Method for preparing multiphase coupled WS2/WN solid lubrication film

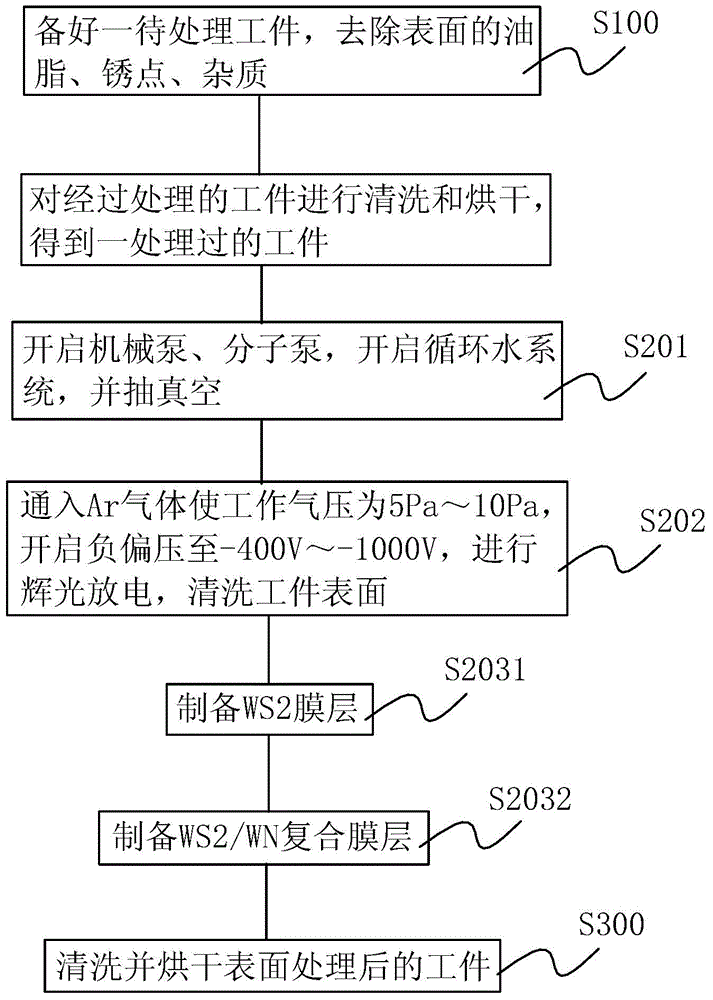

A film manufacturing method and solid lubrication technology, which are applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of easy wear and failure of solid lubricating films, improve the friction and wear performance of the film, and have a low friction coefficient. , optimize the effect of thin film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] see Figure 5 , Figure 5 It is a structural schematic diagram of a manufacturing device according to an embodiment of the present invention. The manufacturing device comprises a vacuum chamber 10 and a low-energy ion source 20 connected with the vacuum chamber 10, a magnetron sputtering target 30 and a microwave source 40, and the microwave source 40 is provided with N gas inlet 50, and the magnetron sputtering target 30 An Ar gas inlet 60 and a cooling water inlet 70 are provided.

[0066] Put the metal material substrate 1 as the sample on the sample stage of the vacuum chamber 10, and vacuumize to 3.0×10 -4 After Pa, through N 2 The gas inlet 50 is filled with argon gas with a purity of 99.99%, and the low-energy ion source 20 is turned on to perform ion bombardment cleaning on the sample to remove the gas or impurities attached to the surface. After the cleaning is completed, use the magnetron sputtering target 30 and the microwave source 40 to start the sputte...

Embodiment 2

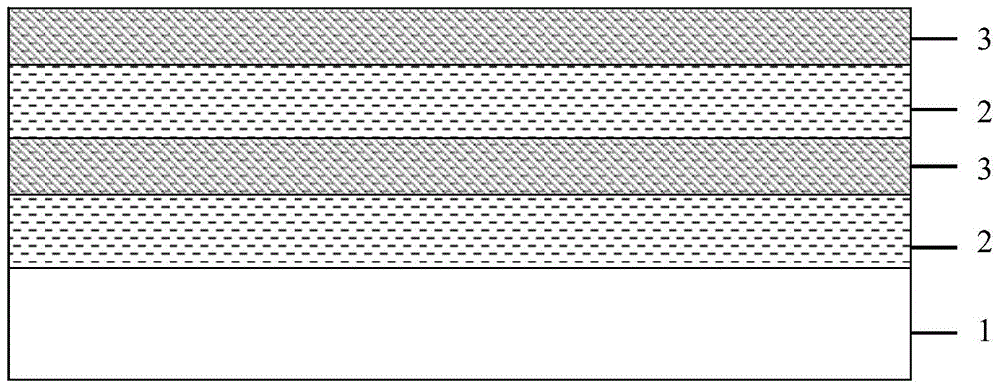

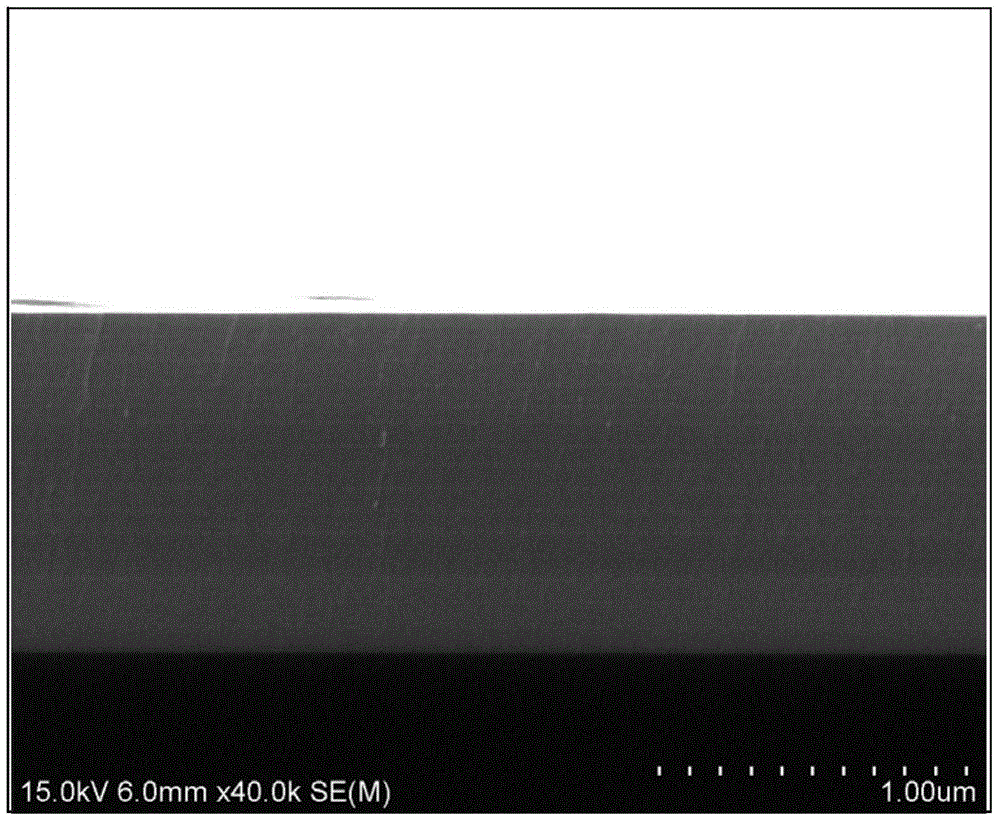

[0070] Put the metal material matrix 1 on the sample stage of the vacuum chamber 10, and evacuate to 3.0×10 -4 Pa, filled with 99.99% argon, turned on the low-energy ion source 20 to clean the sample by ion bombardment. After the cleaning is completed, the sputtering deposition process starts, the sputtering gas uses Ar, and the reaction gas uses N 2 . First deposit a layer of WS 2 Film layer 2, and then deposit a layer of WS 2 / WN composite film layer 3, cycled sequentially, where WS 2 Film layer 2 deposited ten layers, WS 2 / WN composite film layer 3 deposited ten layers.

[0071] deposited WS 2 The parameters used for film layer 2 are preferably: sputtering voltage -600~-800V, sputtering current 2A, sputtering pressure 8×10 -2 -1×10 -1 Pa, sputtering time 5-8min. Ar gas flow 30-40sccm.

[0072] deposited WS 2 The parameters used during the / WN composite film layer 3 are preferably: sputtering voltage-800~-900V, sputtering current 2A, sputtering pressure 8×10 -2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com