Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Avoid friction and wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

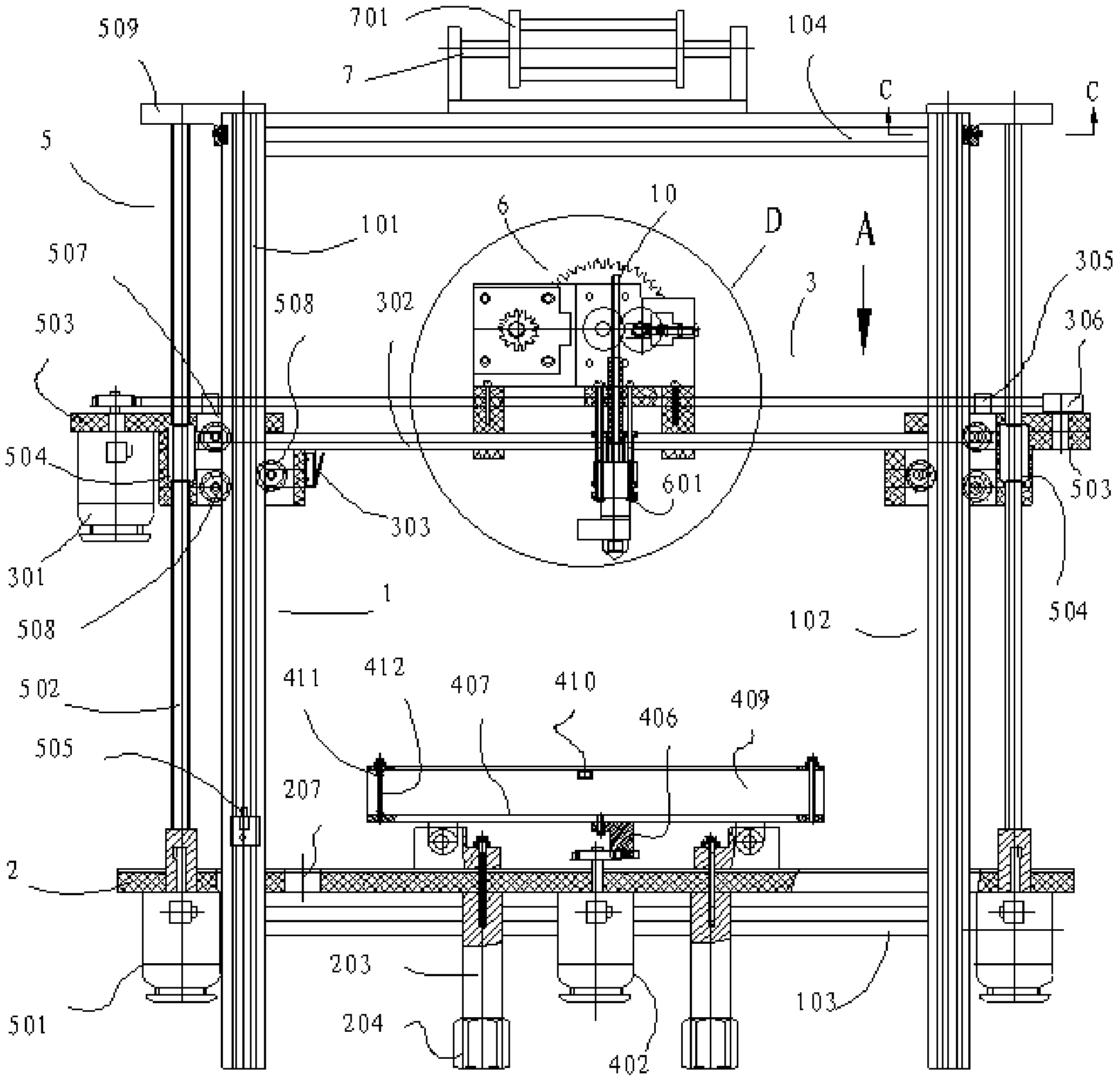

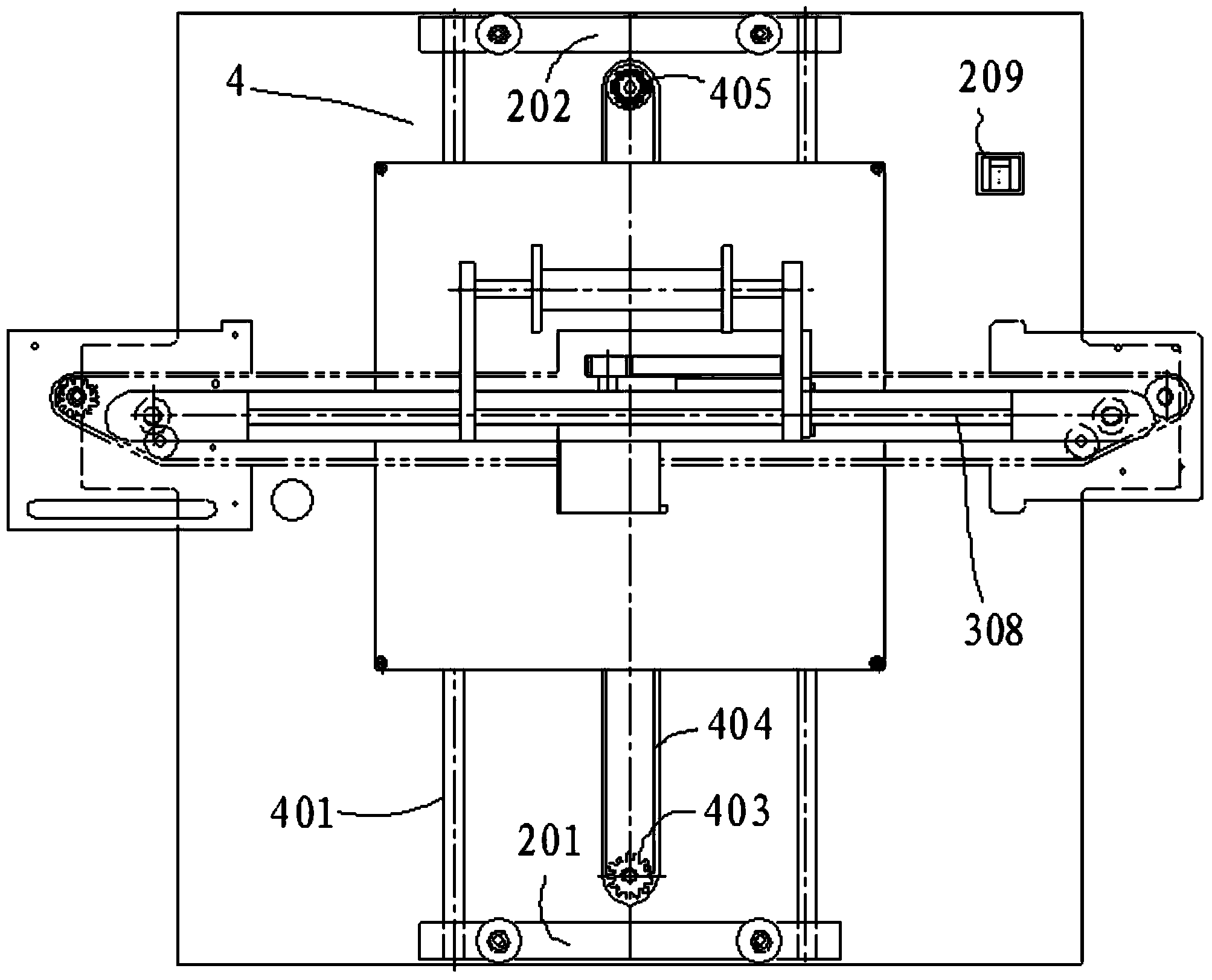

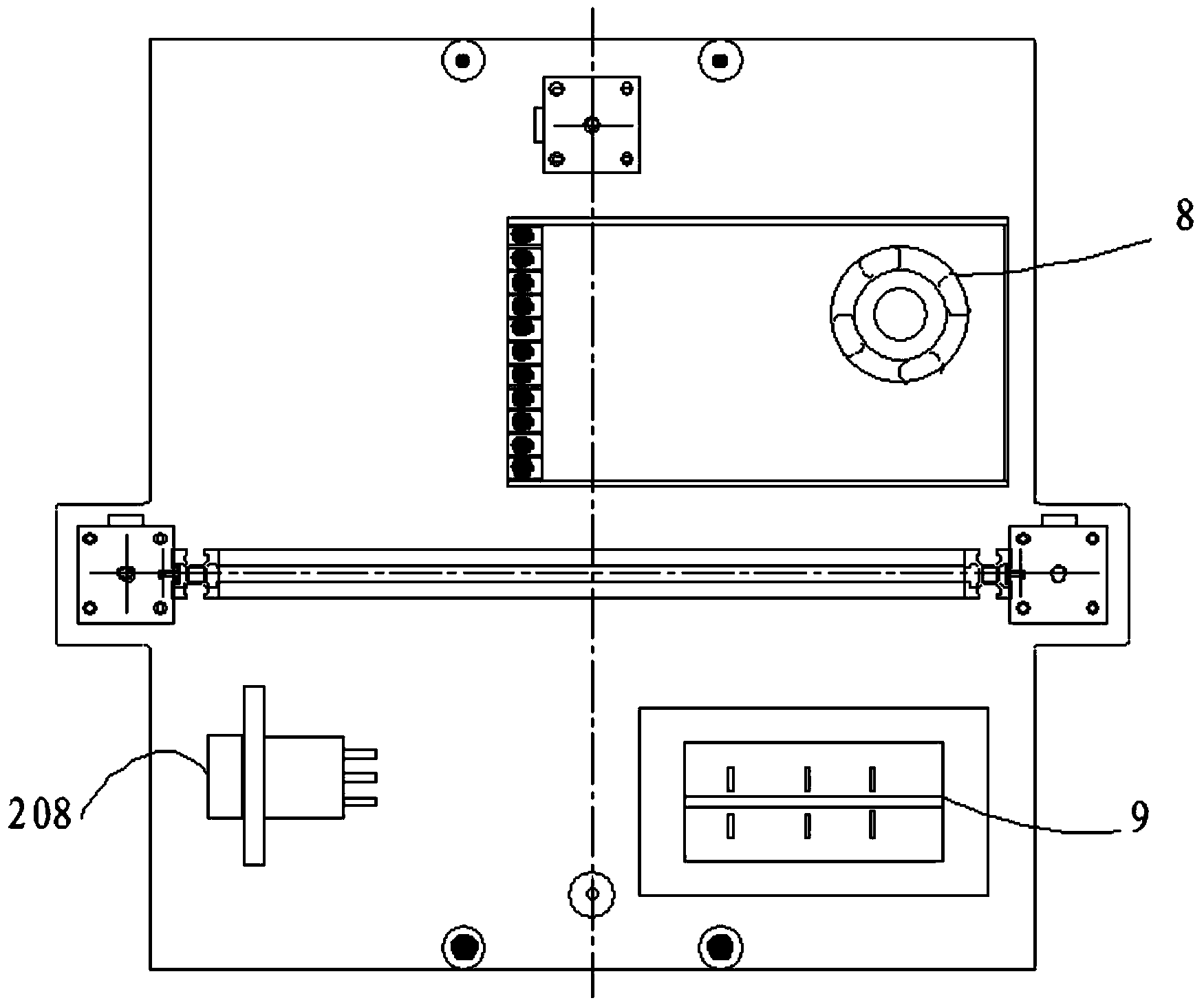

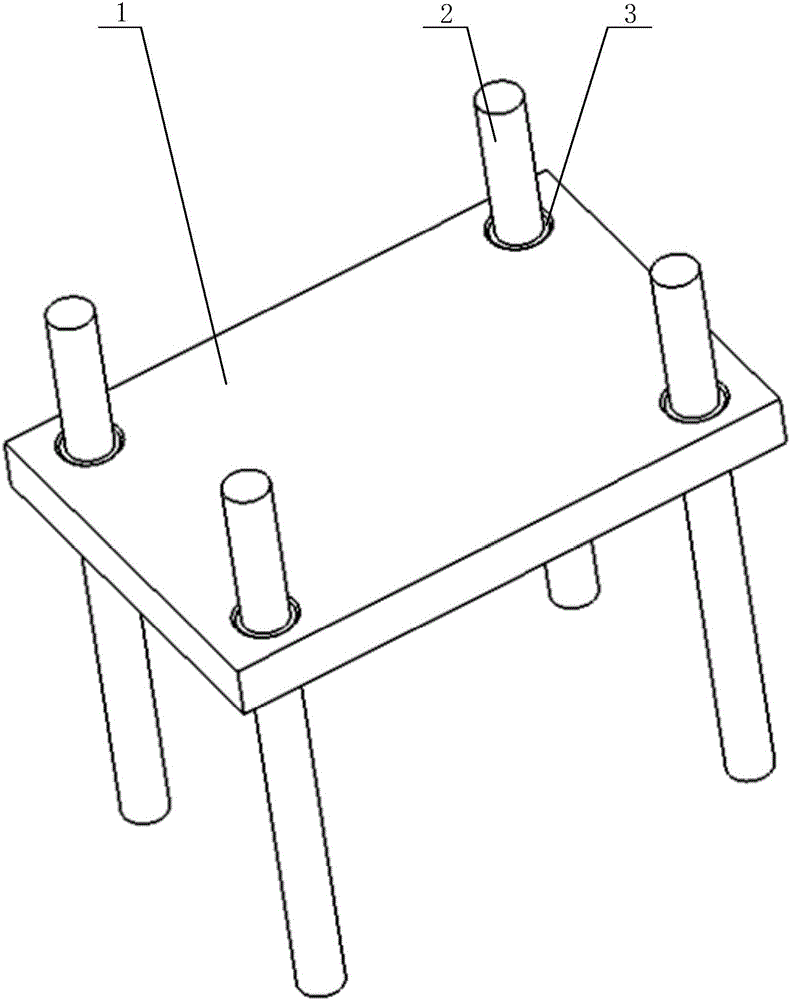

Three-dimensional (3D) printer

The invention discloses a three-dimensional (3D) printer which comprises a rack, a base, an X-axis movement system, a Y-axis movement system, a Z-axis movement system and a printing device, wherein the rack comprises a left upright post, a right upright post, an upper connecting plate and a lower connecting plate; the upper connecting plate and the lower connecting plate are connected with the left upright post and the right upright post, respectively; the base is connected with the lower connecting plate; the upper connecting plate is connected with a printing supplies connecting rack; the printing supplies connecting rack is connected with a printing supplies fixing disc; the printing device is connected with the X-axis movement system; the X-axis movement system is connected with the Z-axis movement system; the Z-axis movement system is connected with a guide rail of the left upright post and the right upright post; the Y-axis movement system is connected with the base; the X-axis movement system is provided with an X-axis movement guide rail through which the printing device moves; a power supply and a controller which are connected with each other are arranged at the bottom of the base; the controller is connected with the X-axis movement system, the Y-axis movement system, the Z-axis movement system and the printing device. The 3D printer is simple and compact in structure, small in size and low in manufacturing cost.

Owner:UNIV OF JINAN

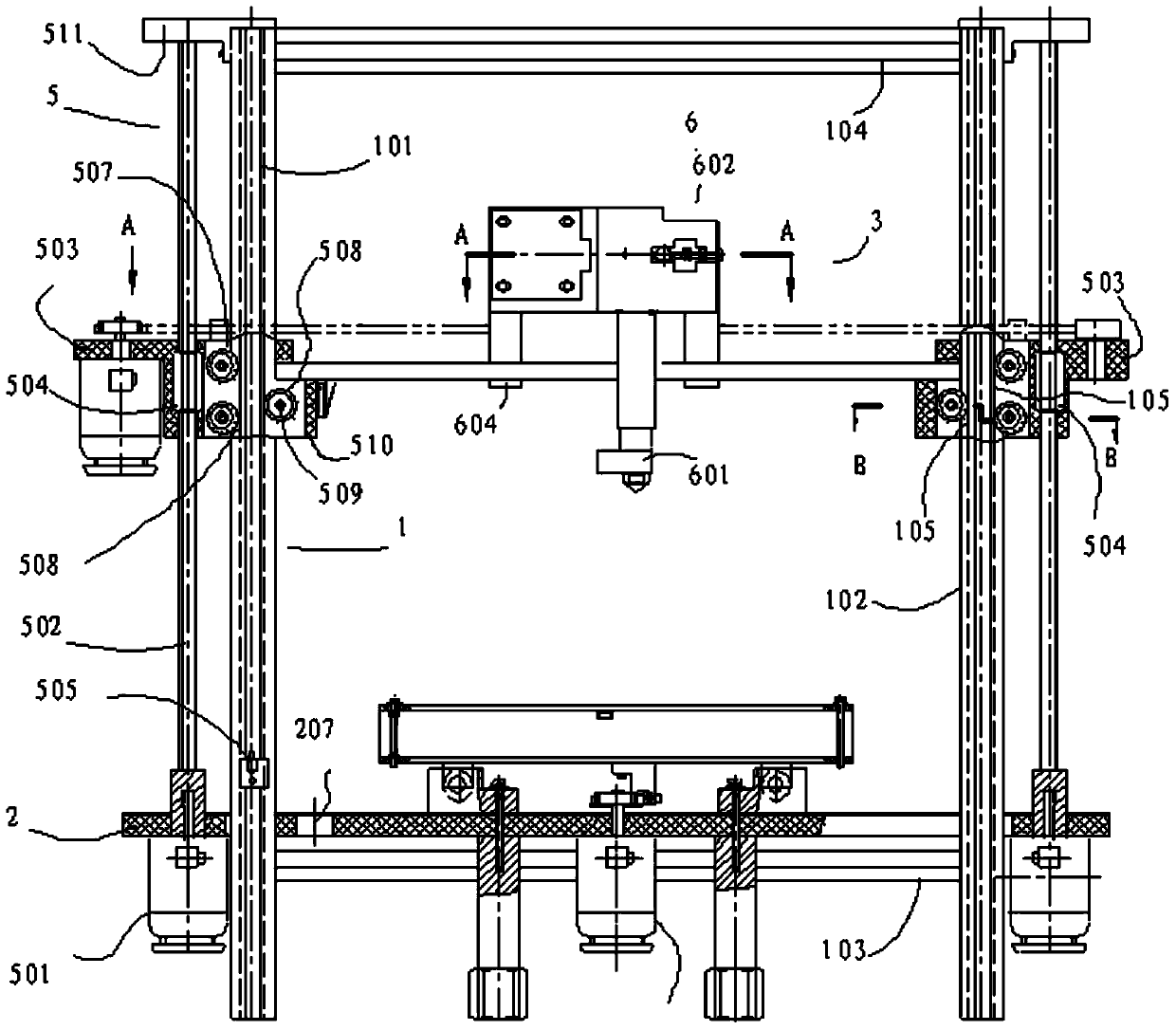

Frequency-division multiplexing (FDM)-based three-dimensional (3D) printer

InactiveCN103802322AMeet consumer demandSimple structureNumerical controlFrequency-division multiplexing

The invention discloses a frequency-division multiplexing (FDM)-based three-dimensional (3D) printer, comprising a frame, a base, an X-axis mobile system, a Z-axis mobile system and a printing device, wherein the printing device is connected with the X-axis mobile system; the X-axis mobile system is connected with the Z-axis mobile system; the Z-axis mobile system is connected with a guide rail of an upright post; a power supply and a controller are arranged on the base; the controller is connected with the Z-axis mobile system; the Z-axis mobile system comprises a third numerical control motor, a left screw and a right screw, a Z-axis fixed base and a limit switch; the left screw and the right screw are respectively arranged at the outer sides of a left upright post and a right upright post; the third numerical control motor is connected with the lower ends of the screws; the screws are connected with screw nuts; the screw nuts are connected with the Z-axis fixed base; the Z-axis fixed base is connected with the X-axis mobile system; a fixed base through hole is formed in the Z-axis fixed base; the left upright post and the right upright post pass through the fixed base through hole; the bearing is matched with the guide rail of the upright post. Thus, the FDM-based 3D printer is simple and compact in structure, small in volume and low in manufacturing cost.

Owner:UNIV OF JINAN

Diamond coating cutter, and preparation method and application thereof in high speed graphite processing

ActiveCN105563665AReduce cutting shock and vibrationAvoid breakingChemical vapor deposition coatingStone-like material working toolsHardnessLow friction

The invention discloses a diamond coating cutter, and a preparation method and the application thereof in high speed graphite processing. The diamond coating cutter comprises a cutter tip, a blade and a clamping cutter holder, wherein the clamping cutter holder is made of a hard alloy matrix, the cutter tip and the blade are coated with diamond coatings on matrix materials, the diamond coating cutter is characterized in that the end cutting edge front angle gamma o1 of the blade is 2 to 6 degrees, the end cutting edge rear angle alpha 1 is 5 to 13 degrees, the peripheral cutting edge front angle gamma o2 is 5 to 15 degrees, the peripheral cutting edge rear angle alpha 2 is 10 to 14 degrees, and the helical angle beta is 15 to 45 degrees. The diamond coating cutter provided by the invention has the characteristics of high hardness, wear resistance, low friction coefficient, good heat conduction and the like, is suitable for high speed graphite processing, can effectively overcome frictional wear caused by graphite dust to the surface of the cutter, and is classified as an ideal cutter for cutting graphite.

Owner:GUANGDONG UNIV OF TECH

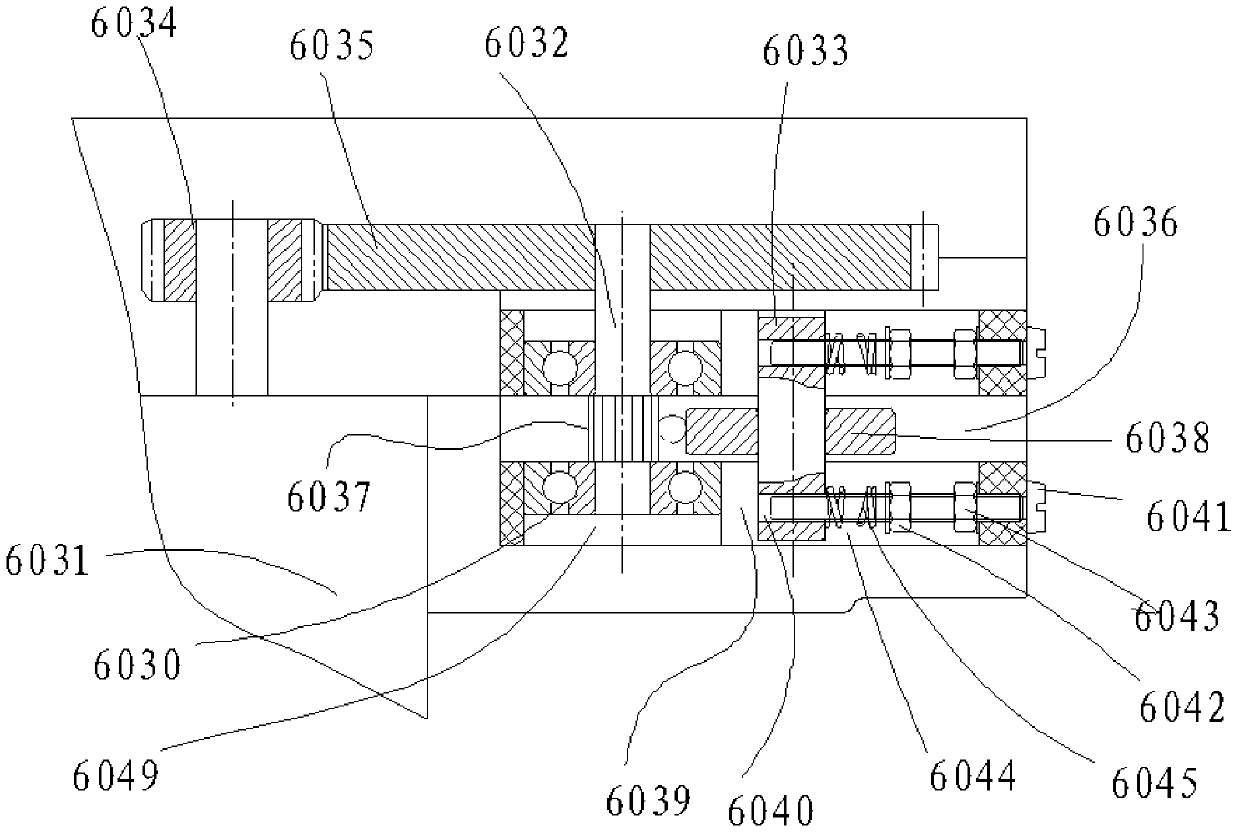

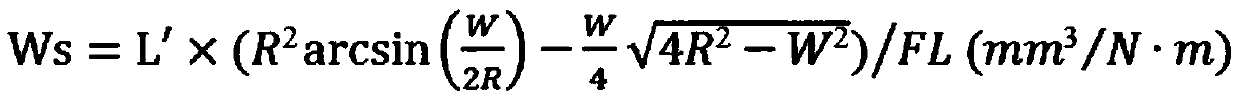

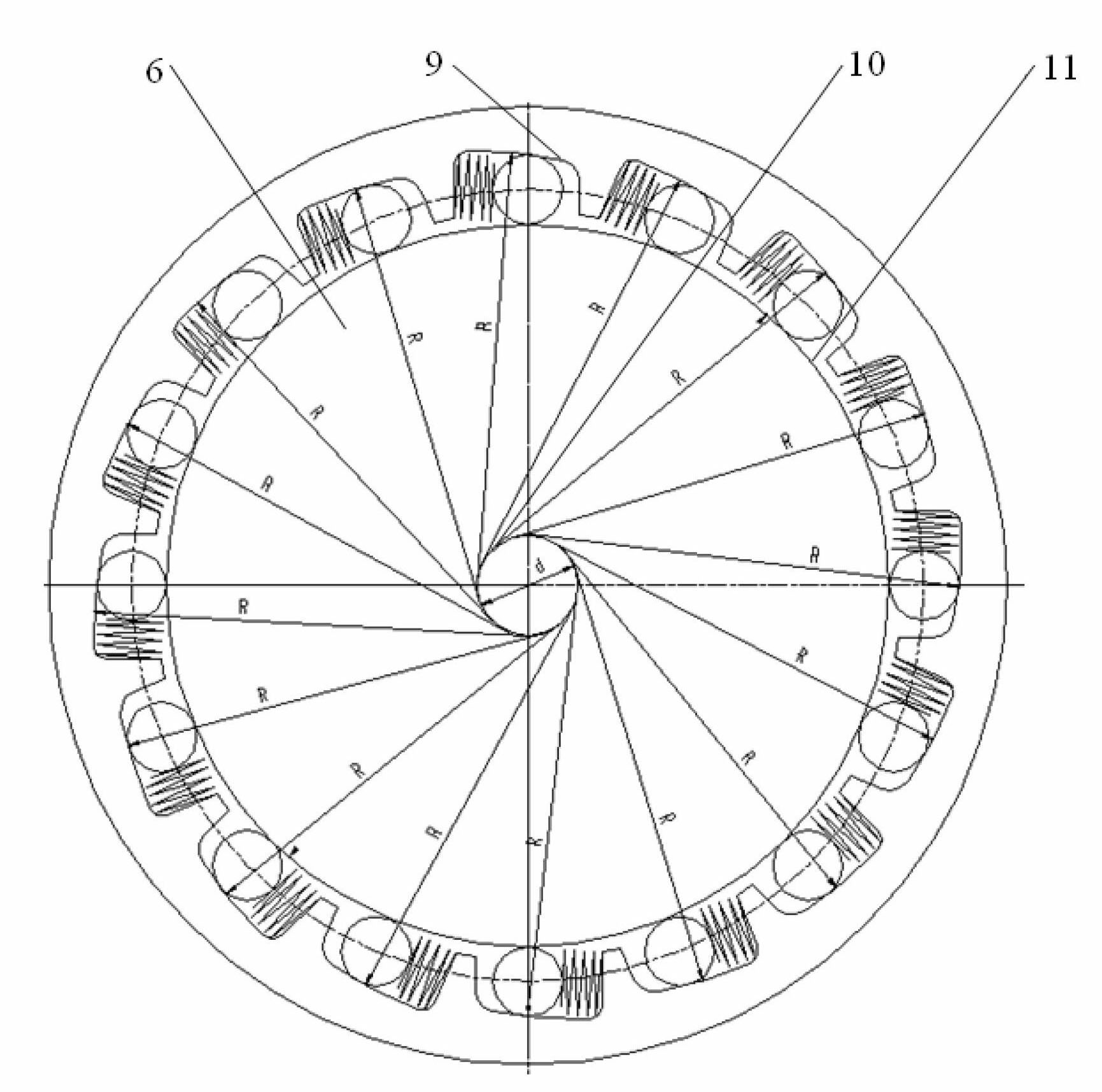

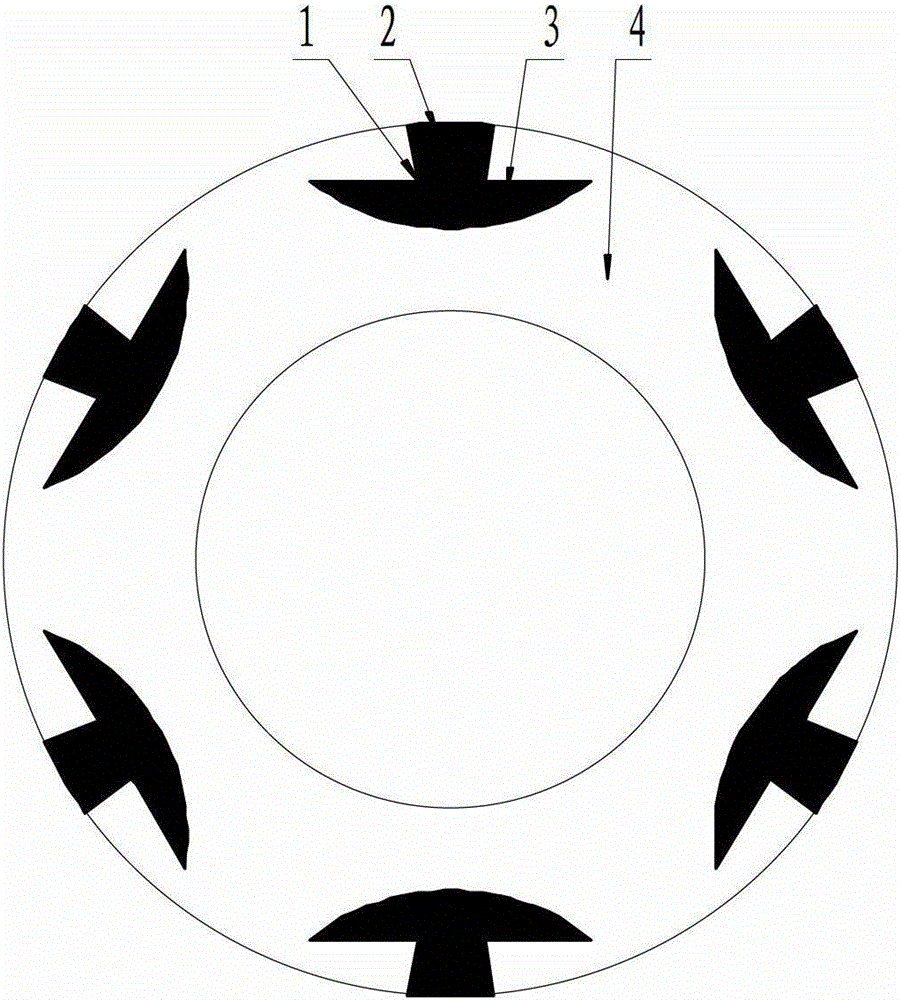

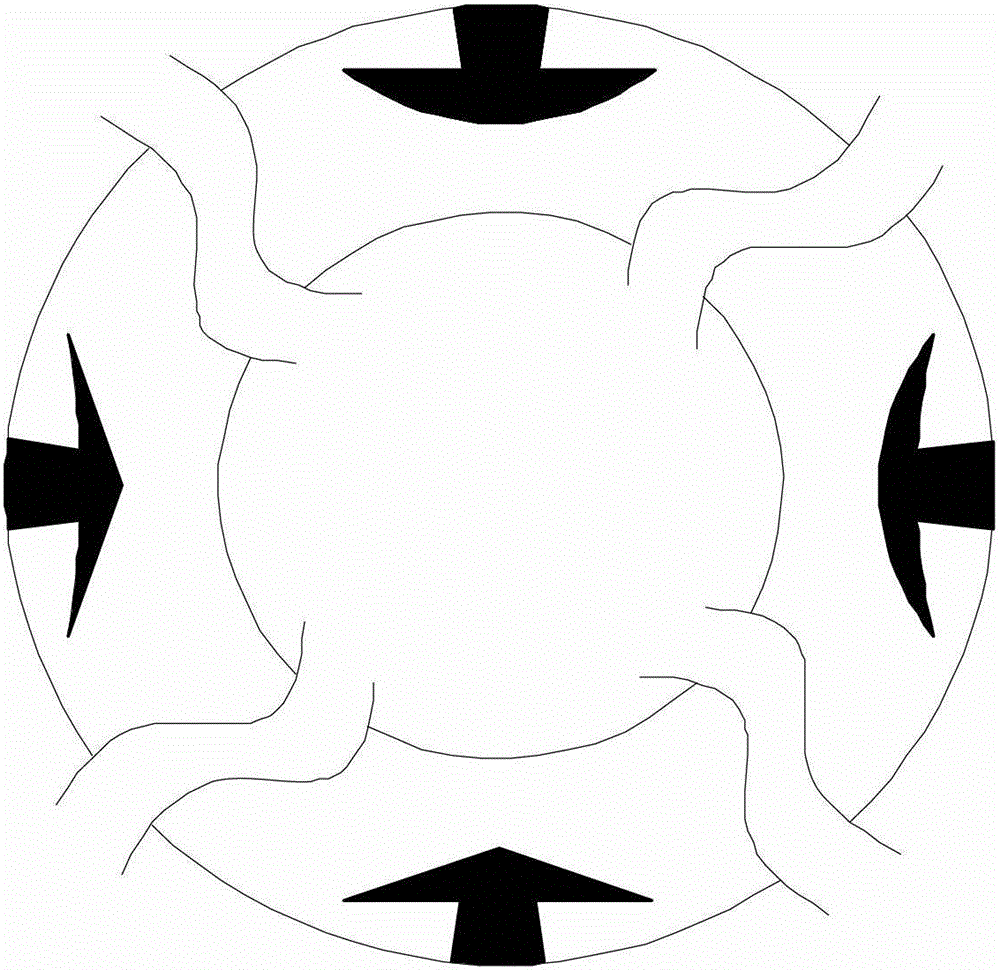

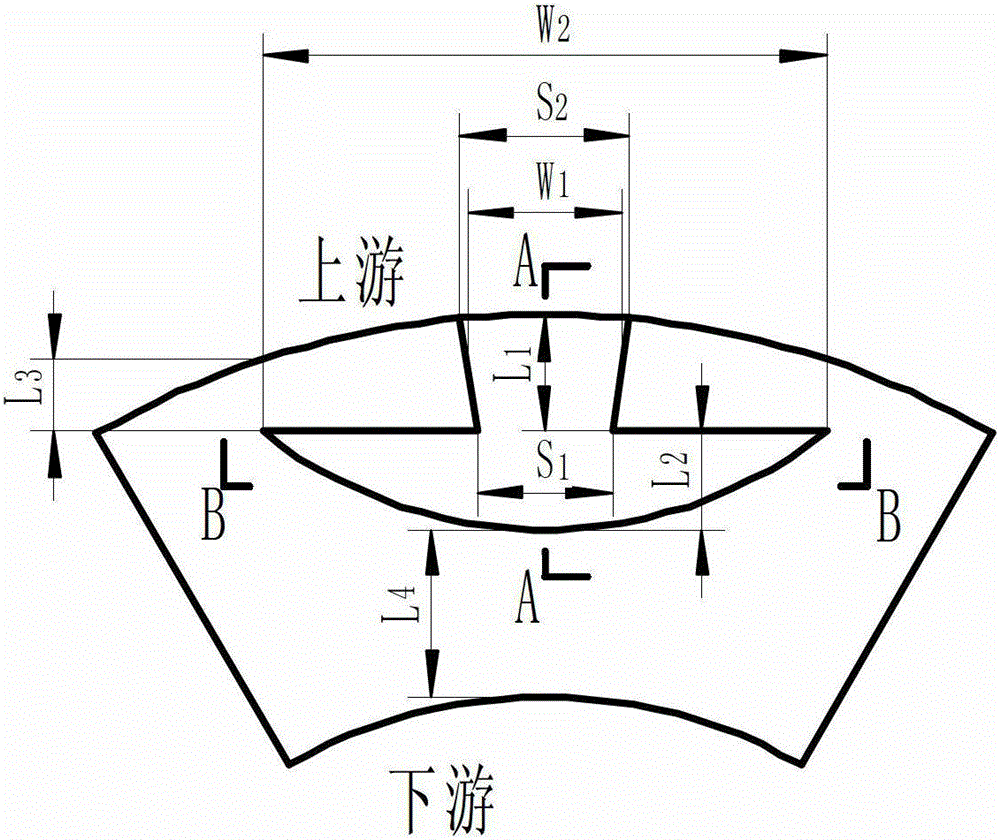

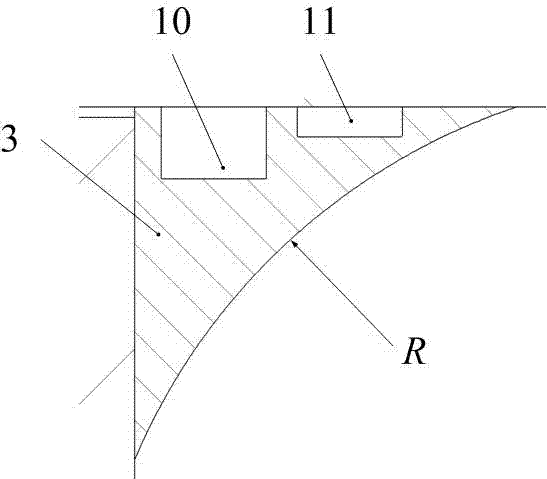

Mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure

A mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure comprises two sealing rings of mechanical seal. The two sealing rings refer to a movable ring and a static ring. A plurality of mushroom-like grooves for sealing liquid are evenly distributed on the circumference of the sealing end face of at least one of the movable ring and the static ring. Each mushroom-like groove is composed of a drainage groove and a returning groove. Each drainage groove extends in the radial direction, and the width of each drainage groove gradually becomes narrower from an upper stream (a higher-pressure side) to a lower stream (a lower-pressure side) along the end face in the radial direction. Each returning groove extends in the circumference direction and the radial direction and is in the shape of an arc, an oval arc, a curved arc, or a straight line. The tail end of each drainage groove is connected with each returning groove. Areas which are not provided with grooves and are between the mushroom-like grooves are sealing weirs. A ring belt formed by an area which is not provided with grooves on the circumference of the end face is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

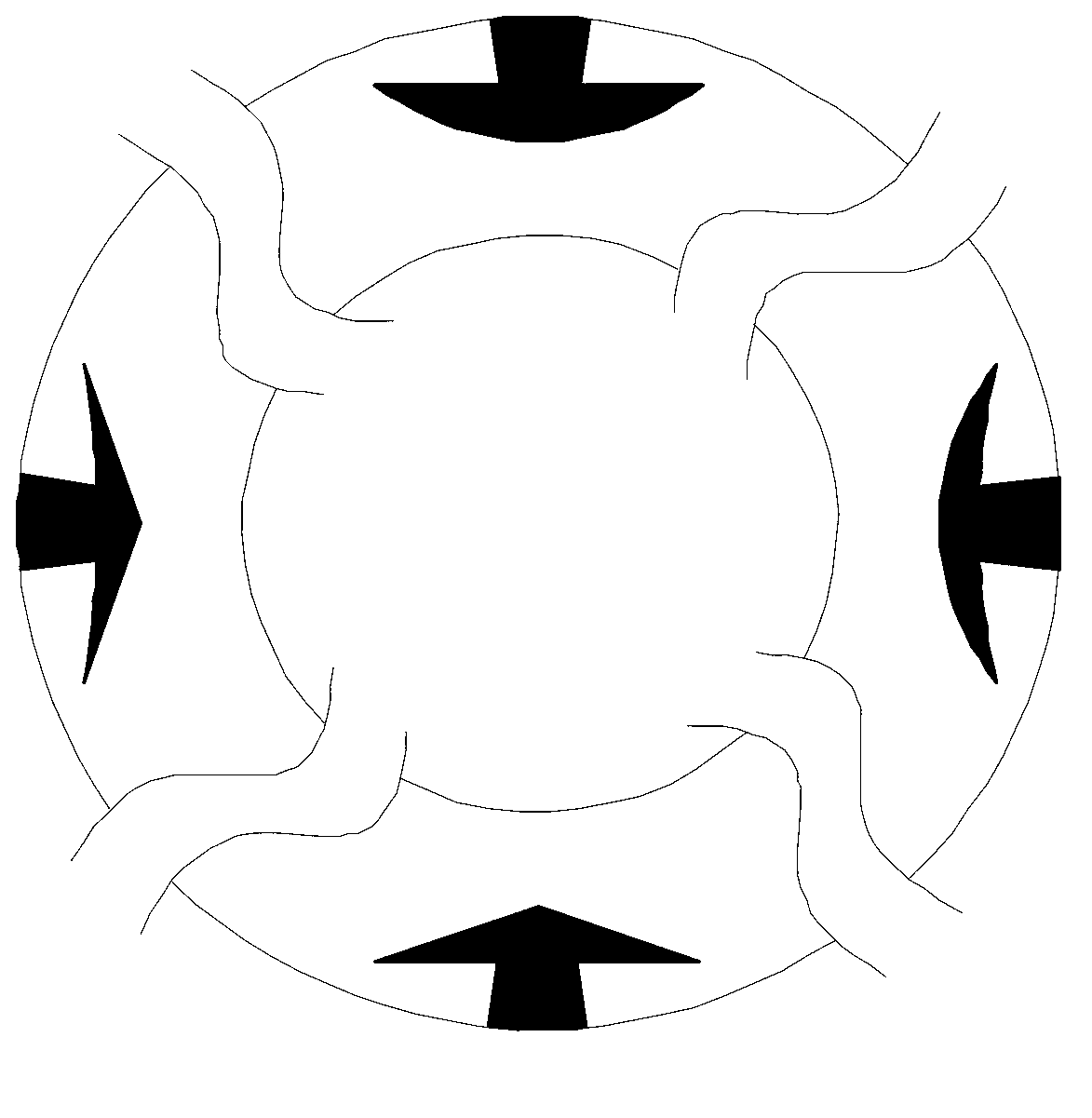

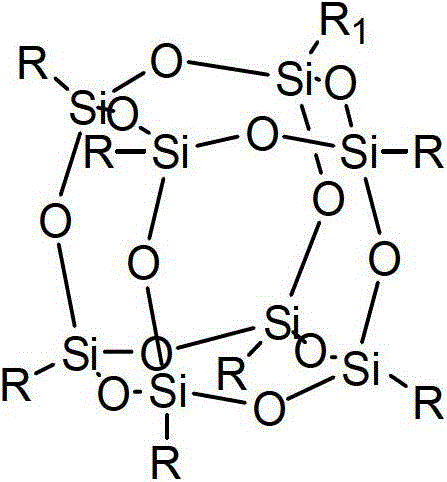

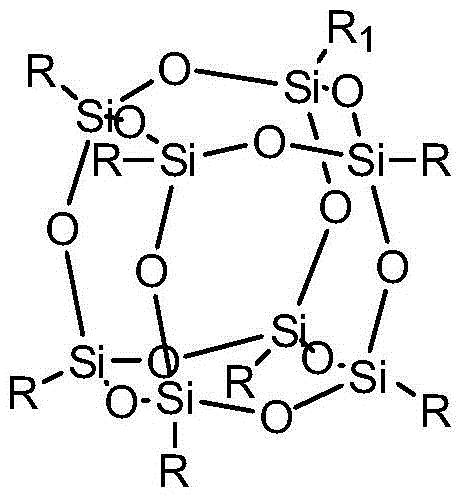

Fabric liner coating material of self-lubricating joint bearing and preparation method thereof

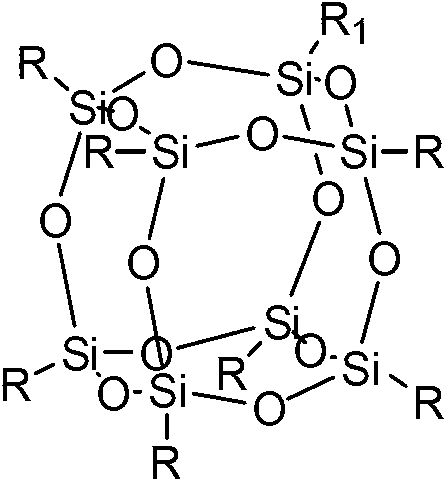

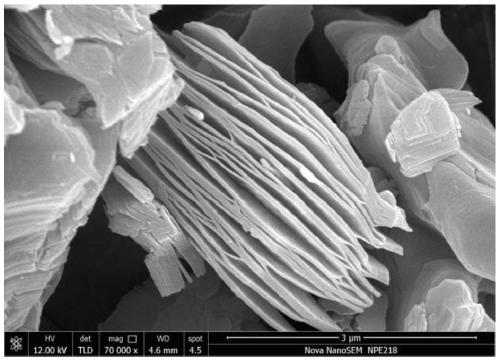

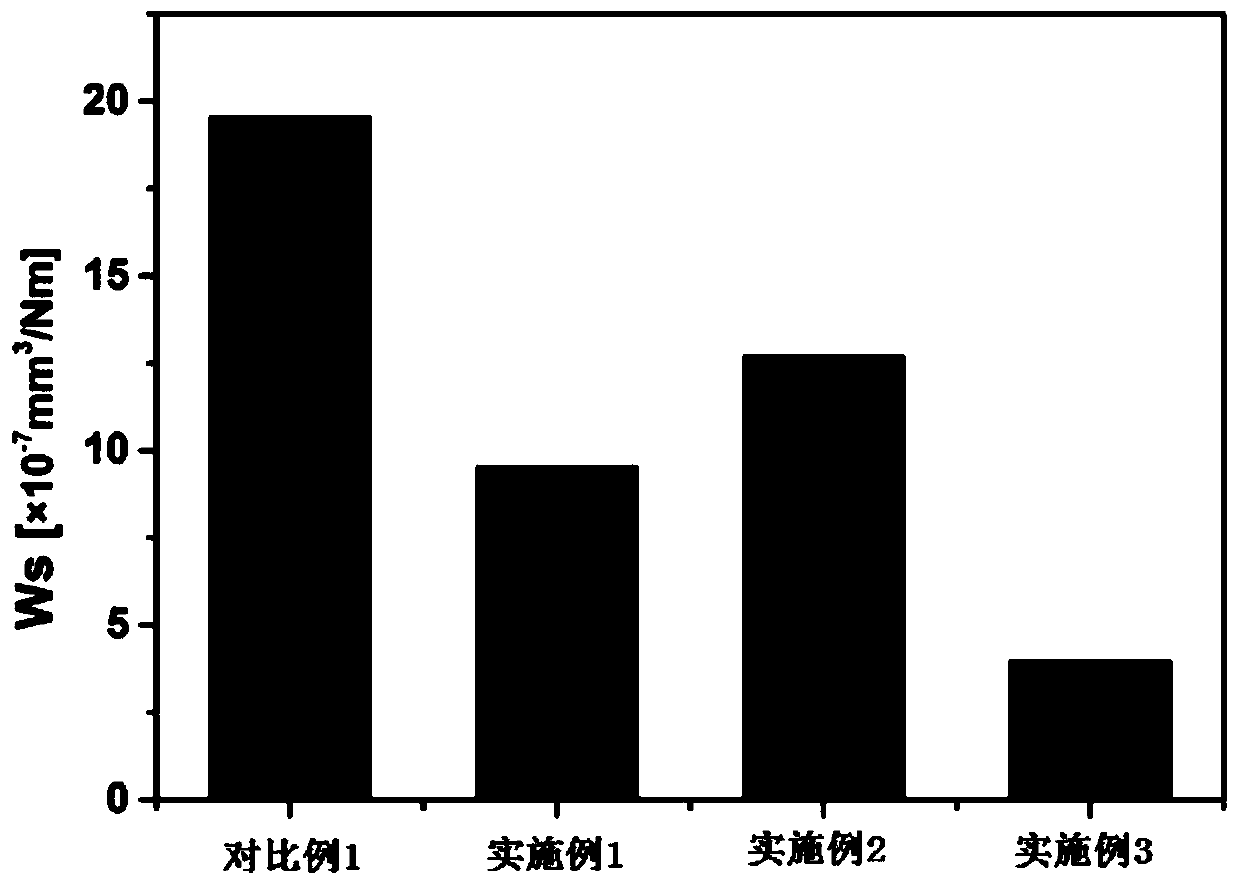

The invention provides a fabric liner coating material of a self-lubricating joint bearing and a preparation method thereof, and relates to a self-lubricating coating material and the preparation method thereof. The coating comprises the following components: 60 to 80 parts of epoxy resin, 0.1 to 5 parts of POSS (Polyhedral Oligomeric Silsesquioxane), 5 to 25 parts of polytetrafluoroethylene powder, 15 to 35 parts of a diluent, 0.5 to 5 parts of a silane coupling agent, 10 to 25 parts of a curing agent and 0.1 to 1 part of a surface active agent. The environment-friendly method and a way for preparing the self-lubricating abrasion-resistant liner coating material is provided; and the nanoscale polytetrafluoroethylene powder which is the same as the material of a fabric body is served as a filler in the formula, so that the friction coefficient is decreased greatly and the product appearance is improved. In addition, the nanoscale, the high surface energy and the similar 'bearing ball' effect of a cage shaped structure of the POSS are utilized, so that the friction reducing performance, the abrasion resisting performance and the self-lubricating performance of the coating are improved effectively.

Owner:XIAMEN UNIV +1

Self-lubricating composite material as well as preparation method and application thereof

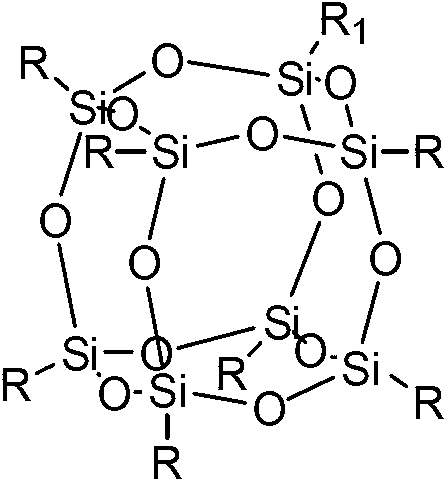

The invention relates to the technical field of composite materials, in particular to a self-lubricating composite material and a preparation method and application thereof. The self-lubricating composite material is prepared from the following raw materials: a two-dimensional layered nano material, epoxy resin and a curing agent, wherein each sheet layer of the two-dimensional layered nano material consists of a plurality of layers of MXene units; the mass ratio of the two-dimensional layered nano material to the epoxy resin is (0.1-40):(60-99.9); and the mass of the curing agent is 10-15% ofthe mass of the epoxy resin. The two-dimensional layered nano material with a graphene-like structure is added into the epoxy resin matrix, so that the self-lubricating composite material with excellent tribological properties under boundary and mixed lubrication conditions is obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spinning finish for asphalt carbon fiber

The invention belongs to the technical field of spinning auxiliary for an asphalt-based carbon fiber precursor fiber, and particularly relates to a spinning finish for an asphalt carbon fiber, and the spinning finish is mainly used for solving the problems that the existing spinning finish for asphalt-based carbon fiber can be molten when used for spinning a large bundle of asphalt-based carbon fibers. According to the technical scheme, the spinning finish for asphalt carbon fiber is prepared by performing ultrasonic mixing on the following raw materials in percentage by weight for 0.5h-3h: 5%-45% of carbon powder, 3%-6% of silicone oil, 0.1%-3% of antistatic agent, 0-0.3% of cohesive agent, 0.02%-2% of wetting agent, 0-0.2% of fiber splitting agent and the balance of deionized water. The spinning finish has the following advantages that the melting phenomenon in a process of spinning a large bundle of asphalt-based carbon fibers cannot exist, the friction and wear of fiber surface and a roller during production can be prevented, and the spinning finish has good antistatic property and toughness effect.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

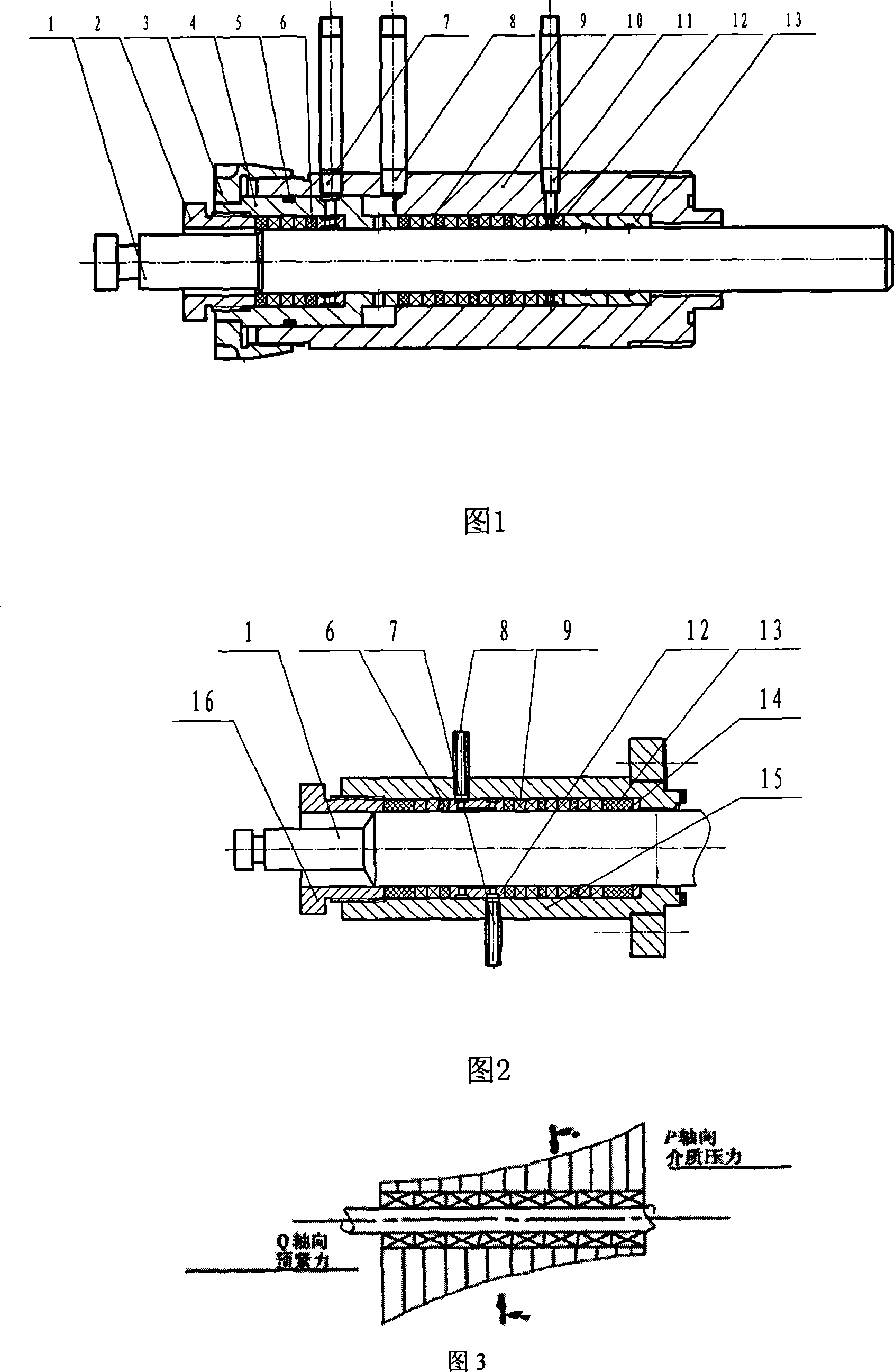

High-pressure-resistant wear-resisting contact type reciprocation sealing with washing ring

InactiveCN101070841AAvoid solid friction and wearExtended service lifePositive displacement pump componentsLiquid fuel engine componentsReciprocating pumpEngineering

A high pressure resistance and anti-abresive reciprocating seal with flushing ring relates to the lunger pistom of reciprocating pump and packing seal, it is characterized in that two set of packing seal combines with a set of muff clearance seal, namely two guide sleeve closing side of cylinder combines with a flushing ring and main packing seal with subsidiary packing seal closing air. The gland of main packing seal is a seal box of subsidiaty one. Injecting flushing lubricating oil into between main and subsidiary packing seal, the front-end of main packing seal has a flushing ring, which adopting synchronized hydraulic oil to be as flush fluid of packing box, the effect of flush fuid is that flushing the particle medium between lunger pistom and main packing seal, at the same tine between filling and lunger pistom formed a fluid film to avoid directing friction between filling and lunger pistom,and takes away heat caused by friction, which can prolong the life of seal. The invention is applicable to all conveyors solid particles media reciprocating pump.

Owner:JIANGSU UNIV

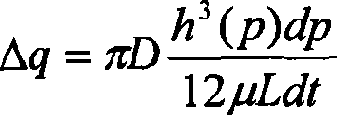

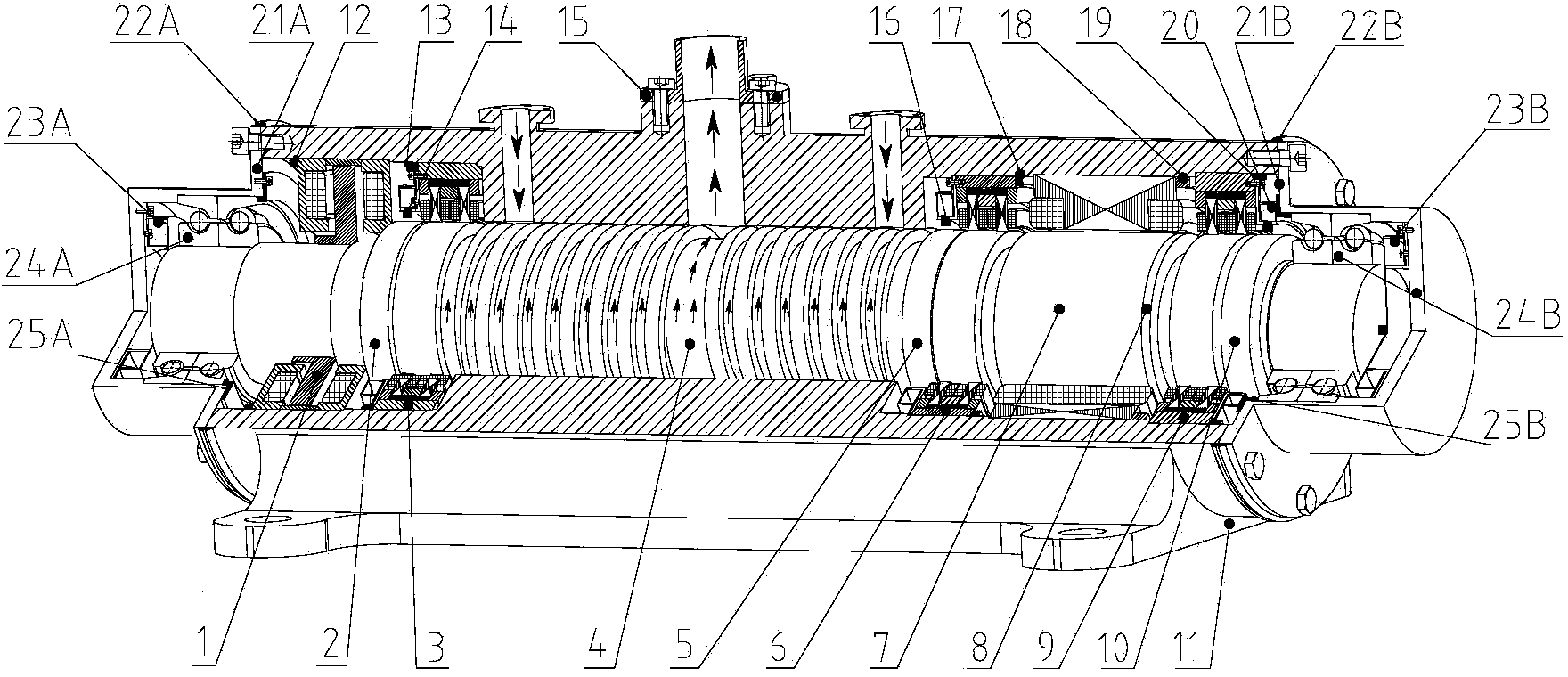

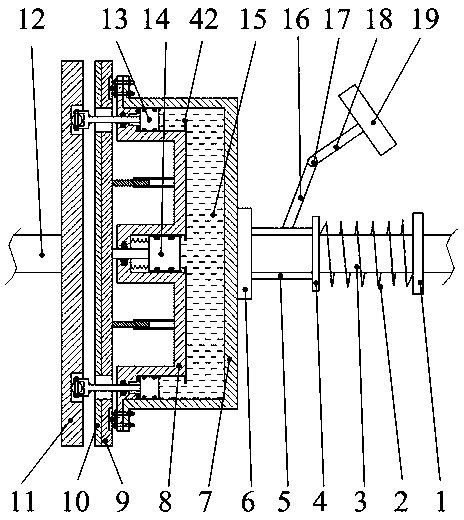

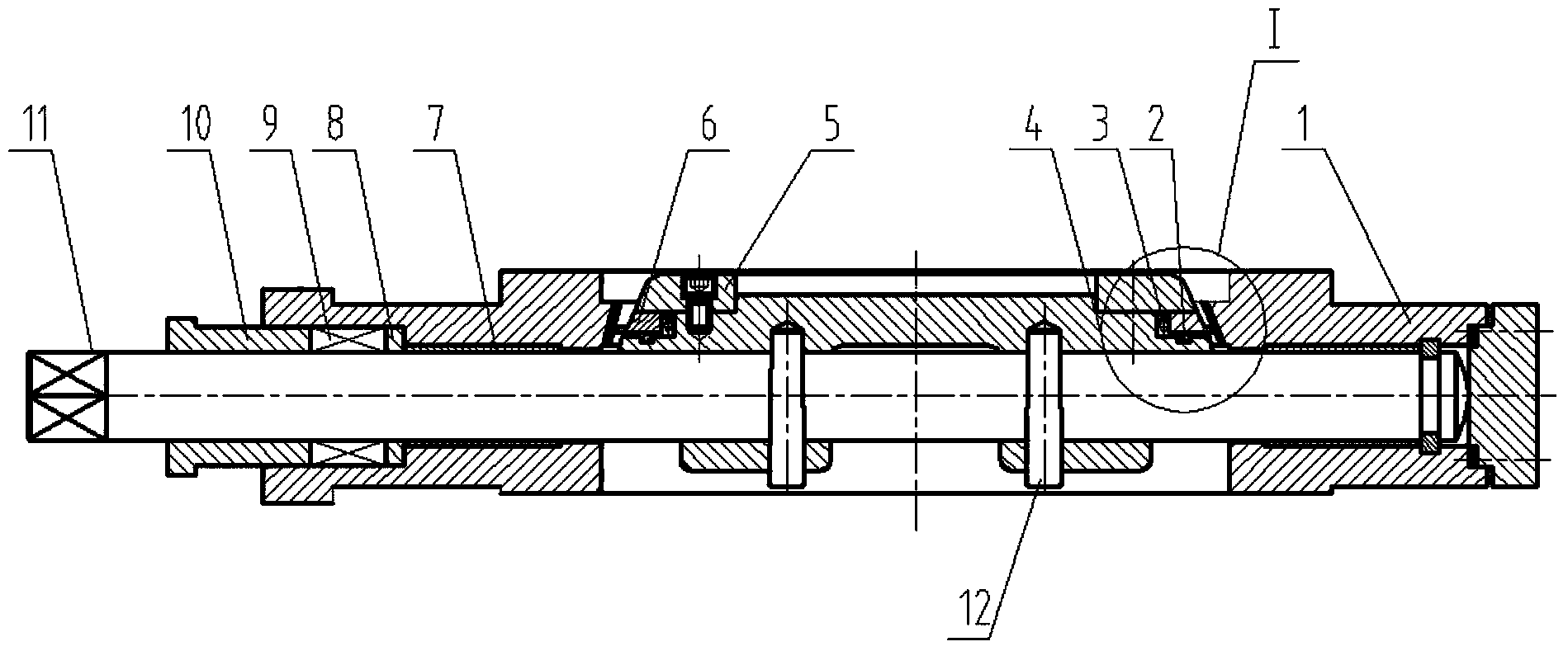

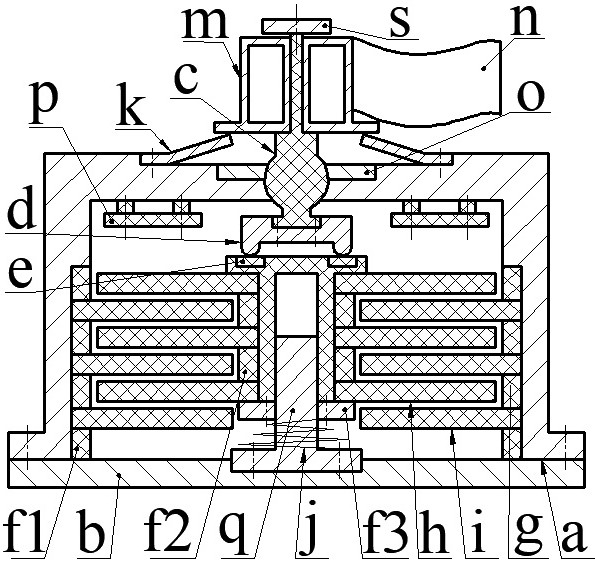

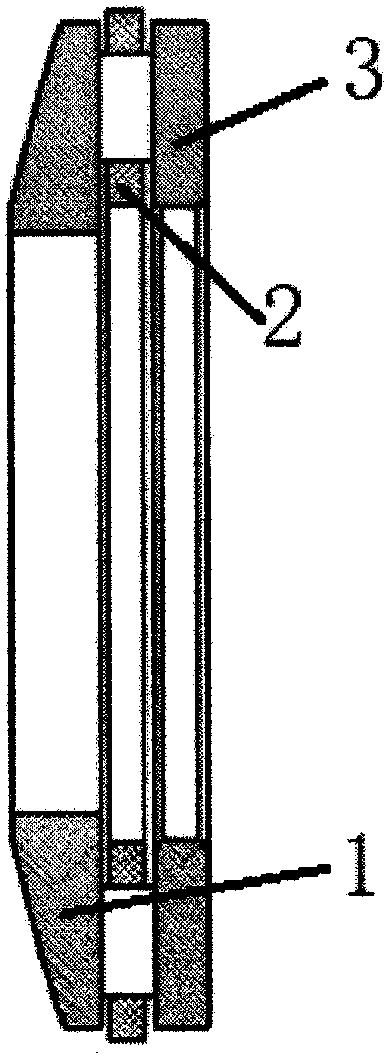

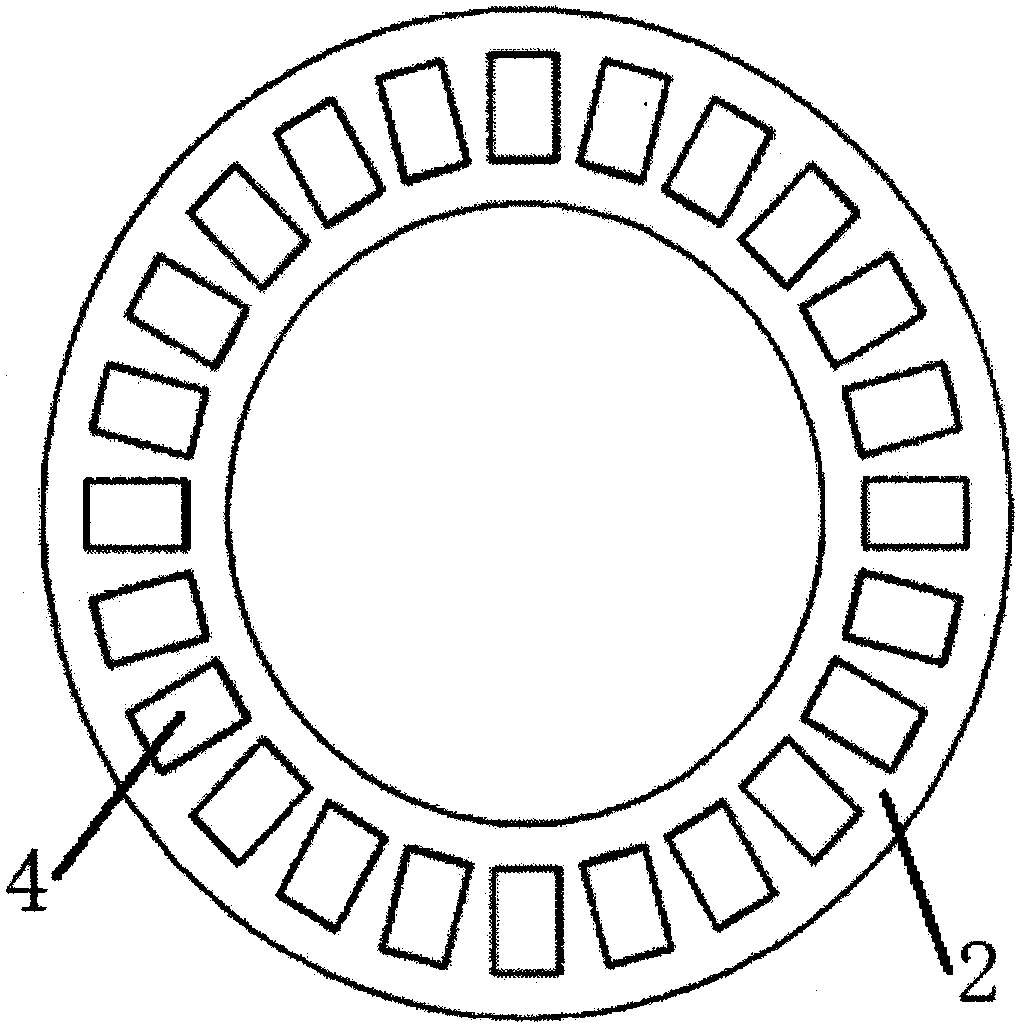

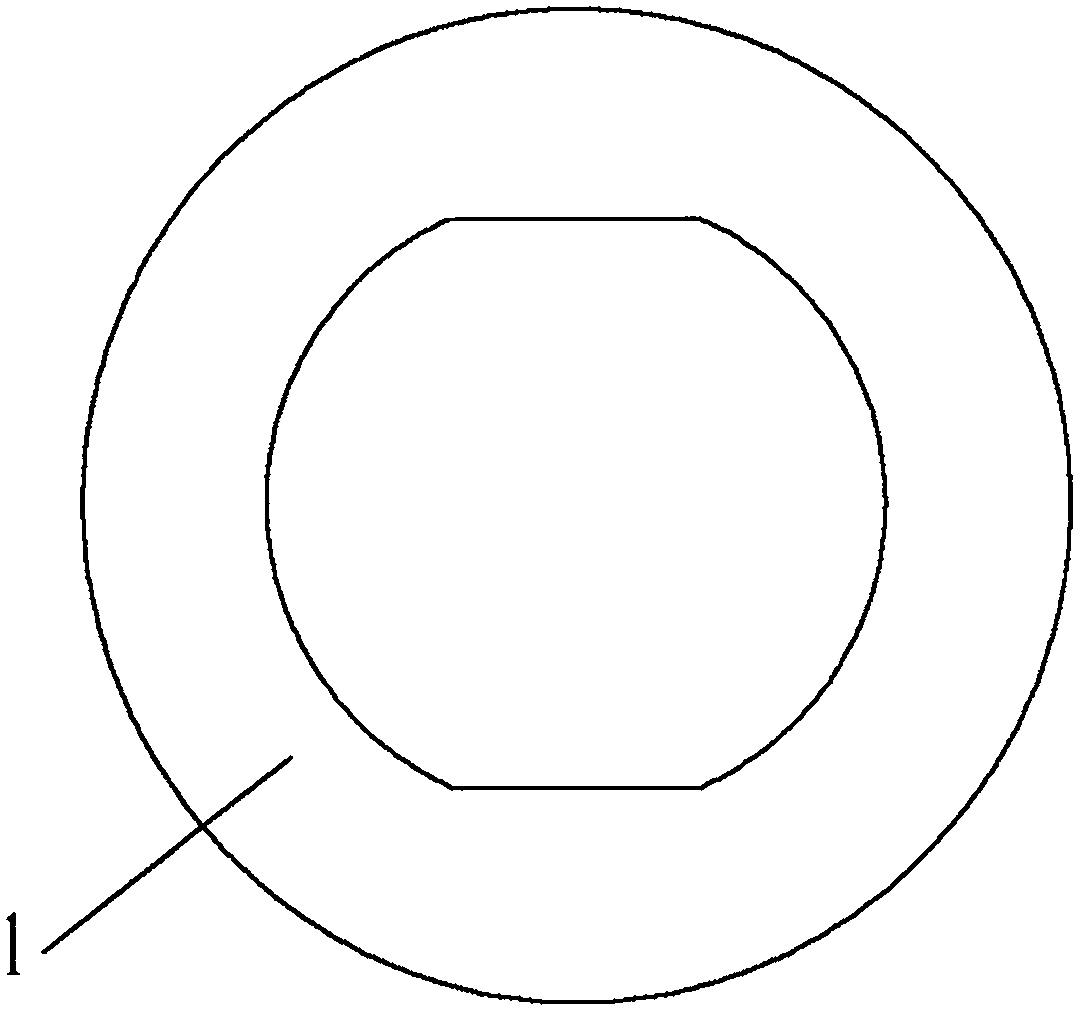

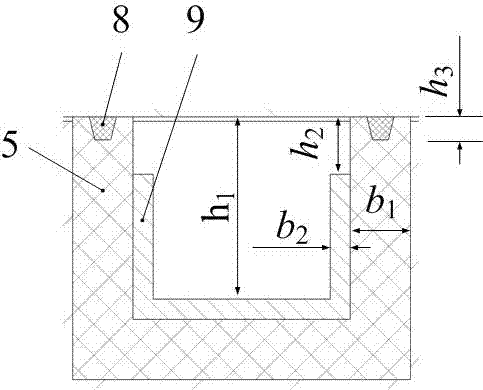

Magnetic suspension uniaxial direct-driven compressor

ActiveCN104373352AAvoid friction and wearEliminate friction and wearRotary/oscillating piston combinations for elastic fluidsMachines/enginesStatorMagnetic levitation

The invention discloses a magnetic suspension uniaxial direct-driven compressor which comprises two parts, namely a rotor system and a stator system, wherein the rotor system comprises a rotor of an axial magnetic bearing, a left radial displacement sensor detection ring, a rotor of a left radial magnetic bearing, a middle radial displacement sensor detection ring, a rotor of a middle radial magnetic bearing, a rotor of a motor, a pressure ring, a rotor of a right radial magnetic bearing and a right radial displacement sensor detection ring which are sequentially arranged on a screw shaft; the stator system comprises a stator of the axial magnetic bearing, a stator of the left radial magnetic bearing, a stator of the middle radial magnetic bearing, a stator of the motor and a stator of the right radial magnetic bearing which are sequentially arranged on a machine base; and non-mechanical contact magnetic suspension is realized between the rotor system and the stator system through the axial magnetic bearing, the left radial magnetic bearing, the middle radial magnetic bearing and the right radial magnetic bearing. The magnetic suspension uniaxial direct-driven compressor disclosed by the invention has the advantages of compact structure, energy conservation, environmental protection, high operation efficiency and high reliability.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Double-way friction stir welding method for dissimilar material mismatching processing

ActiveCN108127244AReduce contact areaReduce frictional heat generationNon-electric welding apparatusButt jointCopper

The invention discloses a double-way friction stir welding method for dissimilar material mismatching processing. The problems are solved that in the butt joint and friction stir welding process of dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper, the situations easily exist that a stirring head is abraded, formation of welding seams is poor due to a material glued tothe stirring head, and the defects exist in intermetallic compounds in the welding seams and exist in the welding seams. The method comprises the steps that 1, two parent materials to be welded are preprocessed, the thickness of a welding area is subjected to differentiation, and a mismatching connector is formed; 2, firstly, the parent materials to be welded are subjected to ultrasonic cleaning and preprocessing, and then acetone is used for wiping the surfaces of the parent materials; 3, the two parent materials to be welded are clamped and located; 4, the stirring head with a large-sized shaft shoulder is shifted to the sides of the low-melting-point parent materials, a small quantity of high-melting-point parent materials are inserted in the stirring head, and first-time welding is conducted; 5, the stirring head is replaced by a small-sized stirring head, the small-sized stirring head is further shifted to the sides of the low-melting-point parent materials, second-time repair welding is conducted, and accordingly the good-quality connection between dissimilar materials is formed. The double-way friction stir welding method is applied to butt joint and friction stir welding ofthe dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper.

Owner:安徽万宇机械设备科技有限公司

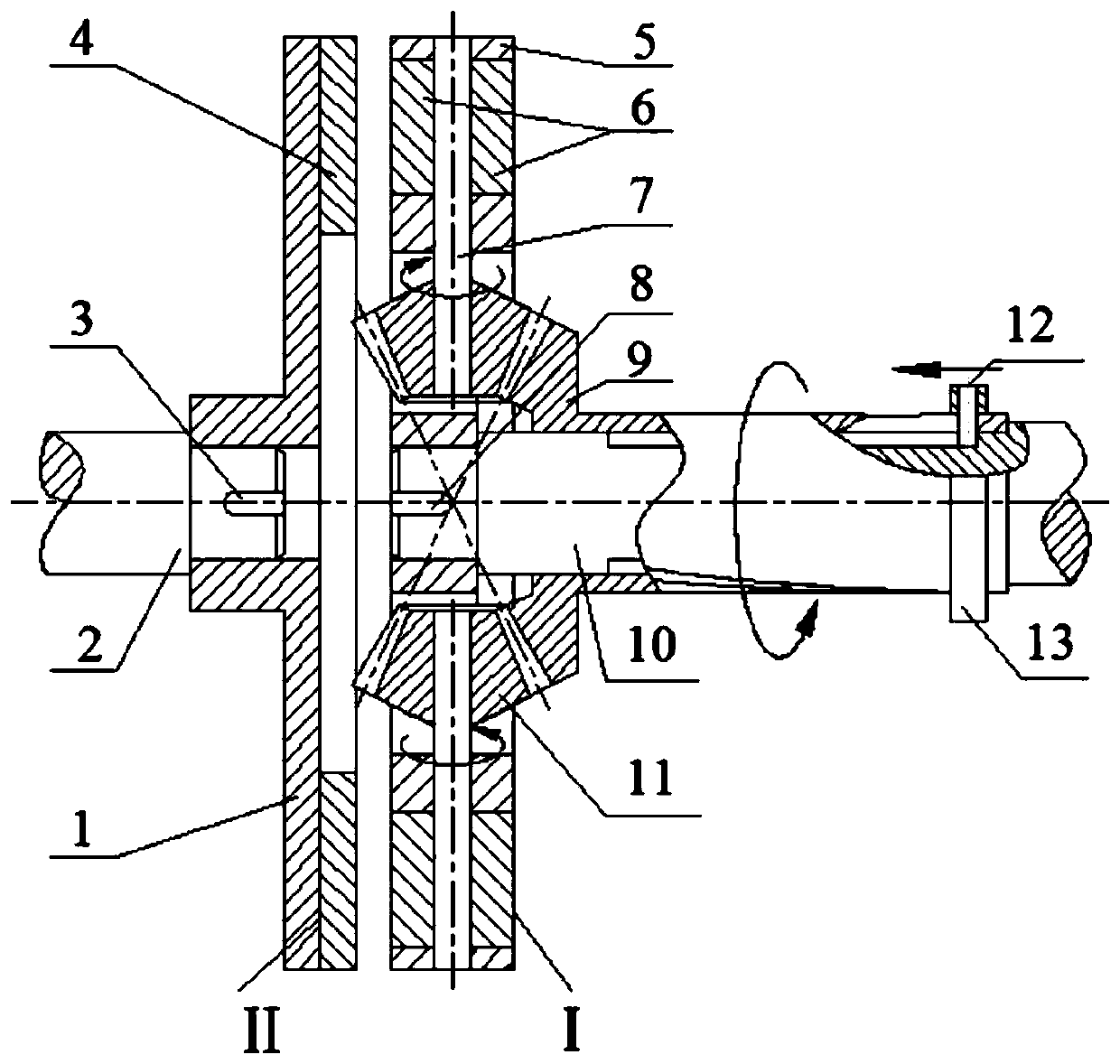

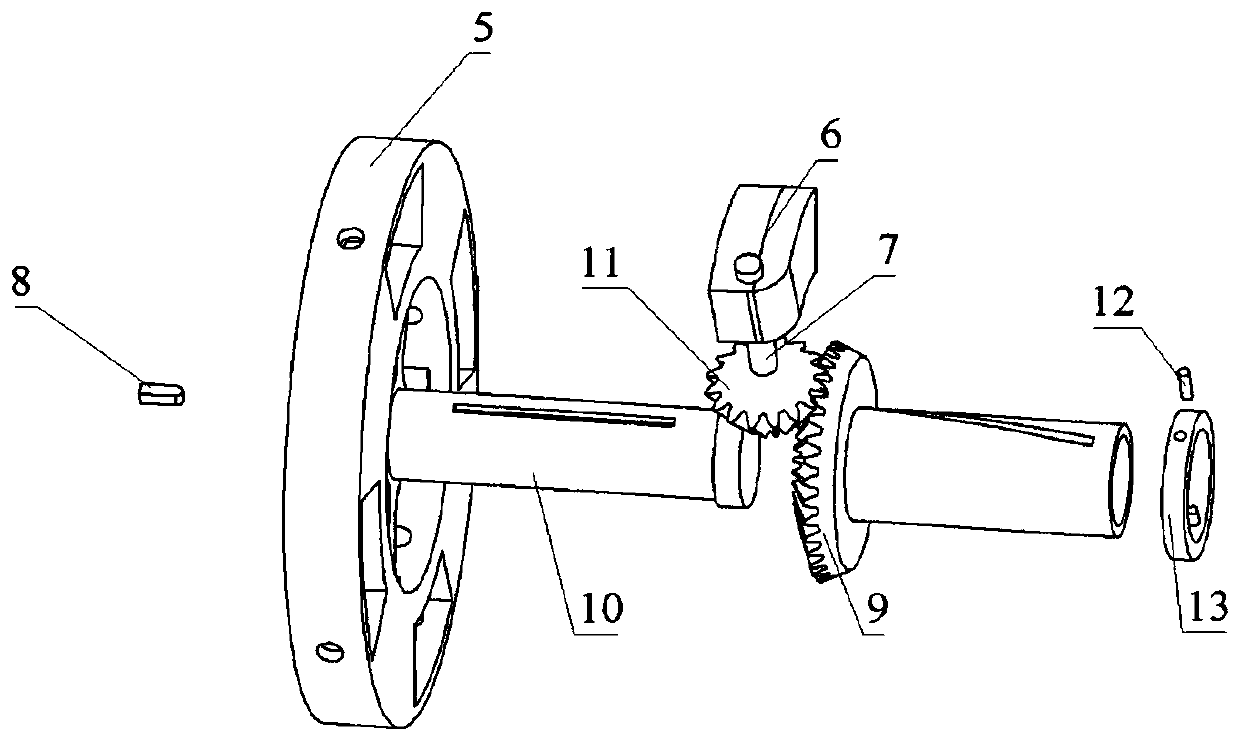

Monopole magnet rotating speed adjustable cage type magnetic coupling

ActiveCN110504816AAchieving a soft startAchieve protectionPermanent-magnet clutches/brakesMechanical energy handlingInterference fitElectrical conductor

The invention relates to the field of mechanical transmission, and is a monopole magnet rotating speed adjustable cage type magnetic coupling. In the invention, the copper disc uses a cage type copperdisc, all the fan-shaped grooves generate fan-shaped ring current around, the generated eddy current loss is small and the transmission efficiency is high, the fan-shaped grooves of the cage type copper disc and the small bumps on the surface of the yoke are in interference fit, and the small bumps of the yoke modulate the magnetic field, thereby further increasing the electromagnetic torque of the coupler. The coupler provides three speed adjustment methods that the first is to adjust the air gap between the copper disc and the permanent magnet disc through an axial moving device, the secondis to change the rotation angle of the rotating permanent magnet by fixing the air gap to further adjust the head-on area between a conductor disc and the permanent magnet disc, and the third is to use the composite speed adjustment of the air gap between the two disks in axial movement and the rotating permanent magnet, so that the coupler can meet different degrees of speed adjustment requirements.

Owner:JIANGSU UNIV

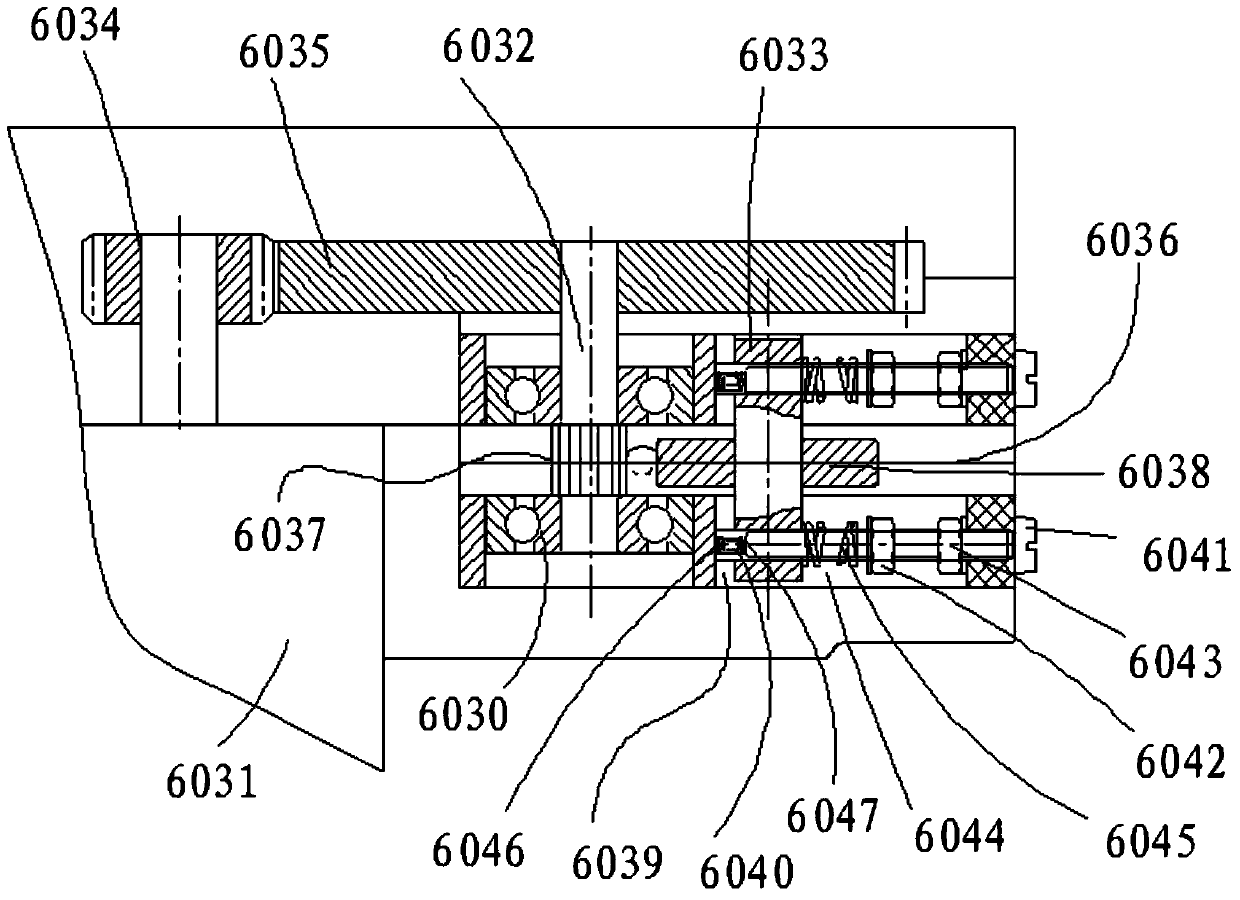

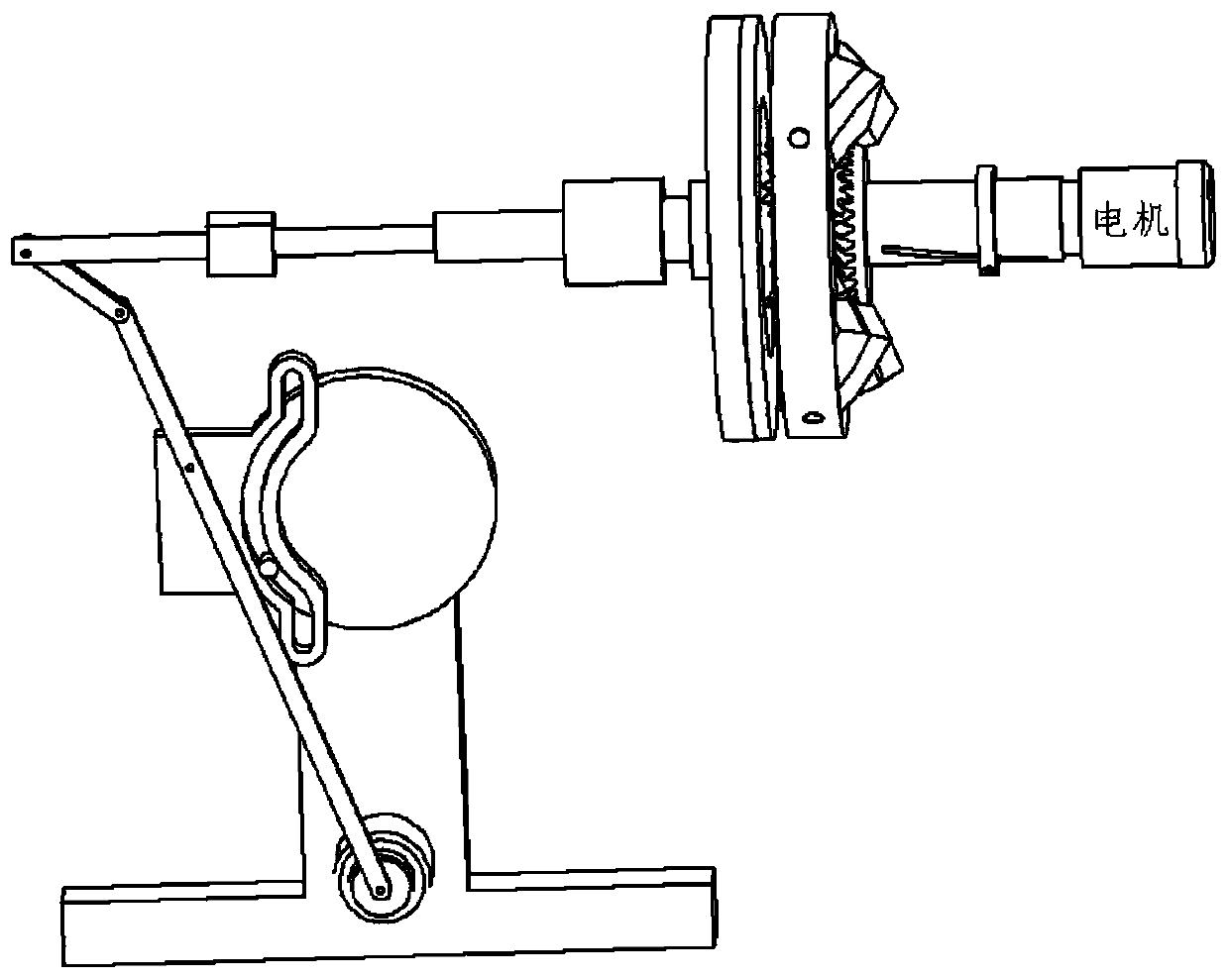

Flexible damping clutch based on hydraulic pressure

ActiveCN107763114APrevent disengagementPressure balanceFriction clutchesVibration absorptionControl theory

The invention provides a flexible damping clutch based on hydraulic pressure. The flexible damping clutch mainly comprises a hydraulic auxiliary device, a flexible pressing device, a guide device, a control device, and driving and driven devices; the flexible pressing device, the guide device and the control device are respectively mounted on the hydraulic auxiliary device; and the driving and driven devices are connected with the hydraulic auxiliary device through the flexible pressing device and the guide device. The flexible damping clutch has the characteristics of rolling flexible joint and hydraulic vibration absorption. The no-vibration automatic clutching of the clutch is realized through the hydraulic auxiliary device; the low-wear flexible joint and the quick separation of the clutch are realized through the flexible pressing device; the no-deviation oriented motion of a pressing disc and a driven disc is realized through the guide device; the free clutching of the clutch isrealized through the control device; and the power transfer is realized through the driving and driven devices.

Owner:UNIV OF JINAN

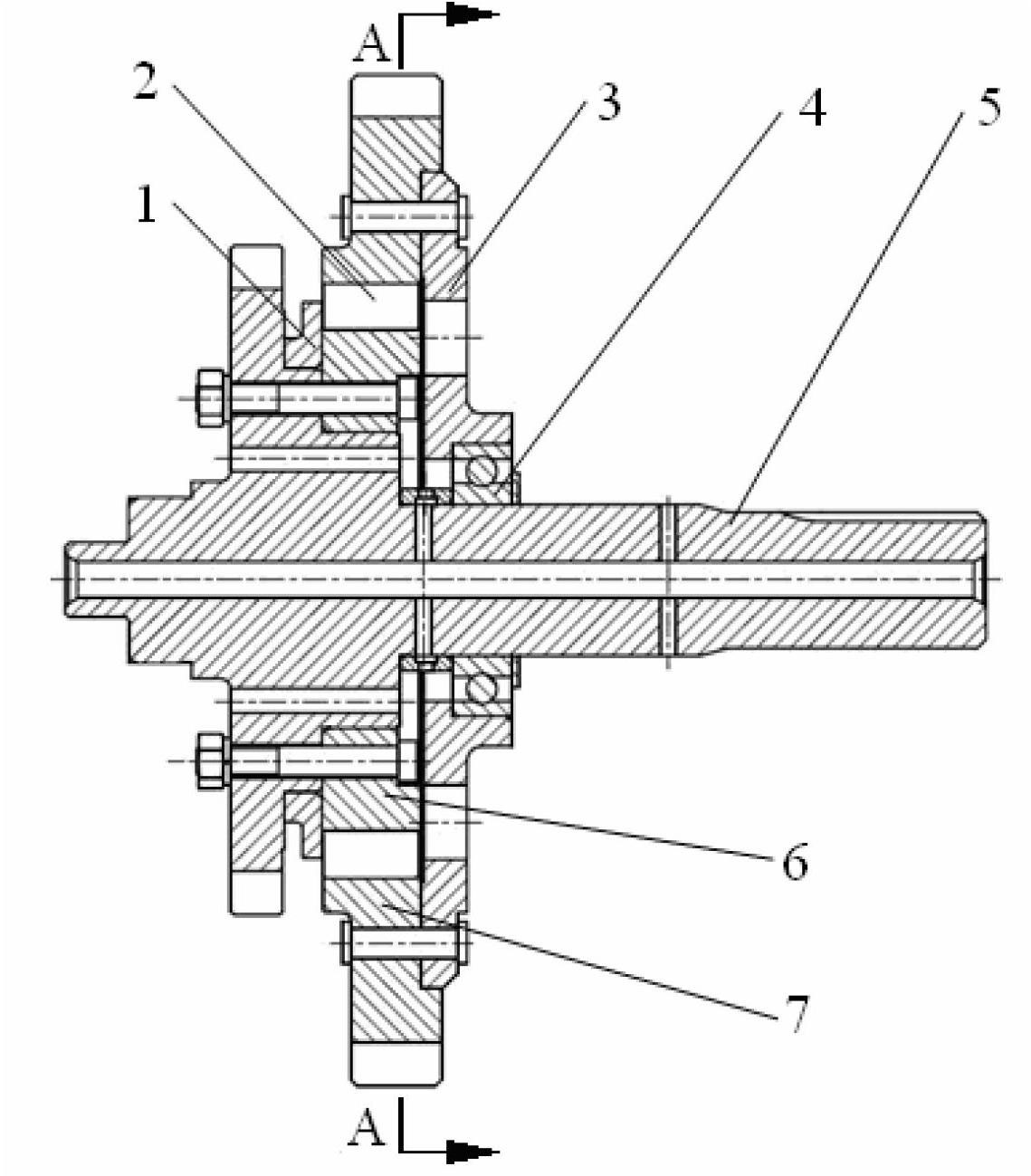

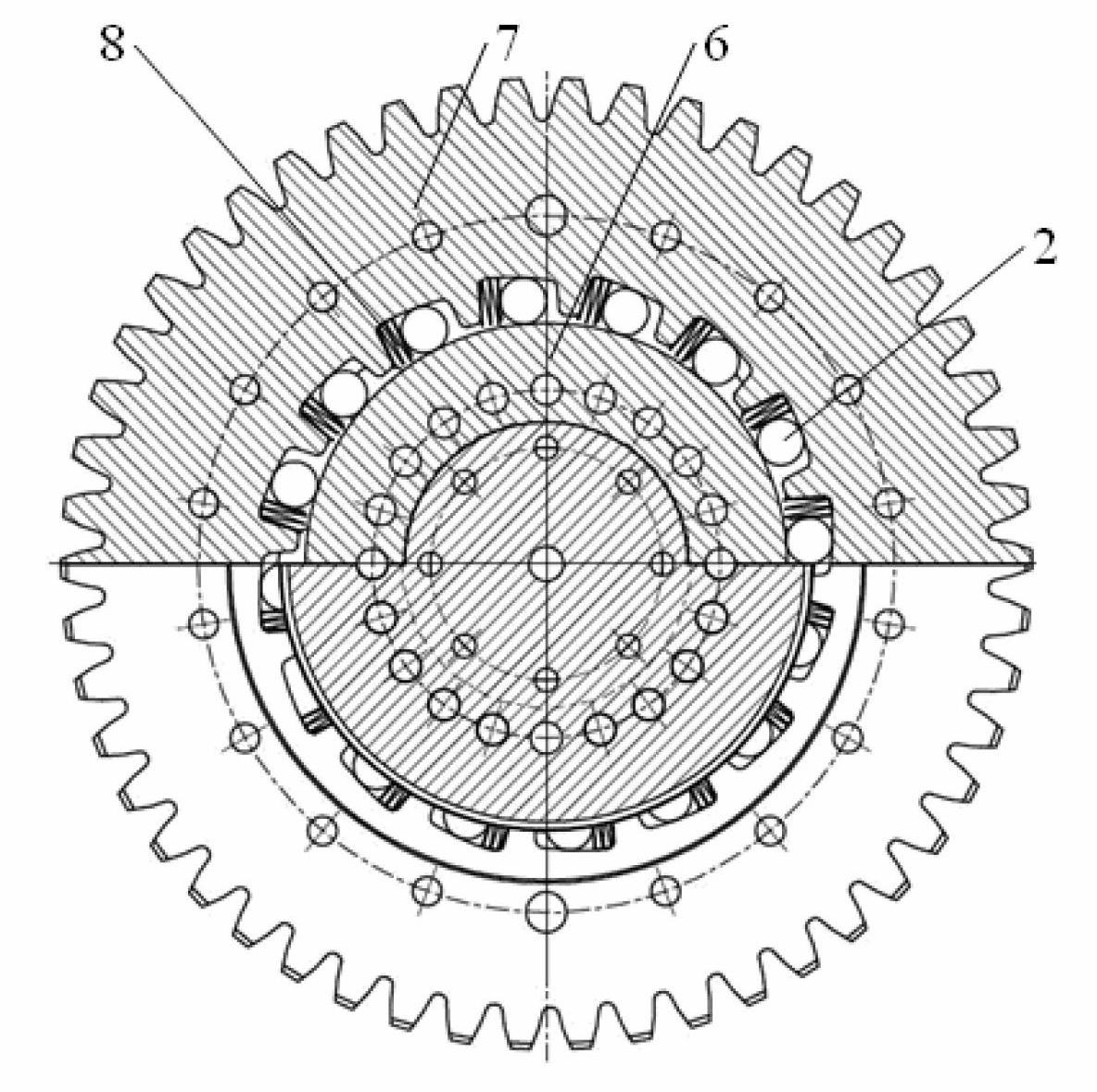

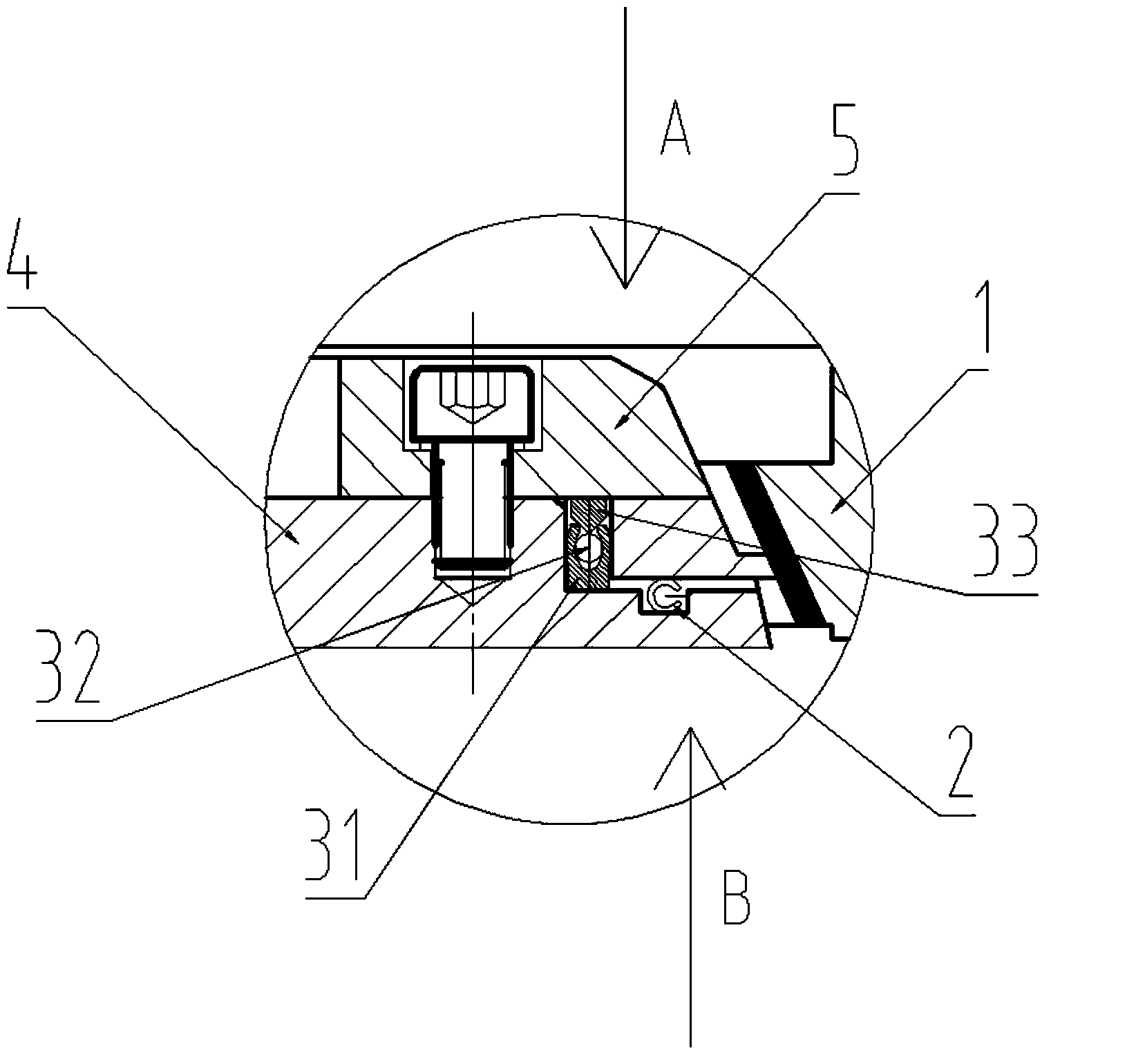

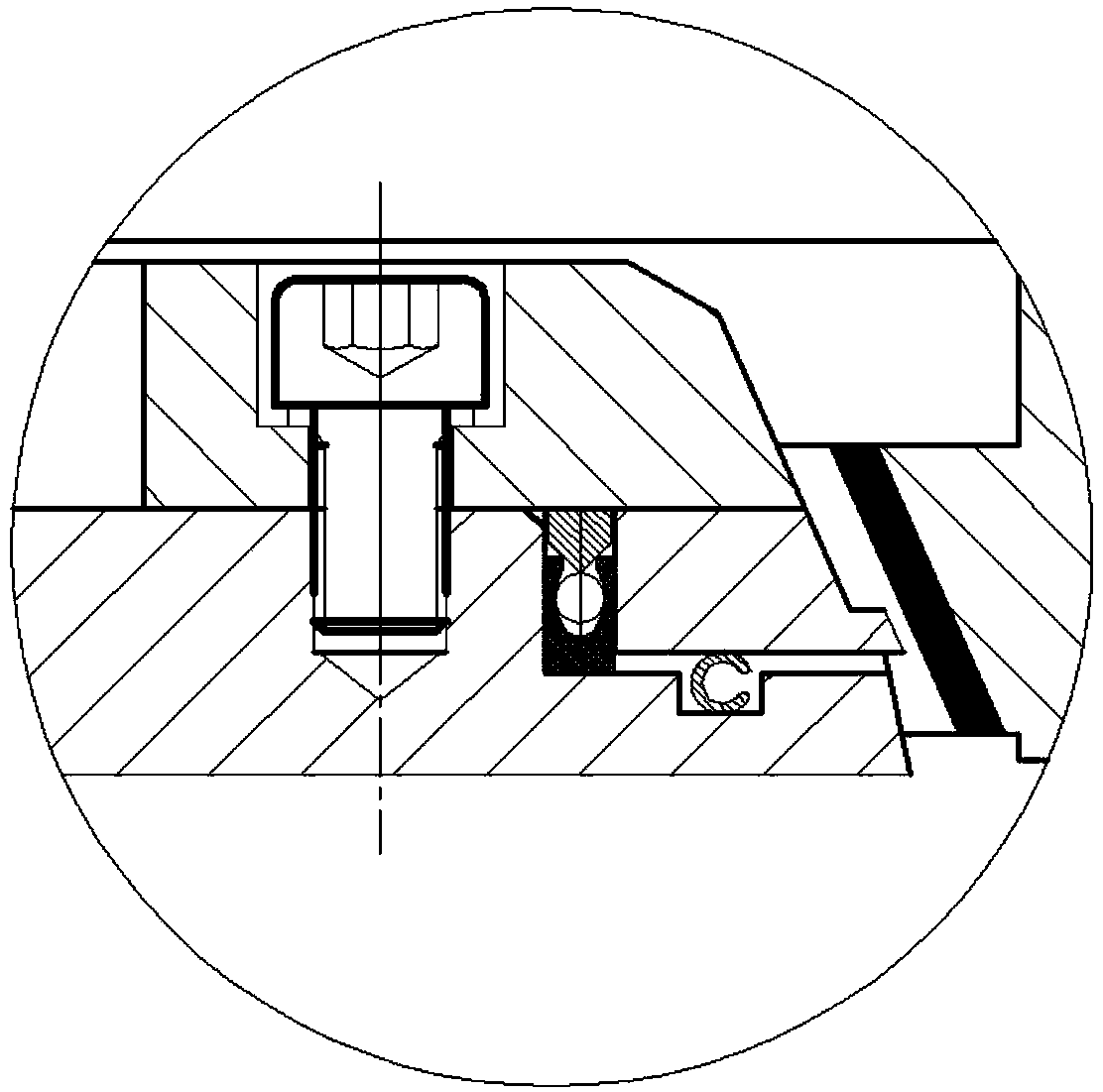

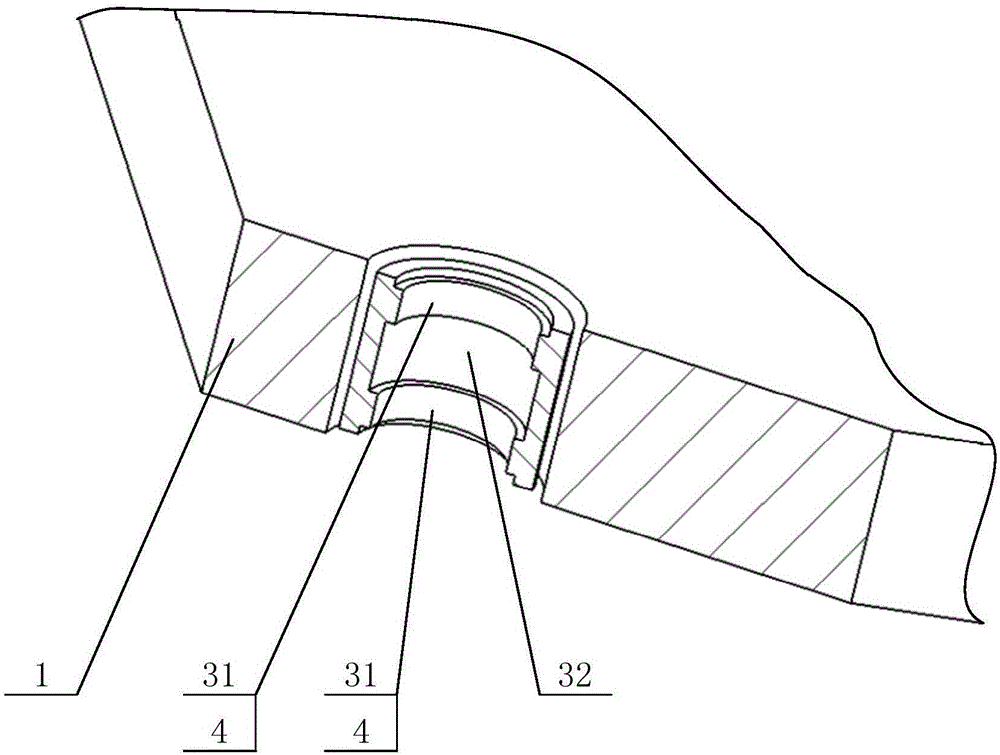

Overrunning clutch for confluence mechanism of double-turbine hydraulic torque converter

InactiveCN102661337AImprove stress conditionImprove the stress condition of the structureFreewheel clutchesLocking mechanismEngineering

The invention relates to an overrunning clutch for a confluence mechanism of a double-turbine hydraulic torque converter. A cam surface of a self-locking mechanism is arranged in an inner bore of an outer ring gear, and an inner planetary gear is of a cylindrical surface. The outer ring gear is positioned on a middle shaft gear and positioned by utilizing self locking of a deep groove ball journal and a pin roller, thus changing the existing three-point over-positioning structure. The outer ring gear of the overrunning clutch has low rotation speed, and the pin roller is arranged on the cam surface of the outer ring gear, thus greatly reducing the self radial centrifugal force; and furthermore, no normal action force exists in the contact process of the pin roller and the inner planetary gear, thus avoiding frictional wear and prolonging the service life. The inner planetary gear and the middle shaft gear adopt an equal length locating surface structure, and the stress surface can not generate plastic deformation due to increasing of a load, thus improving the bearing capacity of parts. The left side of the pin roller is limited by a baffle plate and the right side of the pin roller is limited by a supporting disc in the axial direction. The structure form that the cam surface of the existing overrunning clutch is arranged on the inner planetary gear is changed, the machining is simple and convenient and the manufacturing cost is low.

Owner:JILIN UNIV

Double-slope eccentric butterfly valve

ActiveCN103470793AExtended service lifeEasy to useSpindle sealingsLift valveEngineeringButterfly valve

The invention provides a double-slope eccentric butterfly valve. The double-slope eccentric butterfly valve comprises a valve body, a valve rod, a valve plate and a metal sealing socket, wherein an inlet, an outlet and a valve cavity capable of communicating the inlet with the outlet are arranged in the valve body, a shaft hole is formed in the valve cavity part of the valve body, and the valve rod penetrates through the shaft hole to be fixedly connected with the valve plate; a metal valve seat integrated with the valve body into a whole is arranged on the valve body, and the valve plate is driven by the valve rod to open and close on the metal valve seat; the metal sealing socket is arranged on the valve plate in a clamping manner through a sealing ring cover plate and is in seal fit with the metal valve seat; a first gap and a second gap communicated with one another are formed between the metal sealing socket and the valve plate, a metal C-ring is arranged in the first gap, and the metal C-ring is partially embedded in a groove formed on the surface of the valve plate; a self-sealing combined structure is arranged in the second gap. According to the double-slope eccentric butterfly valve provided by the invention, the integrated metal seating socket and a floating sealing structure are adopted, and the service life and usability of the butterfly valve are remarkably improved.

Owner:ZHEJIANG BEIER CONTROL VALVE

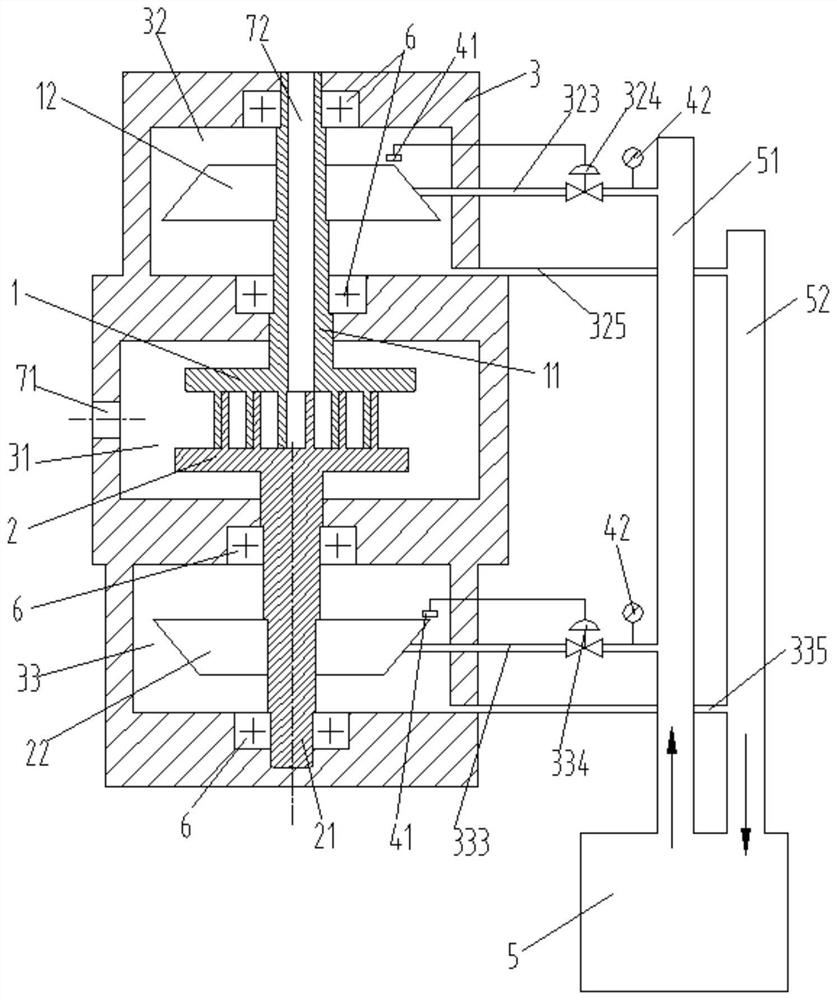

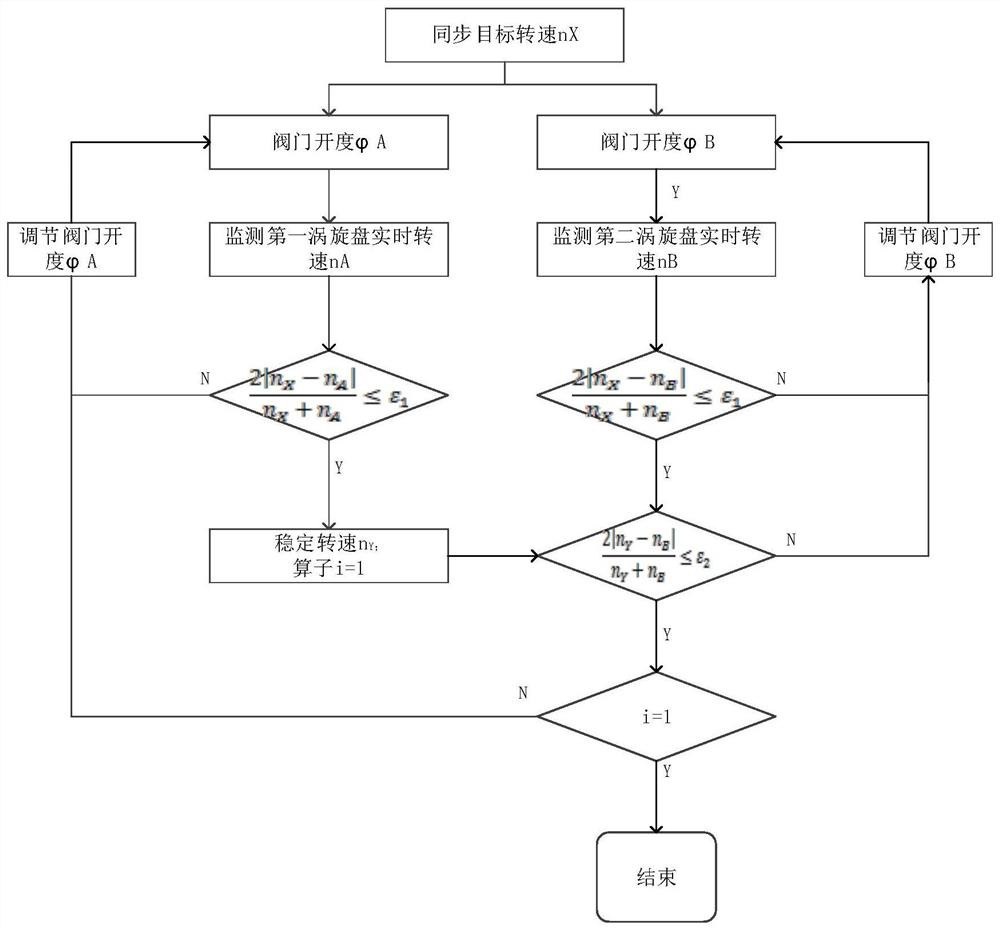

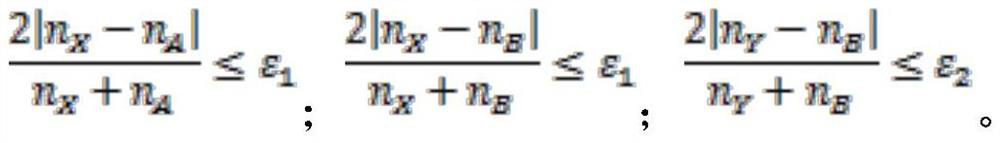

Vortex rotary compressor and control method thereof and air conditioner

PendingCN111637056ASpeed stepless adjustmentAvoid friction and wearRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRotation control

The invention provides a vortex rotary compressor and a control method thereof and an air conditioner. The vortex rotary compressor comprises a first vortex plate and a second vortex plate. The firstvortex plate and the second vortex plate are arranged in an opposite inserting manner at a preset eccentric distance and the eccentric distance between the first vortex plate and the second vortex plate is staggered at 180 degrees. The vortex rotary compressor further comprises a hydraulic power system. A pressure fluid of the hydraulic power system can drive the first vortex plate and the secondvortex plate to rotate in the same direction, separately. According to the vortex rotary compressor and the control method thereof and the air conditioner, the two vortex plates are driven to rotate synchronously in the same direction by way of hydraulic transmission. In the transmission process, the vortex rotary compressor is free of frictional wear, high in transmission efficiency and high in rotary control reliability, and is in particular suitable for a working condition of high speed operation of the vortex rotary compressor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

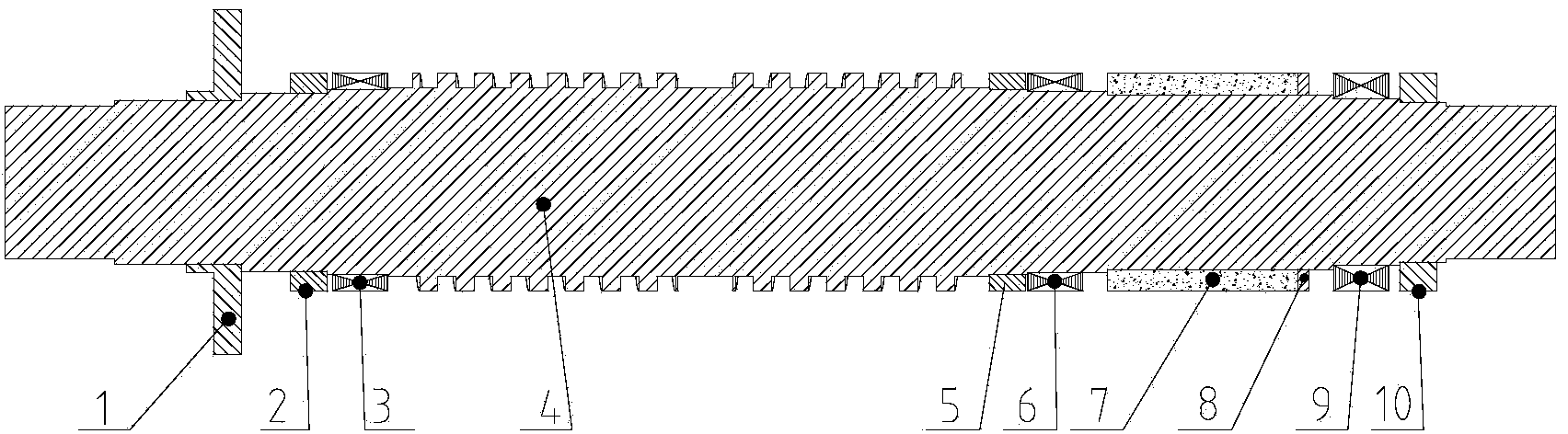

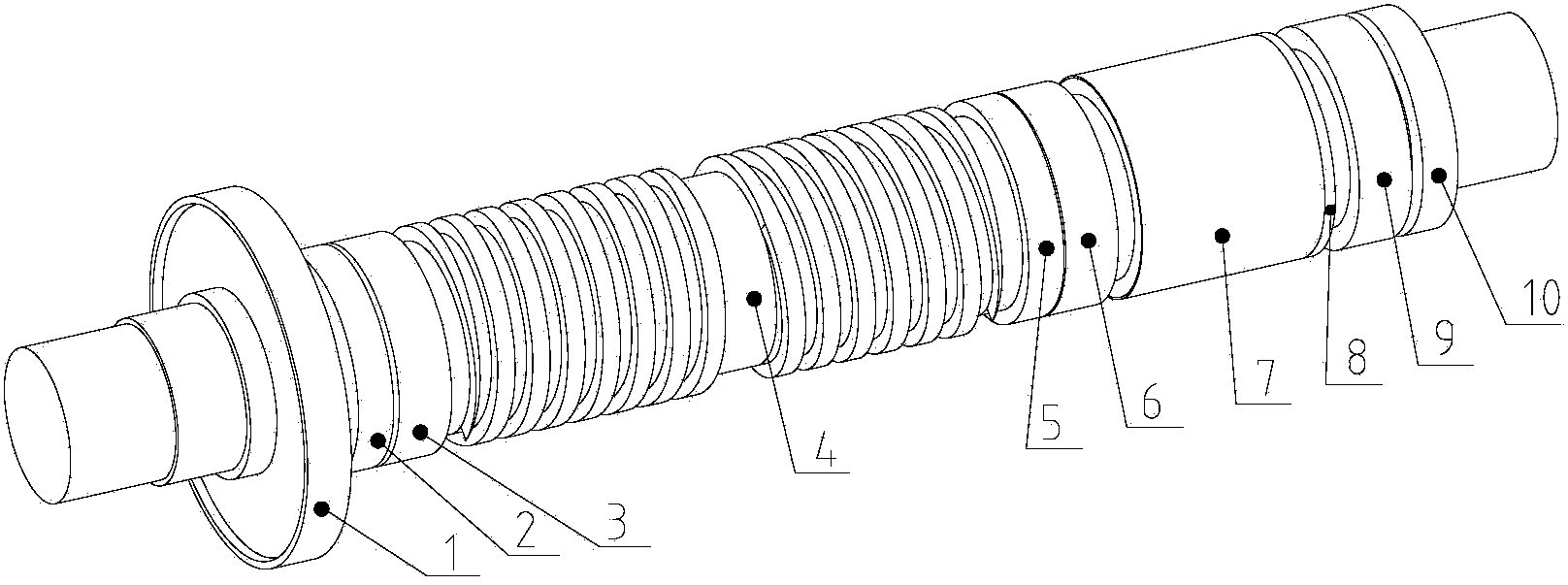

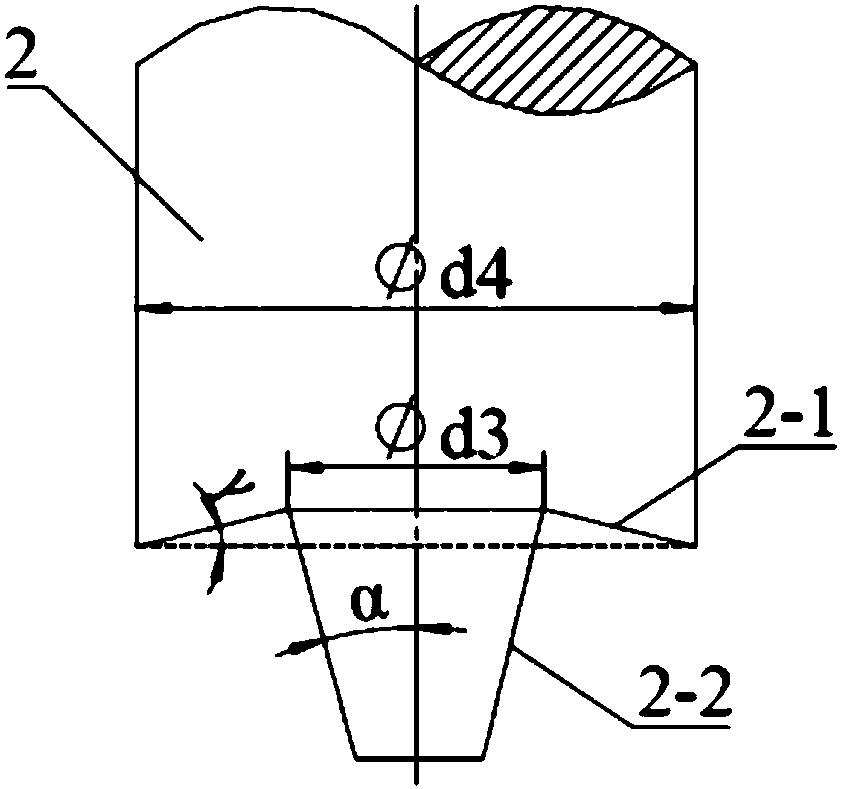

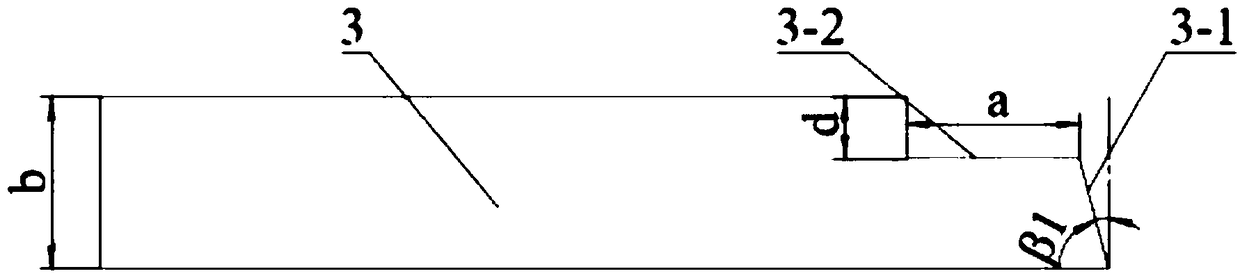

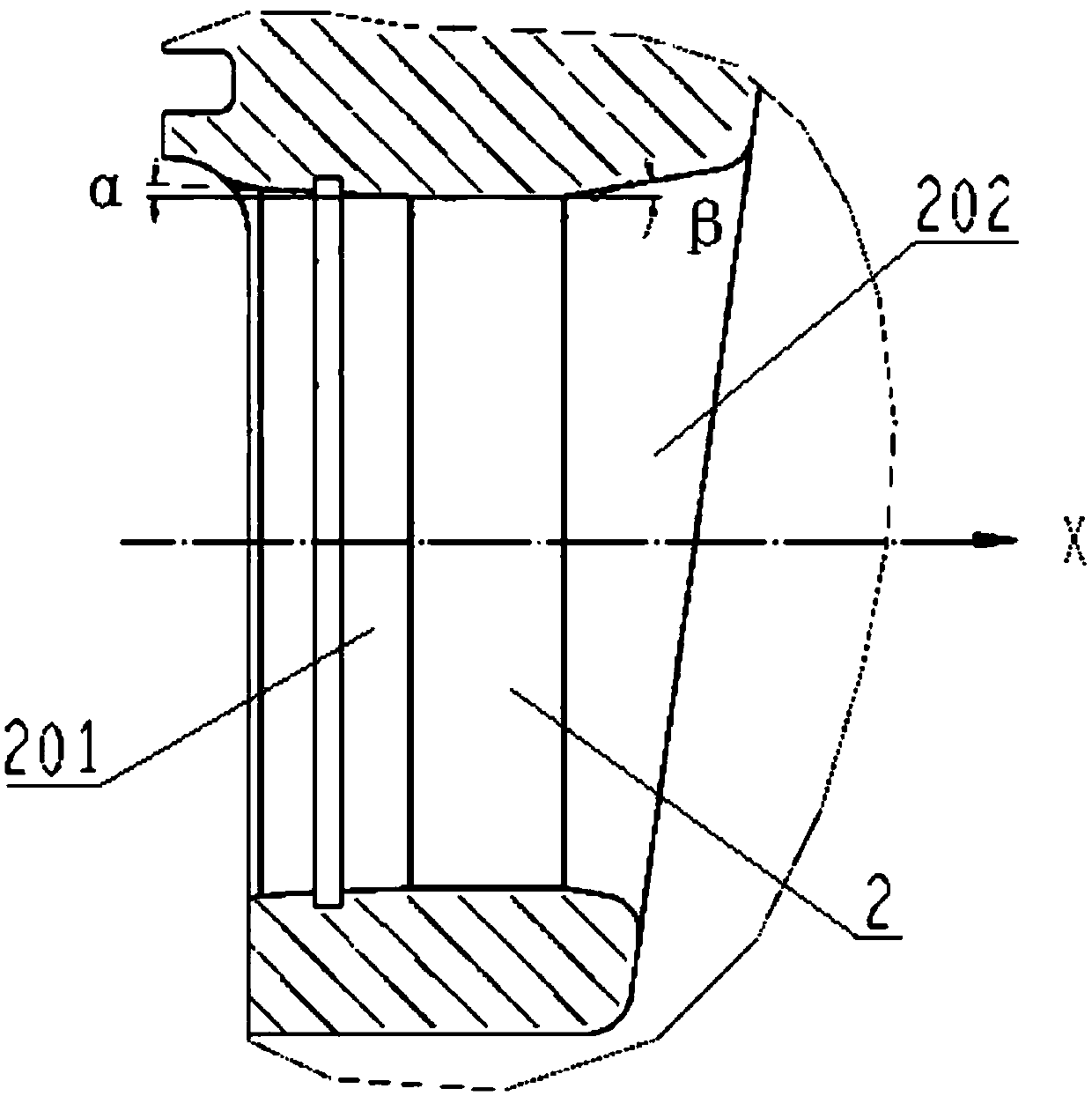

Piston-piston pin-connecting rod combined unit matched structure

ActiveCN107939522AReduce mechanical stressExtended service lifeMachines/enginesPistonsEngineeringOvality

The invention provides a piston-piston pin-connecting rod combined unit matched structure comprising a piston, a connecting small head and a piston pin. A through pin seat hole is formed in the pistonand comprises two parts which are symmetrical with respect of the connecting rod small head, each part sequentially comprises an inner hole section, a middle hole section and an outer hole section from inside to outside, and the middle hole section is a straight hole. The two ends of the middle hole section are connected with the end, with a smaller diameter, of the inner hole section and the end, with a smaller diameter, of the outer hole section correspondingly. The connecting rod small head is located at one end of a connecting rod, and a connecting rod small head hole is formed in the connecting rod small head and extends into the piston. The piston pin penetrates through the pin seat hole and the connecting rod small head hole enable the connecting rod small head and the piston to behinged. According to the piston-piston pin-connecting rod combined unit matched structure, by improving the molded line structure of the pin seat hole, mechanical stress borne by the piston in work is effectively reduced, and thus the service life of the piston is prolonged. By increasing the ovality of the pin seat hole perpendicular to the longitudinal axis of the piston, the phenomenon of jamming of the piston pin in the pin seat hole can be effectively avoided.

Owner:CHINA NORTH ENGINE INST TIANJIN

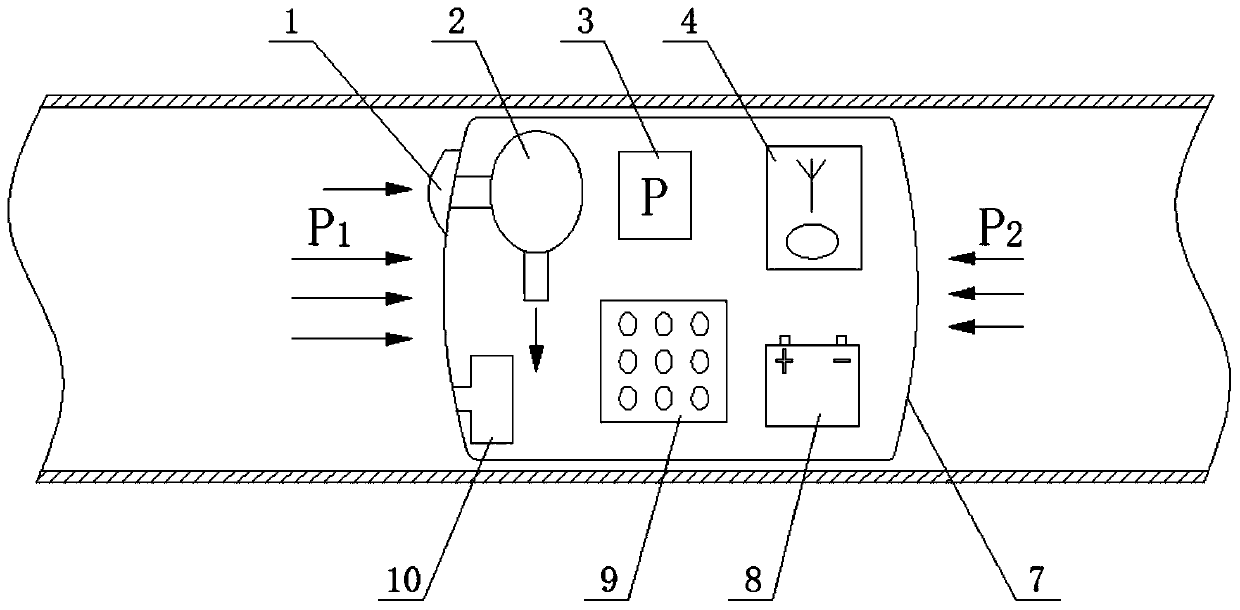

Plugging control technology based on low-frequency electromagnetic signal communication and plugging ball intelligent positioning

ActiveCN109736817ASufficient deflectionPrevent buckling damagePipe elementsTunnelsControl systemEngineering

The invention provides a plugging control technology based on low-frequency electromagnetic signal communication and intelligent plugging ball positioning. The plugging control technology comprises afilter screen, a slurry pump, a pressure measuring device, an in-pipe wireless communication device, an out-pipe wireless communication device, an out-pipe plugging control system, a corrugated pipe,a battery, an in-pipe plugging control system and a pilot-operated electromagnetic release valve. The invention provides the plugging control technology based on low-frequency electromagnetic signal communication and plugging ball intelligent positioning. An efficient and accurate plugging process is carried out through accurate positioning of a plugging ball and timely pressurization and decompression of the plugging ball. A control system in the plugging control technology can efficiently and accurately control actions of all devices, finally all the devices can work in an optimal action fitmode, enough deflection can be provided for the plugging ball when the plugging ball passes through a three-way reversing valve through the structure of the corrugated pipe, and meanwhile the plugging position of the plugging ball can be mainly concentrated on two sides of the plugging ball in the plugging process.

Owner:ANHUI TONGDU FLOW TECH

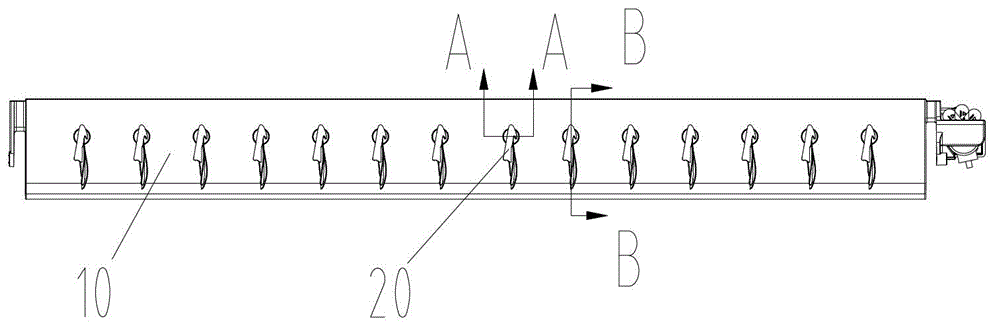

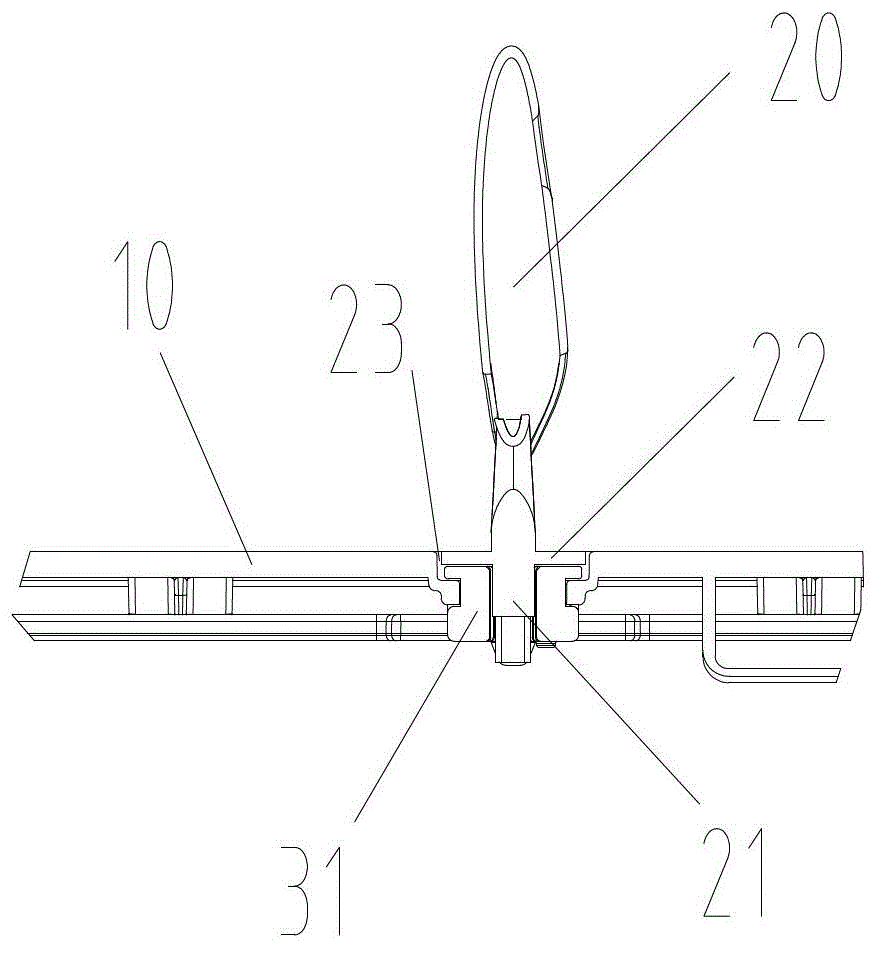

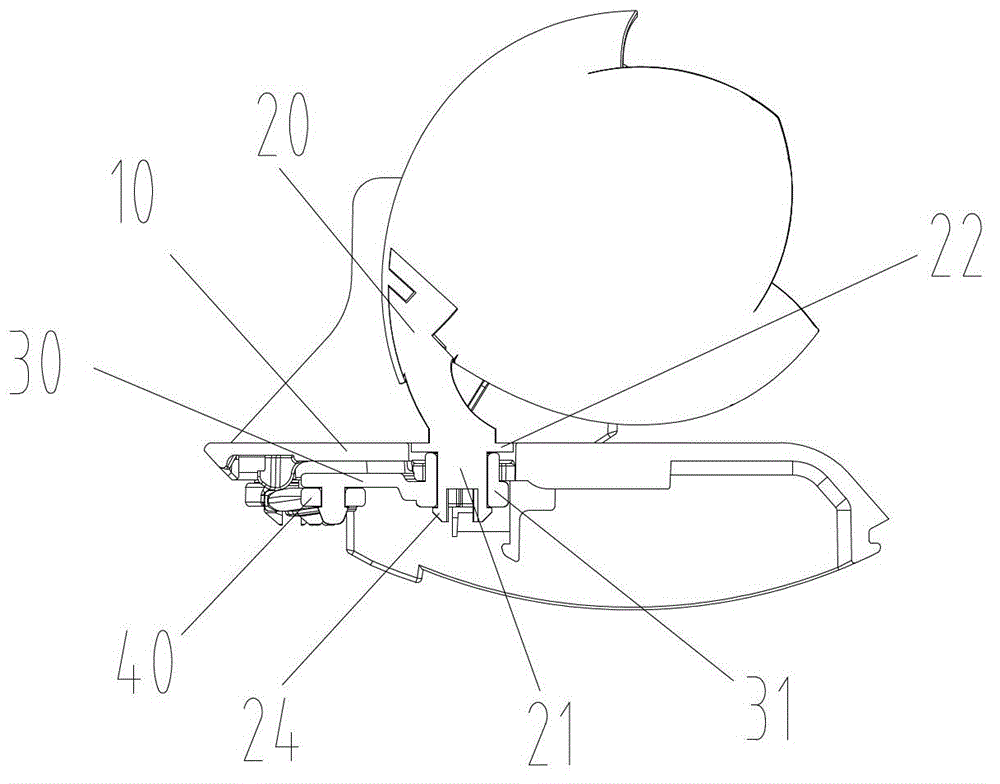

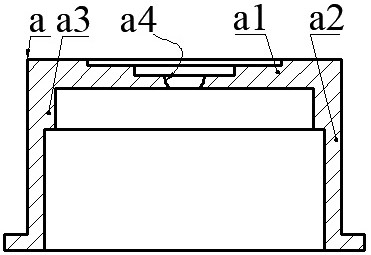

Air louver unit and air conditioner with same

ActiveCN104101072AAvoid friction and wearExtended service lifeAir-flow control membersEngineeringRotational stability

The invention discloses an air louver unit and an air conditioner with same. The air louver unit comprises a louver-fastening board, air louvers and cranks, the louver-fastening board is provided with mounting holes, each crank is provided with a mounting shaft, the mounting shafts are pivotally connected with the mounting holes, the mounting shafts are provided with louver-fixing holes, and louver shafts of the air louvers are fixedly inserted in the louver-fixing holes. The mounting shafts of the cranks in the air louver unit can rotate in the mounting holes of the louver-fastening board to drive the air louvers to rotate, the air louvers are not in contact with the louver-fastening board, i.e., the air louvers do not have rotational friction, the cranks can bear rotational friction because the wear resistance of the material of the cranks is better than the wear resistance of the air louvers, consequently, the friction and abrasion of the air louvers are prevented, the service lives of the air louvers are prolonged, and the rotational stability of the air louvers is enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

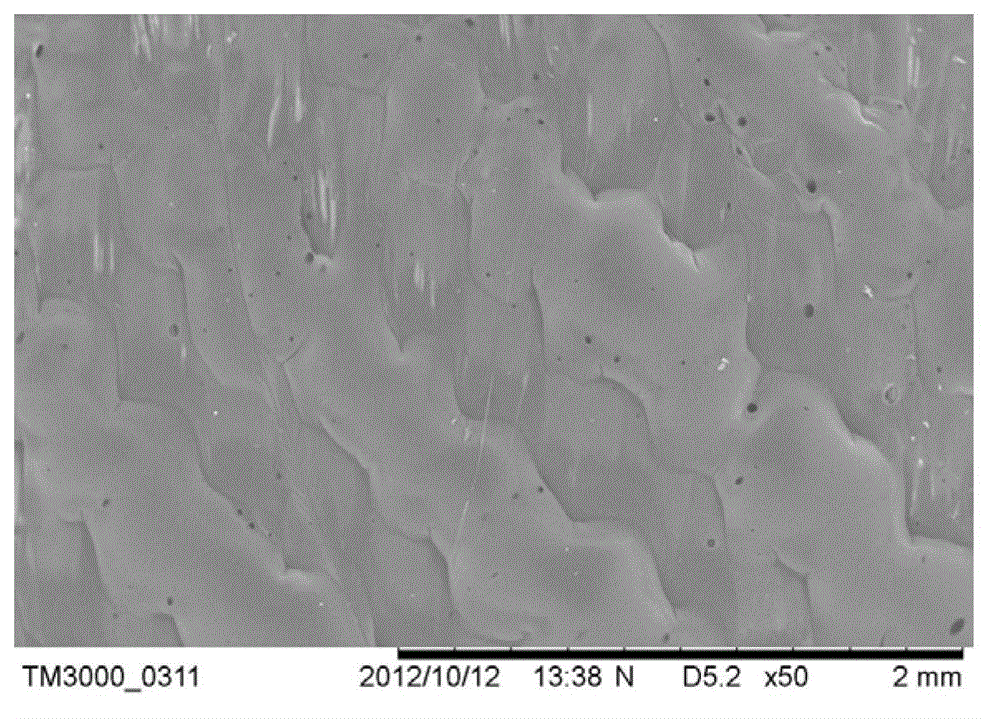

Base manufacture technology of four-high mill

ActiveCN105414888AImprove toughnessNo stress concentrationMetal rolling stand detailsMetal rolling arrangementsManufacturing technologyHardness

The invention belongs to the field of base manufacture, in particular to a base manufacture technology of a four-high mill. The base manufacture technology comprises the following technical steps: using Cr steel as a material; carrying out annealing treatment on the Cr steel used; machining the Cr steel; carrying out stress relieving annealing thermal treatment on the Cr steel subjected to machining; adopting friction stir welding to carry out welding molding on the Cr steel so as to obtain a base; carrying out homogenizing annealing treatment on the base obtained through welding, and after the base is cooled with the furnace, carrying out full annealing treatment again; carrying out surface strengthening treatment, that is sequentially carrying out shot blasting treatment and surface carburizing treatment on the base obtained; and coating the surface, subjected to surface strengthening treatment, of the base with anti-rust oil and a finish paint. The whole base produced has tenacity, but the surface has high hardness, so that in the application process of the base, even if the surface of the base cracks, the base is still full, and the influence of the brittle failure of the base on the mill is avoided.

Owner:NANTONG HONGFENG ELECTRO MECHANIC

Mushroom-shaped groove bidirectional rotating hydrodynamic mechanical seal structure

A mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure comprises two sealing rings of mechanical seal. The two sealing rings refer to a movable ring and a static ring. A plurality of mushroom-like grooves for sealing liquid are evenly distributed on the circumference of the sealing end face of at least one of the movable ring and the static ring. Each mushroom-like groove is composed of a drainage groove and a returning groove. Each drainage groove extends in the radial direction, and the width of each drainage groove gradually becomes narrower from an upper stream (a higher-pressure side) to a lower stream (a lower-pressure side) along the end face in the radial direction. Each returning groove extends in the circumference direction and the radial direction and is in the shape of an arc, an oval arc, a curved arc, or a straight line. The tail end of each drainage groove is connected with each returning groove. Areas which are not provided with grooves and are between the mushroom-like grooves are sealing weirs. A ring belt formed by an area which is not provided with grooves on the circumference of the end face is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

Fabric liner coating material of self-lubricating joint bearing and preparation method thereof

The invention provides a fabric liner coating material of a self-lubricating joint bearing and a preparation method thereof, and relates to a self-lubricating coating material and the preparation method thereof. The coating comprises the following components: 60 to 80 parts of epoxy resin, 0.1 to 5 parts of POSS (Polyhedral Oligomeric Silsesquioxane), 5 to 25 parts of polytetrafluoroethylene powder, 15 to 35 parts of a diluent, 0.5 to 5 parts of a silane coupling agent, 10 to 25 parts of a curing agent and 0.1 to 1 part of a surface active agent. The environment-friendly method and a way for preparing the self-lubricating abrasion-resistant liner coating material is provided; and the nanoscale polytetrafluoroethylene powder which is the same as the material of a fabric body is served as a filler in the formula, so that the friction coefficient is decreased greatly and the product appearance is improved. In addition, the nanoscale, the high surface energy and the similar 'bearing ball' effect of a cage shaped structure of the POSS are utilized, so that the friction reducing performance, the abrasion resisting performance and the self-lubricating performance of the coating are improved effectively.

Owner:XIAMEN UNIV +1

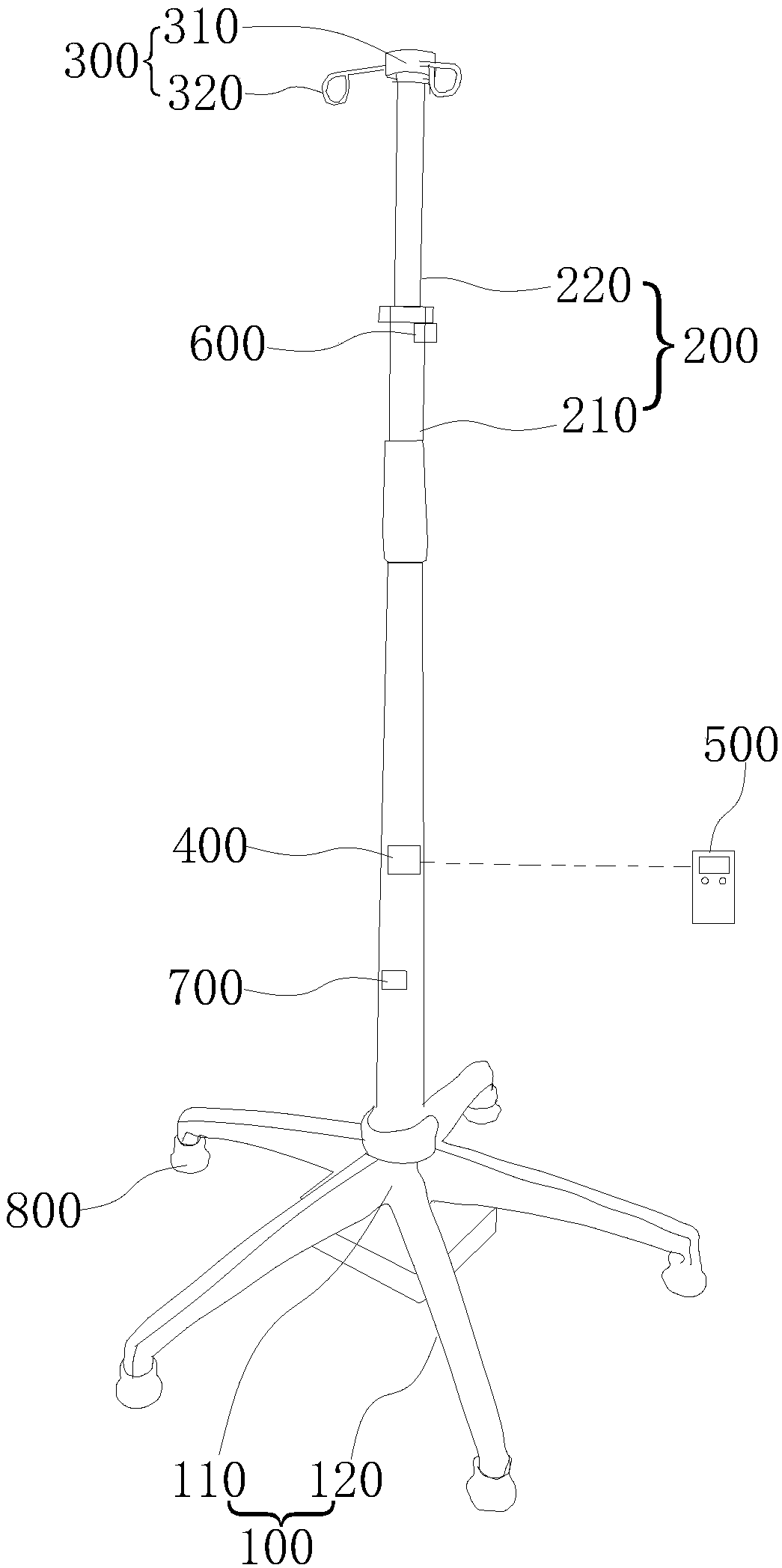

Endoscopic irrigation solution lifting and suspending device

InactiveCN107929847AAvoid friction and wearReduce contact frictionEnemata/irrigatorsEngineeringIrrigation Solutions

The invention discloses an endoscopic irrigation solution lifting and suspending device. The endoscopic irrigation solution lifting and suspending device comprises a support base; an upright rod, wherein the upright rod comprises a fixing rod installed on the support base and provided with a receiving cavity, and a telescopic rod which is slidably sheathed in the receiving cavity; a hanging frame,wherein the hanging frame is installed at one end, away from the fixing rod, of the telescopic rod; a driving device, wherein the driving device is installed at the fixing rod and is in the drive connection with the telescopic rod; a signal receiving device, wherein the signal receiving device is installed on the support base, and is in the communication connection with the driving device; and asignal sending device, wherein the signal sending device is in the communication connection with the signal receiving device. While the device is positioned in a suspending station, the telescopic rodis descended and drives the hanging frame to be close to the fixing rod; and while the device is positioned in a solution feeding station, the telescopic rod is ascended and drives the hanging frameto be away from the fixing rod. The above device is capable of effectively reducing the operation difficulty of the suspension of the irrigation solution, improving the medical working efficiency, andeliminating the potential safety hazard.

Owner:广东云曌医疗科技有限公司

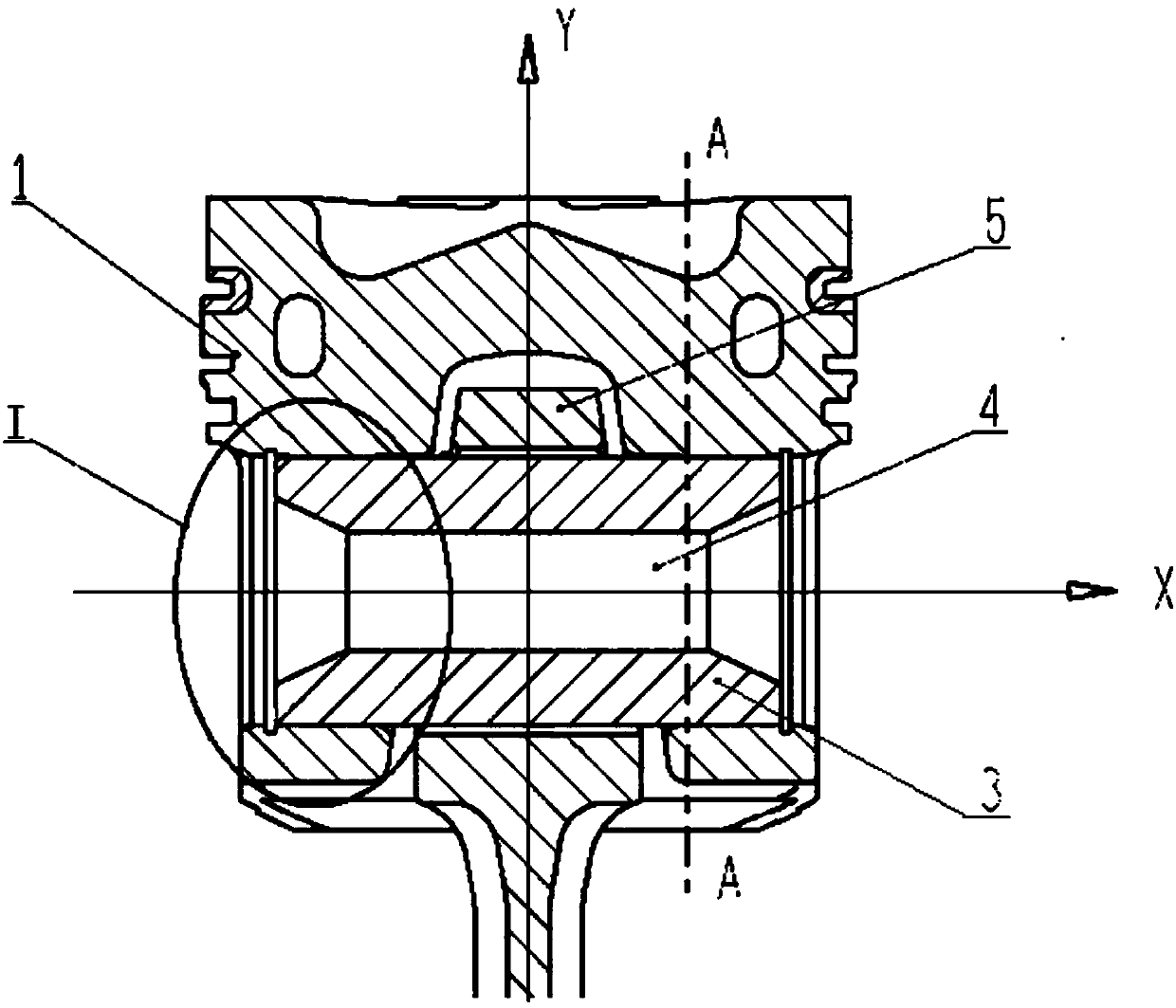

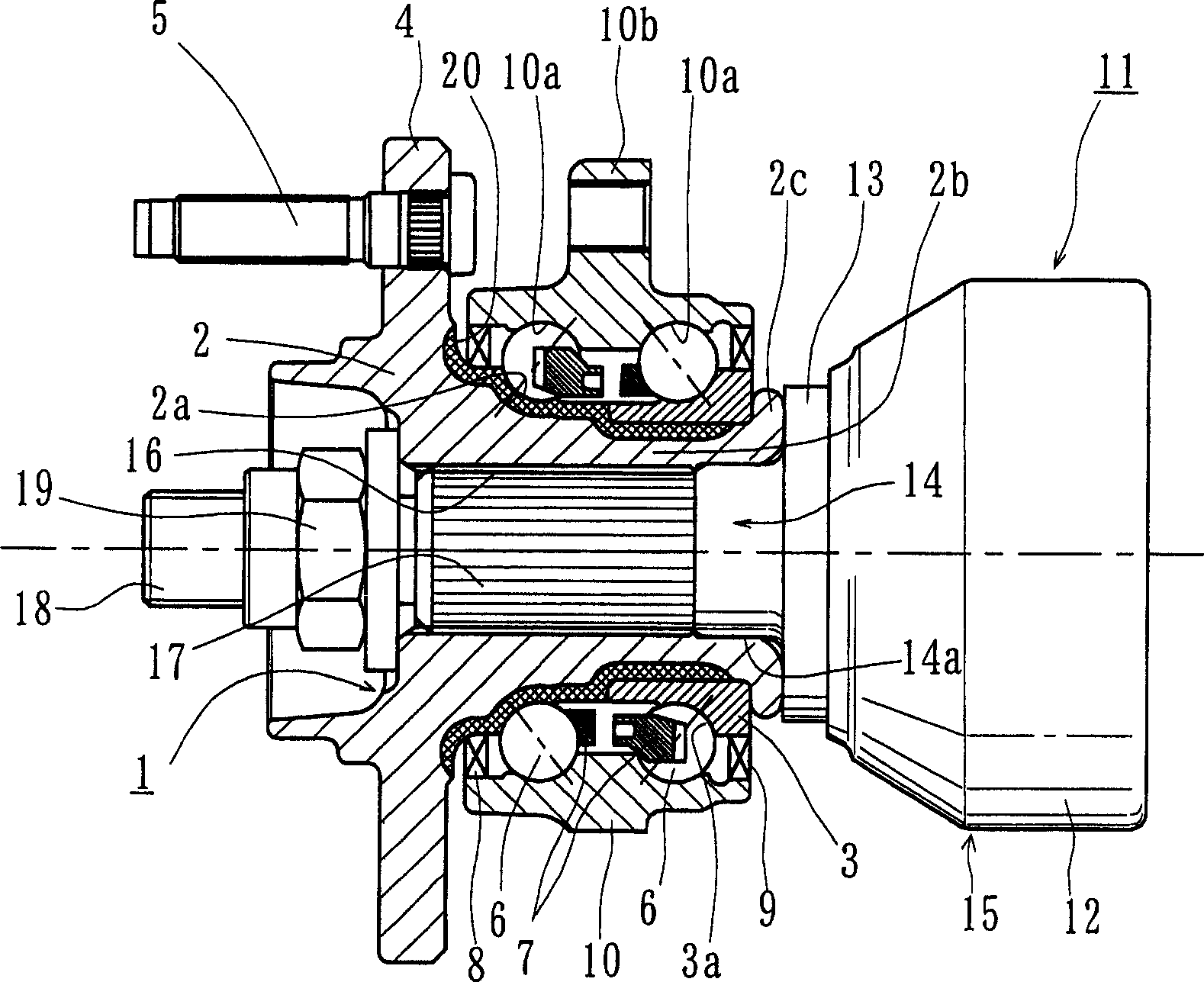

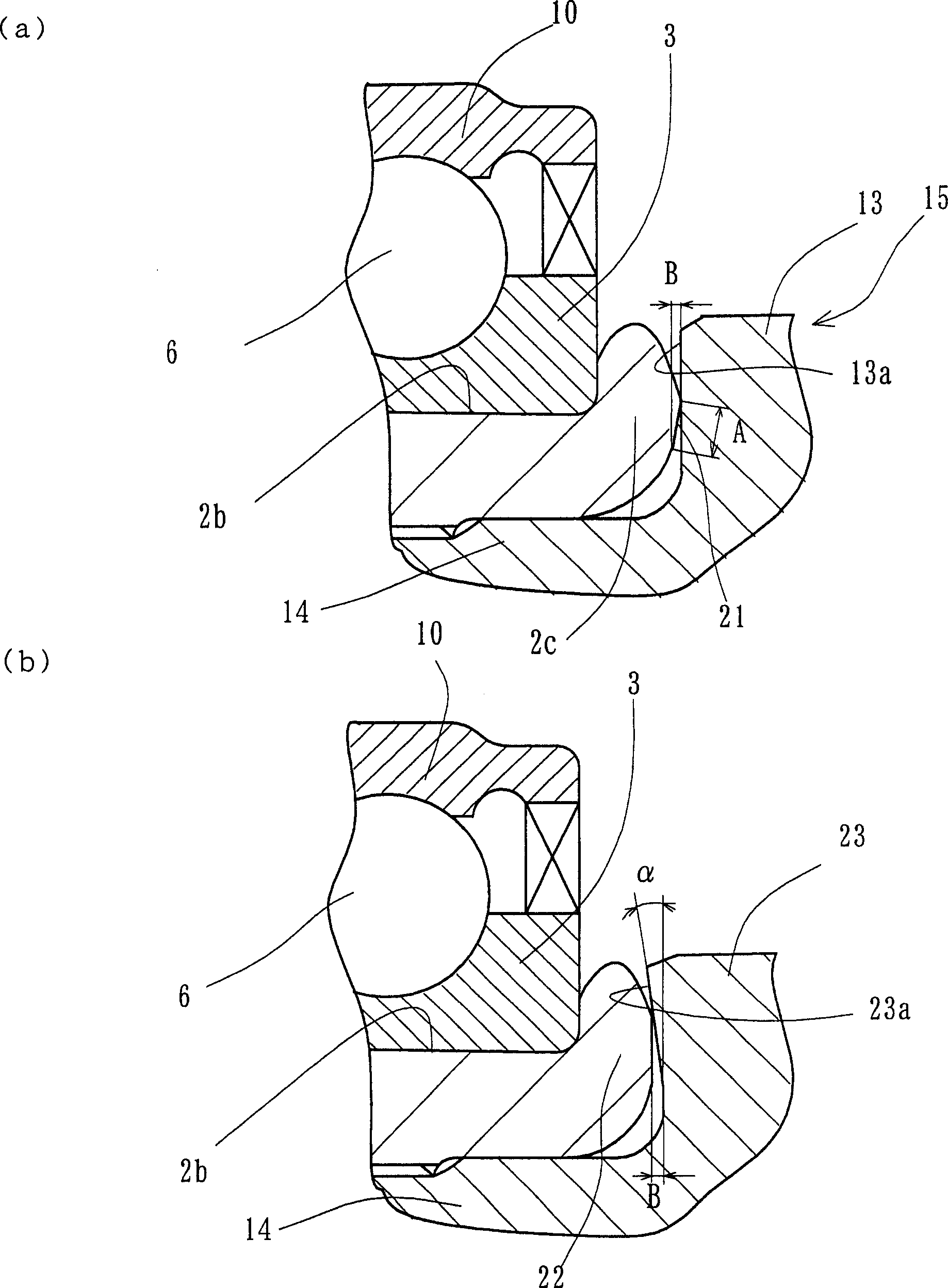

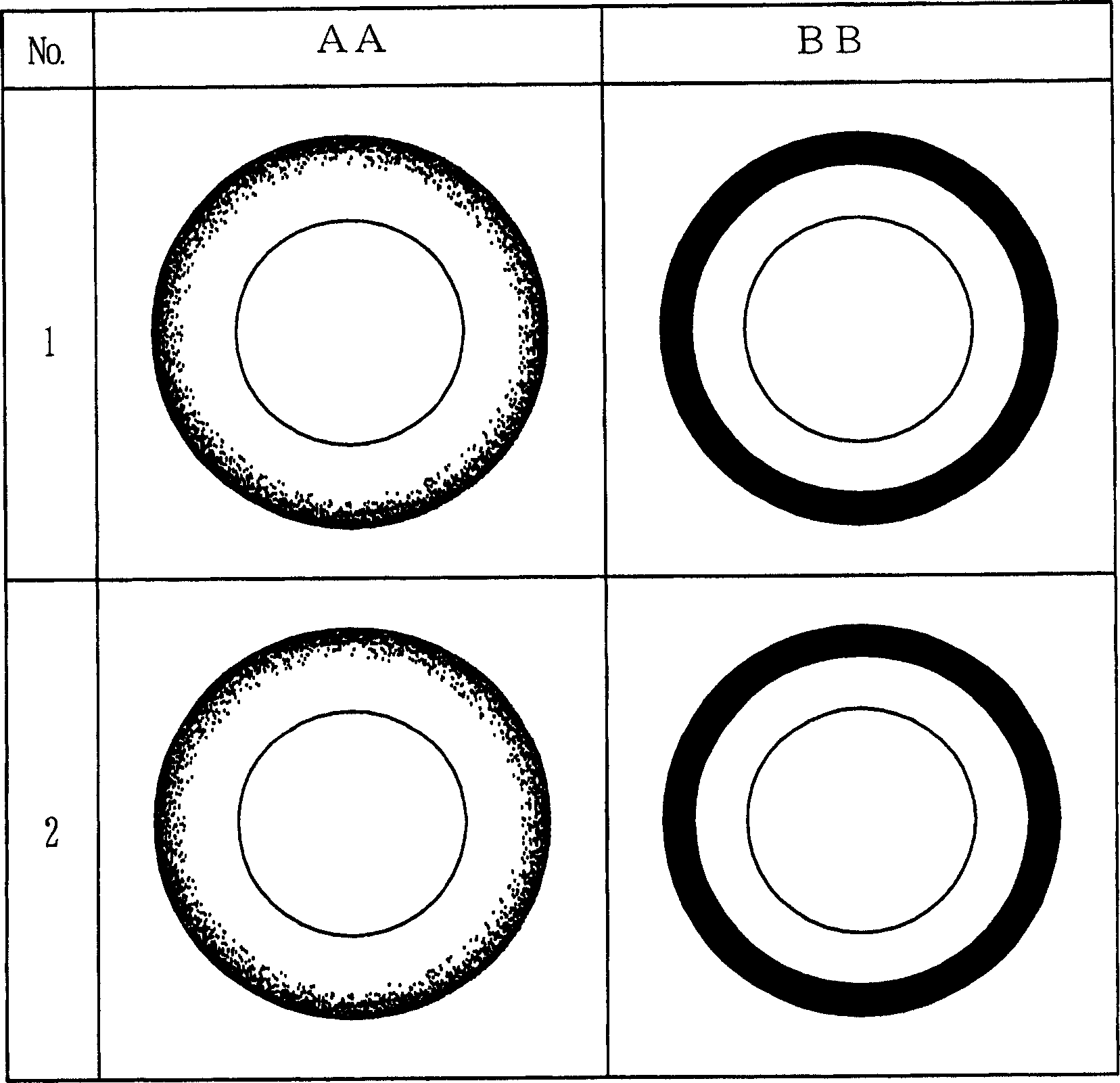

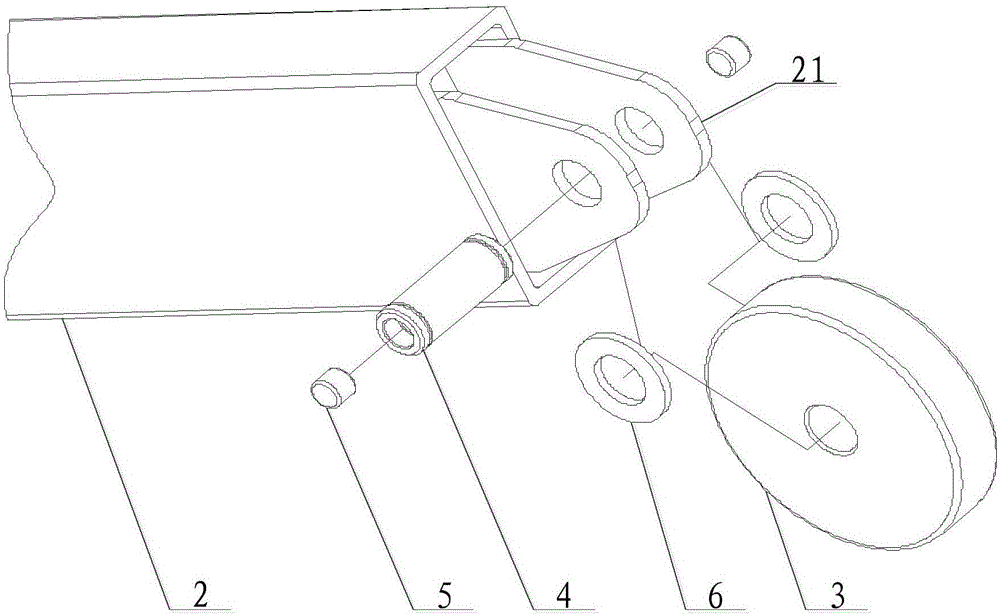

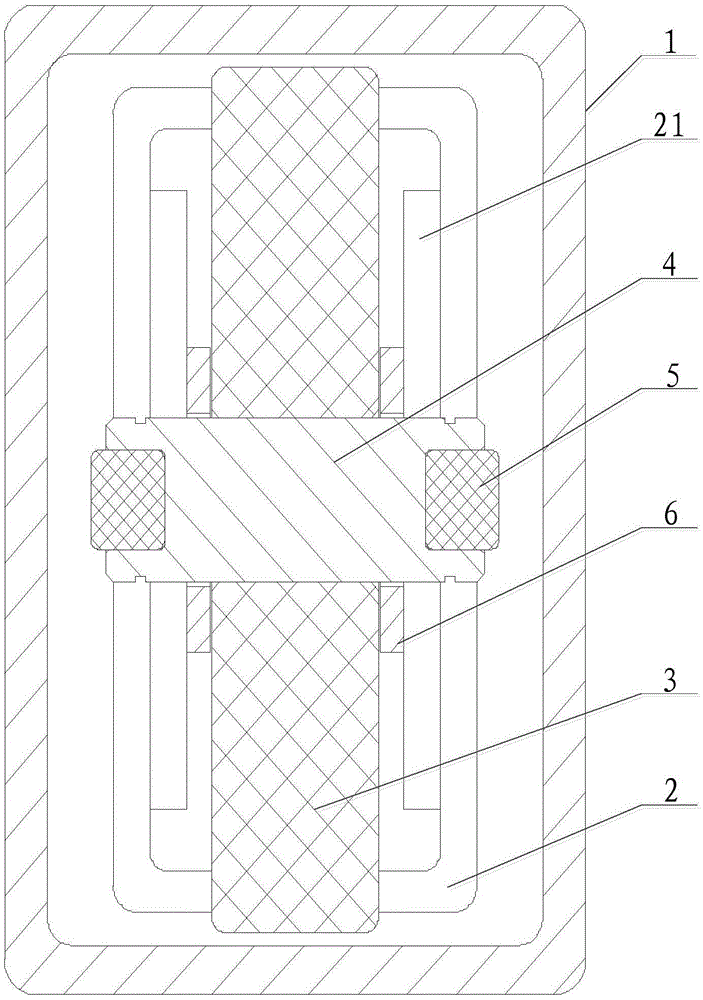

Bearing apparatus for a driving wheel of vehicle

InactiveCN1727708AExtend your lifeAvoid noiseYielding couplingRolling contact bearingsDrive wheelUniversal joint

The present invention provides a bearing apparatus for a vehicle driving wheel which prevents generation of stick-slip noise as well as fretting wear to improve durability of the bearing apparatus has an outer member ( 10 ) formed with double row outer raceway surfaces ( 10 a , 10 a) on its inner circumferential surface. An inner member ( 1, 27 ) is formed with double row inner raceway surface ( 2 a ( 24 a), 3 a) opposite to the double row outer raceway surfaces ( 10 a , 10 a). Double row rolling elements ( 6 ) are freely rollably maintained between the outer and inner raceway surfaces ( 10 a , 10 a ; 2 a ( 24 a), 3 a), respectively, of the outer and inner member ( 10; 1, 27 ). A constant velocity universal joint ( 11, 26 ), for torque transmission, is inserted into the inner member ( 10; 1, 27 ). The constant velocity universal joint abuts and is axially separably connected to the inner member via a nut ( 19 ). The end surface ( 13 a , 23 a , 28 a) of a shoulder ( 13, 28 ) of an outer joint member ( 15, 29 ) and an end surface of the inner member ( 1, 27 ) are previously formed so that these end surfaces line contact with each other at a vertex formed by inclined surfaces on the end of the inner member ( 1,27 ).

Owner:NTN CORP

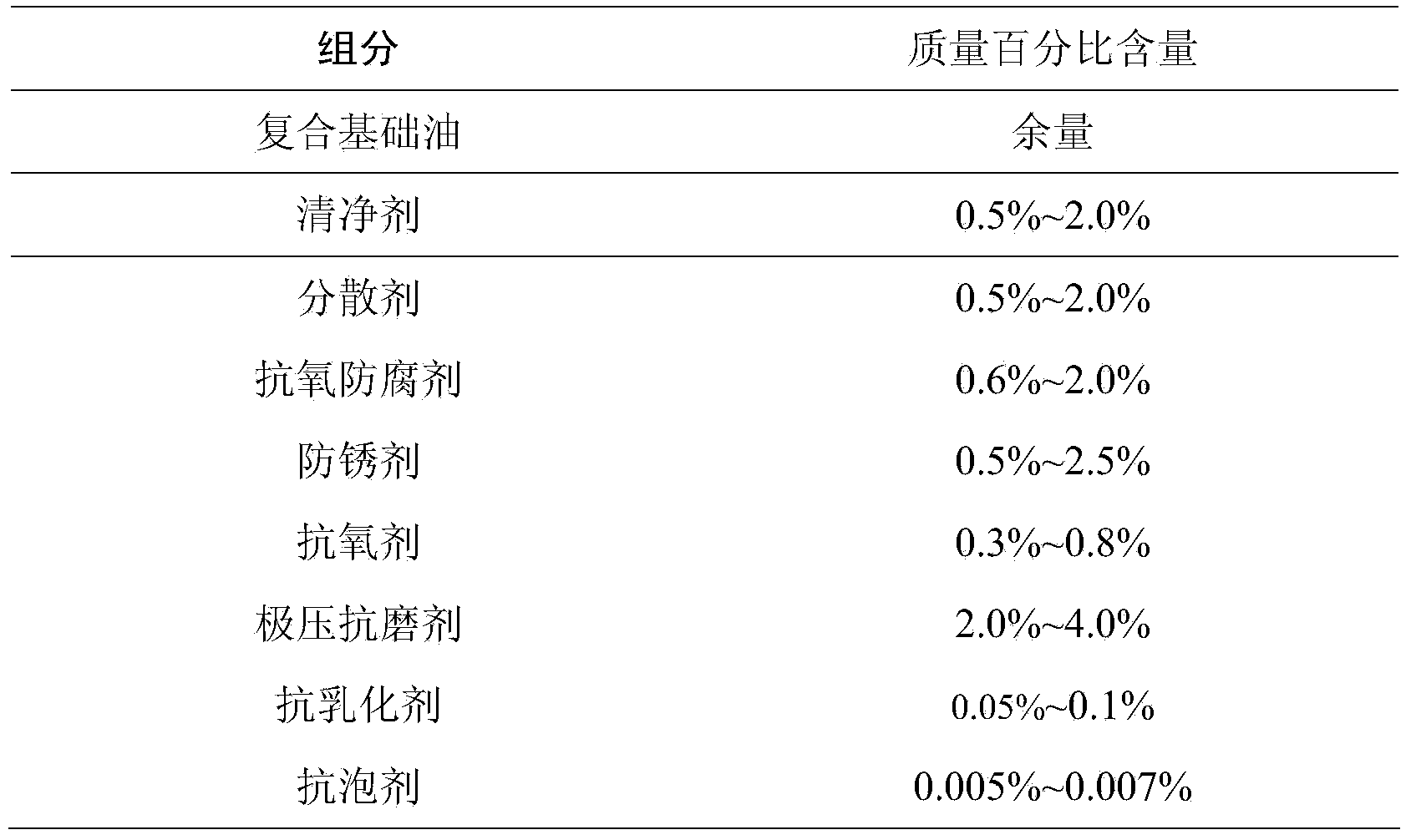

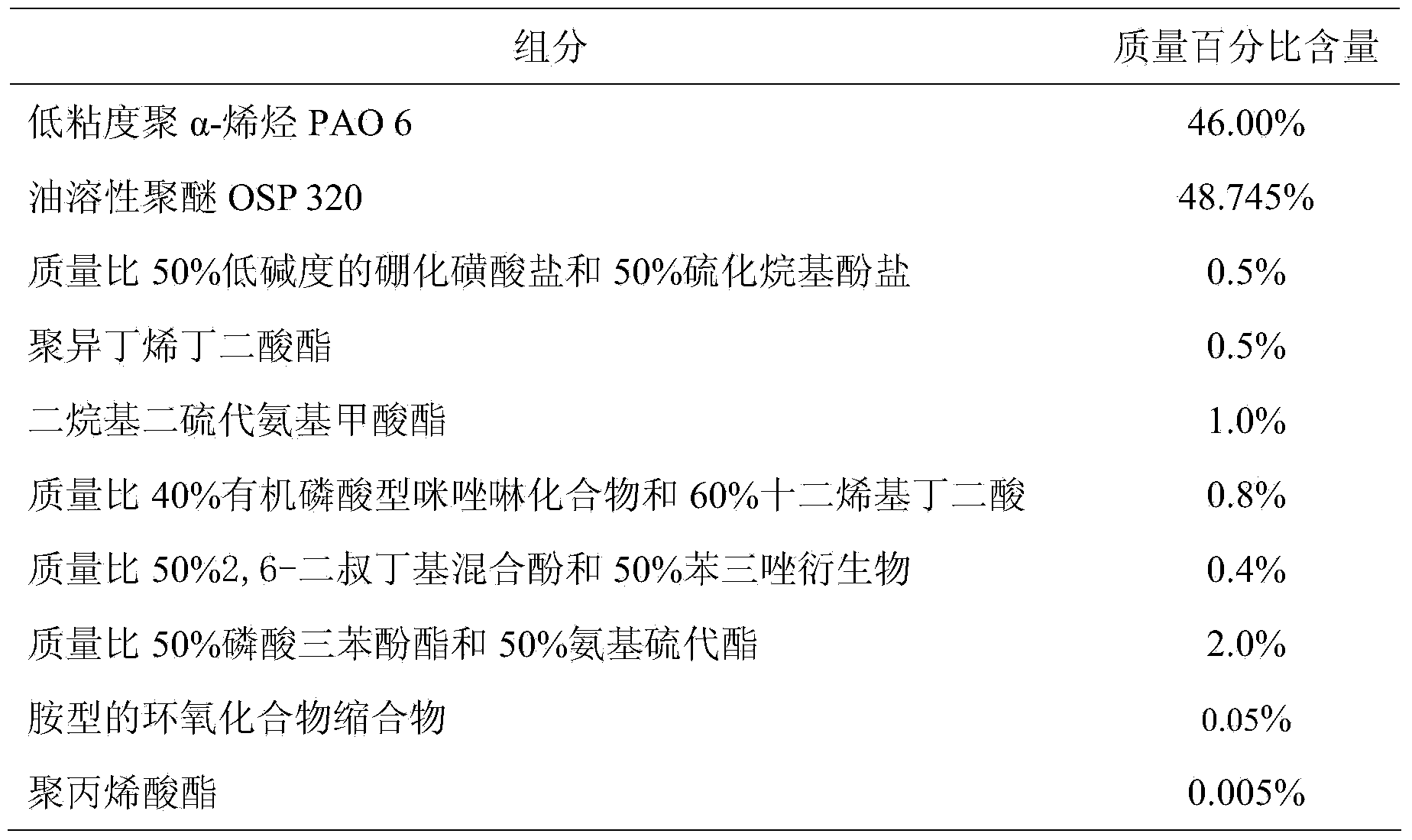

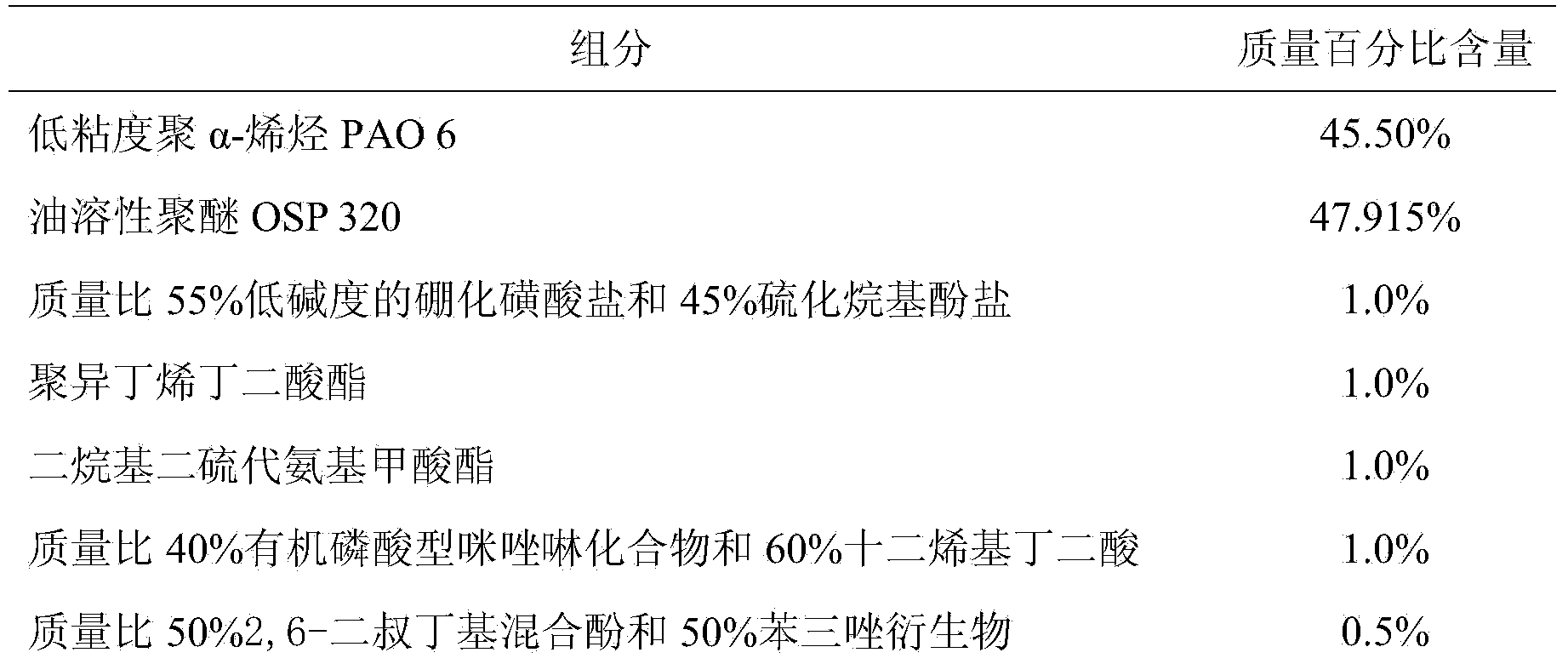

Lubricating agent of sulfur dioxide compressor

ActiveCN103525520AMeet the requirements of harsh working conditionsReduce dilutionBase-materialsOil sludgeAlpha-olefin

The invention relates to a lubricating agent of a sulfur dioxide compressor. The lubricating agent is prepared by compounding oil-soluble polyether and low-viscosity poly alpha-olefin to be base oil and mixing with various additives. The lubricating agent effectively alleviates the dilution degree on oil products caused by sulfur dioxide and avoids frictional wear due to insufficient oil film thickness caused by ultralow viscosity of the oil products, has excellent sediment controllability, does not generate carbon deposit and oil sludge, increases safety coefficient, has excellent viscosity-temperature property, low-temperature property, volatility, cooling property, high anti-shearing stability, hydrolytic stability and thermal oxidation stability, can reduce the friction coefficient of the surface of metal, and can meet the using requirement of the sulfur dioxide compressor under the harsh working condition.

Owner:GUANGXI UNIV

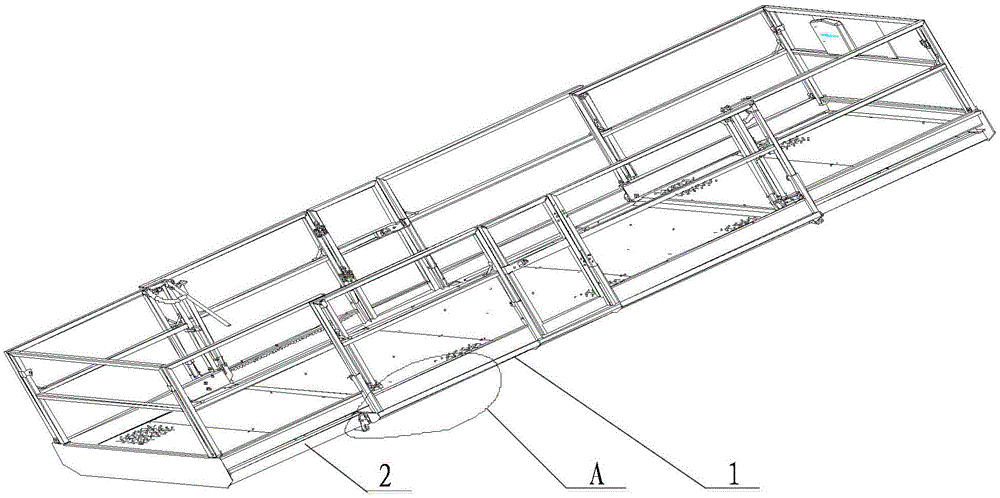

Offshore lifting platform system

InactiveCN106245617ARealize lifting and movingComfortable lifting processArtificial islandsUnderwater structuresRadial positionMarine engineering

The invention relates to the technical field of ocean operation, in particular to an offshore lifting platform system. The offshore lifting platform system comprises a platform and pile legs used for supporting the platform. The offshore lifting platform system further comprises trunks mounted on the platform. Each trunk comprises a limiting hole segment used for limiting the corresponding pile leg in the radial direction and an allowing hole segment used for allowing deflection deformation of the corresponding pile leg. Each limiting hole segment is coaxial with the corresponding allowing hole segment, each limiting hole segment is arranged at the longitudinal end of the corresponding trunk, each allowing hole segment is arranged in the longitudinal interior of the corresponding trunk, and the outer diameter of each allowing hole segment is larger than the inner diameter of the corresponding limiting hole segment. By means of the above structural arrangement, the limiting hole segments limit the radial positions of the pile legs, meanwhile, the allowing hole segments allow partial deflection deformation, generated by stress, of the pile legs, partial deformation structures and the trunks are prevented from generating abutting extrusion, and therefore the durability of the offshore lifting platform system is improved, and meanwhile the fault rate is decreased.

Owner:JINHAI HEAVY IND ZHOUSHAN DESIGN RES INST +1

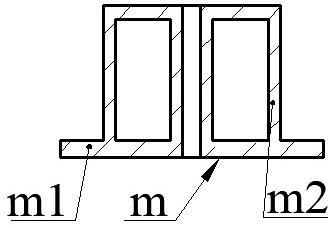

Friction energy harvesting self-powered monitoring system

ActiveCN114123844ASimple structureEasy to adjustPiezoelectric/electrostriction/magnetostriction machinesBeacon systems using radio wavesNew energyMonitoring system

The invention relates to a self-powered monitoring system for friction energy harvesting, and belongs to the field of measurement and new energy, a base is arranged at the end part of the side wall of a machine shell, a fixed disc is pressed in the machine shell, and fixed electrode plates and fixed friction plates are arranged on the upper side and the lower side of a fixed disc body; long and short step rods are respectively arranged on the upper and lower sides of a ball head of the torsion rod; the ball head is arranged in a ball cavity in the top wall of the shell; a frequency modulation block and a bluff body with a ribbon on the side wall are arranged on the long step rod; the bottom wall of the bluff body abuts against a disc spring arranged above the top wall of the machine shell. The end part of the short step rod is provided with an excitation disc; a sleeve barrel consisting of a sleeve barrel wall and a barrel top wall is arranged on a guide column on the base, and sensors are uniformly distributed on the top wall of the sleeve barrel; the sensor is in contact with a top ring of the excitation disc; a group of movable discs are sleeved on the wall of the sleeve barrel and are fixed through a pressing ring; the pressing ring is arranged at the end part of the wall of the sleeve barrel and presses the disc-shaped spring on the base; a gap is reserved between the movable disc and the fixed disc; movable electrode plates and movable friction plates are adhered to the upper side and the lower side of the movable disc body; and the movable friction plates and the fixed friction plates are made of different materials.

Owner:ZHEJIANG NORMAL UNIVERSITY

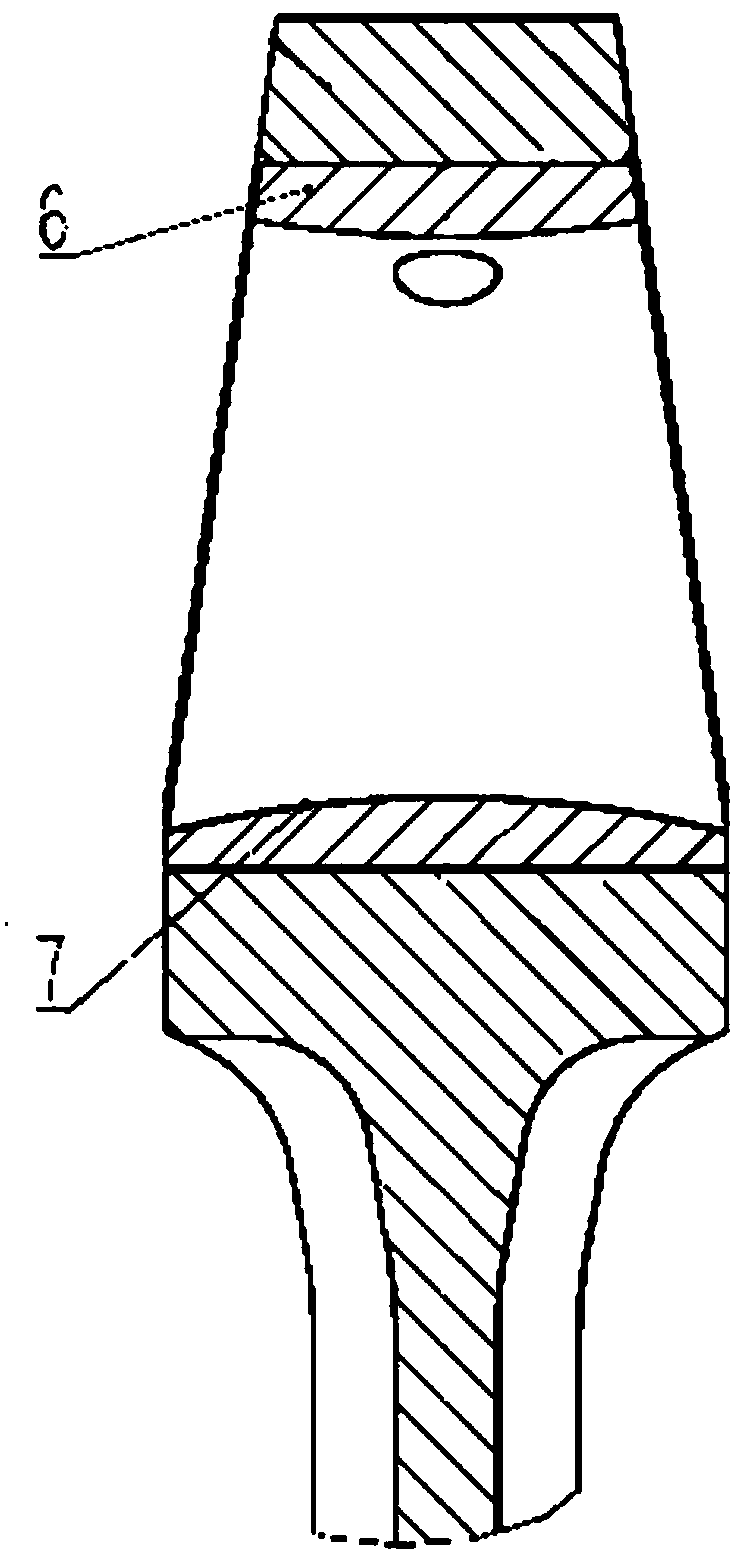

Thrust cylindrical roller spherical bearing for differential mechanism assembly and machining method of thrust cylindrical roller spherical bearing

PendingCN109027011AReduce friction and wearExtended service lifeBearing componentsSpherical bearingRolling resistance

The invention discloses a thrust cylindrical roller spherical bearing for a differential mechanism assembly and a machining method of the thrust cylindrical roller spherical bearing. The thrust cylindrical roller spherical bearing comprises a seat ring. The inner diameter and the outer diameter of the seat ring are two concentric circles, and the outer diameter is matched with a concave spigot ofa planetary gear. One side of the seat ring is connected with a holder. The inner diameter of the holder is the same as that of the seat ring. The inner diameter of the seat ring and the inner diameter of the holder are in small clearance fit with a cross shaft. One side of the holder is connected with a shaft ring. The shaft ring is of a structure with one end being a plane, the other end being aconvex spherical surface, an inner hole being in a non-continuous round shape and the thickness being a non-constant value. After the thrust cylindrical roller spherical bearing replaces an originalspherical surface gasket, inherent sliding friction between two parts with relative rotation or rotating tendency between original contact faces in the differential mechanism assembly is changed intorolling friction between the shaft ring, the seat ring and a roller of the bearing, and friction wear is reduced.

Owner:洛阳华冠齿轮股份有限公司

A hydraulic cylinder piston sealing device with anti-deformation and oil leakage storage capacity

InactiveCN105179377BPrevent oil spillsTemporary storage prevention of oil spillEngine sealsFluid-pressure actuatorsHydraulic cylinderEngineering

Owner:UNIV OF JINAN

Aerial work platform

ActiveCN105060201ADoes not prevent offsetAvoid not being able to slide relative to each otherLifting devicesEngineeringAerial work platform

The invention discloses an aerial work platform. The work platform comprises a fixed platform and a movable platform, the fixed platform and the movable platform are in sliding fit with a guide rod through a guide rail, a pulley which can slide in the guide rail and a pin shaft which is used for hinging the pulley to the guide rod are arranged at one end of the guide rod, and the work platform further comprises abutting-against pieces which are installed at the two ends of the pin shaft and can prevent the side wall of the guide rail from being in contact with the side wall of the guide rod; when the pulley reaches the preset position, the abutting-against pieces can move in the axis direction of the pin shaft. When the pulley is within the offset-permitted range, the circumstance that friction force between the abutting-against pieces and the guide rail is generated, so that the frictional wear is caused can be avoided through the abutting-against pieces, and meanwhile the relative sliding between the guide rail and the guide rod is guaranteed. After the pulley breaks away from the preset position, the abutting-against pieces are located between the side wall of the guide rail and the pin shaft, and the side wall of the guide rail can be prevented from abutting against the guide rod so that the abutting-against problem between the guide rod and the guide rail can be effectively solved.

Owner:HUNAN SINOBOOM HEAVY IND

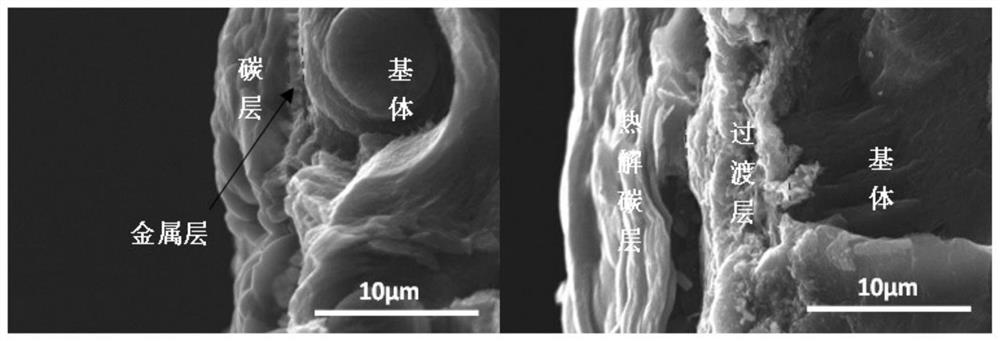

Carbon-based composite material artificial bone repair material and preparation method thereof

ActiveCN112190761AAvoid friction and wearLow thermal conductivityTissue regenerationProsthesisCarbon layerRepair material

The invention provides a carbon-based composite material artificial bone repair material and a preparation method thereof. The carbon-based composite material artificial bone repair material is prepared by sequentially forming a ceramic layer and a pyrolytic carbon layer on the surface of a carbon-based porous material. The preparation method is that a metal layer and a low-temperature carbon layer are sequentially generated on the surface of a carbon-based porous material matrix of a profiling artificial bone, the metal layer and the low-temperature carbon layer are converted into a ceramic layer by high-temperature heating treatment, then the pyrolytic carbon layer is deposited to obtain an artificial bone repair material with biomimetic form and biomimetic function. The artificial bonerepair material has high internal porosity, low thermal conductivity and low elastic modulus, and the surface composite coating can be used as a developing and blocking layer of an artificial bone contour, and provides a smoother surface and a soft contact surface, so that frictional wear between the hard ceramic inner layer and the autologous bone stump in human body is avoided.

Owner:HUNAN TANKANG BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com