Self-lubricating composite material as well as preparation method and application thereof

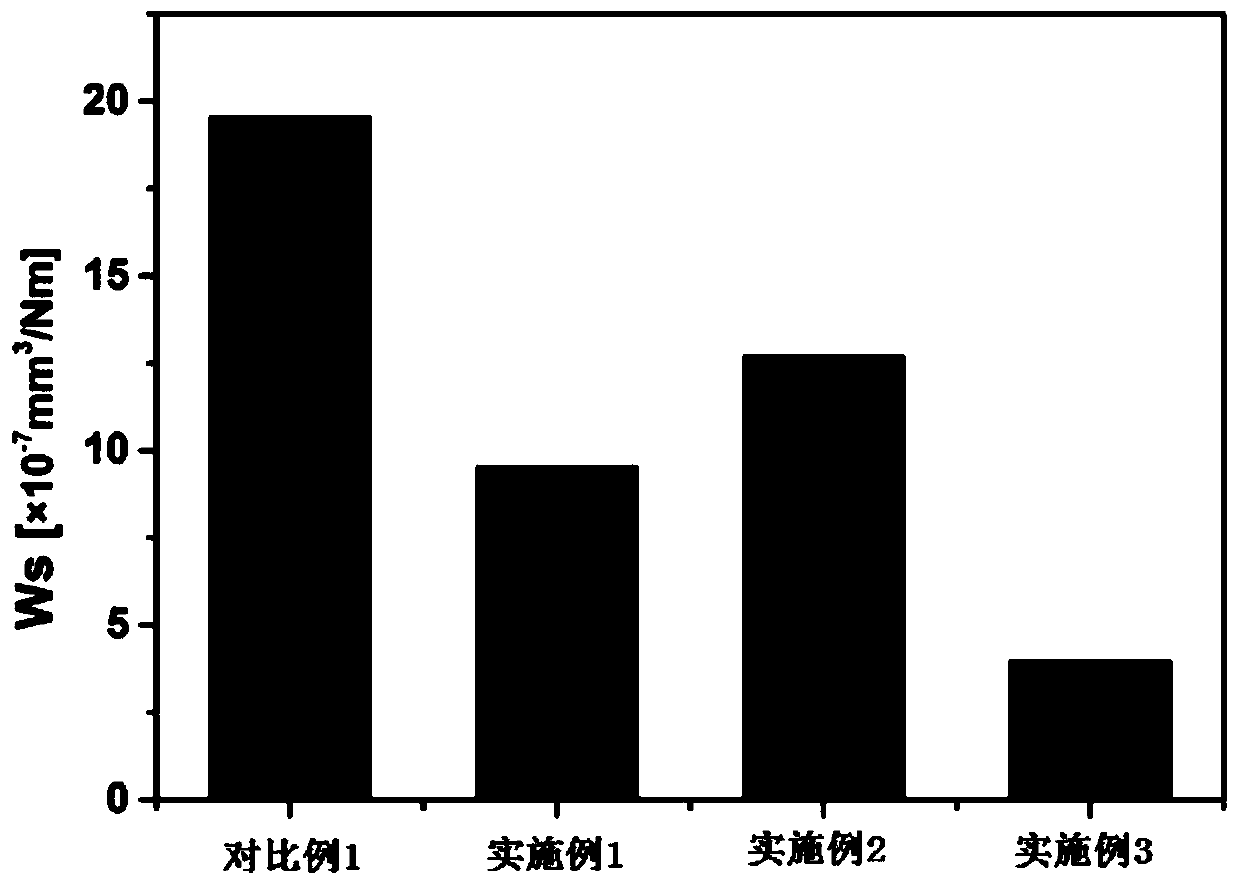

A composite material, self-lubricating technology, applied in the field of composite materials, can solve the problems of unsuitable self-lubricating materials, pure epoxy resin adhesive wear, etc., and achieve the effect of overcoming adhesive wear and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

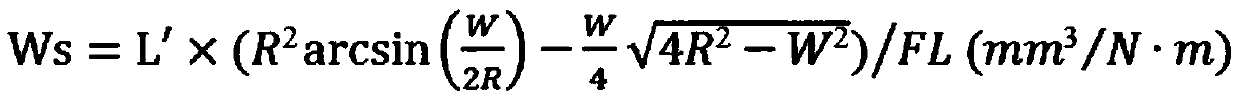

Examples

preparation example Construction

[0024] In the present invention, the preparation method of the two-dimensional layered nanomaterial preferably includes the following steps:

[0025] The ternary layered compound MAX ceramic powder is placed in a hydrofluoric acid solution and etched to obtain an acid solution containing MXene;

[0026] The MXene-containing acid solution is centrifuged to obtain a two-dimensional layered nanomaterial.

[0027] In the present invention, the ternary layered compound MAX ceramic powder is preferably placed in a hydrofluoric acid solution for etching to obtain an acid solution containing MXene. In the present invention, the two-dimensional layered compound MAX ceramic powder is preferably Ti 3 AlC 2 powder; the particle size of the ternary layered compound MAX ceramic powder is preferably 50-100 μm, more preferably 74 μm.

[0028] In the present invention, the mass concentration of the hydrofluoric acid solution is preferably 35-55%, more preferably 40%.

[0029] In the presen...

Embodiment 1

[0046] Slowly add 1.0 g of Ti with a particle size of 74 μm to 11.25 mL of hydrofluoric acid solution with a mass concentration of 40%. 3 AlC 2 Powder, Ti 3 AlC 2 The speed of powder addition was controlled within 5 minutes, and the temperature was slowly raised to 35°C, and the reaction was continued for 24 hours with stirring to obtain an acid solution containing MXene;

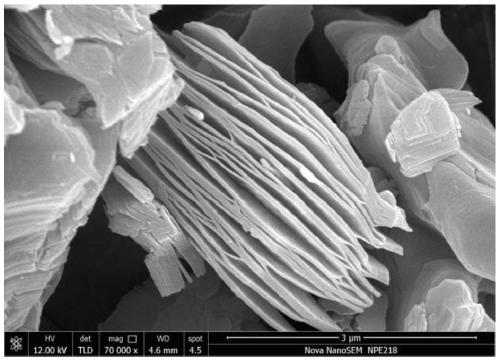

[0047] Place the MXene-containing acid solution in a centrifuge tube, perform centrifugal cleaning at a speed of 3500r / min for 10 min, discard the supernatant, continue to add deionized water to the centrifuge tube, centrifuge, and repeat the above process until the above The pH value of the clear liquid is neutral; the sediment after centrifugation and washing is freeze-dried to obtain a two-dimensional layered nanomaterial; the size of the two-dimensional layered nanomaterial is 3-5 μm, and the sheet thickness is 20 nm.

[0048] The scanning electron microscope picture (SEM figure) of gained two-dimens...

Embodiment 2

[0055] The preparation method is basically the same as in Example 1, except that the mass ratio of the two-dimensional layered nanomaterial to the liquid bisphenol A epoxy resin is 1:99.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com