Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Improve friction and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-lubricating type epoxide resin material and preparation thereof

InactiveCN101348600AImprove stabilityReduce pollutionMicroballoon preparationLubricant compositionFirming agentEpoxy resin composite

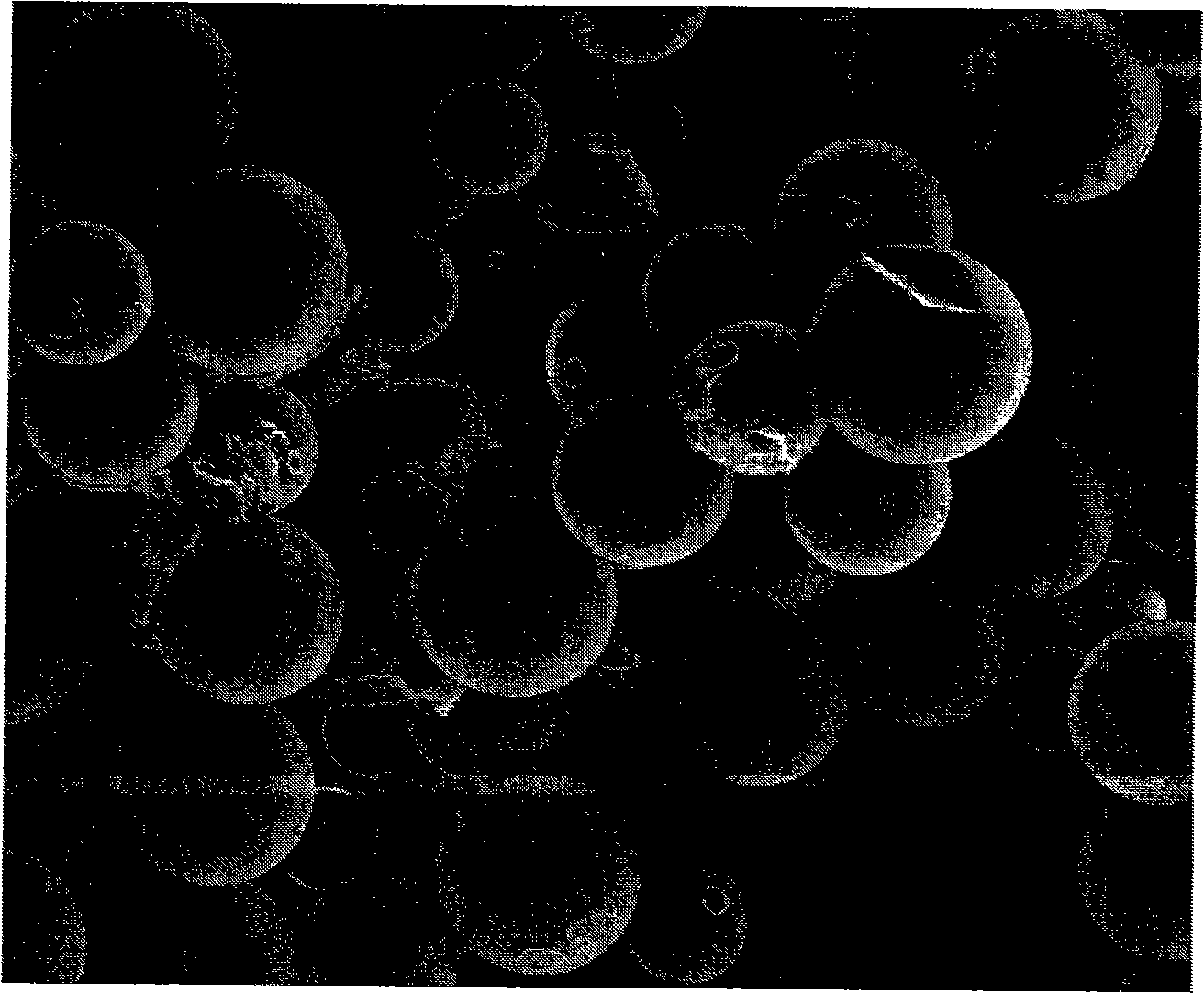

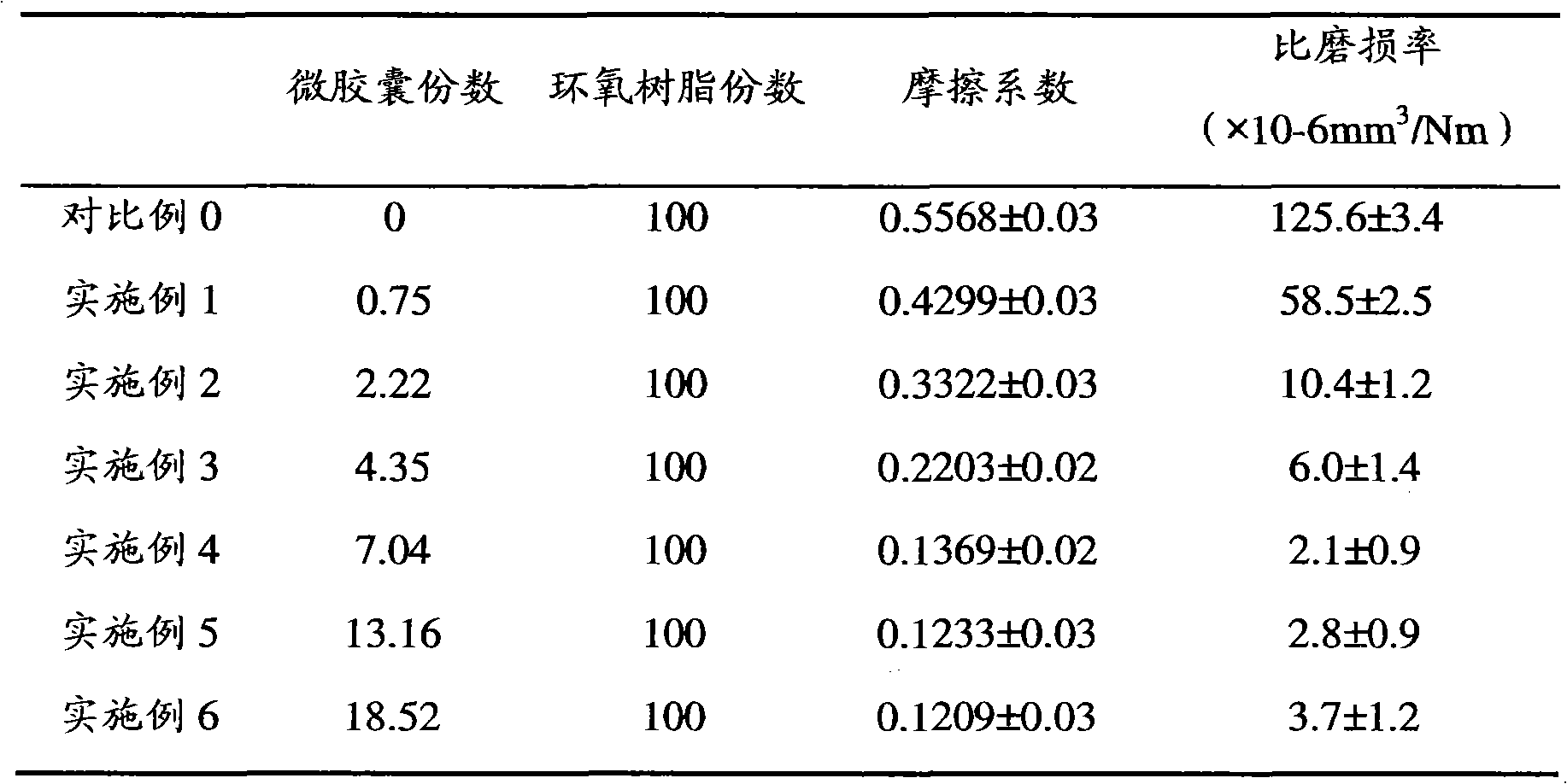

The invention discloses a self-lubricating type epoxy resin material and a preparation method thereof, belonging to the polymer material field. The self-lubricating type epoxy resin material comprises the following components in weight percentage: 60 to 80 percent of epoxy resin, 0.5 to 25 percent of lubricating oil microcapsules and 15 to 35 percent of curing agents. The preparation method for the self-lubricating type epoxy resin material comprises the following steps of well mixing the lubricating oil microcapsules, the epoxy resin with the curing agents and casting rapidly when to-be-mixed matter has gel phenomena, so as to obtain the self-lubricating type epoxy resin material. The invention also provides a lubricating oil microcapsule needed in the preparation of the epoxy resin material and a preparation method for the lubricating oil microcapsule. A technical proposal provided by the invention adds the lubricating oil microcapsules to the epoxy resin so as to prepare the epoxy resin compound material, which can remarkably improve the wear reducing-resisting performance of the epoxy resin material and has broad application prospects.

Owner:SUN YAT SEN UNIV

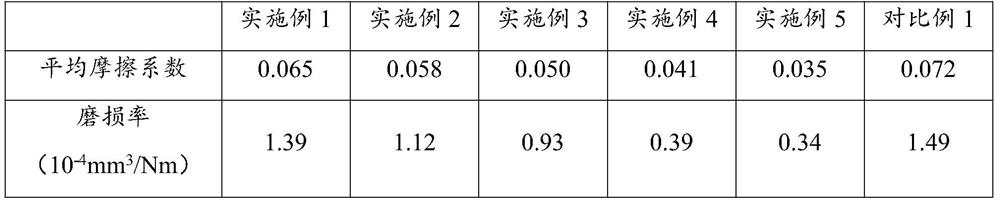

Polyetheretherketone-base composite, preparing method thereof and application thereof in friction reduction and wear resistance

InactiveCN104927298AReduce coefficient of frictionReduce wear rateOther chemical processesDispersityFiber

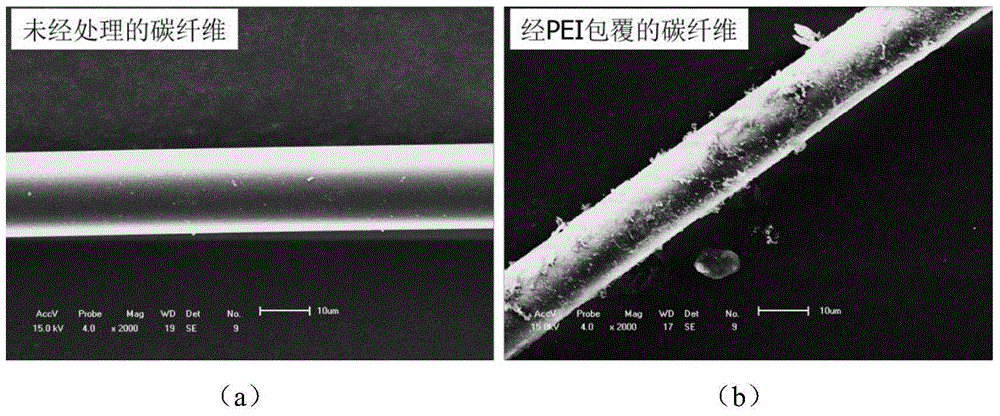

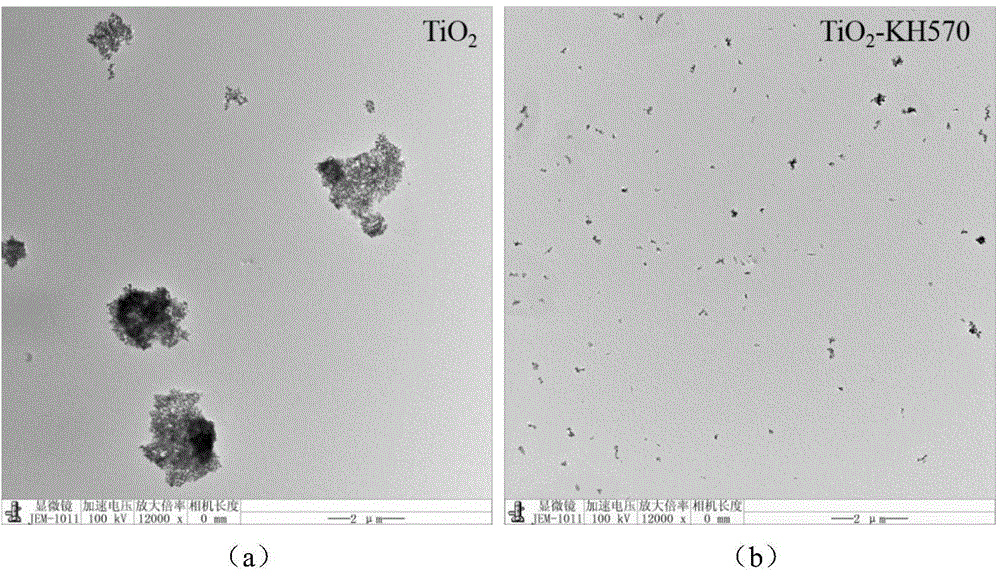

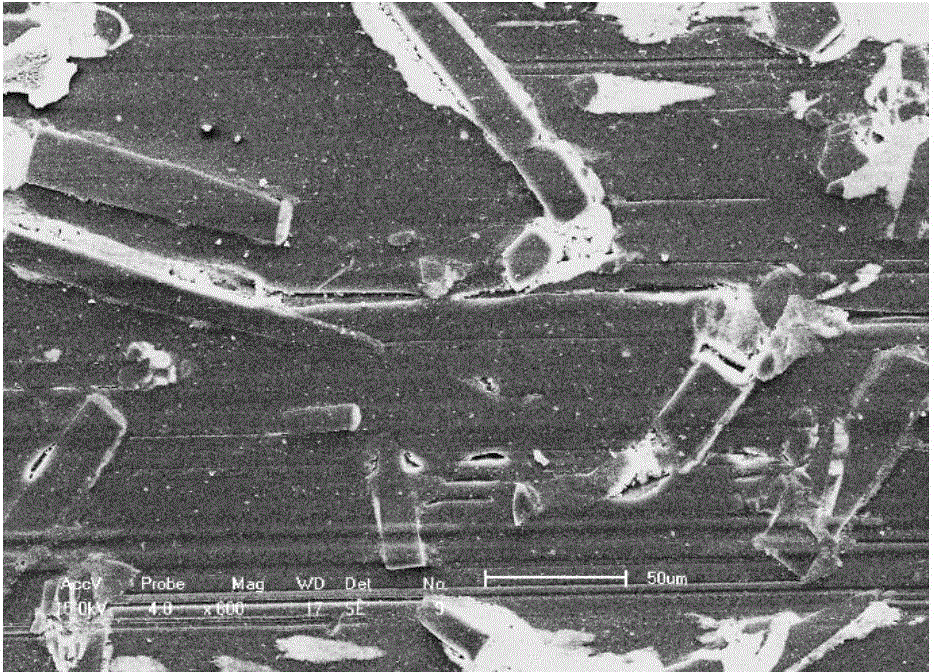

The invention relates to a polyetheretherketone-base composite, a preparing method thereof and application thereof in friction reduction and wear resistance and belongs to the technical field of polymer composites. The polyetheretherketone-base composite, by 100% weight, 65% to 87% of polyetheretherketone, 10% to 30% of polyetherimide-coated carbon fiber, and 3% to 5% of coupler-modified titanium dioxide. In order to optimize the dispersity of micrometer chopped carbon fiber, polyetherimide which is well compatible with the polyetheretherketone and resistant to high temperature is used to coat the carbon fiber; the nano titanium dioxide is subjected to coupler inarching to reduce its agglomeration degree. Compared with fillers subjected to no treatment, the carbon fiber has the advantages such as uniform dispersity in composites and high interfacial action with matrixes. By adding the coated carbon fiber and the coupler-modified titanium dioxide, the friction and wear performance of the polyetheretherketone-base composite can be effectively improved, and the application in the friction-reducing wear-resistant environments is satisfied.

Owner:JILIN UNIV

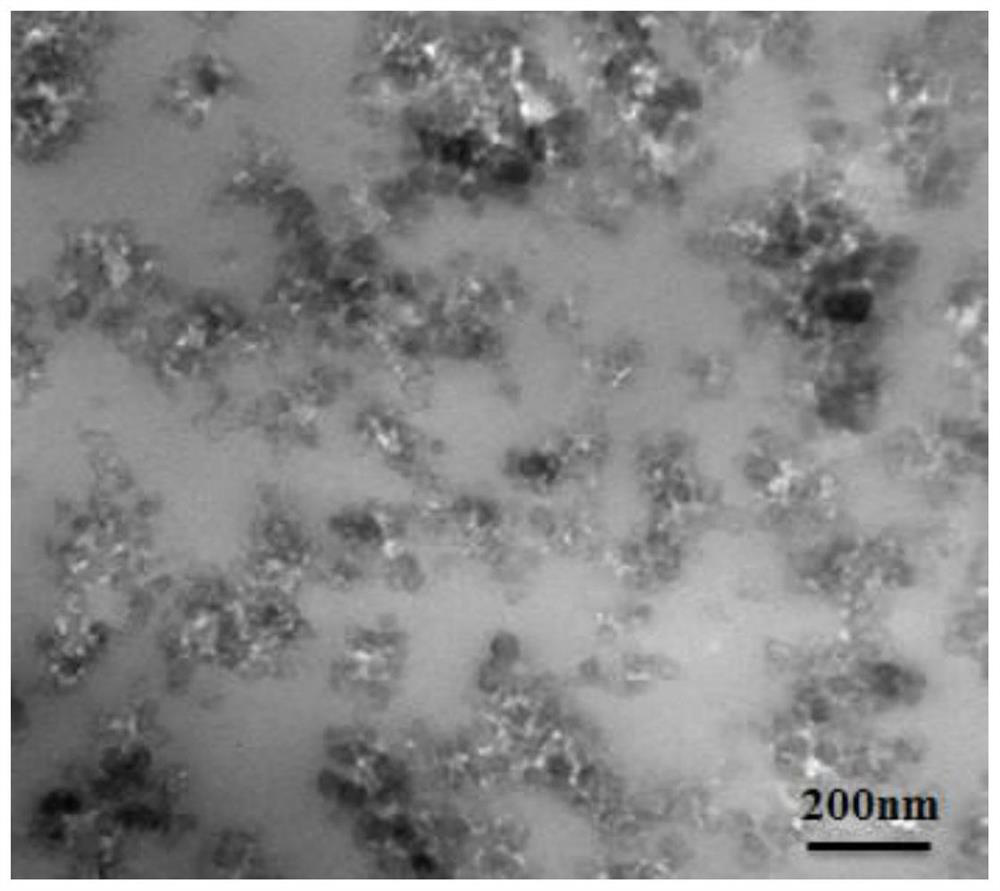

Preparation method of graphene/carbon nano tubes reinforced aluminum oxide ceramic coating

InactiveCN106946551AImprove toughnessHigh bonding strengthHeat inorganic powder coatingCeramic coatingComposite ceramic

The invention provides a preparation method of a graphene / carbon nano tubes reinforced aluminum oxide ceramic coating. The preparation method includes the following steps: adding a less amount of graphene and processed carbon nano tubes to aluminum oxide to obtain a composite ceramic coating, and brush-coating a substrate with the coating, wherein slurry is composed of Al2O3 powder, graphene powder, the processed carbon nano tubes, and an adhesive. The processed carbon nano tubes are dried and ground, and then are subjected to ball milling with the graphene and Al2O3 for 6-8 h according to the ratio; the mass percentage of nano material is not more than 0.4%; the mixed aggregate is fully stirred with the adhesive according to mass ratio of 1:0.8 to obtain a mixture; the mixture is naturally dried for 2 h at a ventilated and shade place, and is gradiently heated at 50-300 DEG C for 5 h to produce the aluminum oxide composite ceramic coating. Compared with a common method of processing ceramic coatings, the method is simpler in equipment and technology and has high adaptability. The ceramic coating has good dispersibility and high binding strength, and is anti-wear and anti-corrosion.

Owner:JIANGNAN UNIV

Modified inorganic nanoparticle/epoxy resin composite material with higher friction and wear properties and preparation method thereof

ActiveCN102924872AImprove wear resistanceImprove friction and wear propertiesLiquid/solution decomposition chemical coatingEpoxyFriction reduction

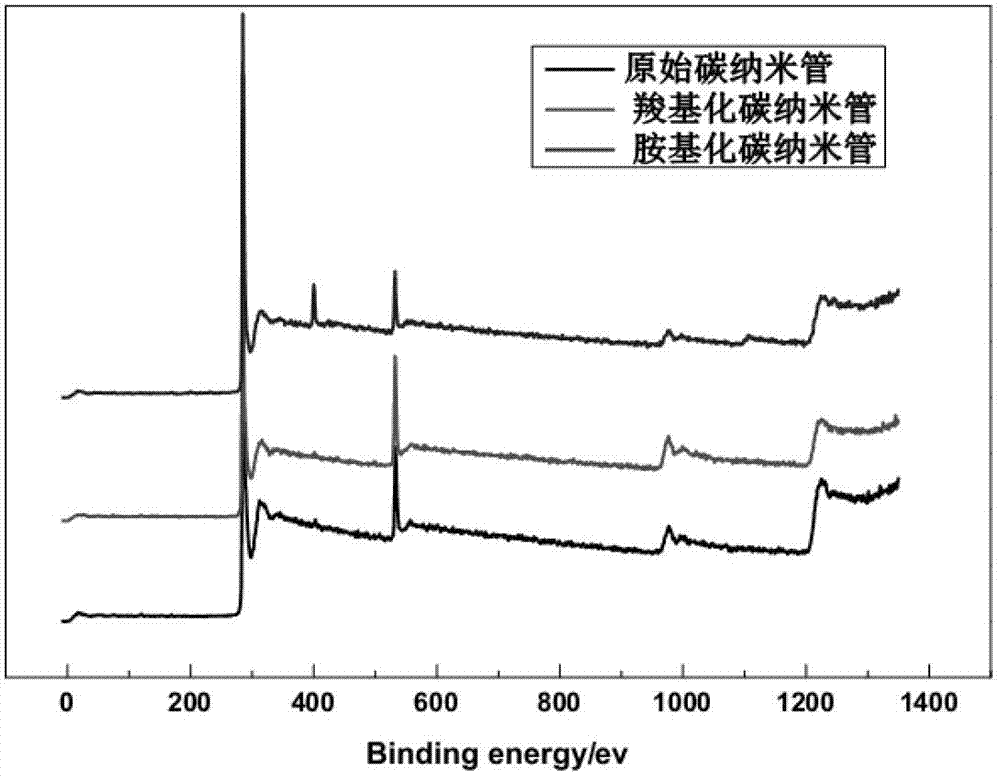

The invention provides a modified inorganic nanoparticle / epoxy resin composite material with higher friction and wear properties, comprising the following components by weight percentage: 95-99.9% of epoxy resin and 0.1-5.0% of modified inorganic nanoparticle, wherein the total quantity of the components is 100%. A preparation method of the material comprises the following steps of: firstly, respectively carrying out carboxylation modification and amino functionalization modification on an original carbon nano tube, mechanically mixing the obtained aminated carbon nano tube and epoxy resin, curing to obtain the carbon nano tube-enhanced epoxy resin composite material, and plating a layer of Ni-P-CNTs composite plating layer on the surface of the epoxy resin composite material by a surface chemistry composite plating technology. The effect of friction reduction and wear resistance can be achieved due to the organic synthesis between the filling of the nano-particles and the surface chemistry composite plating technology. Furthermore, the method is simple in technology and easy to implement, so that the abrasive resistance of the epoxy resin can be obviously improved.

Owner:TIANJIN POLYTECHNIC UNIV

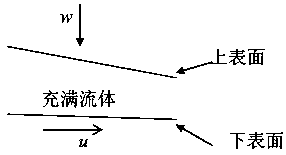

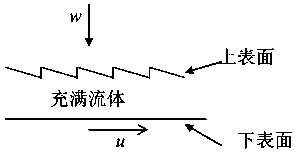

Special-shaped micro stepped bearing

The invention provides a special-shaped micro stepped bearing. The special-shaped micro stepped bearing comprises a static flat plate and a moving flat plate which are paired. The static flat plate is provided with a stepped surface. The convex surface of the static flat plate is coated with an oleophylic coating. The concave surface of the static flat plate is coated with an oilphobic coating. The motion direction of the moving flat plate is that the convex surface of the static flat plate points to the concave surface of the static flat plate. A clearance between the paired static flat plate and moving flat plate is full of lubricating oil. The clearance between working surfaces of the paired static flat plate and moving flat plate is in a nanometer scale. The special-shaped micro stepped bearing is formed by the paired static flat plate and moving flat plate. The special-shaped micro stepped bearing is suitable for occasions where surface clearances of bearing inlet areas are smaller than surface clearances of bearing outlet areas, and a traditional stepped bearing cannot be suitable for the occasions. The bearing is simple in structure, easy to manufacture and low in cost, has certain bearing capacity, is provided with a good lubricating oil film and can achieve good antifriction and wear-resisting effects.

Owner:怀宁吉利来精密机械科技有限公司

Active lubricant for wear-resistant material and high-strength wear-resistant nylon material

InactiveCN101781597AImprove friction and wear resistanceGood physical and mechanical propertiesBase-materialsWear resistantGraphite

The invention relates to an active lubricant for wear-resistant materials and a high-strength wear-resistant nylon material. The active lubricant for wear-resistant materials comprises the following substances: molybdenum disulfide, graphite and an active treating agent; and the solid-state active lubricant is prepared through feeding the substances to a high-speed mixer according to the formulation and then mixing the substances. The high-strength wear-resistant nylon material comprises the following substances: 100 parts of nylon, 6-20 parts of solid-state active lubricant, 3-6 parts of toughening agent and 1-10 parts of additive; and the high-strength wear-resistant nylon material is prepared through feeding the substances to the high-speed mixer for high-speed mixing, and then pouring the substances to an extruder. When applied in nylon resin, the active lubricant can significantly improve the friction reducing capability, wear resistance, relative viscosity and comprehensive mechanical properties of the nylon matrix material, and can also prolong the service life of the material. Meanwhile, the active lubricant integrates the functions of activation modification of the surface of the solid lubricant and chain extension of the nylon resin, and enhances the physical and mechanical properties of nylon. The preparation method is simple and convenient, has good effect and is easy to be industrialized.

Owner:HEFEI UNIV OF TECH

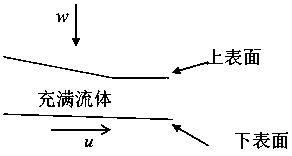

Modified heat-resistant plastic

InactiveCN105061950AImprove mechanical propertiesImprove friction and wear resistanceGlass fiberWeather resistance

The invention discloses a modified heat-resistant plastic which is prepared from a polyvinyl chloride resin, an acrylic resin, aluminum powder, modified glass fibers, calcium stearate, a dispersing agent, a heat stabilizer and a plasticizer. In order to overcome the defects in the prior art, a special method is adopted to modify the glass fibers, thereby enhancing the mechanical properties of the polyvinyl chloride plastic, improving the anti-friction and wear-resistant properties, and enhancing the weather resistance; the aluminum powder and calcium stearate subjected to high-temperature treatment are adopted to further enhance the heat resistance; and the production technique is simple and low in cost, and the prepared plastic has excellent heat stability.

Owner:JIESHOU SHENFA RAIN BOOT CO LTD

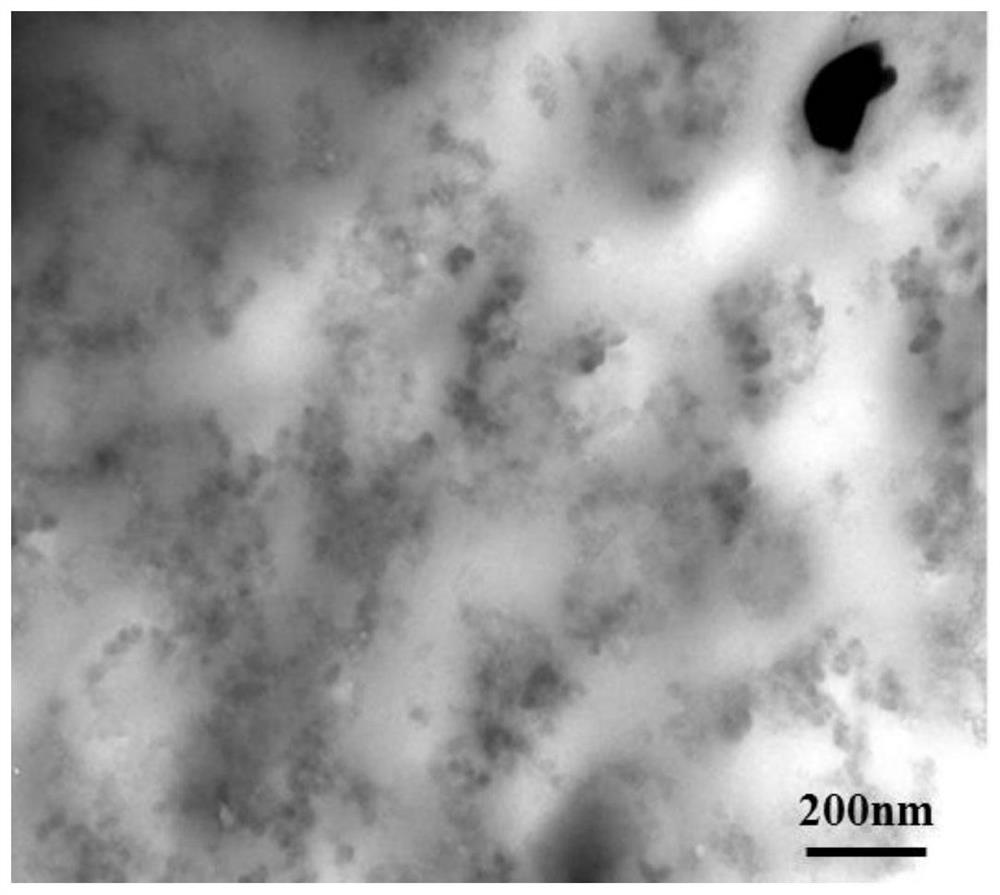

Preparation method of friction-reducing and wear-resisting lubricant

ActiveCN107653024AImprove friction and wear resistanceNo pollution in the processAdditivesGraphiteCvd graphene

The invention discloses a preparation method of friction-reducing and wear-resisting lubricant, which is characterized by including steps of preparing graphite solution; preparing graphite / titanium dioxide sol; sintering the preparing graphite / titanium dioxide sol at high temperature to obtain graphite / titanium dioxide nano powder; adding the graphite / titanium dioxide nano powder in liquid paraffin; and dispersing it evenly; and so on. After adding graphite / titanium dioxide nano powder to the liquid paraffin, the friction-reducing and wear-resisting performance of the liquid paraffin is greatly promoted under the high load condition; the preparation method is simple in technique, low in cost and free from environment pollution.

Owner:DONGHUA UNIV

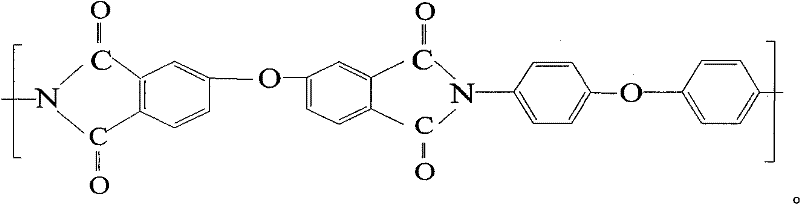

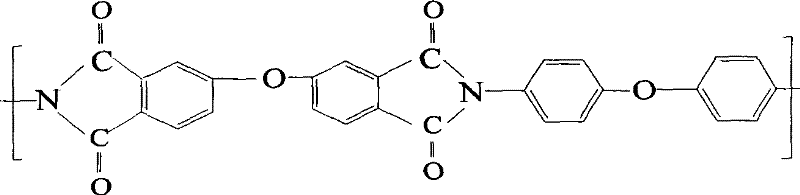

Self-lubrication composite material of polyimide

The invention discloses a self-lubrication composite material of polyimide, which is composited and padded with carbon fibers, a solid lubricant and nanometer particles. The self-lubrication composite material has the characteristics of high mechanical strength, small friction coefficient, low wear rate and the like. The self-lubrication composite material can be processed into slip sheets, bearings and the like, the anti-friction and wear resisting capabilities of the material are improved, and the service life of the material is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

TiCrN/MoS2 multi-element anti-wear lubricating coating tool and preparation process thereof

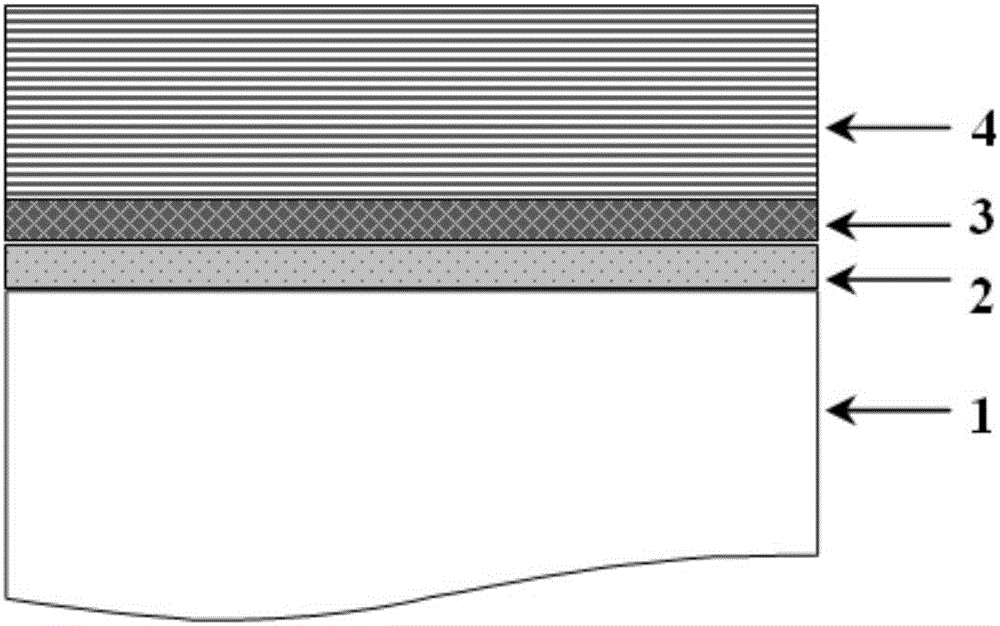

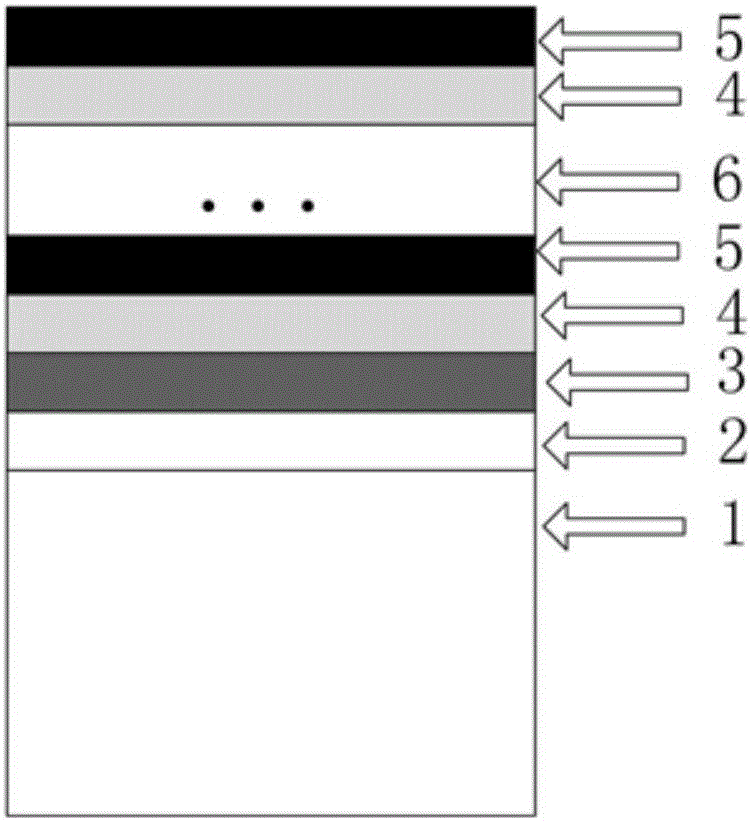

ActiveCN105861997AImprove binding performanceRelieve interlayer stressVacuum evaporation coatingSputtering coatingCemented carbideBoron nitride

The invention belongs to the field of mechanically manufactured metal cutting tools, and particularly relates to a TiCrN / MoS2 multi-element anti-wear lubricating coating tool and a preparation process thereof. A tool base body comprises high-speed steel, hard alloy, ceramics, diamond or cubic boron nitride, a coating is of a multi-layer structure, and a Ti transition layer, a Ti / Cr transition layer and a TiCrN and MoS2 compounded coating are sequentially arranged between the base body and the surface of the coating. According to the coating tool, the advantages of a TiCrN multi-element hard coating and a MoS2 lubricating coating are synthesized, high hardness is achieved, a lubricating function is achieved, the good lubricating performance of the coating can be kept in the whole life period, and the cutting performance of the coating tool can be remarkably improved.

Owner:安徽锦鹏纺织有限公司

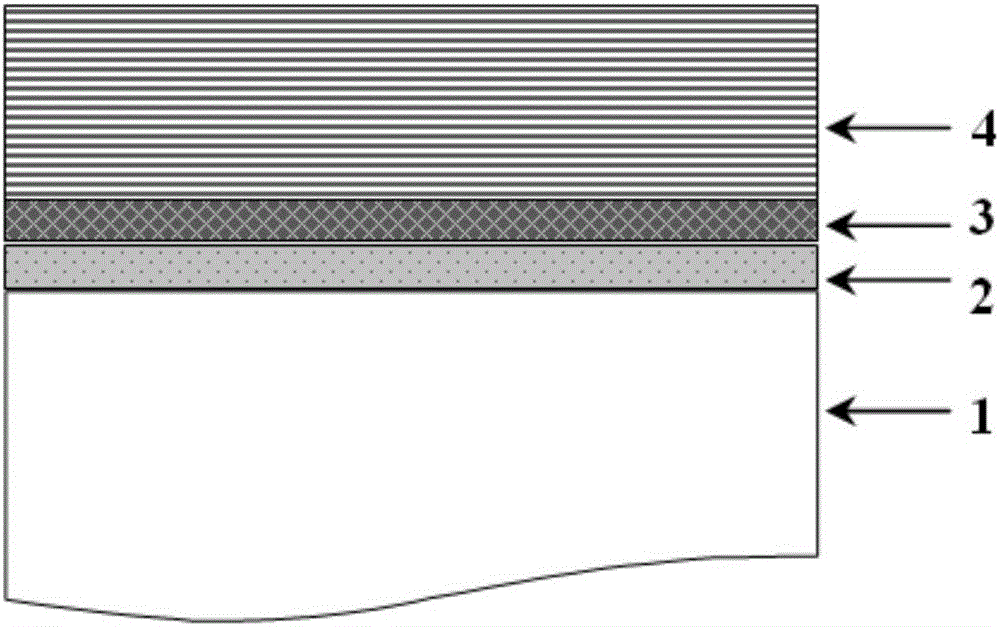

ZrTiN/MoS2 composite antifriction wear-resistant coated tool and preparation process thereof

ActiveCN105887025AGood technical effectImprove the lubrication effectVacuum evaporation coatingSputtering coatingWear resistantBoron nitride

The invention belongs to the field of mechanically manufactured metal cutting tools and particularly relates to a ZrTiN / MoS2 composite antifriction wear-resistant coated tool and a preparation process thereof. A base of the tool is made of high-speed steel or hard alloy or ceramic or cubic boron nitride. A Ti transition layer, a Ti / Zr transition layer and a ZrTiN / MoS2 composite coating are sequentially arranged from the base to the coated surface. By controlling the content of MoS2 in a ZrTiN multi-element hard coating, the composite coating has high hardness of the hard coating and a low friction coefficient of MoS2, and the coating can maintain good lubricating performance in the whole life cycle, so that the comprehensive performance of the coated tool is remarkably improved.

Owner:安徽锦鹏纺织有限公司

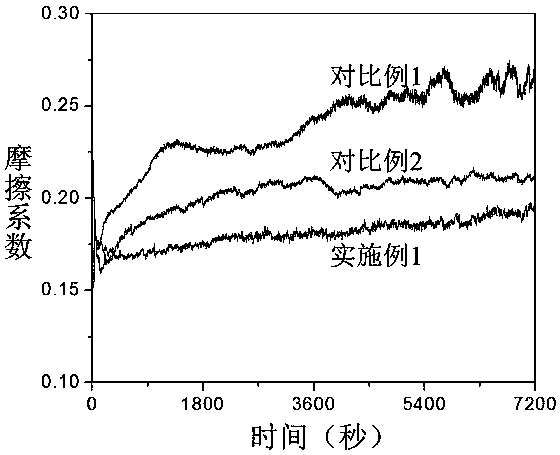

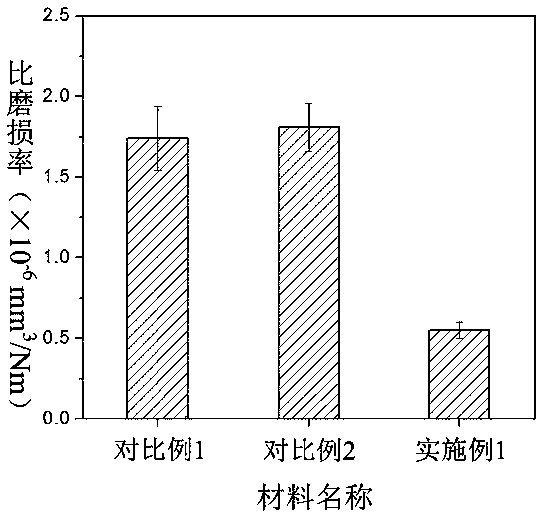

Method for improving wear resistance of polymer material by composite filling

InactiveCN110540724AIdeal anti-friction and wear-resisting effectTribological performance controlPolymer scienceWear resistant

The invention relates to a method for improving wear resistance of a polymer material by composite filling. According to the method, first a polymer resin matrix, a cleaned micron-reinforcing material, and a solid lubricant are fully dried according to material drying parameters, and then according to different molding requirements of the polymer resin matrix, the cleaned micron-reinforcing material and the solid lubricant with different elastic moduli and hardness are simultaneously added into the polymer matrix with the help of corresponding equipment, and a composite material is prepared ora granular material is extruded. For the first time, a combination of reinforcing materials with different physical properties is used to jointly regulate tribology properties of a polymer, the process is simple, the cost is low, and production is easy. The prepared anti-friction and wear-resistant polymer composite material can be widely used in automobiles, aerospace, machinery manufacturing and other fields as important components of polymer sliding bearings, sealing rings, thrust washers and other moving mechanisms.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

TiAlCrN&MoS2/Ti/Al/Cr multi-element laminated lubricating coating tool and preparation process thereof

ActiveCN105862004AImprove bindingImprove cutting performanceVacuum evaporation coatingSputtering coatingCoated surfaceMachine building

The invention belongs to the field of mechanically manufactured metal cutting tools, and particularly relates to a TiAlCrN&MoS2 / Ti / Al / Cr multi-element laminated lubricating coating tool and a preparation process thereof. A tool base body comprises high-speed steel, hard alloy, ceramics, diamond or cubic boron nitride. A MoS2 / Ti / Al / Cr lubricating coating is arranged on the surface of the tool, and a laminated structure coating with a Ti transition layer, a Ti / Al / Cr transition layer, a TiAlCrN hard coating and a MoS2 / Ti / Al / Cr lubricating coating alternating is sequentially arranged between the base body and the surface of the coating. According to the method, the advantages of a multi-element hard alloy, the lubricating coating, the laminated structure and three coating preparation methods are synthesized, high hardness is achieved, a lubricating function and a low friction coefficient are achieved, and the performance of the coating tool is remarkably improved.

Owner:安徽锦鹏纺织有限公司

Carbon-fiber-reinforced wear-resistant polyformaldehyde gear and preparation method thereof

The invention relates to a carbon-fiber-reinforced polyformaldehyde gear which is prepared from polyformaldehyde resin, chopped carbon fiber, molybdenum disulfide, calcium stearate, coupling agent and phenolic resin. The invention also relates to a preparation method of the carbon-fiber-reinforced polyformaldehyde gear, which comprises the following steps: carrying out composite surface treatmenton the carbon fiber; and putting the raw materials into a high-speed mixer according to the percentage in the formula, sufficiently mixing, granulating, and carrying out injection molding in an injection molding machine. The composite surface treatment, which is carried out on the chopped carbon fiber, greatly improves the wettability of the carbon fiber surface, and maximally enhances the interfacial adhesiveness between the carbon fiber and the polyformaldehyde matrix, thereby greatly enhancing the mechanical properties of the composite material. The gear prepared from the carbon-fiber-reinforced wear-resistant polyformaldehyde has the advantages of low specific gravity, low noise, favorable wear resistance, favorable self-lubrication effect, chemical corrosion resistance, high specificstrength, large specific modulus, small thermal expansion coefficient, static resistance and the like, and does not produce sparks, thereby being capable of replacing the original steel part. In addition, the invention reduces the labor intensity of workers, and lowers the energy consumption.

Owner:常州神鹰碳塑复合材料有限公司

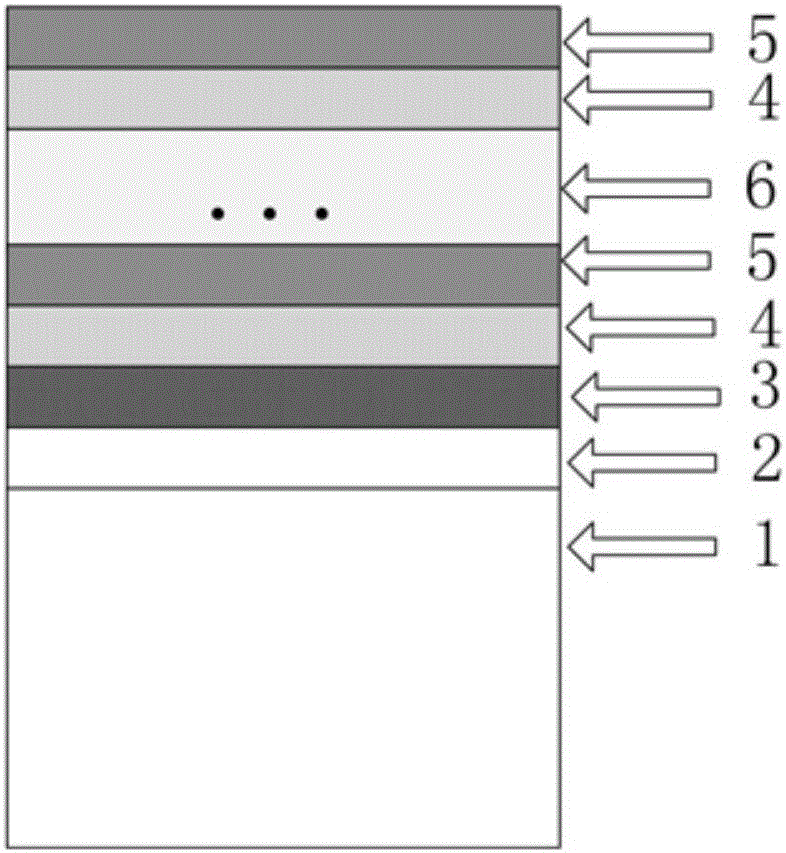

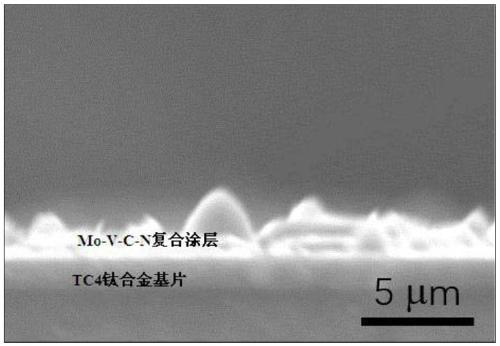

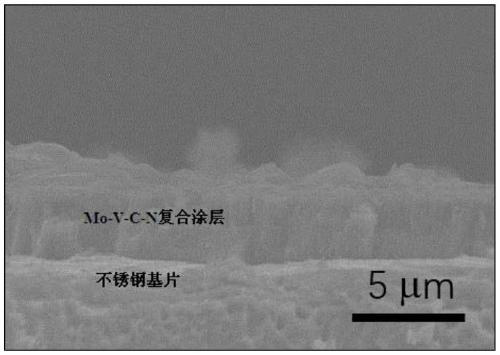

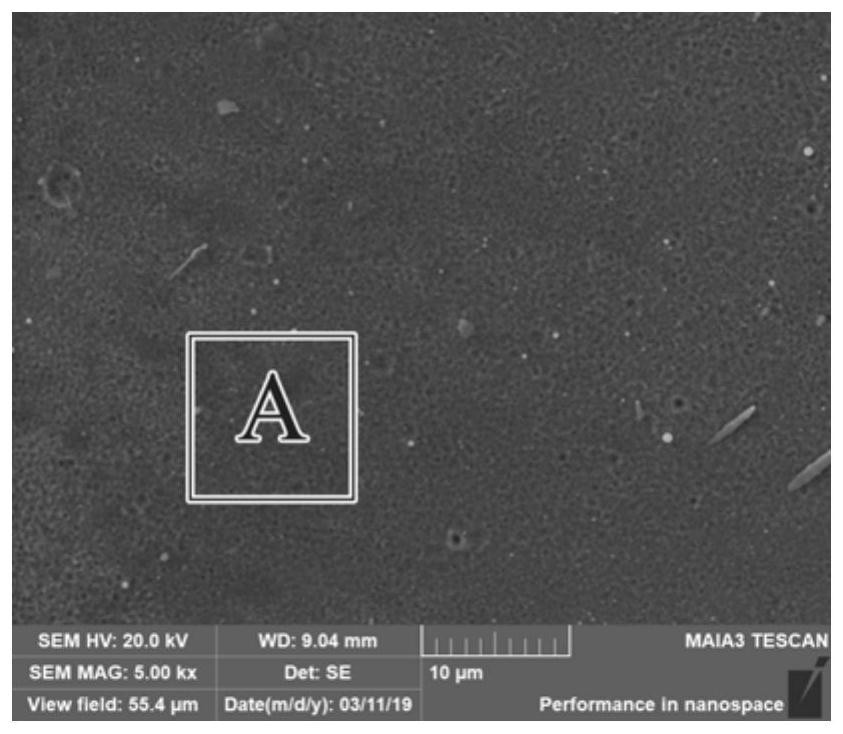

Preparation method of Mo-V-C-N composite coating

ActiveCN111534803AExcellent friction reductionImprove wear resistanceVacuum evaporation coatingSputtering coatingHardnessWear resistance

The invention discloses a preparation method of an Mo-V-C-N composite coating. The method comprises the steps that firstly, a substrate is treated; secondly, an Mo target, a V arc target and the substrate are placed, and a vacuum chamber is vacuumized and heated; thirdly, the substrate is etched; fourthly, an Mo priming layer is formed through deposition; fifthly, an Mo-V buffer layer is formed through deposition; sixthly, an Mo-V-N transition layer is formed through deposition; seventhly, an Mo-V-C-N body layer is formed through deposition; eighthly, vacuum annealing treatment is performed; and ninthly, the substrate provided with the Mo-V-C-N composite coating on the surface is obtained through cooling. According to the preparation method, through layered arrangement of the Mo-V-C-N composite coating, good component transition is formed, good combination with the substrate is ensured, and cracking and stripping of the Mo-V-C-N composite coating are avoided; and the prepared Mo-V-C-Ncomposite coating is uniform and dense in structure, high in hardness, good in toughness, low in friction coefficient and good in wear resistance, has a lubricating effect under both high temperatureand low temperature and is suitable for serving as a space self-lubricating layer.

Owner:西安稀有金属材料研究院有限公司

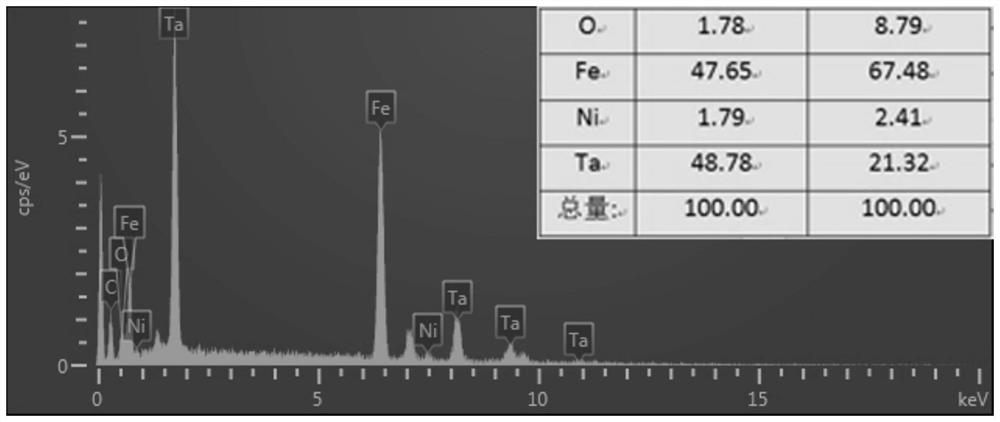

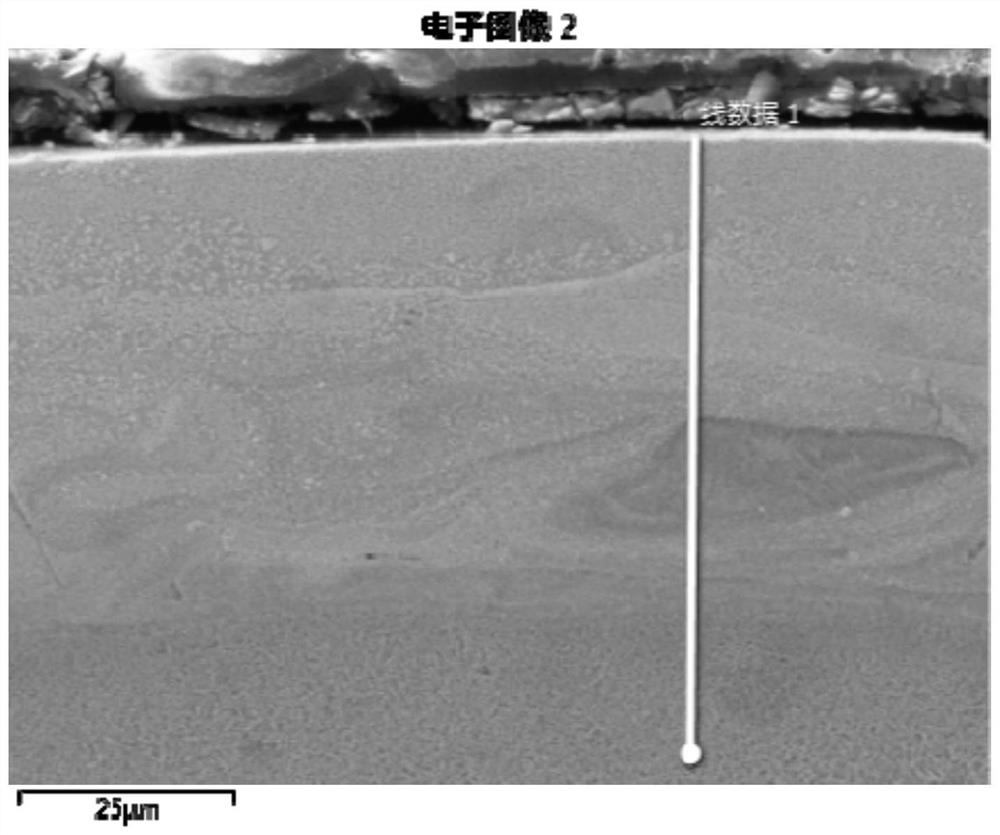

Electric spark deposition preparation method of self-lubricating coating containing tantalum oxide

ActiveCN114086176AImprove bindingImprove mechanical propertiesMetallic material coating processesElectrospark depositionElectric spark

The invention relates to the field of preparation of an anti-wear coating on the surface of a steel member, and particularly relates to an electric spark deposition preparation method of a self-lubricating coating containing tantalum oxide. Steel is adopted as a base body material, a pure tantalum electrode is adopted as an electric spark deposition electrode, and a self-lubricating coating containing tantalum oxide is deposited on the surface of a steel base body by adopting an electric spark deposition technology. The self-lubricating coating and a steel substrate are metallurgically bonded with a strong bonding force, and tantalum oxide enhances the hardness of the self-lubricating coating so that the self-lubricating coating has better antifriction and wear-resistant effects, and the problem of wear of the surface of a steel member in a frictional wear environment can be solved.

Owner:SHENYANG LIGONG UNIV

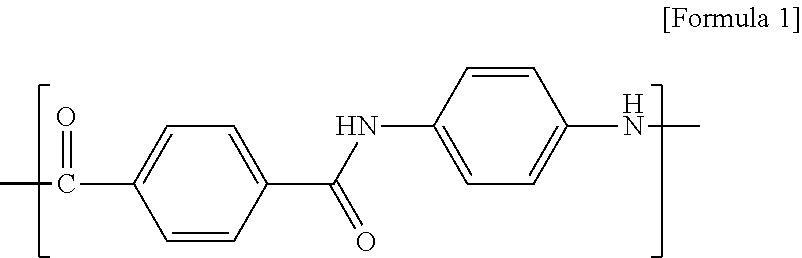

Polyoxymethylene resin composition

ActiveUS20150184110A1Improve friction and wear resistanceImprove thermal stability and tribology propertyWing fastenersAdditivesChemistryThermoplastic polyurethane

A novel polyoxymethylene resin composition is provided, which may be availably used as engineered plastics in various industrial fields and products, such as vehicle parts. The poly resin includes polyoxymethylene, aramide fibers, and thermoplastic polyurethane, thereby providing the novel composition of polyoxymethylene resin and improving various physical properties thereof, such as thermal stability.

Owner:HYUNDAI MOTOR CO LTD +1

ZrTiN-MoS2/Ti/Zr laminated coating tool and preparation process thereof

ActiveCN105861995AHigh hardnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingCoated surfaceMachine building

The invention belongs to mechanically manufactured metal cutting tools, and particularly relates to a ZrTiN-MoS2 / Ti / Zr laminated coating tool and a preparation process thereof. A tool base body comprises high-speed steel, hard alloy, cubic boron nitride or diamond. A MoS2 / Ti / Zr lubricating coating is arranged on the surface of the tool, and a laminated compounded structure with a Ti transition layer, a Ti / Zr transition layer, a ZrTiN hard coating and a MoS2 / Ti / Zr lubricating coating alternating is sequentially arranged between the base body and the surface of the coating. According to the tool, the advantages of a ZrTiN multi-element hard coating, a MoS2 / Ti / Zr lubricating coating and a laminated structure are synthesized, the high hardness of the coating can be kept, the friction coefficient of the coating can be reduced, and the cutting performance of the coating tool is remarkably improved. By means of the laminated structure, the good anti-wear lubricating performance of the coating tool can be kept in the service life period all the time, and the service cycle of the lubricating coating is prolonged.

Owner:安徽锦鹏纺织有限公司

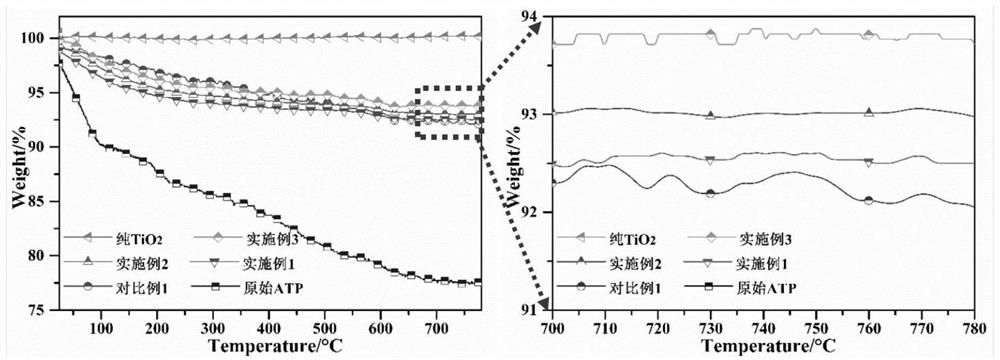

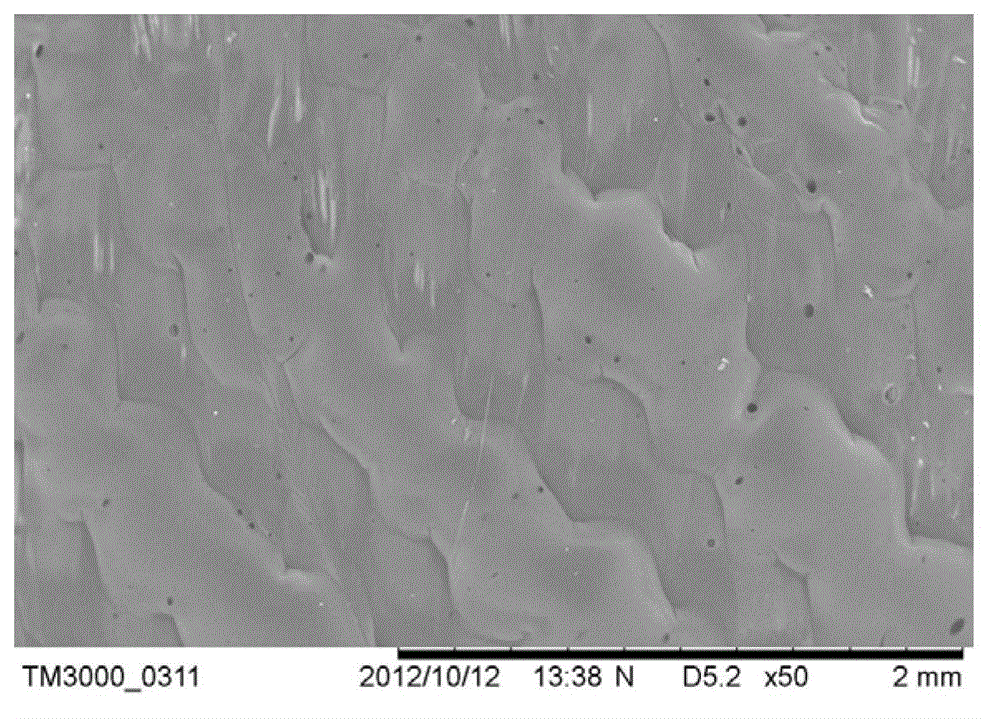

Attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as preparation method and application thereof

ActiveCN112226264AHigh surface energyInhibit wearLubricant compositionPigment physical treatmentHigh surfaceTitanium oxide

The invention provides an attapulgite- titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as a preparation method and application thereof, and belongs to thetechnical field of solid lubricating materials. According to the invention, attapulgite- titanium dioxide is used as a filler in ultrahigh molecular weight polyethylene, titanium dioxide particles have high surface energy, hard high-roughness particles can be formed after the titanium dioxide particles are loaded on attapulgite, and after attapulgite-titanium dioxide serving as filler is combinedwith ultrahigh molecular weight polyethylene, a better bearing effect can be achieved in the friction process, and abrasion of the material can be prevented; and meanwhile, the attapulgite-titanium dioxide is added, so that the heat resistance of an ultrahigh molecular weight polyethylene matrix can be improved, the composite material is not prone to deformation under the condition that frictionheat is concentrated, the deformation degree of the material is reduced to a certain extent, correspondingly, adhesive wear is also reduced to a certain extent, and the anti-friction and wear-resisting properties of the material are further improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

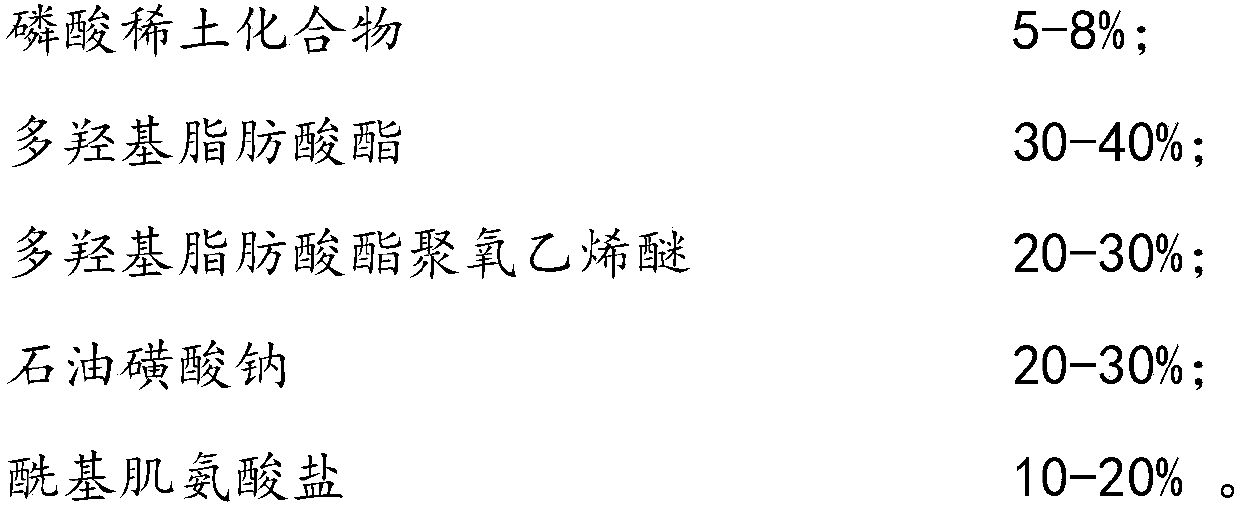

Fire-resistant hydraulic fluid composition, preparation method of fire-resistant hydraulic fluid composition and hydraulic fluid prepared by using composition

InactiveCN107603713AImprove friction and wear resistanceAdequate adsorptionAdditivesPhosphoric acidPhosphate

The invention provides a fire-resistant hydraulic fluid composition, which is characterized by being prepared from a raw material comprising 5 to 8 percent by mass of phosphate rare earth compound. The prepared fire-resistant hydraulic fluid composition can obviously improve frictional wear resistance and rust protection of hydraulic fluid; meanwhile, both swelling and shrinkage of the prepared fire-resistant hydraulic fluid composition for sealing materials, such as chemigum, accord with related standard requirements.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

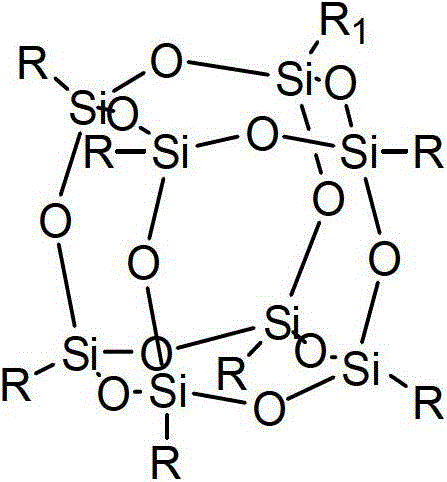

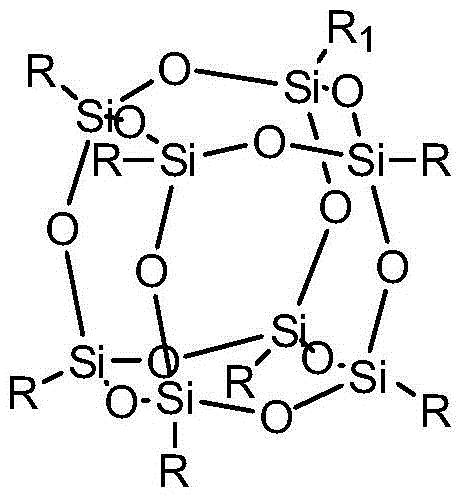

Fabric liner coating material of self-lubricating joint bearing and preparation method thereof

The invention provides a fabric liner coating material of a self-lubricating joint bearing and a preparation method thereof, and relates to a self-lubricating coating material and the preparation method thereof. The coating comprises the following components: 60 to 80 parts of epoxy resin, 0.1 to 5 parts of POSS (Polyhedral Oligomeric Silsesquioxane), 5 to 25 parts of polytetrafluoroethylene powder, 15 to 35 parts of a diluent, 0.5 to 5 parts of a silane coupling agent, 10 to 25 parts of a curing agent and 0.1 to 1 part of a surface active agent. The environment-friendly method and a way for preparing the self-lubricating abrasion-resistant liner coating material is provided; and the nanoscale polytetrafluoroethylene powder which is the same as the material of a fabric body is served as a filler in the formula, so that the friction coefficient is decreased greatly and the product appearance is improved. In addition, the nanoscale, the high surface energy and the similar 'bearing ball' effect of a cage shaped structure of the POSS are utilized, so that the friction reducing performance, the abrasion resisting performance and the self-lubricating performance of the coating are improved effectively.

Owner:XIAMEN UNIV +1

Wear-resistant copper alloy material and preparation method thereof

InactiveCN102051553AImprove the strengthening and toughening effectWith wear resistanceMetallurgyCopper wire

The invention provides a wear-resistant copper alloy material and a preparation method thereof. The wear-resistant copper alloy material has good performance; and the preparation method has the advantages of simple process and low production cost and is suitable for industrial production. Copper alloys are utilized as substrates for the wear-resistant copper alloy material, wherein metal wire clusters formed by copper wires and iron wires are distributed in the substrates; the diameter of the copper wires and diameter of the iron wires are 1-2mm; the diameter of the metal wire clusters is 10-15cm; the length of the copper wires is equivalent to that of the iron wires; and the copper wires and the iron wires account for 5-40% of the material by volume.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Water-lubricated bearing composite material and preparation method thereof

The invention provides a water-lubricated bearing composite material and a preparation method thereof, belonging to the technical field of composite materials. The water-lubricated bearing composite material comprises the following steps: mixing toluene diisocynate and polybutylene glycol, and carrying out an addition reaction to obtain a PU prepolymer; mixing the PU prepolymer, epoxy resin and a first organic solvent to obtain a first mixture; mixing nitrile rubber with a second organic solvent to obtain a nitrile rubber solution; mixing the first mixture, a nitrile rubber solution, an additive, a vulcanizing aid, an anti-aging agent D, a vulcanizing agent and a curing agent, and conducting drying to obtain a premix; and sequentially subjecting the premix to mixing, vulcanization and curing forming so as to obtain the water-lubricated bearing composite material. According to the invention, PU and EP are introduced into the NBR material at the same time for the first time; the introduction of PU can enhance the elasticity and damping shock absorption performance of the material and reduce the influence and loss caused by friction vibration; and the introduction of EP can greatly improve the antifriction wear resistance of the material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silt environment resistant long-life water-lubricated bearing composite material

InactiveCN105646964AImprove mechanical propertiesImprove friction and wear resistancePolymer scienceAcrylonitrile

The invention discloses a silt environment resistant long-life water-lubricated bearing composite material. The composite material is composed of a rubber matrix, a reinforcement body, a solid lubricant, an inorganic nanofiller and an organic polymer filler. The composite material has the characteristics of excellent silt inclusiveness, high mechanical strength, small friction coefficient, low wear rate and the like, and has good silt containing water lubrication performance, through the synergistic effect of the solid lubricant, the inorganic nanofiller and the organic polymer filler, the friction coefficient of a butadiene-acrylonitrile rubber water-lubricated bearing material can be effectively reduced, the antifriction and antiwear ability of the bearing material can be improved, and the service life of the material is prolonged. The material can form seal rings, bearings and other materials for use, especially in the field of pump shafts, marine tail shafts and other water-lubricated bearings under high silt content water quality working conditions.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

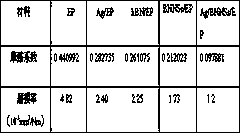

Ag/BNNSs nano material modified epoxy resin composite coating layer

InactiveCN111154376AImprove friction and wear resistanceExtended service lifeEpoxy resin coatingsEpoxyHexagonal boron nitride

The invention discloses a preparation method of a silver / hexagonal boron nitride nano hybrid material modified epoxy resin self-lubricating composite coating layer. The method mainly comprises the following steps: firstly, preparing hexagonal boron nitride nanosheets through simple hydrothermal stripping under mild reaction conditions; preparing a silver / hexagonal boron nitride nano hybrid material through a hydrothermal method, adding the silver / hexagonal boron nitride nano hybrid material into epoxy resin, a curing agent and an organic solvent according to a certain ratio, and carrying out mechanical stirring and ultrasonic dispersion to obtain a mixed solution; and finally, spraying the mixed solution on a base material, naturally drying, and curing and molding in a vacuum drying oven to obtain the epoxy resin self-lubricating composite coating layer. The prepared composite coating layer shows a low friction coefficient and high wear resistance, reaction conditions are mild, the preparation method is easy to operate, a large-area anti-friction and wear-resistant surface is easy to prepare, and the composite coating is suitable for large-scale production.

Owner:宁波宁静新材料科技有限公司

Preparation method of polyformaldehyde self-lubricating sieve plate

InactiveCN111675879AExcellent surface hardnessImprove friction and wear resistanceSievingScreeningCompression moldingPolyoxymethylene

The invention relates to the technical field of screen production, in particular to a preparation method of a polyformaldehyde self-lubricating sieve plate. Raw material source is wide, and the preparation method is simple and convenient. Polyformaldehyde is modified by taking microcapsule filler and butadiene rubber latex as raw materials, and the self-lubricating property and the toughness of the polyformaldehyde are improved. The prepared polyformaldehyde self-lubricating sieve plate has the advantages of antifriction, self-lubrication, fatigue resistance, stable size and the like. The sieve plate is simple to process and form, long in service life, free of blockage of holes in the surface of the sieve plate, high in sieving efficiency, capable of effectively preventing adhesion of wetfine particles, and suitable for sieving and grading of the wet fine particles. A sintering compression molding process is adopted, and the sieve plate is accurate in aperture, high in sieving quality, high in strength, impact-resistant, wear-resistant, high in tensile strength and high in bearing capacity.

Owner:安徽屹翔滤材有限公司

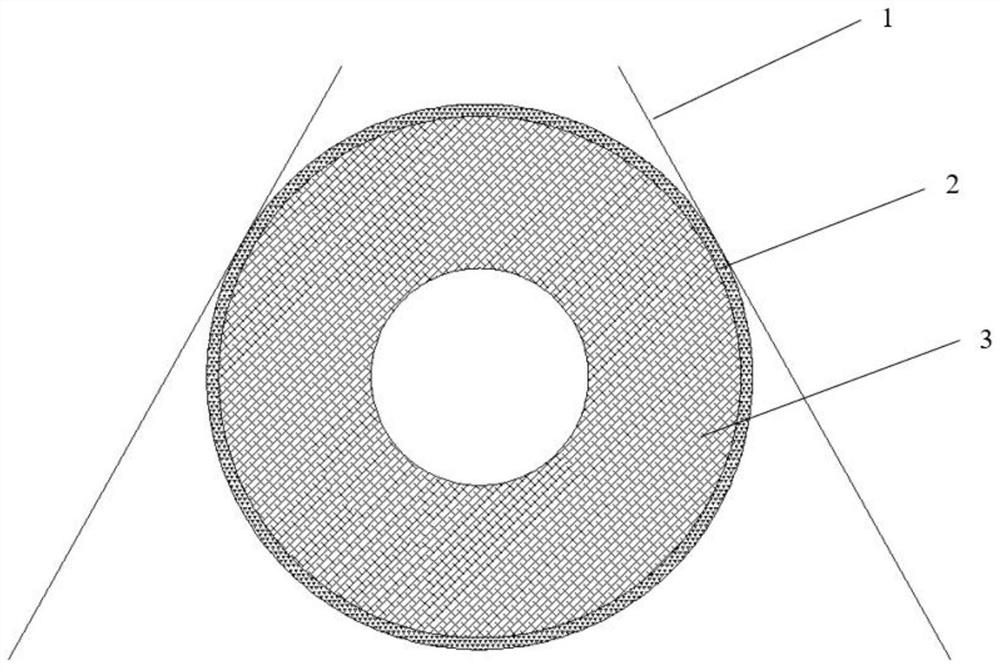

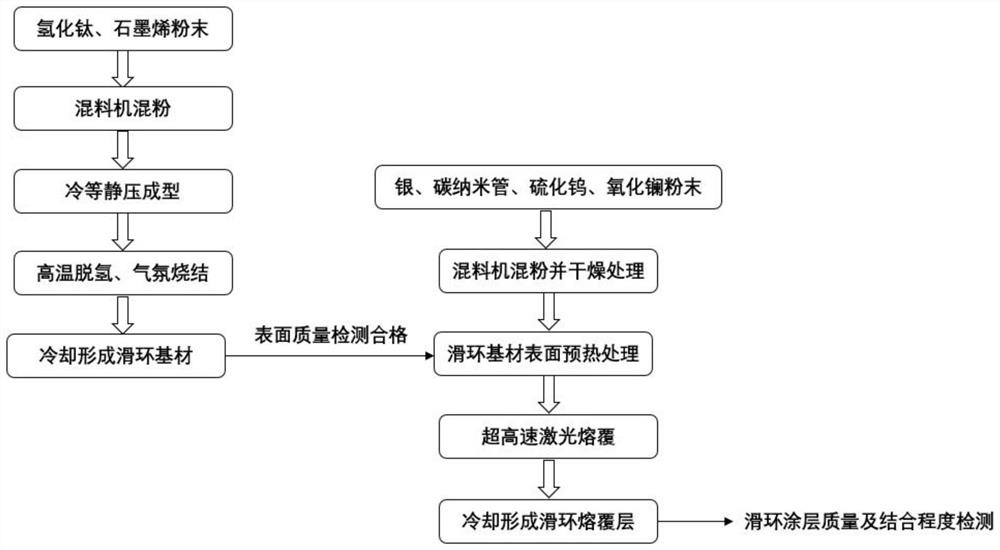

Light high-conductivity slip ring and preparation method thereof

PendingCN114069360AHigh strengthGood heat resistanceRotary current collectorMetallic material coating processesPowder metallurgyCarbon nanotube

The invention discloses a light high-conductivity slip ring and a preparation method. the light high-conductivity slip ring comprises a base material and a coating covering the base material; the base material comprises, by mass, 5-10% of graphene and 90-95% of titanium hydride; and the coating comprises, by mass, 0.5-1.3% of lanthanum oxide, 1-2% of tungsten sulfide and 7-12% of carbon nanotubes, and the balance is silver. The coating is cladded on the surface of the base material made of powder metallurgy through an ultra-high-speed laser cladding technology to form the coating of the slip ring. According to the conductive slip ring, light weight is achieved, the hardness and the arc corrosion resistance of the slip ring coating are enhanced, the antifriction and wear-resistant capacity of the working face of the slip ring is improved, the current-carrying performance is also improved compared with that of pure silver, the process is simple, and the manufacturing cost of the conductive slip ring for spaceflight is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

tialcrn&mos2/ti/al/cr multi-layered lubricating coating tool and its preparation process

ActiveCN105862004BImprove bindingImprove cutting performanceVacuum evaporation coatingSputtering coatingBoron nitrideAlloy

Owner:安徽锦鹏纺织有限公司

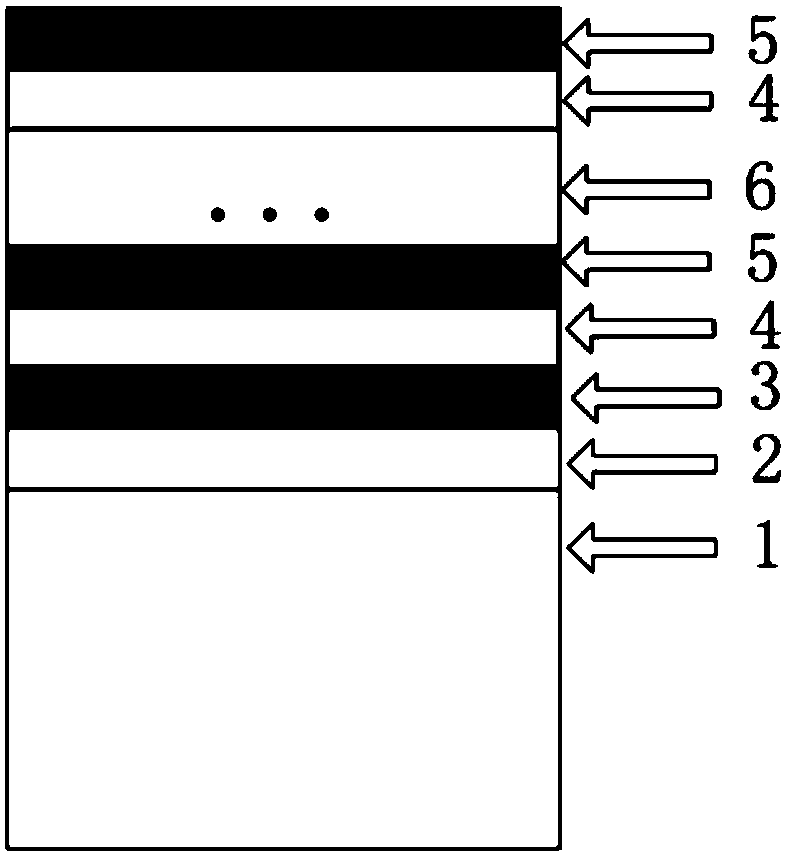

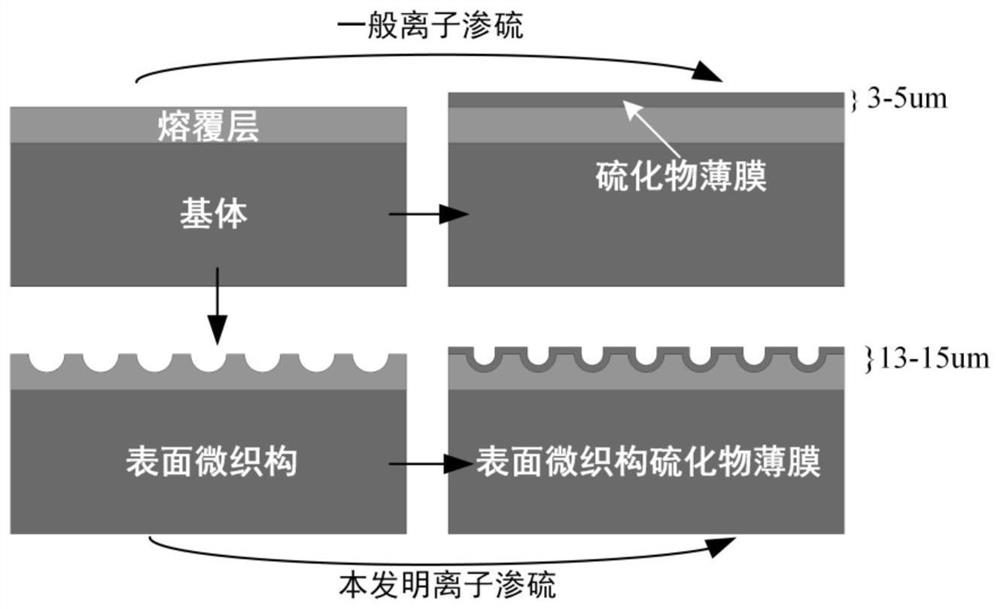

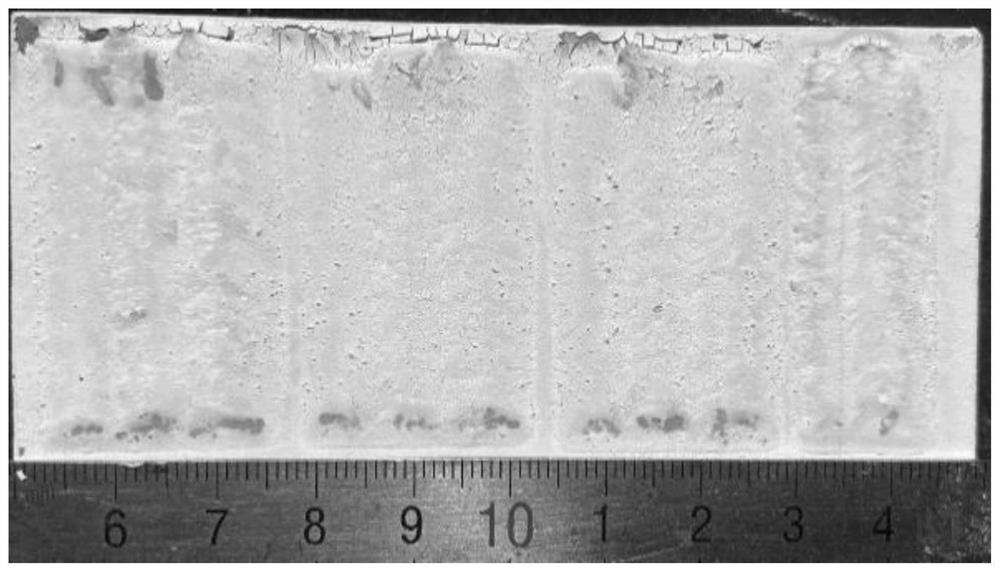

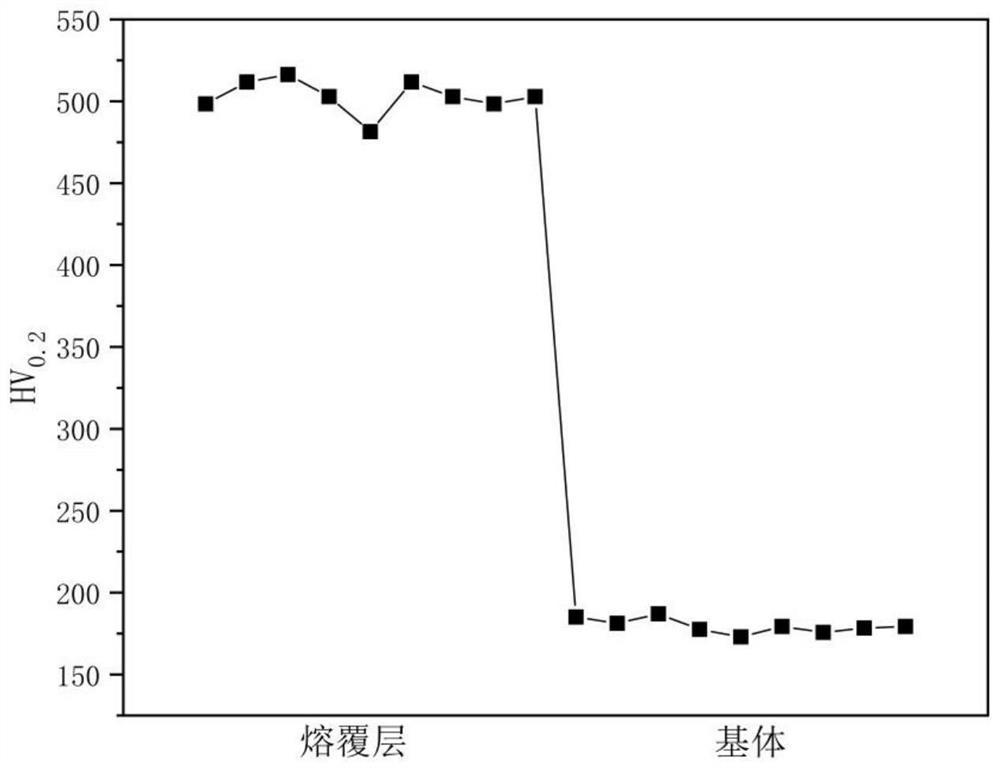

Method for improving friction reduction and wear resistance of matrix

PendingCN114395761AImprove integrityReduce coefficient of frictionSolid state diffusion coatingFriction reductionAlloy

The invention discloses a method for improving friction reduction and wear resistance of a base body, and belongs to the technical field of friction and wear. According to the method, alloy powder is cladded on the surface of a base body to form a cladding layer, then the cladding layer is subjected to texturing and sulfurizing treatment in sequence, and a textured ion sulfurizing cladding layer with antifriction and wear-resisting properties is formed on the surface of the base body, so that the antifriction and wear-resisting properties of the base body are improved, the use efficiency of the base body is improved, and the service life of the base body is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Carbon fiber reinforced polymer-based self-lubricating material and preparation method thereof

InactiveCN101747626BImprove tribological performanceImprove mechanical propertiesFiberAntimony trioxide

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com