Carbon quantum dot doped liquid chromatography filler as well as preparation method and application thereof

A technology of carbon quantum dots and doped liquid phase, which is applied in the field of chromatographic packing, can solve the problems of poor peak shape symmetry and short retention time, and achieve the effect of high specific surface area and abundant action sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

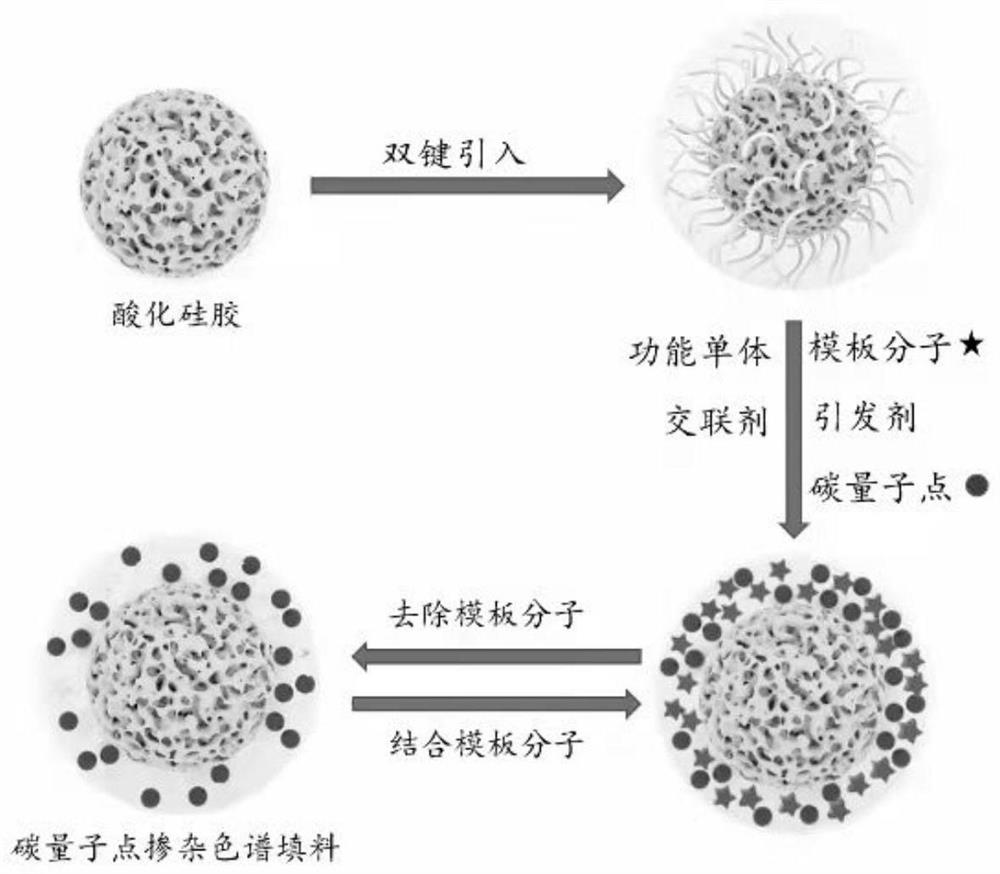

[0026] refer to figure 1 , the preparation method of the carbon quantum dot-doped liquid chromatographic filler provided by the present invention comprises: silica gel acidification and double bond modification steps, carbon dot doping and polymerization steps.

[0027] 1. Silica gel acidification and double bond modification

[0028] Silica gel: select commercial bare silica gel, with a particle size of 1-50 μm and a pore size of 15-50 nm.

[0029] Silylating reagents: γ-methacryloxypropyltrimethoxysilane (γ-MPS), vinyltriisopropoxysilane, vinyltriethoxysilane, vinyltriacetoxysilane, ethylene One or more of yltrimethoxysilane and vinyltris(2-methoxyethoxy)silane.

[0030] Catalyst: pyridine or triethylamine.

[0031] Reaction solvent: toluene.

[0032] (1) Acidification of silica gel

[0033] Prepare an aqueous solution of nitric acid, hydrochloric acid or a mixture of the two. The concentration of hydrogen ions in the aqueous solution is 2-10mol / L. Add silica gel to the...

Embodiment 1

[0049] Prepare a nitric acid aqueous solution with a concentration of 3.35 mol / L, take commercial bare silica gel with a particle size of 5 μm and a pore size of 20 nm, add bare silica gel to the nitric acid aqueous solution at a ratio of 10 mL:1 g, stir at 25 °C for 1.5 h, and wash with water until Wash with neutral and absolute ethanol three times to obtain acidified silica gel, and dry it in vacuum at 50°C for later use.

[0050] Mix γ-methacryloxypropyltrimethoxysilane (silylating agent), triethylamine (catalyst), toluene (reaction solvent) and acidified silica gel according to the ratio of 2.5mL: 0μL: 50mL: 1g Then heat and stir to reflux, wash the material several times with toluene and absolute ethanol respectively, and dry it in vacuum at 50° C. to obtain a double-bond-modified silica gel.

[0051] Methacrylic acid (functional monomer), methanol (porogen) and zidovudine (template molecule) were mixed according to the ratio of 40μL: 100mL: 200mg, and prepolymerized at 4°C...

Embodiment 2

[0064] Prepare a hydrochloric acid aqueous solution with a concentration of 2mol / L, take commercial bare silica gel with a particle size of 20μm and a pore size of 30nm, add bare silica gel to the aqueous hydrochloric acid solution at a ratio of 10mL:1g, stir at 30°C for 2h, and wash with water until neutral , washed 3 times with absolute ethanol to obtain acidified silica gel, dried in vacuum at 55°C for later use.

[0065] Mix vinyltriisopropoxysilane (silylating agent), pyridine (catalyst), toluene (reaction solvent) and acidified silica gel according to the ratio of 1mL: 0.5mL: 100mL: 1g, heat and stir to reflux, and use toluene respectively Wash the material several times with absolute ethanol, and dry it under vacuum at 55°C to obtain a double-bond-modified silica gel.

[0066] Methyl methacrylate (functional monomer), ethanol (porogen) and sulfonamide (template molecule) were mixed according to the ratio of 500μL: 1000mL: 1mg, and prepolymerized at -10°C for 5h to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com