Fabric liner coating material of self-lubricating joint bearing and preparation method thereof

A technology for spherical plain bearings and coating materials, which is applied in textiles and papermaking, fiber types, fiber processing, etc. Lubrication and mechanical properties overcome the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.5 parts of polyvinyl alcohol, 5 parts of tetrafluoroethylene powder, 2 parts of aminopropyltriethoxysilane coupling agent, 2 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. Clean the polytetrafluoroethylene fabric with acetone, use the coating of the present invention for thin layer brushing, place it in a blast oven at 50°C for 1 hour, take it out, apply a pressure of 0.2Mpa and raise the temperature (programmed temperature rise, within 2 hours) to 160 ℃ curing 2h.

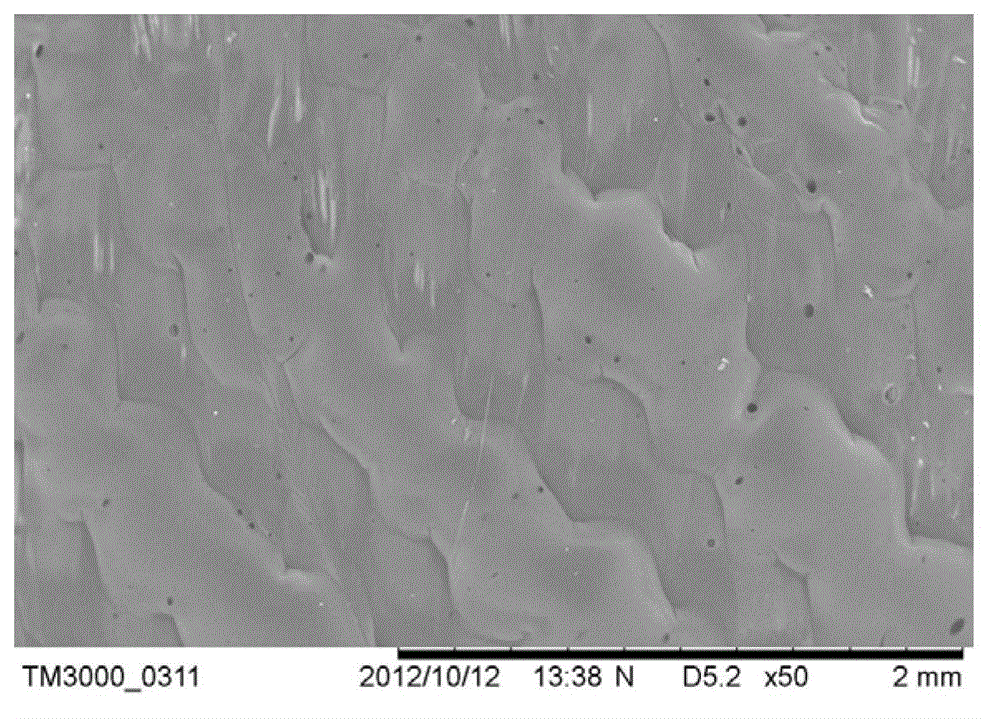

[0029] figure 1 is a schematic diagram of a plain bearing textile liner coated with a self-lubricating coating. The fabric liner is the most core part of the self-lubricating joint bearing. Obviously, the coating of the present invention fills the gaps between the fabric fibers, and when the fabr...

Embodiment 2

[0032] 0.5 parts of polyvinyl alcohol, 10 parts of tetrafluoroethylene powder, 2.5 parts of aminopropyltriethoxysilane coupling agent, 2 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. The PTFE fabric is cleaned with acetone, brushed with a thin layer of the coating of the present invention, placed in a blast oven at 50°C for 1 hour, taken out and applied a pressure of 0.2Mpa and heated (programmed temperature within 2 hours) to 160°C Cured for 2h. After curing, the measured friction coefficient is 0.037, and the specific wear rate is 3.1±0.9 (×10 -6 mm 3 / Nm).

Embodiment 3

[0034] 1.0 parts of polyvinyl alcohol, 5 parts of tetrafluoroethylene powder, 5 parts of aminopropyltriethoxysilane coupling agent, 5 parts of aminopropyl POSS, 20 parts of 4,4'-diaminodiphenylsulfone were dissolved in 35 After stirring for 1 hour, add 80 parts of epoxy resin E51 in 10 times under ultrasonic vibration, and continue stirring for 1 hour to obtain a self-lubricating coating. The PTFE fabric is cleaned with acetone, brushed with a thin layer of the coating of the present invention, placed in a blast oven at 50°C for 1 hour, taken out and applied a pressure of 0.2Mpa and heated (programmed temperature within 2 hours) to 160°C Cured for 2h. After curing, the measured friction coefficient is 0.038, and the specific wear rate is 2.1±0.5 (×10 -6 mm 3 / Nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com