Rib punching device for piston cylinder

A piston cylinder and punching rib technology is applied in the field of machining, which can solve the problems of difficult workpiece processing, high rejection rate, and difficulty in ensuring the dimensional tolerance of the outer diameter of the piston cylinder, so as to reduce the rejection rate, improve production efficiency, and ensure the outer diameter. The effect of dimensional tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

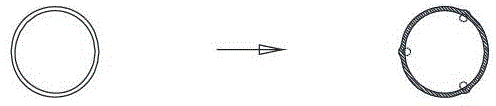

[0017] Such as figure 1 Shown is the schematic structural view of the upper mold assembly and the lower mold assembly of the piston cylinder punching rib mold. The upper mold assembly includes an upper template 2, and a punch fixing plate 4 is fixed below the upper template 2, and the punch fixing plate 4 is fixed with a punch 5; the periphery of the punch 5 is provided with a locking sleeve 8, and the upper template 2 is provided with a compression rod 3 connected with the locking sleeve 8, and the compression rod 3 The outer circumference is covered with a compression spring 7.

[0018] Such as figure 2 As shown, the lower mold assembly includes a lower template 9, and the top of the lower template 9 is sequentially fixed with a die fixing plate 10; the top of the die fixing plate 10 is provided with a die 13, so Described die 13 is provided with the slit that can stretch out rib; The outer edge of described die 13 is respectively provided with outer positioning plate 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com