Non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof

An organic molybdenum and compound technology, applied in the field of non-sulfur-phosphorus organic molybdenum lubricating oil additives, can solve the problems of unfavorable large-scale application, good anti-friction and anti-wear performance, increase product cost, etc. Anti-wear properties, the effect of reducing the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

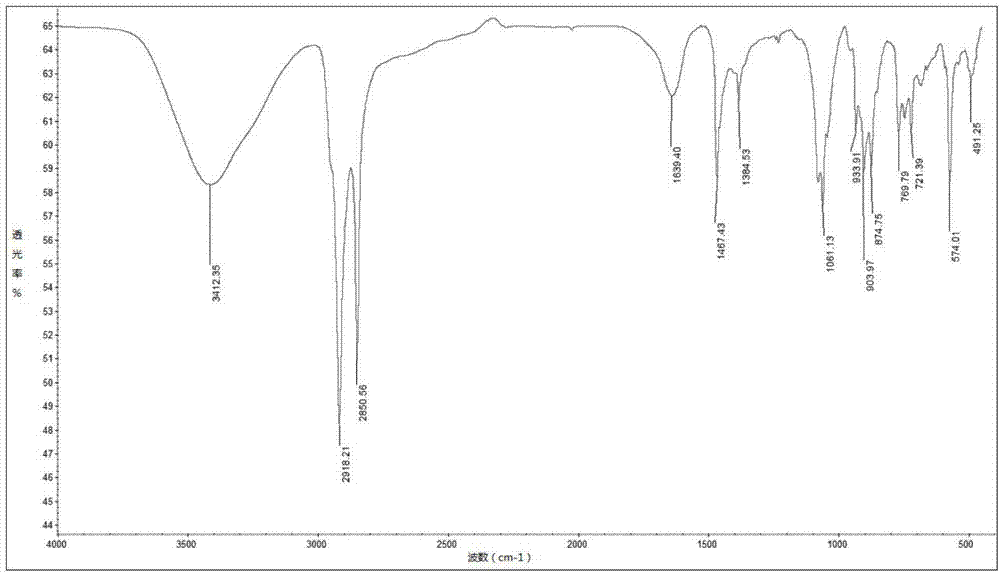

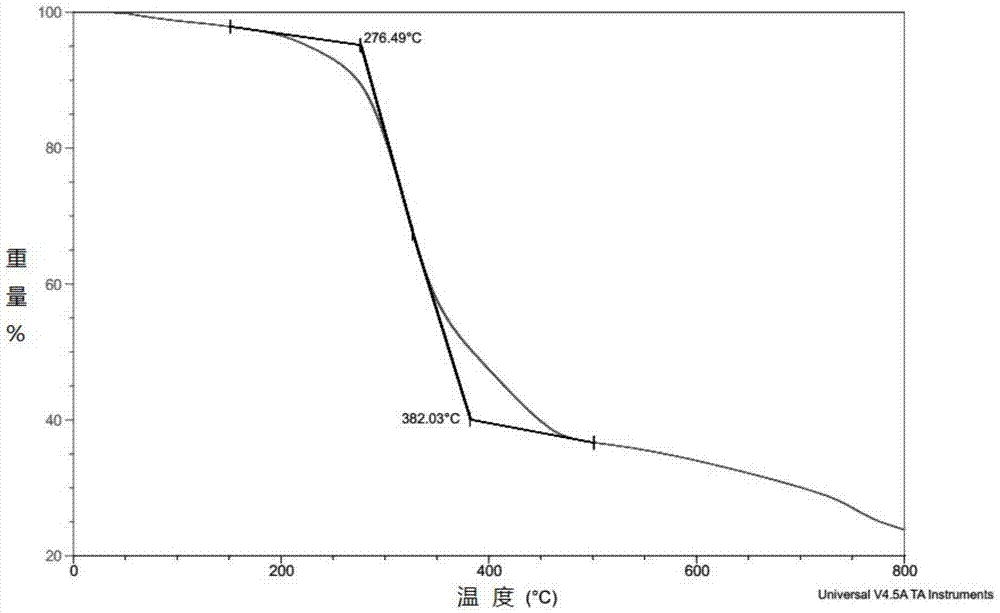

[0037] Example 1 Preparation of N-octadecyliminediethanol molybdic acid diester

[0038] Weigh 53.6 g (0.15 mol) of dihydroxyethyl octadecylamine and directly add it into a 500 ml three-necked flask, then add 0.3 g (0.0075 mol) of sodium hydroxide and 300 ml of xylene solvent into the flask. Weigh 26.0 g (0.15 mol) of ammonium molybdate tetrahydrate, dissolve it in 40 g of deionized water, use an ultrasonic cleaner to accelerate the dissolution, pour it into a water separator, and gradually add it to a three-necked flask during the reaction. Heating in an oil bath at 170°C, mechanical stirring, and reflux of xylene to gradually separate the product from water. The reaction was carried out for 6-7 hours, and the reaction was completed when no water was evaporated. The reaction product is a dark green solution. After the reaction was completed, suction filtration was carried out while it was still hot. After separation, the filtrate was dark green, and the filter paper was ...

Embodiment 2

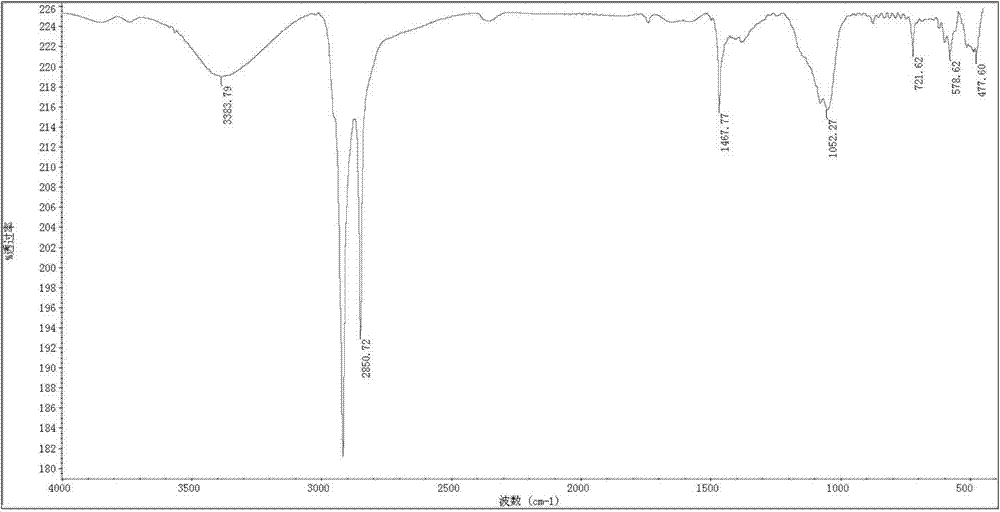

[0043] Example 2 Preparation of N-butyliminediethanol molybdic acid diester

[0044] Weigh 24.2g (0.15mol) of dihydroxyethylbutylamine and directly add it into a 500ml three-necked flask, then add 0.3g (0.0075mol) of sodium hydroxide and 300ml of xylene solvent into the flask. Weigh 26.0 g (0.15 mol) of ammonium molybdate tetrahydrate, dissolve it in 40 g of deionized water, use an ultrasonic cleaner to accelerate the dissolution, pour it into a water separator, and gradually add it to a three-necked flask during the reaction. Heating in an oil bath at 170°C, mechanical stirring, and reflux of xylene to gradually separate the product from water. The reaction was carried out for 6-7 hours, and the reaction was completed when no water was evaporated. After the reaction finished, the follow-up treatment was the same as in Example 1.

Embodiment 3

[0045] Example 3 Preparation of N-isooctyliminediethanol molybdic acid diester

[0046] Weigh 19.3g (0.1mol) of brominated isooctane, 10.5g (0.1mol) of diethanolamine, and 12.6g (0.15mol) of bicarbonate sodium bicarbonate into a 500ml three-necked flask, heat in an oil bath, stir mechanically, and reflux the toluene . After the reaction, it was distilled with ethyl acetate, washed with water, and finally put into a vacuum drying oven to obtain dihydroxyethylisooctylamine.

[0047] Then weigh 21.7g (0.1mol) of dihydroxyethylisooctylamine and directly add it into a 500ml three-necked flask, then add 0.3g (0.0075mol) of sodium hydroxide and 300ml of xylene solvent into the flask. Weigh 26.0 g (0.15 mol) of ammonium molybdate tetrahydrate, dissolve it in 40 g of deionized water, use an ultrasonic cleaner to accelerate the dissolution, pour it into a water separator, and gradually add it to a three-necked flask during the reaction. Heating in an oil bath at 170°C, mechanical st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com