Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Guaranteed Dimensional Tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

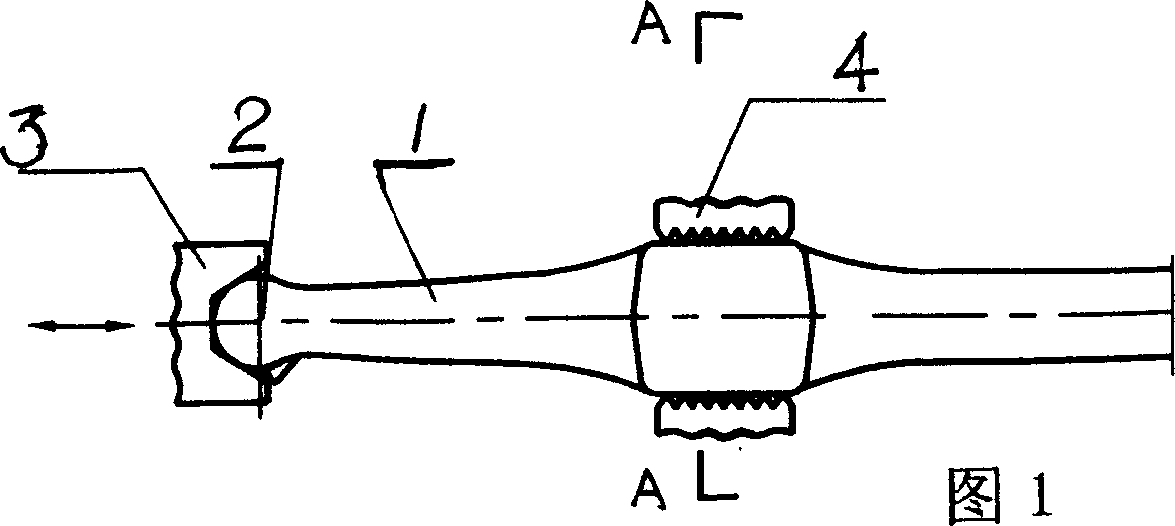

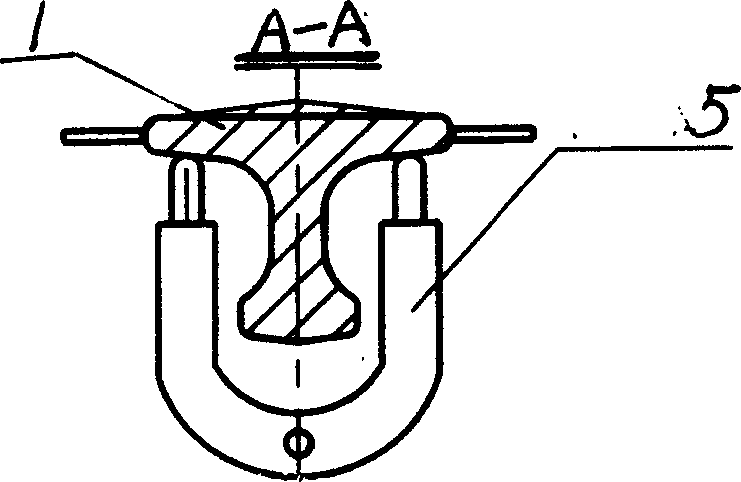

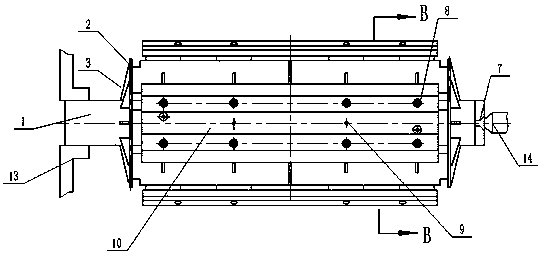

Manufacturing method of pedestal bearing for turbocharger and positioning tool for same

ActiveCN102658458AStress reliefEliminate processing stressGrinding work supportsTurbochargerEngineering

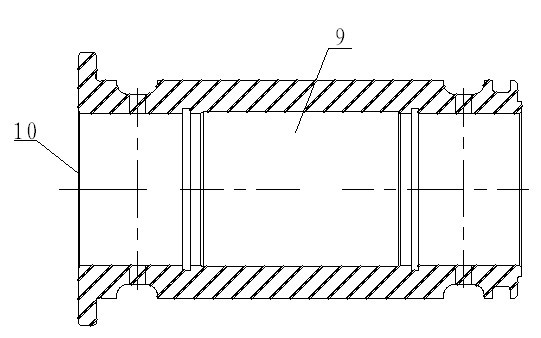

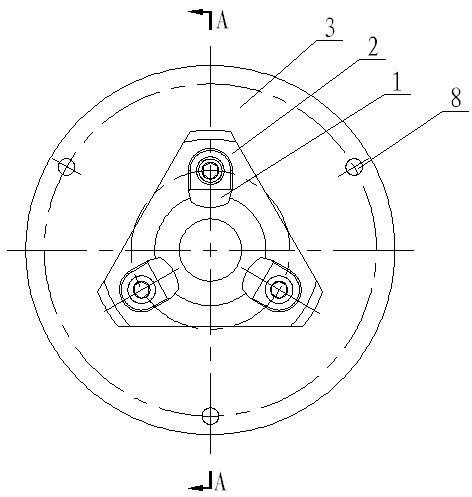

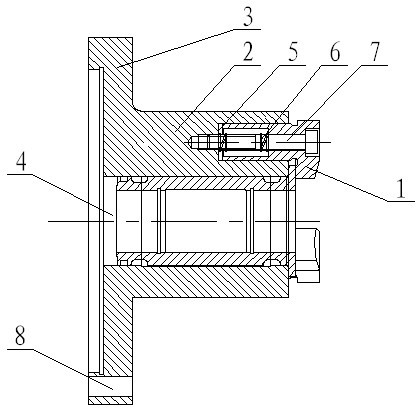

The invention discloses a manufacturing method of a pedestal bearing for a turbocharger and a positioning tool for the same. The manufacturing method comprises the following machining procedures of: 1), roughly turning one end surface and a hole of a workpiece; 2), roughly turning the other end surface and an outer circle of the workpiece; 3), annealing the workpiece to remove stress; 4), carrying out finish turning on the end surface and the hole; 5), carrying out the finish turning on the other end surface and the hole; 6), milling a semicircular positioning groove; 7), drilling radial holes at two ends; 8), milling the flat and square parts of the outer circle; 9), removing burrs by a bench worker; 12), milling an oil applying wedge surface of a thrust surface; 13), carrying out flaw detection; 14), removing the burrs by the bench worker and cleaning a part; and 15), carrying out comprehensive detection. The procedure 3) is adopted between the procedure 2) and the procedure 4) to anneal the workpiece to remove the stress; a procedure 10) and a procedure 11) are adopted between the procedure 9) and the procedure 12); the procedure 10) comprises the following steps of: adopting the positioning tool, positioning the outer circle of the workpiece by utilizing a tool hole, compacting the thrust surface of the workpiece, and accurately grinding the holes; and the procedure 11) comprises the following steps of: positioning the holes by utilizing a taper shaft, and accurately grinding the outer circle and the thrust surface. The manufacturing method and the positioning tool have the advantages that the procedures are arranged reasonably, and the machining quality and the machining efficiency can be effectively improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

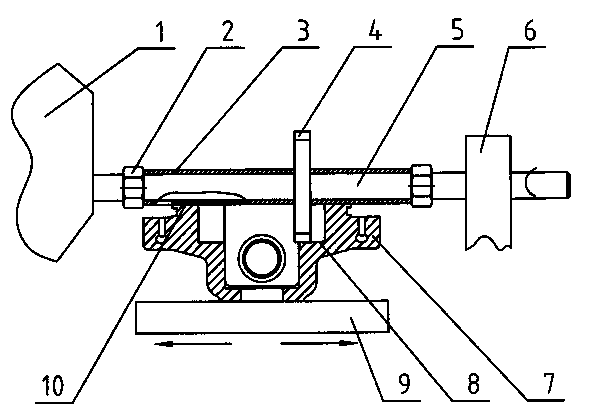

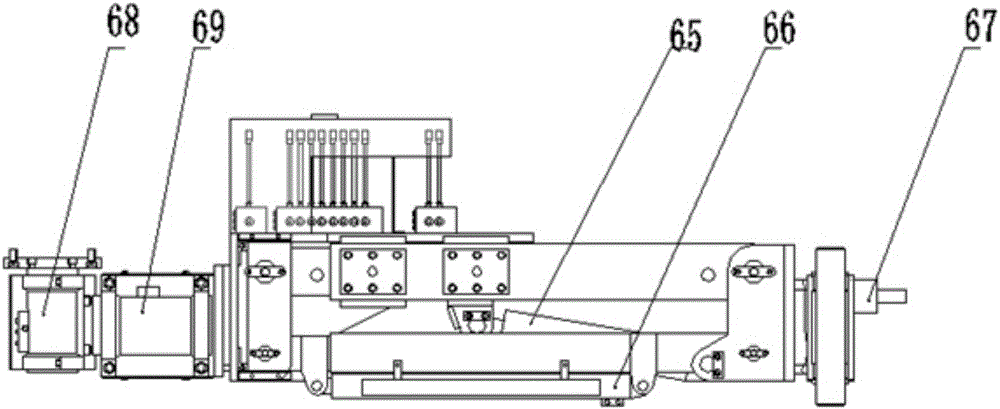

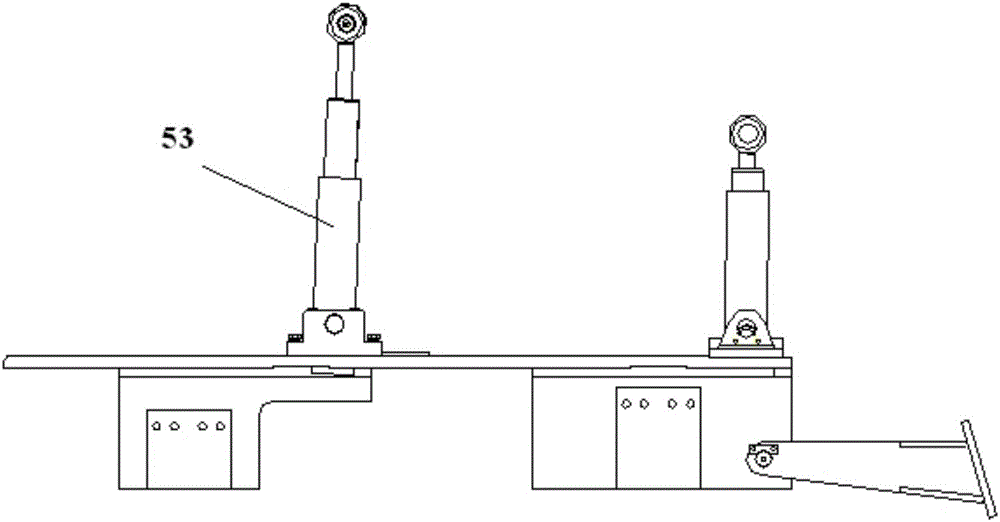

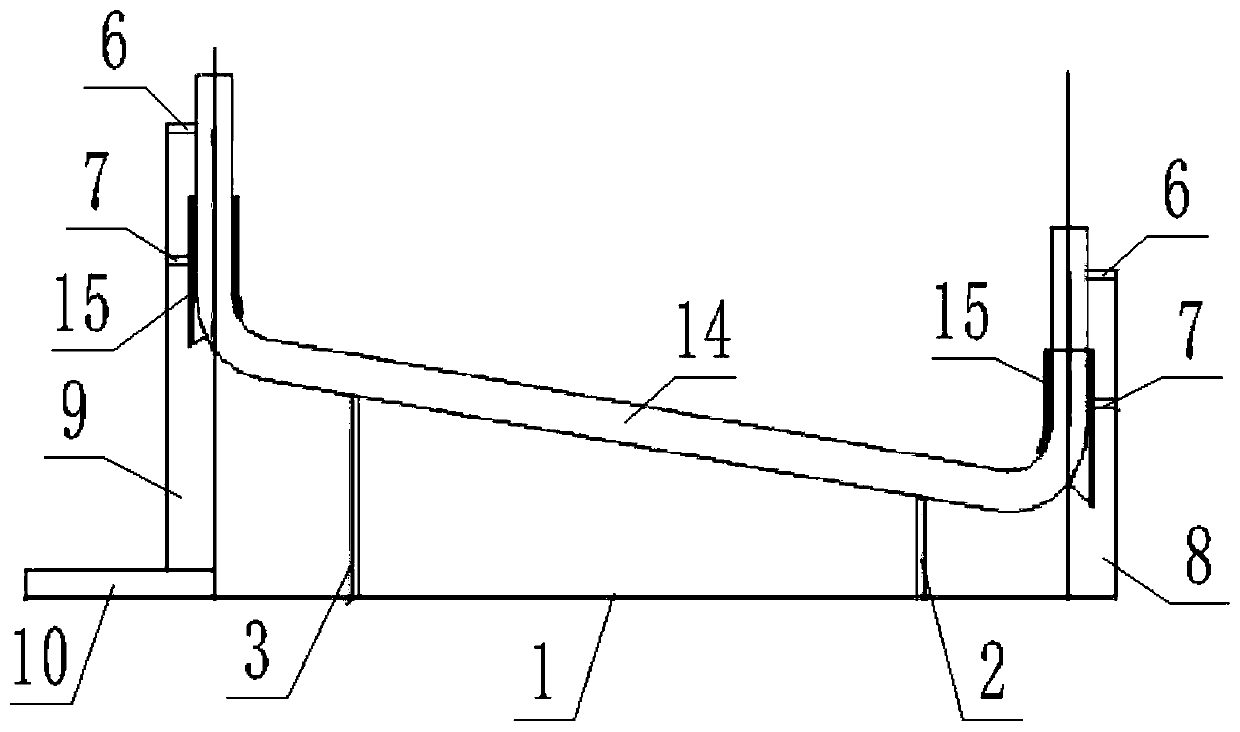

Machine special for automatic welding of baseboard and welding method

ActiveCN103170705AGuaranteed Dimensional TolerancesIncrease productivityWelding/cutting auxillary devicesElectrode supporting devicesBaseboardEngineering

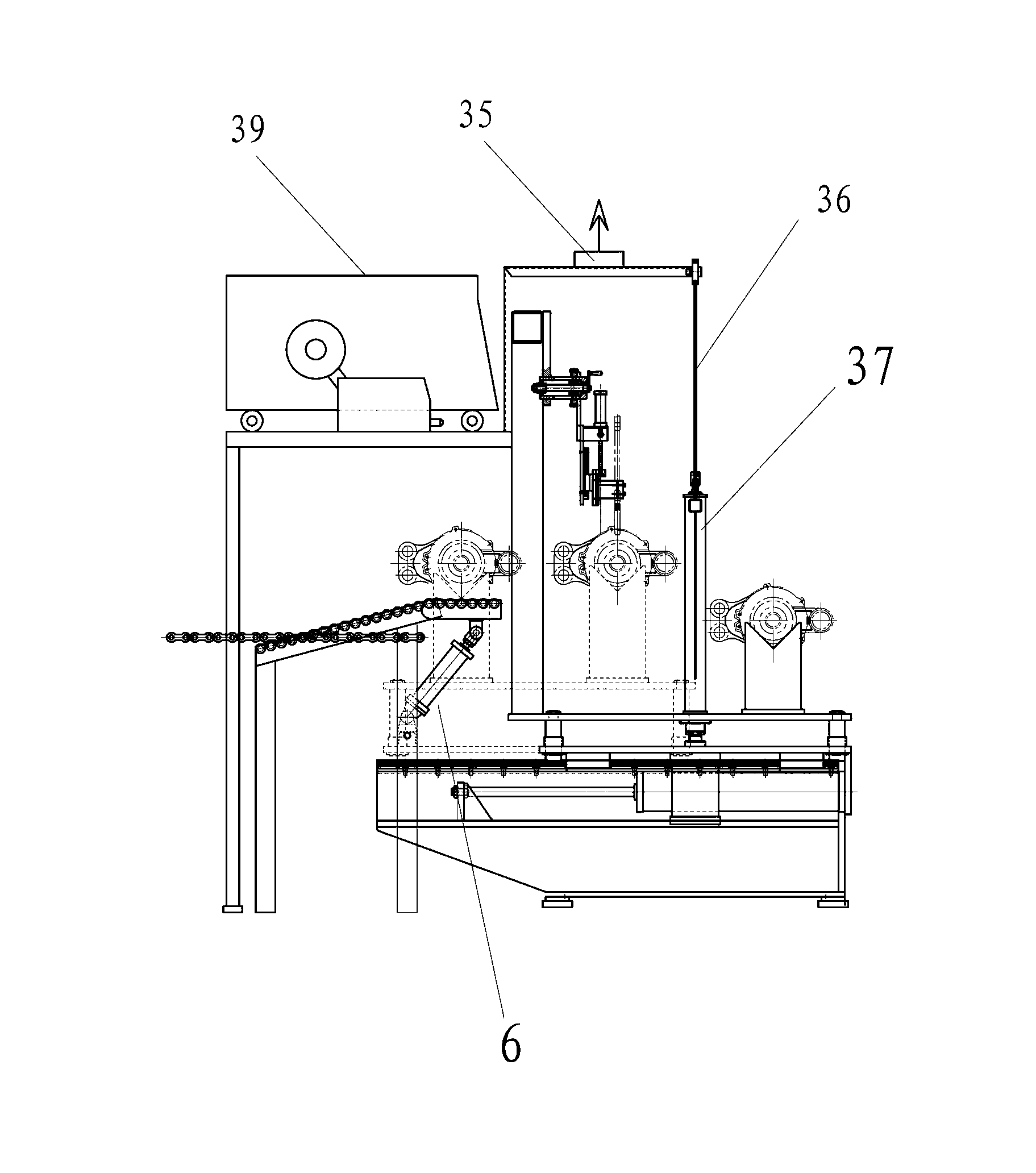

The invention discloses a machine special for automatic welding of a baseboard. The machine comprises a platform and a machine frame, a welding post and a correcting post are arranged on the platform, the machine further comprises a supporting feeding mechanism used for moving shaft bodies to different posts, a first fixed tailstock and a first moving tailstock are arranged on the correcting post, a second fixed tailstock and a second moving tailstock are arranged on the welding post, sliding rails are arranged on two sides of the machine frame, each sliding rail is provided with welding equipment, and a pivot device used for driving the shaft bodies to rotate is further arranged on the welding post. Due to the fact that correcting and welding are divided, corrected shaft bodies are conveyed to the welding post through a conveying belt, production efficiency is improved by one time. The process of correcting is conducted automatically, a worker needs only to operate a point welding machine and click a welding command, the inherent defect of manual locating is overcome, and therefore the machine special for automatic welding of the baseboard has the advantages of being reasonable and accurate in clamping and locating and capable of guaranteeing dimensional tolerance of the shaft bodies, aligning a welding gun automatically, overcoming the phenomenon of partial welding and improving welding assembling quality greatly.

Owner:GUANGDONG FUWA HEAVY IND

Cold-working boring and milling composite technology for automobile front axle

ActiveCN1593841AGuaranteed Aperture SizeGuaranteed surface roughnessOther manufacturing equipments/toolsEngineeringSpring steel

The invention relates to a kind of cold boring and milling technique to process the foreside axis of the car. The main technique is: locate the two spring steel seats, drill ten holes in each steel board, and drill the holes again with U drilling technology to finish the primary process. Fine the holes and corner, the upper and the under board faces with the boring bed. Only one setting and clumping step is needed to finish the holes process. The invention overcomes the excursion phenomenon by combining the boring and milling technology with three work position machine bed to take the drill-bore-drill-hinge procedure. It limits the warp between the chief pin hole and the locking pin hole. The technology is simple and has high processing precision. So the product is high quality, and needs few device and cost. The production efficiency is high and the work steam intensity between the procedures is low. In addition, it can make sure clean working circumstance.

Owner:HUBEI TRI RING AXLE

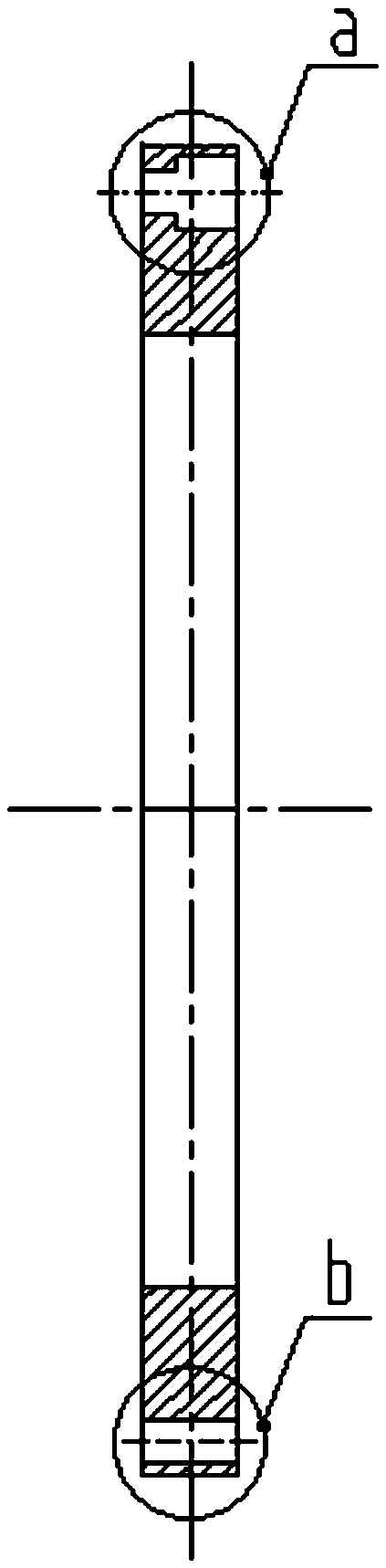

Manufacture process of robot RV reducer spline eccentric shaft

The invention discloses a manufacture process of a robot RV reducer spline eccentric shaft. The manufacture process comprises the following steps: forging a shaft blank; drilling a central tip hole in each of two end faces of the shaft blank, and milling a positioning groove in the circumference of a spline end; finish machining two cams close to the bearing positions of taper-roller bearings and finish machining two end faces of the bearing position simultaneously by adopting the two central tip holes as the positioning reference; finish grinding two end parts of the spline eccentric shaft and the bearing positions of the two taper-roller bearings by adopting the two central tip holes as the positioning reference; finish grinding the circumferential surfaces of the two cams by adopting the two central tip holes as the positioning reference; taking the two central tip holes as the reference, taking the phase difference of the two cams as a starting point to enable the phase difference of the two cams to be 180 degrees; performing gear hobbing and gear grinding on a spline by adopting the positioning groove as the reference. With adoption of the manufacture process, the processing error and the assembling error can be reduced to meet the assembling requirement of a high-precision RV reducer.

Owner:GREATOO SINO GERMAN ROBOT & INTELLIGENT MFG CO LTD +1

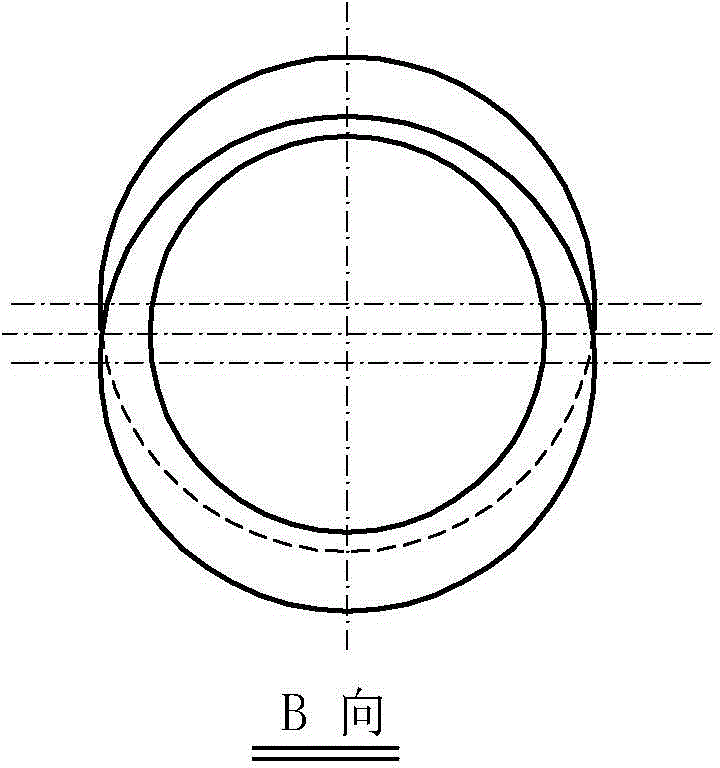

Method for rolling high-precision titanium alloy pipes

ActiveCN104148439AImprove ovalityEliminate bumpsWork treatment devicesMetal rolling arrangementsMetallurgyMicrometer

The invention relates to a method for rolling high-precision titanium alloy pipes. A prepared titanium alloy pipe billet is rolled in a combination way of two rollers and three rollers, and the rolling method adopts single feeding and double slew. The value Q of two-roller rolling is 0.4-2, the value Q of multiple-roller rolling is 0.4-9, and the amount of clearance is 0.2-2mm. The rolled finished pipe is processed in a way of outer surface grinding and inner surface honing to obtain the titanium alloy pipes, wherein the outer surface roughness Ra is less than or equal to 0.6 micrometers, the inner surface roughness Ra is less than or equal to 0.2 micrometers, the outside-diameter size tolerance is less than or equal to 0.04mm, the inside-diameter size tolerance is less than or equal to 0.03mm, and the wall-thickness size tolerance is less than or equal to 3 percent of a nominal wall thickness. Compared with the prior art, the method has the advantages that the size tolerance precision of the obtained products is relatively high, and the inside and outside surface quality is relatively good.

Owner:宁夏中色金航钛业有限公司

Method for processing bearing seat cylinder surface on variable housing of plunger pump

InactiveCN103752922AIncrease productivityAvoid size changeMilling equipment detailsPlunger pumpEngineering

The invention provides a method for processing a bearing seat cylinder surface on a variable housing of a plunger pump. The method is characterized in that an angle head is mounted on a main shaft of a machine tool; a circular cutter is mounted on a transmission shaft of the angle head; a bearing seat is mounted on a clamp which is mounted on four horizontal axles; the angle head and the circular cutter can extend into an inner chamber of the bearing seat to process together; the main shaft of the machine tool rotates to drive the transmission shaft of the angle head to rotate so as to drive the circular cutter to rotate, and a workbench moves left and right to realize cutting and feeding, thus the cylinder surface on one side of the bearing seat can be processed; and when the four axles rotate at 180 degrees together with the bearing seat and the clamp, the cylinder surface on the other side of the bearing seat can be processed. According to the method, the angle head and the circular cutter extend into the inner chamber of the bearing seat to process; a small cylinder surface for process of the variable housing is removed; and the process is reduced, so that the production efficiency and product reliability can be improved.

Owner:SHAOYANG VICTOR HYDRAULICS

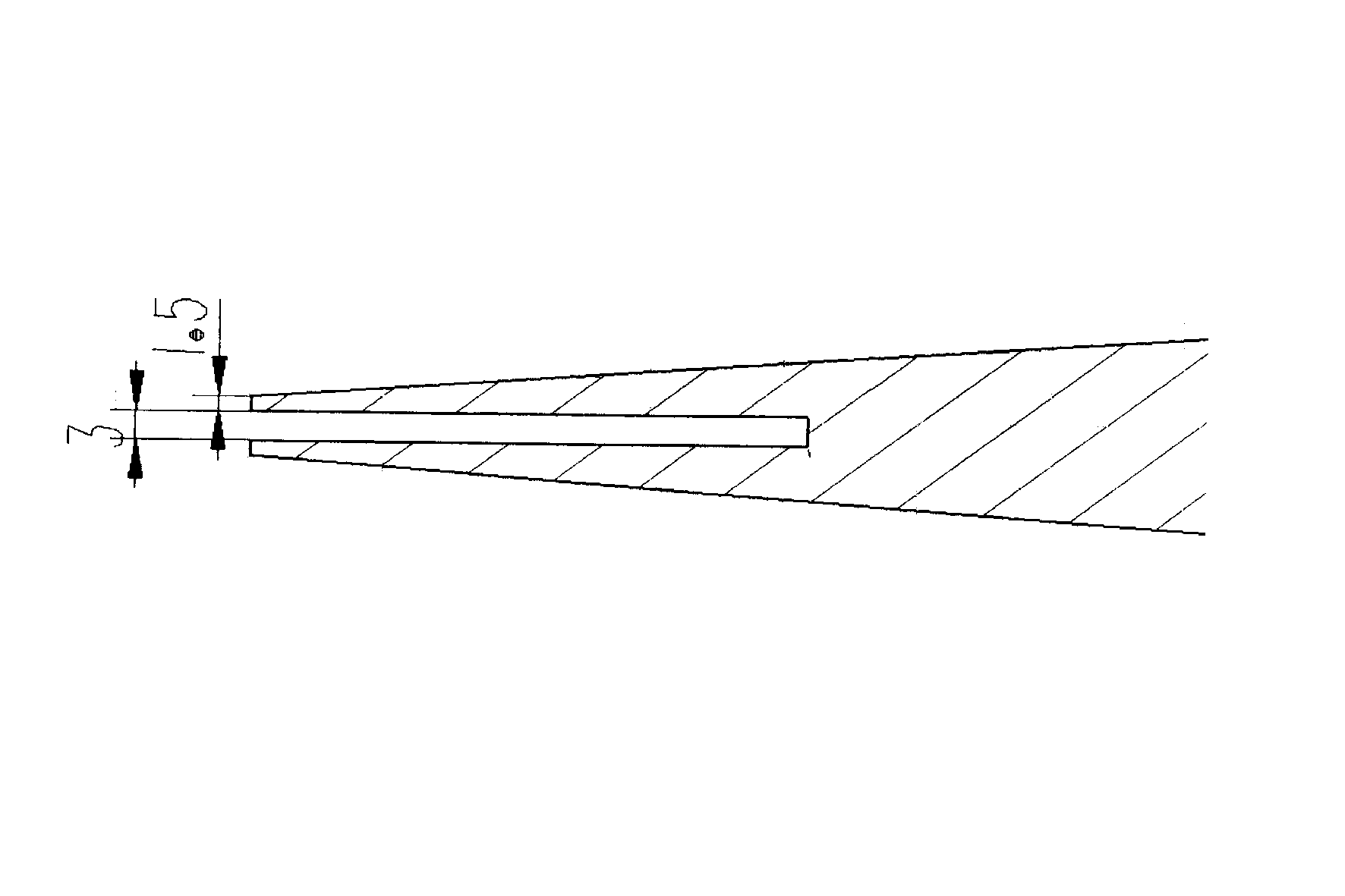

Numerical control machining method for thin narrow notch with thin edge

ActiveCN102699396AAvoid deformationGuaranteed Dimensional TolerancesMilling equipment detailsNumerical controlMilling cutter

The invention relates to a numerical control machining method for a thin narrow notch with a thin edge. The notch is 32 mm in depth, and 3 mm in height, and is formed according to the following steps: 1) fixing a part on a tooling clamp; 2), carrying out roughing with a standard disk miller of which the diameter D is 60 mm and the thickness d is 2 mm; 3), carrying out semi-finishing with a standard disk miller of which the diameter D is 60 mm and the thickness d is 2.5 mm; and 4), carrying out finishing on the notch. According to the method, the problem that the size of the notch is extremely poor is solved; and a more reasonable method is provided for the numerical control machining of the whole tooling, so as to ensure high processing precision of the whole tooling and improve the production efficiency.

Owner:SHENYANG AIRCRAFT CORP

Technological method for processing outer circular-arc surface and rotary bracket used for technological method

ActiveCN106378586AEasy to measureEasy to polishPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a technological method for processing an outer circular-arc surface and a rotary bracket used for the technological method. The rotary bracket comprises a central part which is a seamless steel pipe, wherein circular cover plates are arranged at the two ends of the central part; a plurality of triangular rib plates are arranged at the outer sides of the circular cover plates; and a plurality of groups of fixed parts are arranged at the outer side of the central part. In a processing process, the technological method is convenient in measuring the diameter of an outer circle of a workpiece, so that circular-arc-surface dimension tolerance can be effectively guaranteed; and a lathe is used for processing, so that the outer circle can be conveniently polished, and relatively large steps are prevented from being reserved in a circular arc surface processed by a milling machine; and the technological method is used for processing the circular arc surface of the workpiece, so that drawing requirements can be quickly and simply reached.

Owner:青岛宝鉴科技工程有限公司

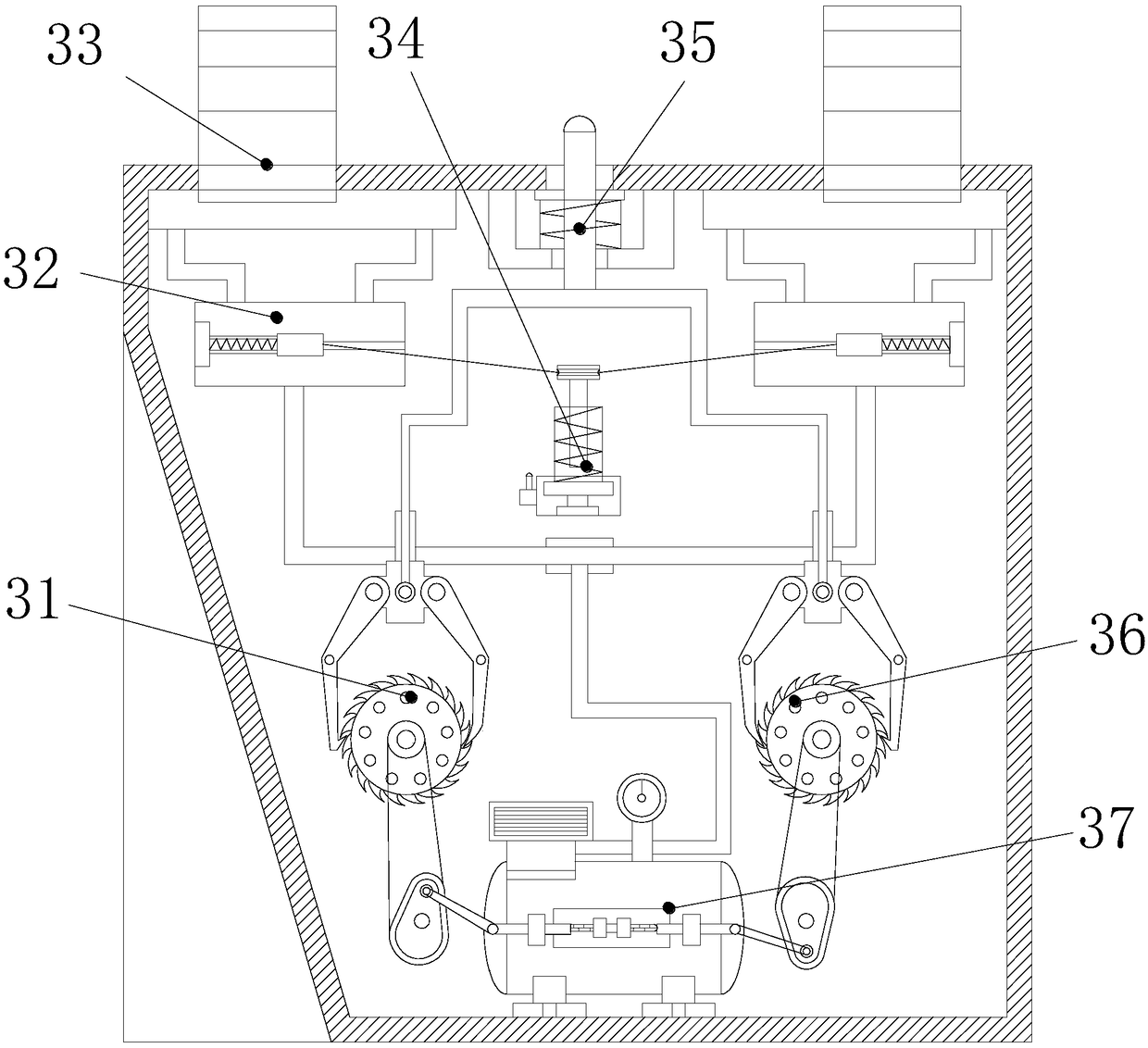

Part contour processing device

InactiveCN108788848AGuaranteed Dimensional TolerancesWork clamping meansLarge fixed membersEngineeringMachine tool

The invention discloses a part contour processing device. The part contour processing device is characterized by structurally comprising anti-sliding supporting legs, a machine tool housing, an all-around automatic clamping device, a handle, a visual protective door, a computer control end, and a supporting plate input table, wherein the four anti-sliding supporting legs are fixedly connected to the four corners of the bottom end of the machine tool housing in an electric-welding way separately; the all-around automatic clamping device is mounted at the bottom end of the inner part of the machine tool housing; the side end of the inner part of the visual protective door is mounted on the front end surface of the machine tool housing through a hinge; and one end, close to the front end surface of the machine tool housing, of the handle is mounted on the front end surface of the visual protective door in the electric-welding way. The part contour processing device mainly utilizes a pneumatic clamping mechanism to perform all-around clamping and fixing on a workpiece, so that the all-around clamping design of the clamped workpiece can be automatically regulated according to the shapeof the outer part of the workpiece to clamp the workpiece in case of not damaging the contour of the workpiece while certain surface of the contour of the material has special dimension requirements,and therefore, the dimensional tolerance after the workpiece is processed is guaranteed to be within a limited value.

Owner:李三源

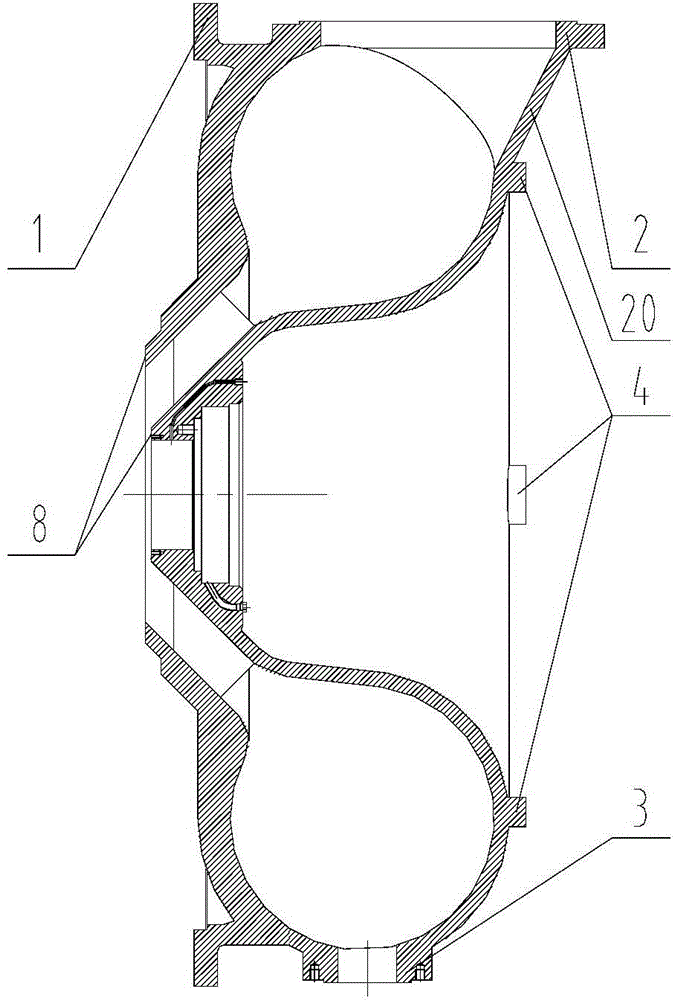

One-stator two-rotor axial magnetic field motor stator and case mounting structure

PendingCN107863829ASimple structureSolve the problem of difficult mechanical installationMagnetic circuit rotating partsMagnetic circuit stationary partsCopper wirePermanent magnet motor

The invention belongs to the technical field of permanent magnetic motors and provides of a one-stator two-rotor axial magnetic field motor stator and case mounting structure which is composed of a grooved annular stator, a stator positioning ring, a motor left case and a motor right case. The mounting structure is characterized in that the grooved annular stator is mounted between the motor leftcase and the motor right case through the stator positioning ring, grooves are formed in two sides of the grooved annular stator, and copper wire windings are placed in the grooves and positioned on two sides of the stator positioning ring. Through several simple structural parts, requirements on axial and radial mounting tolerance and minimum impact on motor performance are meet while the motor annular stator is mounted inside a case safely and reliably.

Owner:SHENYANG POLYTECHNIC UNIV

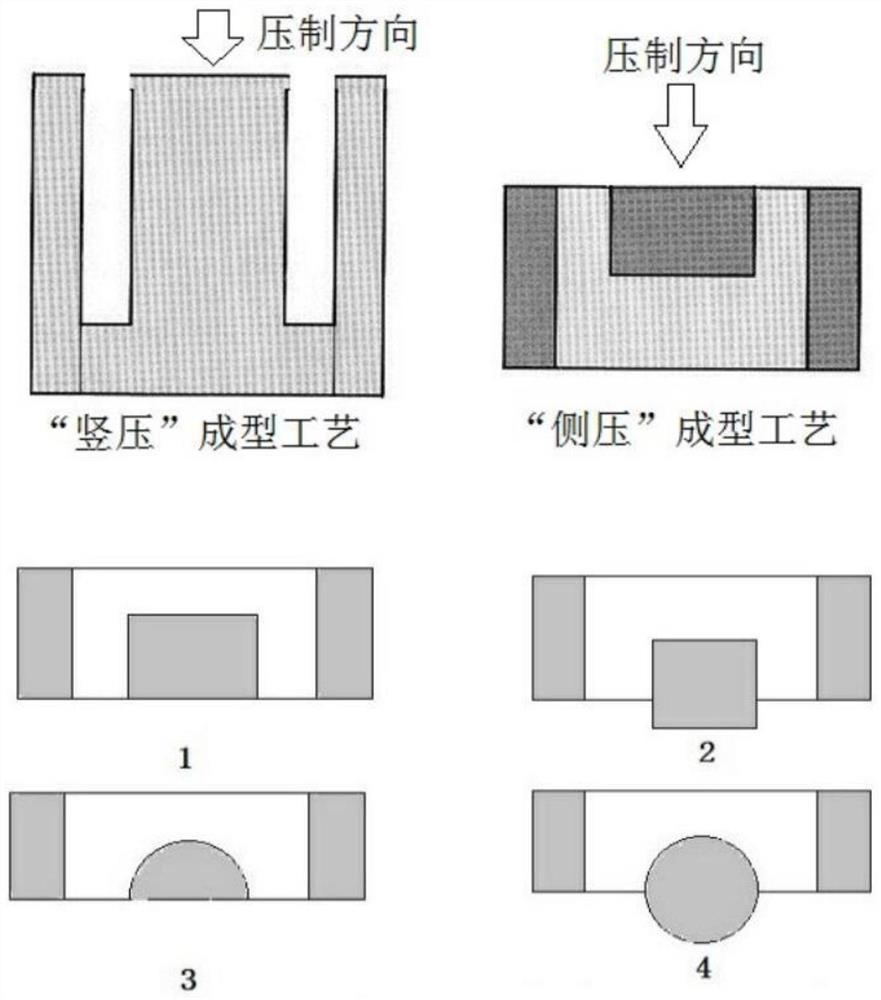

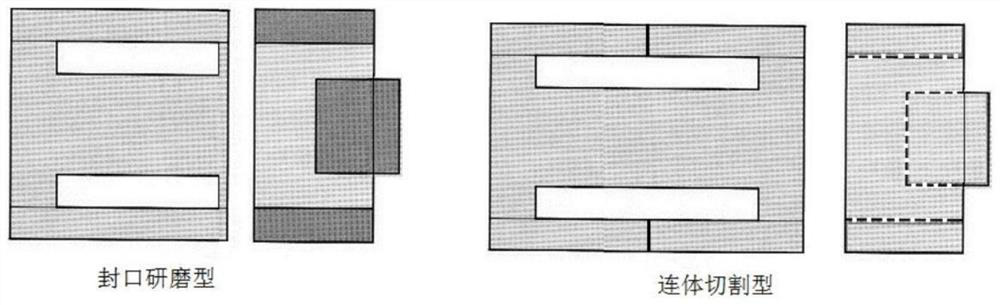

Manufacturing process of special-shaped ferrite magnetic core

PendingCN114005669AHigh dimensional accuracyOvercome the phenomenon that easily leads to product deformationMagnetic core manufactureManufacturing technologyPunching

The invention belongs to the technical field of ferrite, and particularly relates to a manufacturing process of a special-shaped ferrite core. The manufacturing process comprises the steps of (1) conducting punch forming, specifically, selecting soft magnetic ferrite particle powder, and preparing a sealed blank or a connected blank designed by the process on a vertical forming machine or a high-speed rotary forming machine by adopting a mold in a bidirectional punching manner; (2) sintering; (3) cutting and grinding; (4) carrying out ultrasonic cleaning; and (5) inspecting. According to the process, the phenomenon that a conventional preparation method for preparing the special-shaped magnetic core element is prone to causing product deformation can be overcome, the thinking frame that the special-shaped magnetic core element can only be formed in a vertical pressing mode but cannot be formed in a side pressing mode is broken through, and the process is achieved through a density compensation method. The manufacturing process is easy to operate, convenient to process and easy to industrialize, the special-shaped magnetic core element with high dimensional precision can be manufactured, the percent of pass is greatly increased, the cost is saved, and the manufacturing process has high industrial utilization value and is worthy of popularization and application.

Owner:江西尚朋电子科技有限公司

Austenitic stainless steel clad tube and technique of preparing the same

ActiveCN101333631BMeet chemical composition requirementsGuaranteed to dissolveFurnace typesHeat treatment furnacesRare-earth elementSS - Stainless steel

The invention discloses an austenitic stainless steel cladding tube used for a sodium-cooled fast reactor as well as a method for the production thereof. The stainless steel cladding tube has components, in weight proportion: 0.04 percent to 0.08 percent of C; less than or equal to 0.75 percent of Si; less than or equal to 0.02 percent of P; less than or equal to 0.02 percent of S; 1.5 percent to2.0 percent of Mn; 11.0 percent to 14.0 percent of Ni; 16.0 percent to 18.0 percent of Cr; 2.0 percent to 3.0 percent of Mo; 0.3 percent to 0.5 percent of Ti; less than or equal to 0.1 percent of Co;less than or equal to 0.002 percent of B; less than or equal to 0.035 percent of N; balance Fe. The double-smelting is adopted when in smelting, and the adding of rare earth elements is prohibited; the hydrogen protection or vacuum bright annealing treatment is adopted when in hot working; and a drawing process of empty sinking is banned in the cold working process, and the polishing treatment tosurfaces of finished pipes by mechanical method is prohibited. The stainless steel cladding tube made by the process can meet the requirements of the sodium-cooled fast reactor core subassembly.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

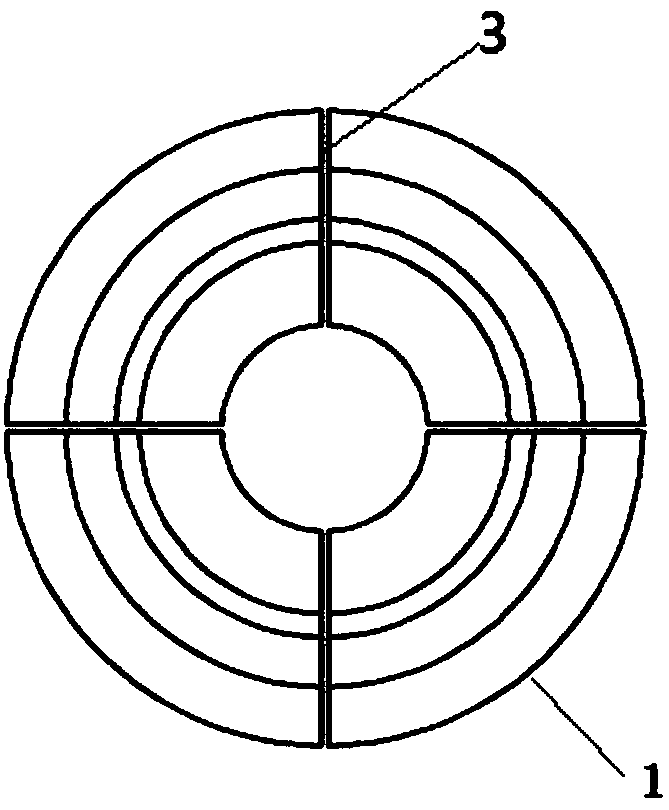

Fixing piece and fixing method for large-size annular bonded NdFeB magnet cutting and shaping

PendingCN108421991AGuaranteed Dimensional TolerancesSolve the positioning accuracyChucksEngineeringLarge size

The invention discloses a fixing piece and fixing method for large-size annular bonded NdFeB magnet cutting and shaping. The fixing piece comprises a chuck and a hoop which is used for restraining thechuck to achieve expanding and clamping of the chuck, wherein a cavity is formed in the axis position of the chuck, the chuck comprises a connecting part and a positioning part, the side wall of thepositioning part is provided with at least one clamping groove used for achieving expanding and retracting of the positioning part, the positioning part comprises a driving segment and a snap ring segment, the outer wall of the driving segment is provided with a tapered face, the front portion of the snap ring segment is provided with a fixing cavity used for positioning an annular piece, and thebottom end of the fixing cavity is provided with a protruding fixing face; and the exterior of the chuck is sleeved with the hoop, the hoop does relative movement along the tapered face to achieve expanding and clamping of the chuck. The fixing piece has the beneficial effect of being long in service life.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

A four-arm fully hydraulic bolt and cable drilling rig

ActiveCN103485717BRealize the mechanization of support workImprove support efficiencyDerricks/mastsAnchoring boltsUltimate tensile strengthDrill

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Clamping and processing method for organic working medium generator shell

ActiveCN104815992AAvoid vibrationAvoid shockTailstocks/centresAuxillary equipmentPulp and paper industryThermodynamics

The invention discloses a clamping and processing method for an organic working medium generator shell. The method includes: 1) drawing an aligning line; 2) polishing and flattening the boss end surface of the small end of the shell; 3) roughly turning the large end of the shell; 4) roughly turning the small end of the shell; 5) fine turning the large end of the shell; and 6) fine turning the small end of the shell. The clamping and processing method for the organic working medium generator shell is more convenient to clamp, easy to align, high in positioning accuracy, higher in accuracy of the dimension of the processed shell, and capable of improving the percent of pass of parts and preventing safety accidents.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Auxiliary tool for manufacturing PTFE gasket and method for manufacturing same

ActiveCN108260278AReduce processing costsProtection platformDielectric materialsPrinted circuit manufactureLaser cuttingEngineering

The invention relates to the field of printed circuit board manufacturing, in particular to an auxiliary tool for manufacturing a PTFE gasket and a method for manufacturing the same. Through manufacturing the auxiliary tool, a PTFE plate is adhered on the auxiliary tool for laser cutting, the small-sized gasket can be machined, the PTFE plate with the thickness ranging from 0.5mm to 1.6mm can be machined, the outer edge of the manufactured PTFE gasket is burr-free, and the dimensional tolerance is ensured to be within a range of + / -0.05 mm. Moreover, the auxiliary tool is a universal tool, thePTFE plate can be positioned by means of optical alignment holes formed in the auxiliary tool, when the PTFE gasket is manufactured, only the corresponding drilling belt of the PTFE gasket needs to be changed without corresponding die sinking independently, the auxiliary tool is suitable for size requirements of various kinds of PTFE gaskets, and can be reused. Meanwhile, the auxiliary tool has the function of protecting a platform of a laser drilling machine, and greatly reduces the processing cost of gasket production.

Owner:JIANGMEN SUNTAK CIRCUIT TECH +1

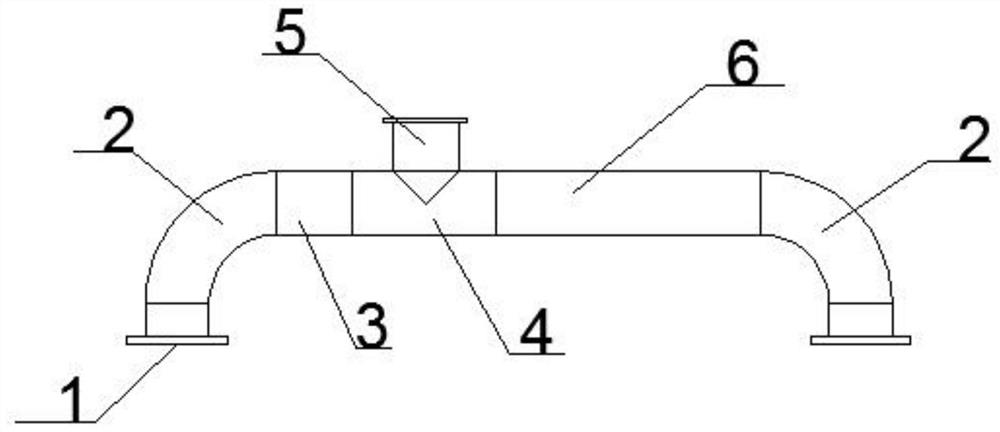

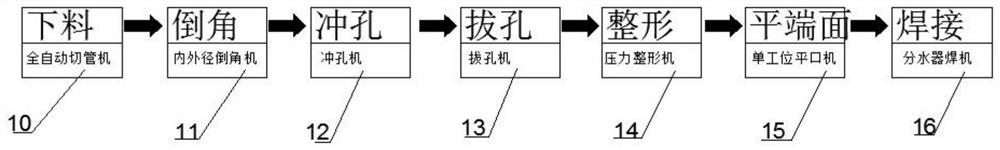

Hole drawing process for thin-wall stainless steel hard tube assembly

The invention provides a hole drawing process for a thin-wall stainless steel hard tube assembly. The hole drawing process comprises the following steps that 1, blanking is conducted, specifically, firstly, a long hard tube is cut into equal small sections through a full-automatic tube cutting machine; 2, chamfering is conducted, specifically, chamfering is conducted on the cut chamfering machine through an inner and outer diameter chamfering machine; 3, punching is conducted, specifically, an elliptical hole is formed through a punching machine; 4, hole drawing is conducted, specifically, the edge of the drawn hole is turned outwards through a hole drawing machine to form a turned edge, the turned edge is ejected out of the outer wall of a metal pipe, hole drawing machining is completed, and the machined drawn hole is a plain-end circle; 5, shaping is conducted, specifically, the hard pipe is bent to 90 degrees through a pressure shaping machine to form an elbow; 6, an end face is flattened, specifically, the end face of a pipe opening is flattened through a single-station opening flattening machine; and 7, welding is conducted, specifically, a second elbow and a second standard cup opening are welded to a third steel pipe through a water segregator welding machine. The dimensional tolerance can be guaranteed, and risks caused by many welding seams are avoided.

Owner:江苏帕卓管路系统股份有限公司

Method for machining lens barrel type part with center of mass deviating from rotation center

InactiveCN107931982AGuaranteed Dimensional TolerancesImprove machining accuracyMachining processOut stress

The method relates to the field of machining, in particular to a method for machining a lens barrel type part with the center of mass deviating from the rotation center. The method comprises the following steps of casting a blank; carrying out heat treatment, and carrying out quench aging treatment; drawing a blank allowance distribution line by taking a non-machining surface as a benchmark by a bench worker; milling the surfaces of a mounting base on a milling machine and reserving 0.1mm as the fine machining allowance for the end surface below a ruler; carrying out rough turning on each holeon a lathe and reserving 0.5mm as the allowance for the single side of the finish machining surface; carrying out heat treatment, carrying out stress-relieving artificial aging so as to eliminate themachining stress; and carrying out finish machining on the benchmark mounting surface until the flatness of the lower end surface scraped by the bench worker is within 0.006mm, and scraping the othersurface until the perpendicularity of the other surface to the surface is within 0.006mm. The method has the advantages that the operation simple, the vibration in the machining process is small, thedimensional tolerance of the part can be guaranteed, and the machining precision and the production efficiency of the part can be improved.

Owner:SHAANXI QIYUAN TECH DEV

Method for machining lens cone part with mass center deviating from rotation center

InactiveCN104625601AGuaranteed Dimensional TolerancesImprove machining accuracyEngineeringMachining process

The invention relates to the field of machining, in particular to a method for machining a lens cone part with the mass center deviating from the rotation center. The method includes the following steps that a blank is cast; heat treatment is conducted, wherein quench aging is adopted; a bench worker scribes a blank allowance distribution line with the non-machining surface as a reference; all the surfaces of an installation seat are milled on a milling machine, and the 0.1 mm finish machining allowance is reserved in the ruler lower end face; holes are roughly turned on a lathe, and the 0.5 mm allowance is reserved for the single side of the finish machining surface; heat treatment is conducted, wherein distressing artificial aging is conducted through heat treatment, and machining stress is removed; the finish reference installation surface is machined, in other words, the planeness of the lower end face scraped by the bench worker is within 0.006 mm, the other surface is scraped, and the perpendicularity of the other surface and the lower end face is within 0.006 mm. The operation is simple, vibration generated in the machining process is low, dimensional tolerances of the part can be guaranteed, and part machining accuracy and production efficiency are improved.

Owner:高晓光

Gyro basal body manufacturing method

The invention discloses a gyro basal body manufacturing method. The gyro basal body manufacturing method comprises the following steps: outer profiles of basal bodies and coaxial upper and lower innerholes positioned on the upper and lower end surfaces of the basal bodies are machined; then, slots whose bottom surfaces are perpendicular to the upper end surfaces and straight surfaces perpendicular to the lower end surfaces are machined on the side surfaces of the basal bodies; mounting lugs are formed between the slots and the straight surfaces; the upper inner holes are finely machined to form upper molding cavities and mounting surfaces positioned in the upper molding cavities; the basal bodies are overturned to machine the lower inner holes to form lower molding cavities and bosses positioned in the lower molding cavities; and finally, the bosses and the mounting surfaces are finished. In the machining process, the upper or lower inner holes are firstly selected as the clamping reference to machine the slots and the straight surfaces to form the mounting lugs; and then, the basal bodies are clamped through cooperation between the mounting lugs and tools to machine the upper molding cavities and the lower molding cavities, so that the machining process reference is unified, the hole system size tolerance is guaranteed, and the machining precision of the basal bodies is improved. The bosses and the mounting surfaces are finished to further improve the size precision of the bosses and the mounting surfaces.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Numerical control machining method for thin narrow notch with thin edge

ActiveCN102699396BAvoid deformationGuaranteed Dimensional TolerancesMilling equipment detailsNumerical controlMilling cutter

Owner:SHENYANG AIRCRAFT CORP

Busbar assembly device, busbar self-piercing riveting system and busbar assembly method

ActiveCN102324285BIncrease productivityGuaranteed positional relationshipCable/conductor manufactureBusbarControl signal

Owner:成方泳

A process method for machining outer circular arc surface and the rotary support used therefor

ActiveCN106378586BEasy to measureEasy to polishPositioning apparatusMetal-working holdersEngineering

The invention discloses a technological method for processing an outer circular-arc surface and a rotary bracket used for the technological method. The rotary bracket comprises a central part which is a seamless steel pipe, wherein circular cover plates are arranged at the two ends of the central part; a plurality of triangular rib plates are arranged at the outer sides of the circular cover plates; and a plurality of groups of fixed parts are arranged at the outer side of the central part. In a processing process, the technological method is convenient in measuring the diameter of an outer circle of a workpiece, so that circular-arc-surface dimension tolerance can be effectively guaranteed; and a lathe is used for processing, so that the outer circle can be conveniently polished, and relatively large steps are prevented from being reserved in a circular arc surface processed by a milling machine; and the technological method is used for processing the circular arc surface of the workpiece, so that drawing requirements can be quickly and simply reached.

Owner:青岛宝鉴科技工程有限公司

Preparation method of composite film layer on surface of rare earth magnesium alloy structural part

ActiveCN112251790AMeet assembly dimensional tolerance requirementsReduce electrophoresis voltageAnodisationElectrophoretic coatingsElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a composite film layer on the surface of a rare earth magnesium alloy structural part. The preparation method sequentially comprises the steps of oil removal, primary water washing, micro-arc oxidation, secondary water washing, electrophoresis, tertiary water washing and drying and curing. A micro-arc oxidation electrolyte is an aqueous solution containing sodium silicate, sodium fluoride, sodium hydroxide, graphene, Cu(NO3)2 and triethanolamine, electrical parameters of micro-arc oxidation are as follows: the positive current density is 5-15A / dm<2>, the negative current density is 2-3A / dm<2>, the positive duty ratio is 25-70%, the negative duty ratio is 40-50%, the positive frequency is 200-800Hz, the negative frequency is 300-500Hz, the positive and negative stages are both one stage, the micro-arc oxidation time is 10-20 min, electrophoresis liquid for electrophoresis is an aqueous solution containing acrylate, a delustering agent andcarbon black pigment, and electrical parameters of electrophoresis are as follows: the voltage is 50-80V, and the time is 10-30s; and through the coordination effect of micro-arc oxidation and electrophoresis, the composite film layer meeting the requirements of high hardness, high bonding strength and ultraviolet aging resistance at the same time can be prepared.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Special-shaped steel pipe, iron-making blast furnace cooling wall, butt-fitting tool and butt-fitting method of special-shaped steel pipe

PendingCN110004259ASolve the situation that the packaging quality is difficult to guaranteeGuarantee drawing requirementsCooling devicesSteel tubeCorrosion

The invention relates to a special-shaped steel pipe, an iron-making blast furnace cooling wall, butt-fitting tool and a butt-fitting method of a special-shaped steel pipe. the butt-fitting tool comprises a bottom plate, the two ends of the upper surface of the bottom plate are provided with a head-end butt-fitting device used for mounting a plurality of head ends of special-shaped steel tubes anda tail-end butt-fitting device used for mounting a plurality of tail ends of special-shaped steel tubes, the tail end butt-fitting device is fixedly connected with the bottom plate, and the head-endbutt-fitting device is movably connected with the bottom plate. According to the butt-fitting tool and the mounting method, the butt-fitting tool structure is reasonably designed, the size of the butt-fitting tool is controlled, the butt-fitting tool manufacturing process is formulated, and the butt-fitting tool is reasonably used, so that the size (interval, radian and taper) of the special-shaped steel pipe can meet drawing requirements before cast in the lower mold. The position of the assembled and formed special-shaped steel pipe cannot be changed in the process of transferring and hoisting, derusting and corrosion preventing because of the addition of the fixed supports. The problem that the assembling quality of the special-shaped steel tube cannot be guaranteed is solved, and meanwhile, the working efficiency is improved.

Owner:LAIWU IRON & STEEL GRP

A manufacturing method of a stator frame

ActiveCN105375712BAvoid deformationGuaranteed coaxialityManufacturing dynamo-electric machinesEngineeringWorkbench

The invention relates to a stator base processing and manufacturing method, comprising the steps of: (1) inspecting the size allowance of a stator base blank piece; (2) using a carrying pole beam to lift the stator base blank piece to a vertical lathe workbench; (3) in a clamping process, welding three layers of pressing plates on a cylinder wall in a step shape, wherein each layer is provided with four pieces in a crossing mode to compress the stator base blank piece; and first performing rough turning, then loosening the pressing plates, and lightly pressing the pressing plates to perform finish turning on the size at each position; (4) measuring on the vertical lathe workbench to record all sizes to be used as a final installation size recording of a stator base; (5) using the carrying pole beam to lift the stator base after finish turning, and installing the stator base on a turning tool after assembling with a stator support; (6) turning the stator base, driving a turning mould to be lifted to a boring mill workbench, and using a drill lifting tool to lift a drill to distribute drilling holes after assembling with a sealing cover plate; and (7) turning trunnion apertures on two sides of a boring mill; and performing circularity regulation when deformation of the stator base is greater. The stator base processing and manufacturing method can effectively solve the problems of deformation and poor dimension.

Owner:甘肃酒钢集团西部重工股份有限公司

A method for preparing a composite film layer on the surface of a rare earth magnesium alloy structural part

ActiveCN112251790BChange surface stateAchieving assembly surface performance requirementsAnodisationElectrophoretic coatingsElectrolytic agentMicro arc oxidation

The invention discloses a method for preparing a composite film on the surface of a rare-earth magnesium alloy structural part, which sequentially includes the steps of degreasing, first water washing, micro-arc oxidation, second water washing, electrophoresis, three times of water washing, and drying and solidification; micro-arc oxidation electrolyte Contains sodium silicate, sodium fluoride, sodium hydroxide, graphene, Cu(NO 3 ) 2 and triethanolamine aqueous solution, the electrical parameters of micro-arc oxidation are: forward current density 5~15A / dm 2 , negative current density 2~3A / dm 2 , the positive duty cycle is 25~70%, the negative duty cycle is 40~50%, the positive frequency is 200~800Hz, the negative frequency is 300~500Hz, the positive and negative series are both 1, and the micro-arc oxidation time is 10~20min; the electrophoresis liquid used for electrophoresis is an aqueous solution containing acrylate, matting agent and carbon black pigment, the electrical parameters of electrophoresis are: voltage 50~80V, time 10~30s; through the coordination of micro-arc oxidation and electrophoresis, it can be prepared A composite film that satisfies high hardness, high bonding strength, and UV aging resistance at the same time.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Fluid filter with secondary filter element of lightweight construction

PendingCN112118899ASpeed up entryEnter reliableGas treatmentDispersed particle filtrationFilter mediaStructural engineering

The invention relates to a fluid filter (10) for filtering a fluid, in particular air, comprising a filter housing (12) having a central support tube (22) which extends along a longitudinal axis (16)of the filter housing (12) within the filter housing (12) and a primary filter element (24) arranged inside the filter housing (12) in an exchangeable manner. There is a secondary filter element (26)positioned inside the filter housing (12) which serves as a safety-element during a replacement of the primary filter element (24). A sealing between a first end portion of the secondary filter element (26) and the filter housing (12) is effected partially or solely by the filter medium (28) of the secondary filter element (26). The first end portion of the secondary filter element may engage in agroove-shaped retaining structure of the filter housing (12). The invention further relates to a secondary filter element (26) for such a fluid filter (10).

Owner:MANN HUMMEL GMBH

A rolling method of high-precision titanium alloy pipe

ActiveCN104148439BImprove ovalityEliminate bumpsWork treatment devicesMetal rolling arrangementsSurface roughnessTitanium

The invention relates to a rolling method of high-precision titanium alloy pipe material. The method is to roll the prepared titanium alloy tube billet by combining two rolls and three rolls. The rolling method is single-feeding and double-turning, controlled The Q value of two-roll rolling is 0.4-2, the Q value of multi-roll rolling is 0.4-9, and the gap is 0.2-2mm. After the rolled finished pipe is processed by external surface polishing and internal surface honing Titanium alloy pipes with outer surface roughness Ra≤0.6μm, inner surface roughness Ra≤0.2μm, outer diameter tolerance≤0.04mm, inner diameter tolerance≤0.03, and wall thickness tolerance≤3% of the nominal wall thickness were obtained. Compared with the prior art, the present invention has higher dimensional tolerance precision of the obtained product and better inner and outer surface quality.

Owner:宁夏中色金航钛业有限公司

Rib punching device for piston cylinder

InactiveCN104416080AGuaranteed outer diameter toleranceReduce scrap rateShaping toolsPunchingRejection rate

The invention discloses a rib punching device for a piston cylinder. The rib punching device comprises an upper die assembly and a lower die assembly, wherein the lower die assembly comprises a lower die plate, and female die fixing plates are sequentially fixed above of the lower die plate from bottom to top; a female die is arranged above the female die fixing plates, and a gap which is used for enabling a rib to be expanded out is formed in the female die; the outer edge of the female die is respectively provided with an outer positioning plate and an inner positioning plate from bottom to top; the periphery of the female die is provided with locking blocks which are matched with locking sleeves, the tail parts of the locking blocks are connected with spring fixing devices, and the bottom parts of the spring fixing devices are fixedly connected with the outer positioning plate; the spring fixing devices are connected with extension springs. Compared with the prior art, the rib punching device for the piston cylinder, disclosed by the invention, has the advantages that the size tolerance of the outer diameter of the piston cylinder is ensured, the rejection rate is greatly reduced, and the production efficiency is also increased.

Owner:TIANJIN YUANDE AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com