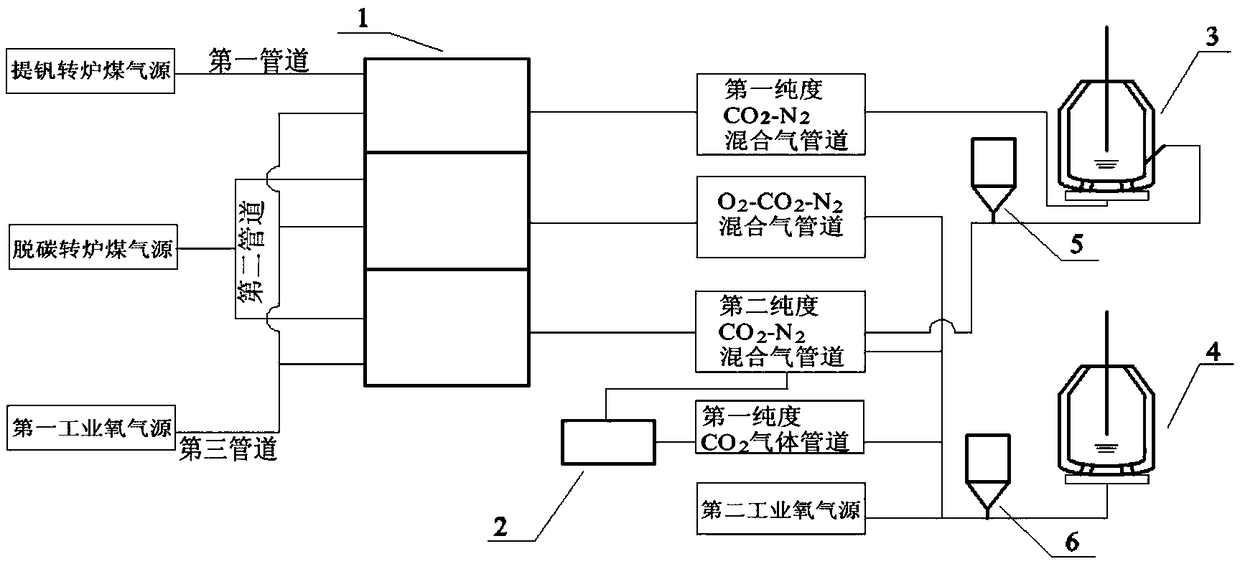

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the method and system are applied in a 100-ton vanadium extraction-decarburization dual converter process.

[0061] The converter gas produced by the vanadium extraction converter contains 20% CO and 15% CO 2 , and the rest are N 2 , due to the low calorific value of the gas, before adopting the present invention, the vanadium extraction converter gas is directly released; the gas of the decarburization converter contains 60% CO and 20% CO 2 , and the rest are N 2 , are stored in the gas cabinet. Before adopting the present invention, the furnace bottom of the vanadium extracting converter was arranged with 8 bottom blowing air bricks, and the gas supply intensity was 0.04Nm 3 / t / min, two spray guns for injecting iron ore powder are arranged on the side of the furnace, and the gas supply intensity is 0.2Nm 3 / t / min, the powder spraying intensity is 1.0kg / t / min, the carrier gas of bottom blowing and side blowing are both N 2 ; The furnace bottom ...

Embodiment 2

[0072] In this embodiment, the method and system are applied in a 150-ton vanadium extraction-decarburization double converter process.

[0073] The converter gas produced by the vanadium extraction converter contains 30% CO and 20% CO 2 , and the rest are N 2 , due to the low calorific value of the gas, before adopting the present invention, the gas from the vanadium extraction converter is directly released; the gas from the decarburization converter contains 55% CO and 25% CO 2 , and the rest are N 2 , are stored in the gas cabinet. Before adopting the present invention, the furnace bottom of the vanadium extraction converter was arranged with 9 bottom-blowing air bricks, and the gas supply intensity was 0.09Nm 3 / t / min, 4 spray guns for injecting iron ore powder are arranged on the side of the furnace, and the gas supply intensity is 0.33Nm 3 / t / min, the powder spraying intensity is 2.0kg / t / min, the carrier gas of bottom blowing and side blowing are both N 2 ; The fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com