Part contour processing device

A technology for contour processing and parts, applied in the field of part contour processing devices, can solve problems such as increased cost and large dimensional tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

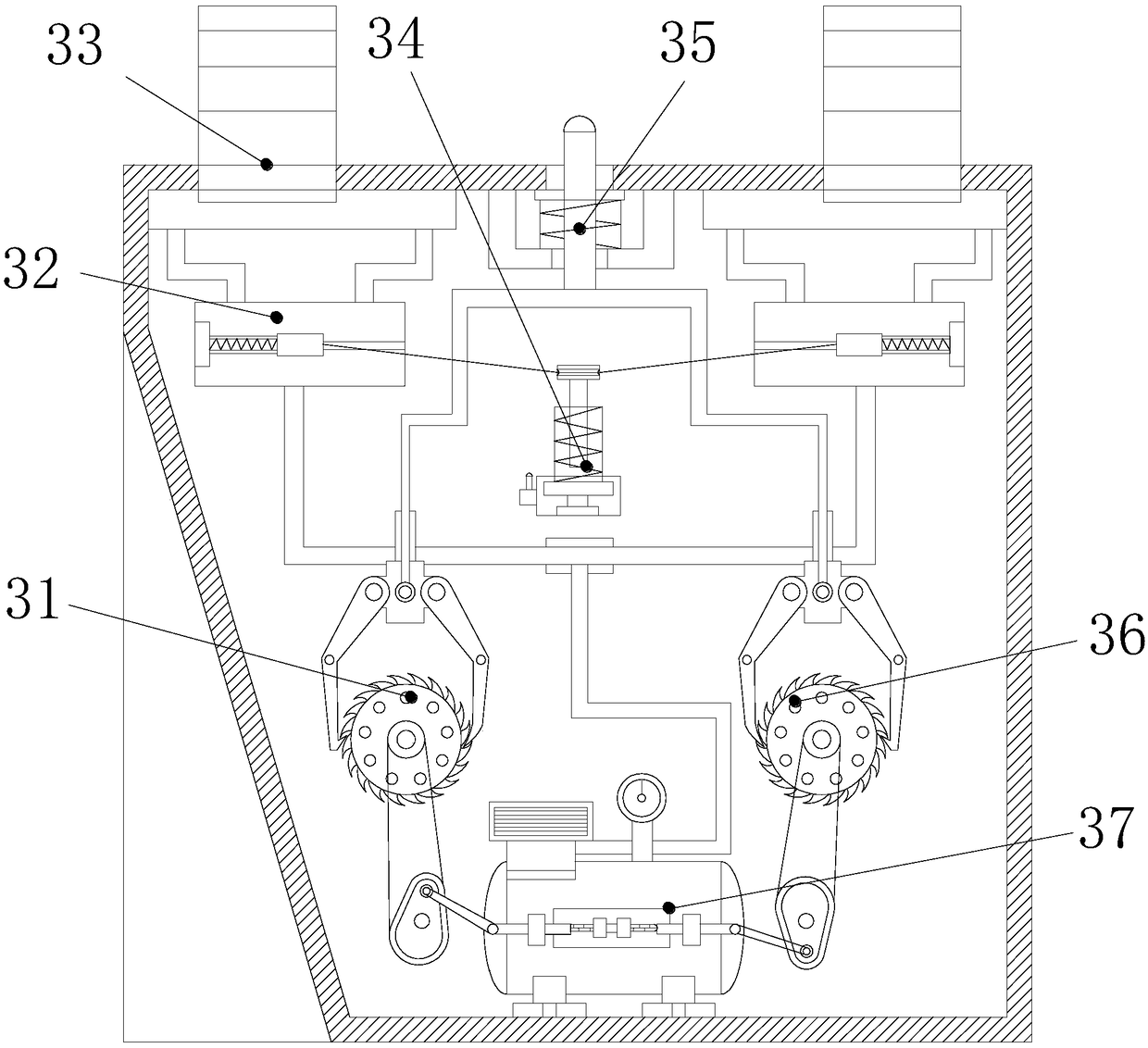

[0024] See Figure 1-Figure 5 , The present invention provides a part contour processing device, a part contour processing device, the structure of which includes a non-slip supporting foot 1, a machine tool housing 2, an omnidirectional automatic clamping device 3, a handle 4, a visual protection door 5, a computer control terminal 6, a support The board input table 7, the non-slip support feet 1 are provided with a total of 4 and the top ends are respectively fixedly connected to the bottom four corners of the machine tool housing 2 by electric welding, and the omnidirectional automatic clamping device 3 is installed at the inner bottom of the machine tool housing 2 , The inner side end of the visual protection door 5 is installed on the front end surface of the machine tool housing 2 through a hinge, and the handle 4 is installed on the front end surface of the visual protection door 5 by electric welding. The support plate input platform 7 is fixedly connected to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com