Heat accumulating temperature regulating fiber and method for preparing same

A technology for heat storage, temperature regulation, and fiber, which is applied in fiber processing, spinning solution preparation, wet spinning, etc. It can solve the problems that it is difficult to meet the needs of different purposes, and there are few types of polymer phase change materials, and achieve various product forms. , wide application range, concentrated heat release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also designs the preparation method of the fiber, the preparation method adopts the fiber composition of the present invention, and is suitable for melt composite spinning, solution composite spinning or solution electrostatic composite spinning. Specifically, according to the composition and structural design of the fibers of the present invention, one of the following processes is adopted:

[0020] (1) Melt composite spinning process:

[0021] ①Using the polymer phase change material of the A component-polyethylene glycol n-alkyl ether, drying, removing the moisture therein, so that the moisture content reaches 50~150ppm;

[0022] ②Using known technology to melt the polyethylene glycol n-alkyl ether, transport it to the metering pump of component A of the fiber, and control the mass fraction of component A of the fiber to be 20-60%;

[0023] ③ using known technology to dry the fiber-forming polymer of component B to remove moisture, so that the ...

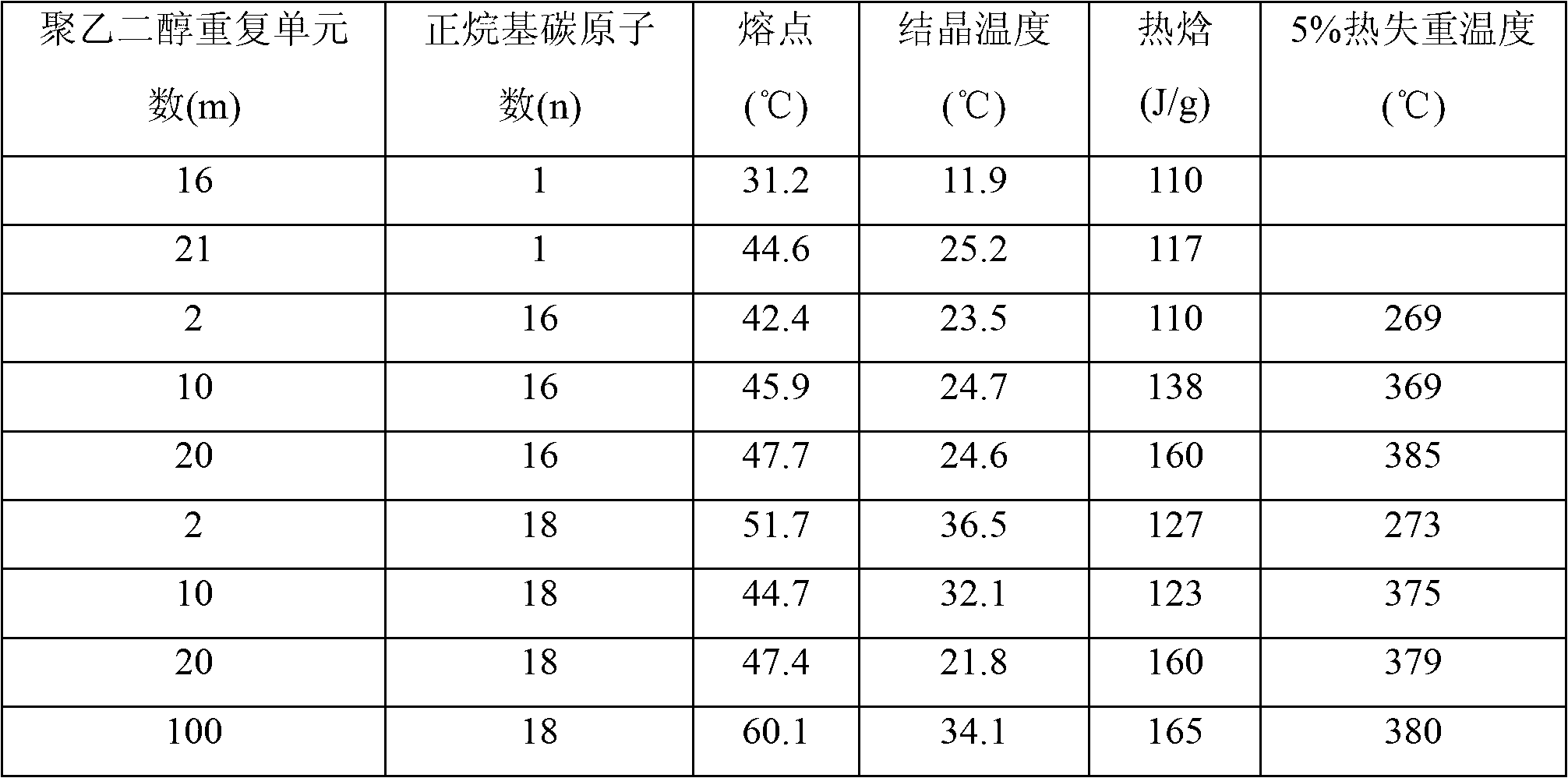

Embodiment 1

[0046] The polyethylene glycol n-hexadecyl ether with m=2, n=16 is used as component A of the fiber, and the acrylonitrile-methyl acrylate (molar ratio is 85 / 15) copolymer (number-average molecular weight: 36,000) is used as the fiber component. Component B, after both components are dried until the moisture content is lower than 150ppm, the mass ratio of A and B is controlled to be 40:60, melted and composite spun at 210°C to make sea-island type spun yarn, and after further drawing, crimping and shaping, Cut into short fibers.

[0047] After inspection, the fineness of the finished fiber is 3.8dtex, the tensile breaking strength is 2.7cN / dtex, and the elongation at break is 31%. ℃, the heat release is 38J / g; the temperature of 5% thermal weight loss is 265℃.

Embodiment 2

[0049] The polyethylene glycol n-hexadecyl ether with m=20 and n=16 is used as the component A of the fiber, and the component B of the fiber is poly-4-methylpentene-1 (number average molecular weight: 210,000). After drying until the moisture content is lower than 150ppm, control the mass ratio of A and B to be 60:40, melt and compound spinning at 230°C to make concentric circular as-spun yarn, and then after further drawing, crimping and shaping, cut into short fibre.

[0050] After inspection, the fineness of the finished fiber is 5.1dtex, the tensile breaking strength is 2.2cN / dtex, and the elongation at break is 28%. It is 31.3°C, and the heat release is 55J / g; the temperature of 5% thermal weight loss is 215°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com