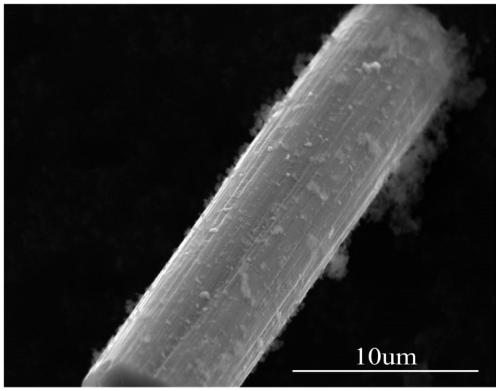

Reinforced poly-ether-ether-ketone composite material with nano SiO2 chemically grafted to surfaces of carbon fibers and preparation method of material

A technology of surface chemistry and polyether ether ketone, applied in the field of material science, can solve problems affecting the excellent performance of composite materials, poor interfacial bonding strength, and few active functional groups, so as to improve mechanical and tribological properties, small size effect, and large The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A carbon fiber surface chemically grafted nano-SiO of the present invention 2 A method for preparing a reinforced polyether ether ketone composite material, comprising the following steps:

[0039] (1) Carbon fiber pretreatment: reflux the carbon fiber in a mixed solution of ethanol and acetone for 48 hours to remove the sizing agent on the surface of the carbon fiber; then wash and dry, and use concentrated nitric acid to ultrasonically oxidize the carbon fiber for 1 hour at a temperature of 60°C , the treated carbon fiber is washed with distilled water several times to neutrality, and dried at a temperature of 150° C. to a constant weight for later use; wherein, the volume ratio of ethanol to acetone in the ethanol and acetone solution is 1:1. The purpose of carbon fiber acid treatment is to introduce active functional groups such as hydroxyl and carboxyl groups on its surface, which is beneficial to the next step of chemical grafting reaction.

[0040] (2) Carbon fi...

Embodiment 1

[0053] A carbon fiber surface chemically grafted nano-SiO 2 Reinforced PEEK composite material preparation method, the specific steps are as follows:

[0054] (1) Carbon fiber pretreatment: Take 20 g of carbon fiber and reflux for 48 hours in a mixed solution of ethanol and acetone with a volume ratio of 1:1 to remove the sizing agent on the surface of the carbon fiber. After washing and drying, the carbon fibers were ultrasonically oxidized at 60 °C for 1 h using concentrated nitric acid. After the reaction, the carbon fiber was washed several times with distilled water to neutrality, and dried at 150°C to constant weight for later use.

[0055] (2) Carbon fiber activation treatment: ultrasonically disperse γ-glycidyl etheroxypropyl trimethoxysilane in absolute ethanol to prepare γ-glycidyl etheroxypropyltrimethoxysilane absolute alcohol with a mass concentration of 3%. solution. Then add the carbon fibers treated with concentrated nitric acid, and react with magnetic stir...

Embodiment 2

[0063] A carbon fiber surface chemically grafted nano-SiO 2 Reinforced PEEK composite material preparation method, the specific steps are as follows:

[0064] (1) Carbon fiber pretreatment: Take 20 g of carbon fiber and reflux for 48 hours in a mixed solution of ethanol and acetone with a volume ratio of 1:1 to remove the sizing agent on the surface of the carbon fiber. After washing and drying, the carbon fibers were ultrasonically oxidized at 60 °C for 1 h using concentrated nitric acid. After the reaction, the carbon fiber was washed several times with distilled water to neutrality, and dried at 150°C to constant weight for later use.

[0065] (2) Carbon fiber activation treatment: ultrasonically disperse γ-glycidyl etheroxypropyl trimethoxysilane in absolute ethanol to prepare γ-glycidyl etheroxypropyltrimethoxysilane absolute alcohol with a mass concentration of 3%. solution. Then add the carbon fibers treated with concentrated nitric acid, and react with magnetic stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Specific wear rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com