Polyurethane prepolymer

A polyurethane prepolymer, polyester polyol technology, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, fasteners, etc., can solve the problem of insufficient adhesive strength, lack of moisture permeability of film, adhesion Insufficient strength and other problems, to achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

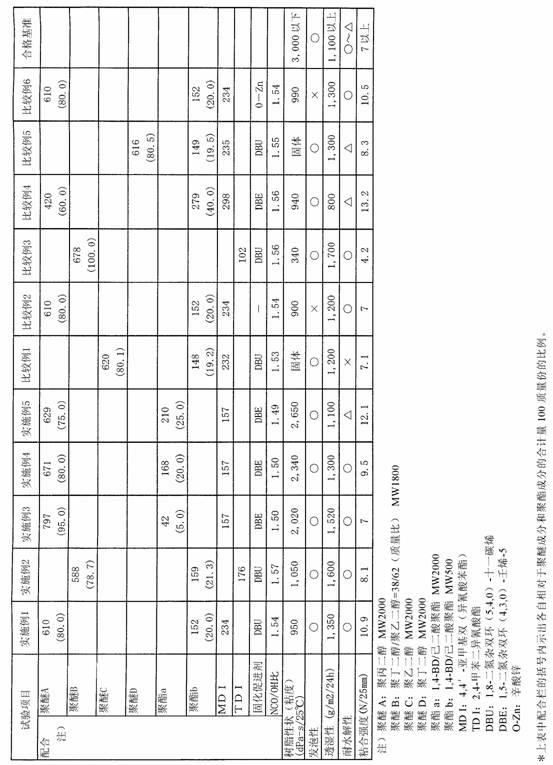

Embodiment 1

[0045] 610 parts of polypropylene glycol (number-average molecular weight: 2000, OH value: 56), and 1,4-butanediol and hexanediol 152 parts of difunctional polyester diol (number average molecular weight: 500, OH value: 235) formed by acid were heated and depressurized, and after dehydration treatment, nitrogen gas was introduced to make the internal temperature 90-100°C. 234 parts of 4,4'-methylene bis(phenylisocyanate) melted by heating beforehand were added, and it stirred at 100 degreeC for 2 hours, and it was made to react. After completion of the reaction, cool to below 40°C, add 3.0 parts of amine-based curing accelerator (1,8-diazabicyclo(5,4,0)-undecene), stir and mix, then take out.

[0046] The viscosity of the obtained polyurethane prepolymer was 950 dPa-s / 25°C. The NCO / OH equivalent ratio of this material was 1.54.

Embodiment 2

[0048] In a 2-liter glass reaction vessel equipped with a stirrer, a thermometer, a gas inlet, etc., a bifunctional polyether polyol (copolymerized polyether polyol of polytetramethylene glycol and polyethylene glycol, the number average molecular weight of 1800, OH value 62) 588 parts, and 159 parts of difunctional polyester diol formed from 1,4-butanediol and adipic acid (number average molecular weight 500, OH value 235), heat and reduce pressure , After the dehydration treatment, nitrogen gas is introduced to make the inner temperature 90-100°C. 176 parts of 2, 4- toluene diisocyanates were added, and it stirred and made it react at 100 degreeC for 2 hours. After completion of the reaction, cool to below 40°C, add 3.0 parts of amine-based curing accelerator (1,8-diazabicyclo(5,4,0)-undecene), stir and mix, then take out.

[0049] The viscosity of the obtained polyurethane prepolymer was 1050 dPa-s / 25°C. The NCO / OH equivalent ratio of this material was 1.57.

Embodiment 3

[0051] Into a 2-liter glass reaction vessel equipped with a stirrer, a thermometer, and a gas inlet, 797 parts of polypropylene glycol (number-average molecular weight: 2,000, OH value: 56), and 1,4-butanediol and 42 parts of difunctional polyester diol (number average molecular weight: 2000, OH value: 56) formed by acid were heated and depressurized, and after dehydration treatment, nitrogen gas was introduced to make the internal temperature 90-100°C. 157 parts of 4,4'-methylene bis(phenylisocyanate) melted by heating beforehand were added, and it stirred at 100 degreeC for 2 hours, and it was made to react. After completion of the reaction, cool to below 40°C, add 2.8 parts of amine-based curing accelerator (1,5-diazabicyclo(4,3,0)-nonene-5), stir and mix, then take out.

[0052] The viscosity of the obtained polyurethane prepolymer was 2020 dPa-s / 25°C. The NCO / OH equivalence ratio of this material was 1.50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com