Fabric liner coating material of self-lubricating joint bearing and preparation method thereof

A technology for spherical plain bearings and coating materials, applied in textiles and papermaking, fiber types, fiber processing, etc., can solve problems such as inability to use coating, restrictions, and complex processes, to improve anti-friction and wear resistance, and improve self-lubricating properties. performance, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

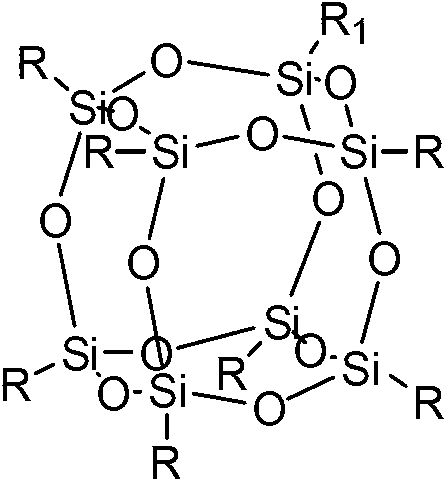

[0028] 0.5 parts of polyvinyl alcohol, 5 parts of tetrafluoroethylene powder, 2 parts of aminopropyltriethoxysilane coupling agent, 2 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. Clean the polytetrafluoroethylene fabric with acetone, use the coating of the present invention for thin layer brushing, place it in a blast oven at 50°C for 1 hour, take it out, apply a pressure of 0.2Mpa and raise the temperature (programmed temperature rise, within 2 hours) to 160 ℃ curing 2h.

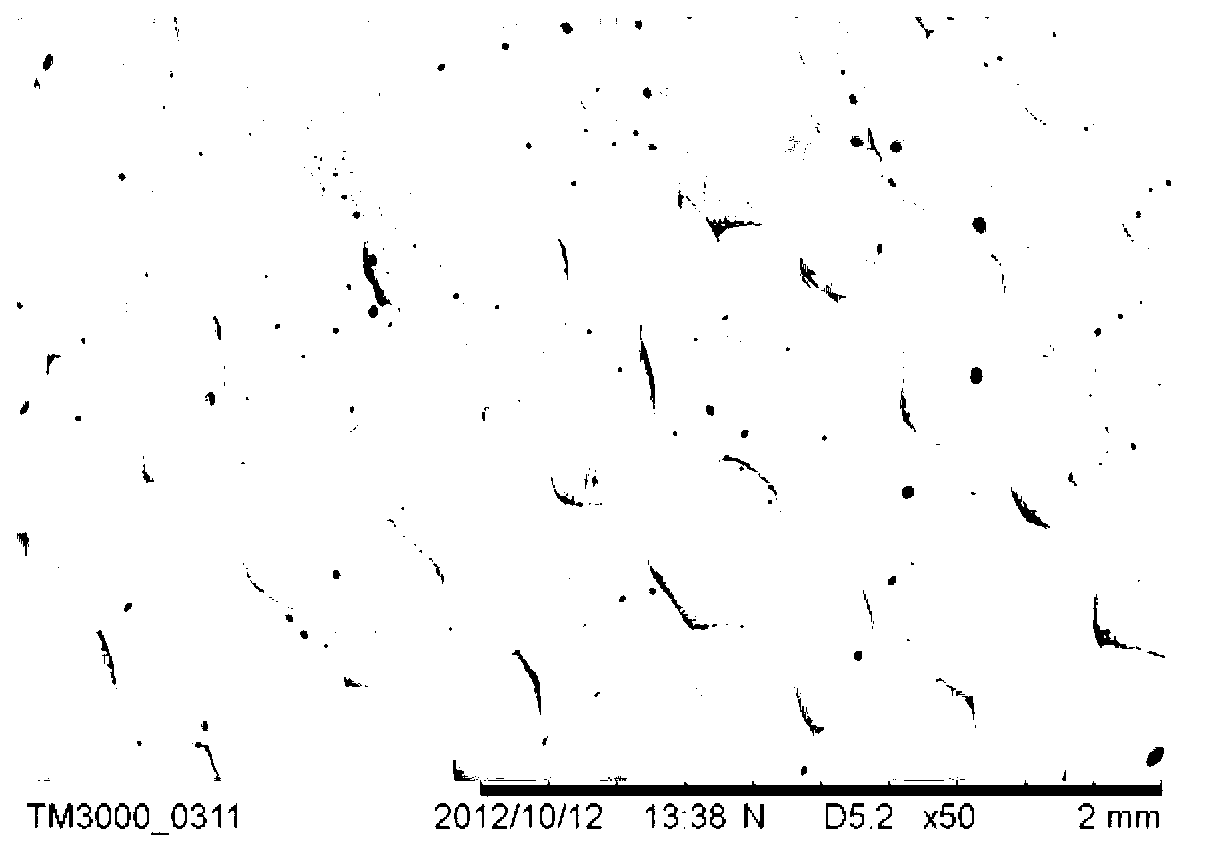

[0029] figure 1 is a schematic diagram of a plain bearing textile liner coated with a self-lubricating coating. The fabric liner is the most core part of the self-lubricating joint bearing. Obviously, the coating of the present invention fills the gaps between the fabric fibers, and when the fabr...

Embodiment 2

[0032] 0.5 parts of polyvinyl alcohol, 10 parts of tetrafluoroethylene powder, 2.5 parts of aminopropyltriethoxysilane coupling agent, 2 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. The PTFE fabric is cleaned with acetone, brushed with a thin layer of the coating of the present invention, placed in a blast oven at 50°C for 1 hour, taken out and applied a pressure of 0.2Mpa and heated (programmed temperature within 2 hours) to 160°C Cured for 2h. After curing, the measured friction coefficient is 0.037, and the specific wear rate is 3.1±0.9 (×10 -6 mm 3 / Nm).

Embodiment 3

[0034] 1.0 parts of polyvinyl alcohol, 5 parts of tetrafluoroethylene powder, 5 parts of aminopropyltriethoxysilane coupling agent, 5 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. The PTFE fabric is cleaned with acetone, brushed with a thin layer of the coating of the present invention, placed in a blast oven at 50°C for 1 hour, taken out and applied a pressure of 0.2Mpa and heated (programmed temperature within 2 hours) to 160°C Cured for 2h. After curing, the measured friction coefficient is 0.038, and the specific wear rate is 2.1±0.5 (×10 -6 mm 3 / Nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com