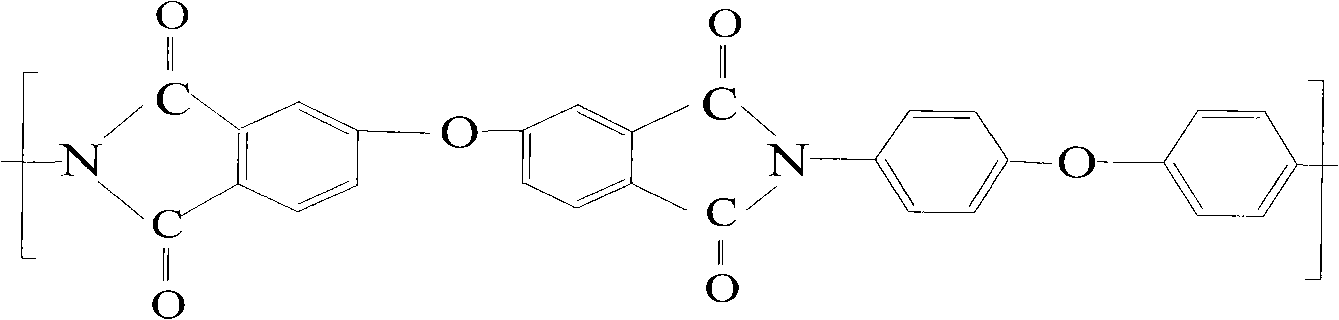

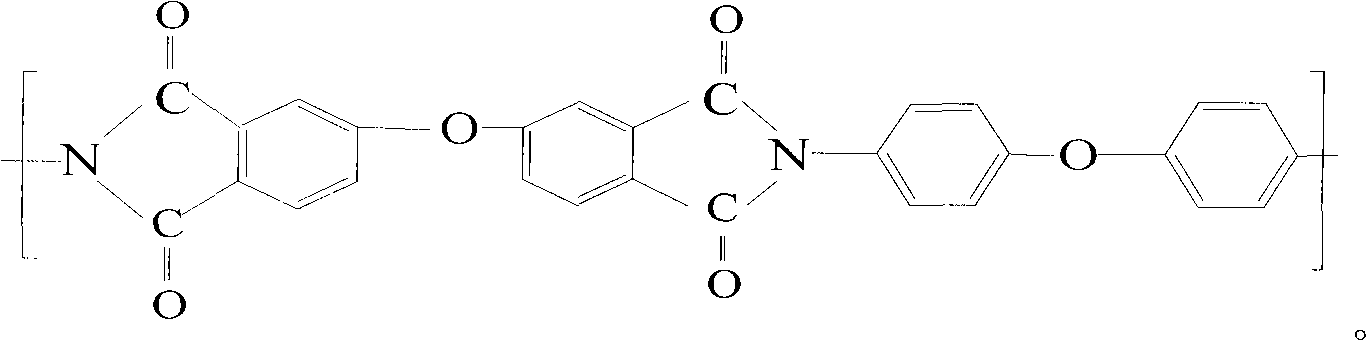

Self-lubrication composite material of polyimide

A technology of polyimide and composite materials, which is applied in the field of polyimide self-lubricating composite materials, can solve the problem of insufficient improvement of polyimide tribological properties, long time to reach steady state, low friction reduction and wear resistance, etc. problems, to achieve the effect of improving tribological properties, low wear rate, and improving anti-friction and wear-resisting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using wet mixing method, adding nano-silicon nitride to industrial alcohol, ultrasonically stirring, then adding polyimide, graphite and carbon fiber in sequence, fully mixing, and then drying by suction filtration; the composition and quality of the raw materials The fraction is polyimide 55%, carbon fiber 20%, graphite 20%, nano silicon nitride 5%. Pour the mixed molding material into the mold and hot press molding, the molding temperature is 360°C, the pressure is 38MPa, heat preservation and pressure holding for 40 minutes, and natural cooling.

Embodiment 2

[0030] Using wet mixing method, adding nano-silicon nitride to industrial alcohol, ultrasonically stirring, then adding polyimide, graphite and carbon fiber in sequence, fully mixing, and then drying by suction filtration; the composition and quality of the raw materials The fraction is polyimide 70%, carbon fiber 10%, graphite 14%, nano silicon nitride 6%. Pour the mixed molding material into the mold and hot press molding, the molding temperature is 380°C, the pressure is 36MPa, heat preservation and pressure holding for 50 minutes, and natural cooling.

Embodiment 3

[0032] Using wet mixing method, adding nano-silicon nitride to industrial alcohol, ultrasonically stirring, then adding polyimide, graphite and carbon fiber in sequence, fully mixing, and then drying by suction filtration; the composition and quality of the raw materials The fraction is polyimide 60%, carbon fiber 17%, graphite 20%, nano silicon nitride 3%. Pour the mixed molding material into the mold and hot press molding, the molding temperature is 370°C, the pressure is 40MPa, heat preservation and pressure holding for 40 minutes, and natural cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com