Vortex rotary compressor and control method thereof and air conditioner

A control method and compressor technology, which is applied in the field of compressor manufacturing, can solve problems such as large friction and wear and low transmission efficiency, and achieve the effect of improving reliability and avoiding friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

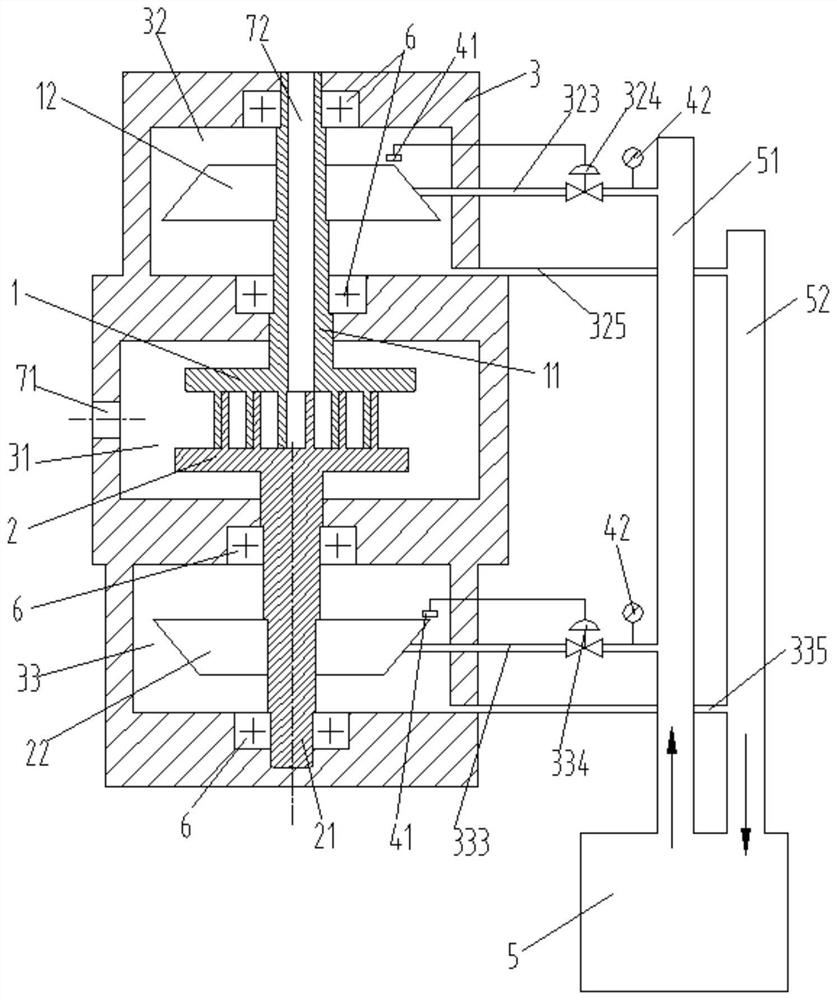

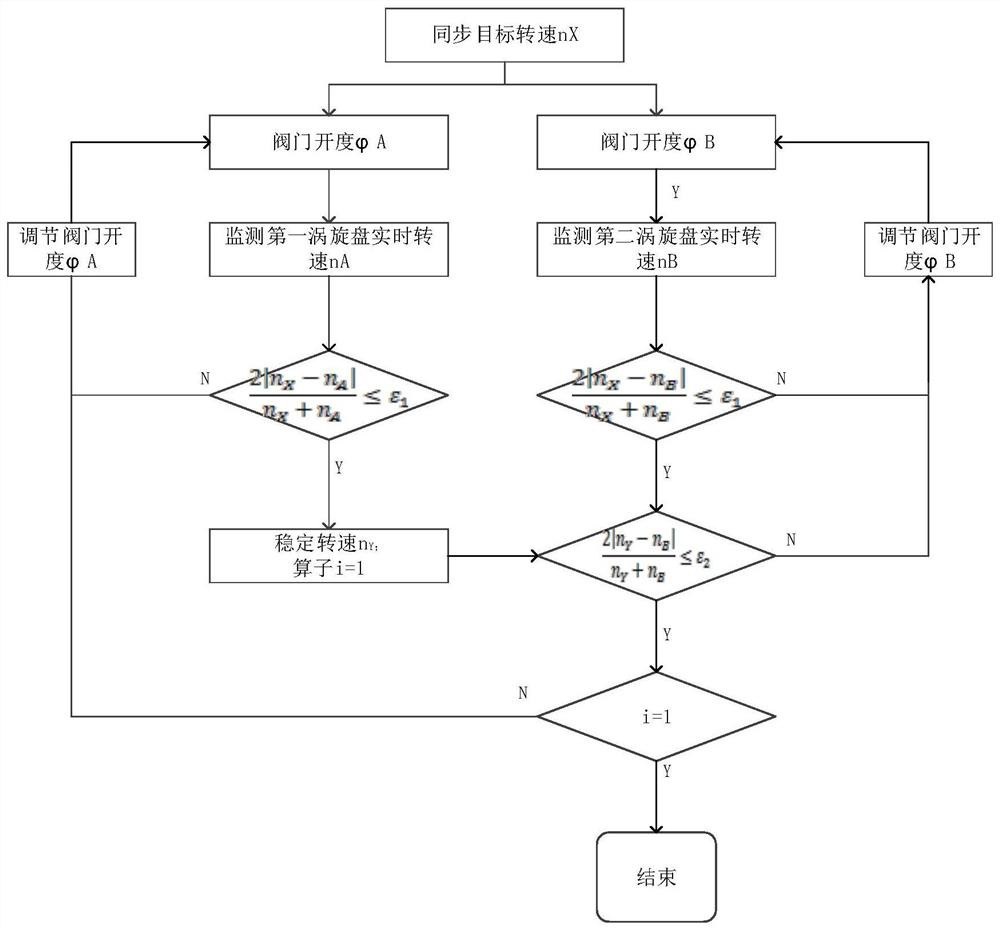

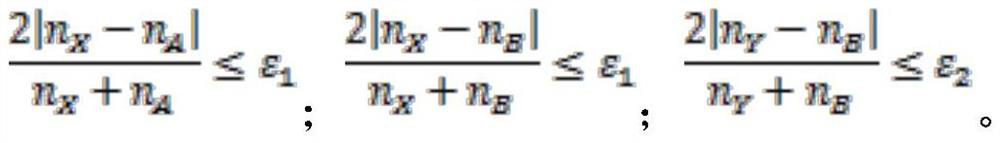

[0029] see in conjunction Figure 1 to Figure 2 As shown, according to an embodiment of the present invention, a scroll rotary compressor is provided, including a casing 3, a first scroll 1, and a second scroll 2, the first scroll 1 and the The second scroll 2 is rotatably supported in the housing 3 with a preset eccentricity interleaving arrangement and the relative angular phase position of the two is staggered by 180°, and also includes a hydraulic power system, the hydraulic power system Pressurized fluid (such as fluid with low compressibility such as hydraulic oil) can respectively drive the first scroll 1 and the second scroll 2 to rotate in the same direction. In this technical solution, the pressure fluid of the hydraulic power system is used to drive the synchronous and co-rotation of the first scroll 1 and the second scroll 2, which can realize the control of the first scroll 1 and the second scroll. The stepless adjustment of the rotational speed of the disk 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com