Radiating device of chip radiation using low-melting-point metal or its alloy as flow working medium

A technology of low melting point metal and heat sink, applied in the fields of instruments, electrical digital data processing, electrical components, etc., can solve problems that have not yet been proposed, and achieve large and fast heat transport capabilities, novel concepts, and high heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further describe the present invention below in conjunction with accompanying drawing and specific embodiment:

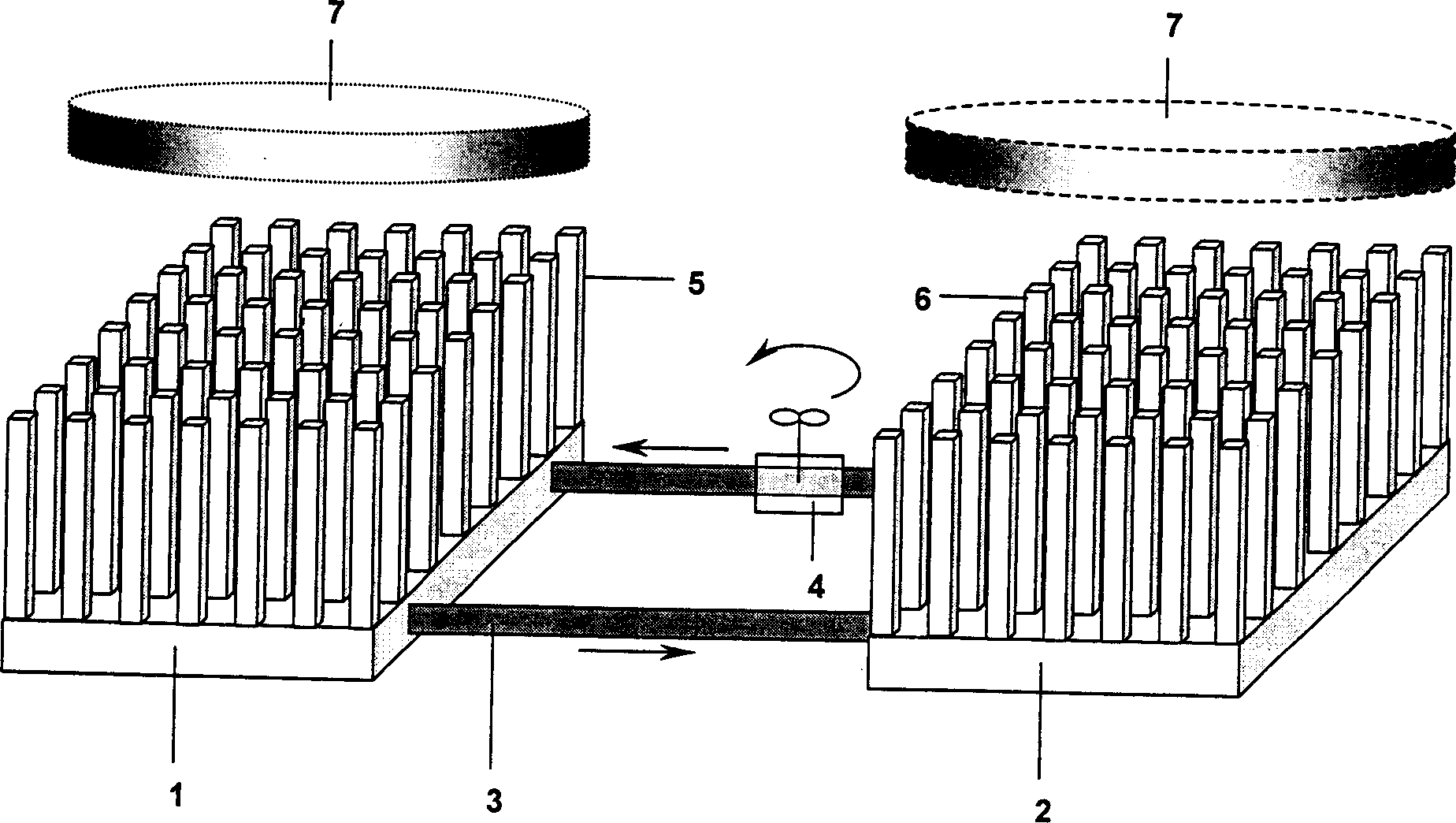

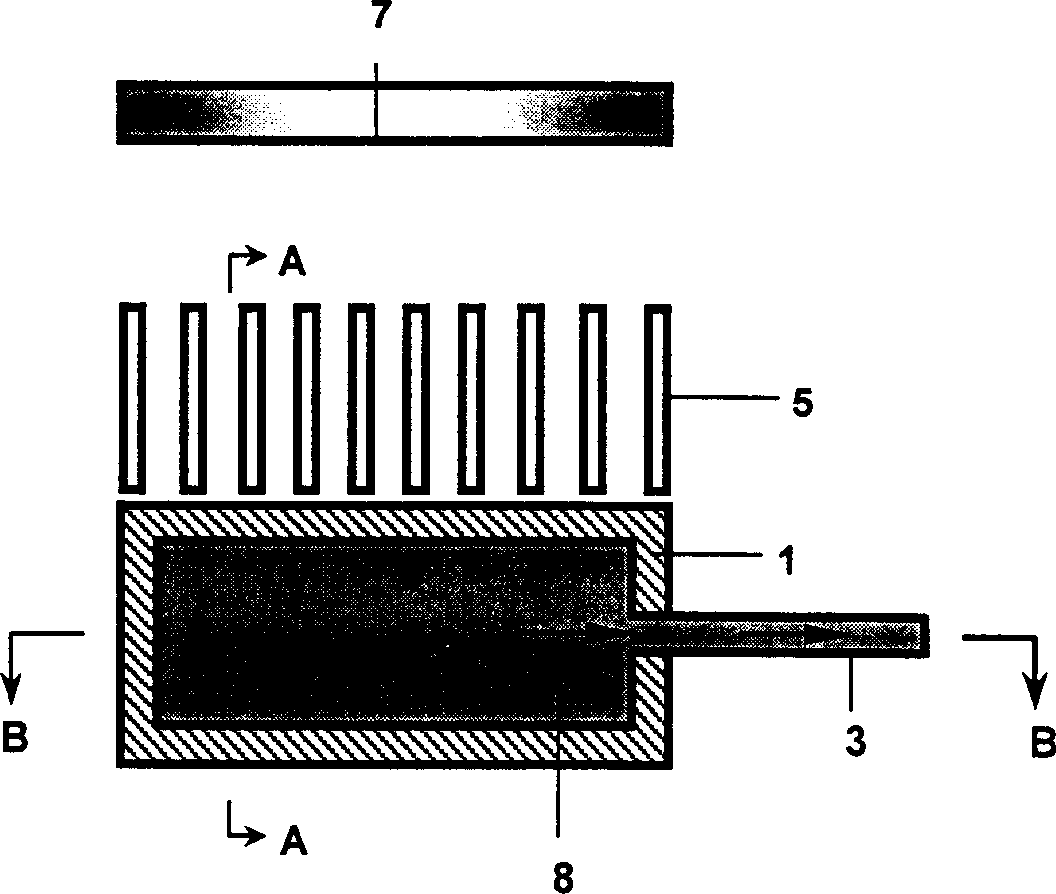

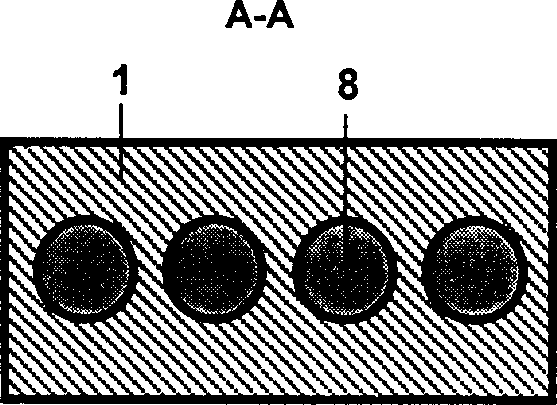

[0034] figure 1 It is a structural schematic diagram of the present invention, which is also an embodiment of the present invention; figure 2 It is a schematic diagram of the cross section (radiating ribs 5 and circulation channels) of the main radiator 1 of the present invention; Figure 2a to attach figure 2 Schematic diagram of the A-A section of ; attached Figure 2b to attach figure 2 The schematic diagram of the B-B cross-section; As can be seen from the figure, the chip heat dissipation device provided by the present invention as a flowing working medium with a low melting point metal or its alloy includes:

[0035] A main radiator 1 with a circulation channel inside, and a liquid low-melting point metal or its alloy flowing fluid is installed in the circulation channel, and the other surface of the main radiator 1 that is in contact with the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com