Hole drawing process for thin-wall stainless steel hard tube assembly

A stainless steel and hard pipe technology is applied in the field of thin-walled stainless steel hard pipe assembly hole drawing process to ensure the effect of dimensional tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

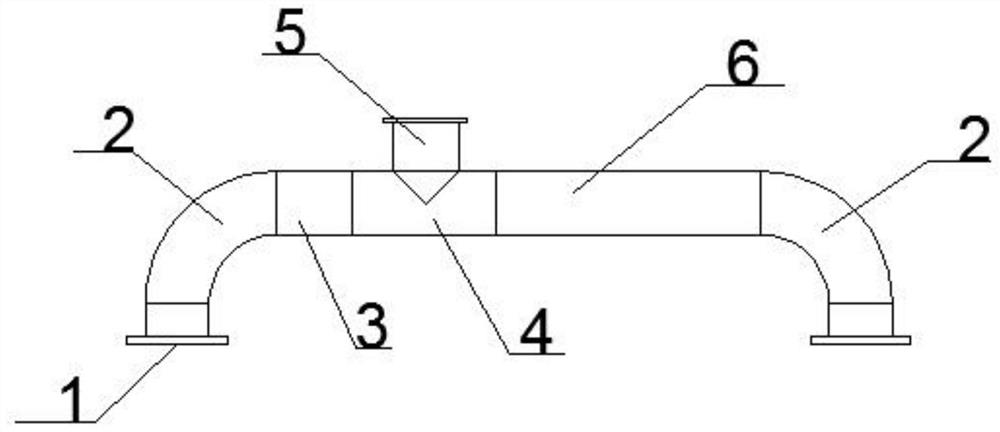

[0024] Such as figure 1 and 2 As shown, a tower crane rotation angle control device of the present invention cuts long steel pipes into several 644mm lengths through the automatic pipe cutting machine 10, and performs a punching process at a position of 126.2mm at the left end of the second steel pipe 9. The hole pulling machine 13 pulls out the second standard cup mouth 8 with an inner diameter of 50.8mm, the second elbow 7 is welded to the second steel pipe 9, and the second steel pipe 9 is fixedly connected to the second standard cup mouth 8 , the lower side of the second elbow 7 is welded with a wire-cut cup mouth 1, and the total length of the thin-walled stainless steel hard tube assembly is 815.8mm, and the total height is 160.5mm.

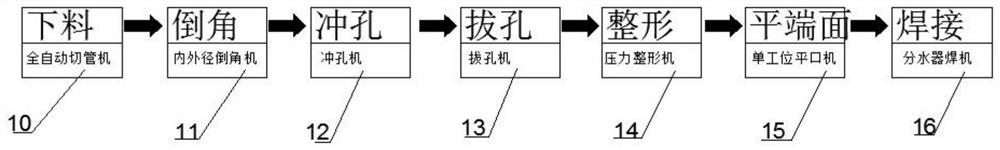

[0025] Such as image 3 The following steps are shown:

[0026] Step 1, blanking, first cut the long hard pipe into equal small sections through the automatic pipe cutting machine 10;

[0027] Step 2, chamfering, chamfering the cut cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com