Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Reduce contact friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

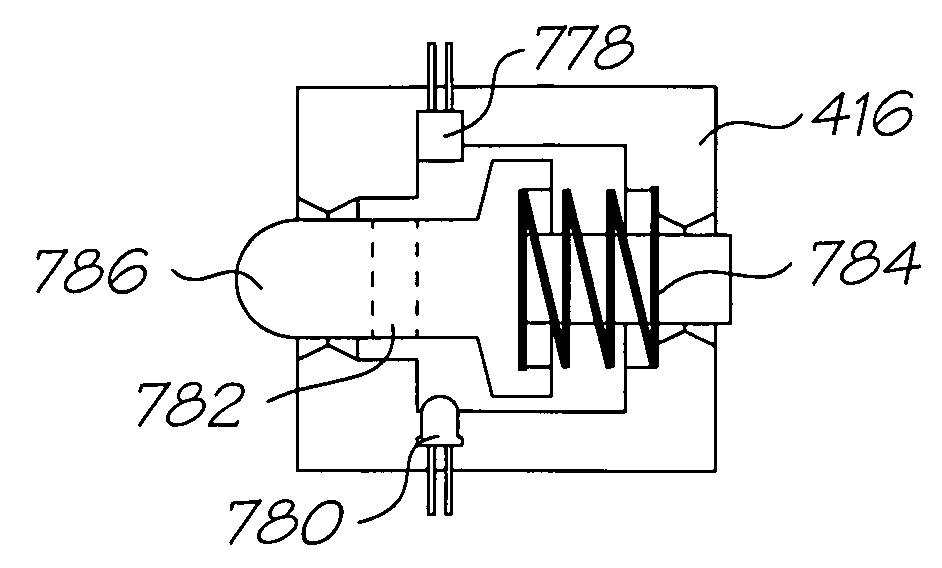

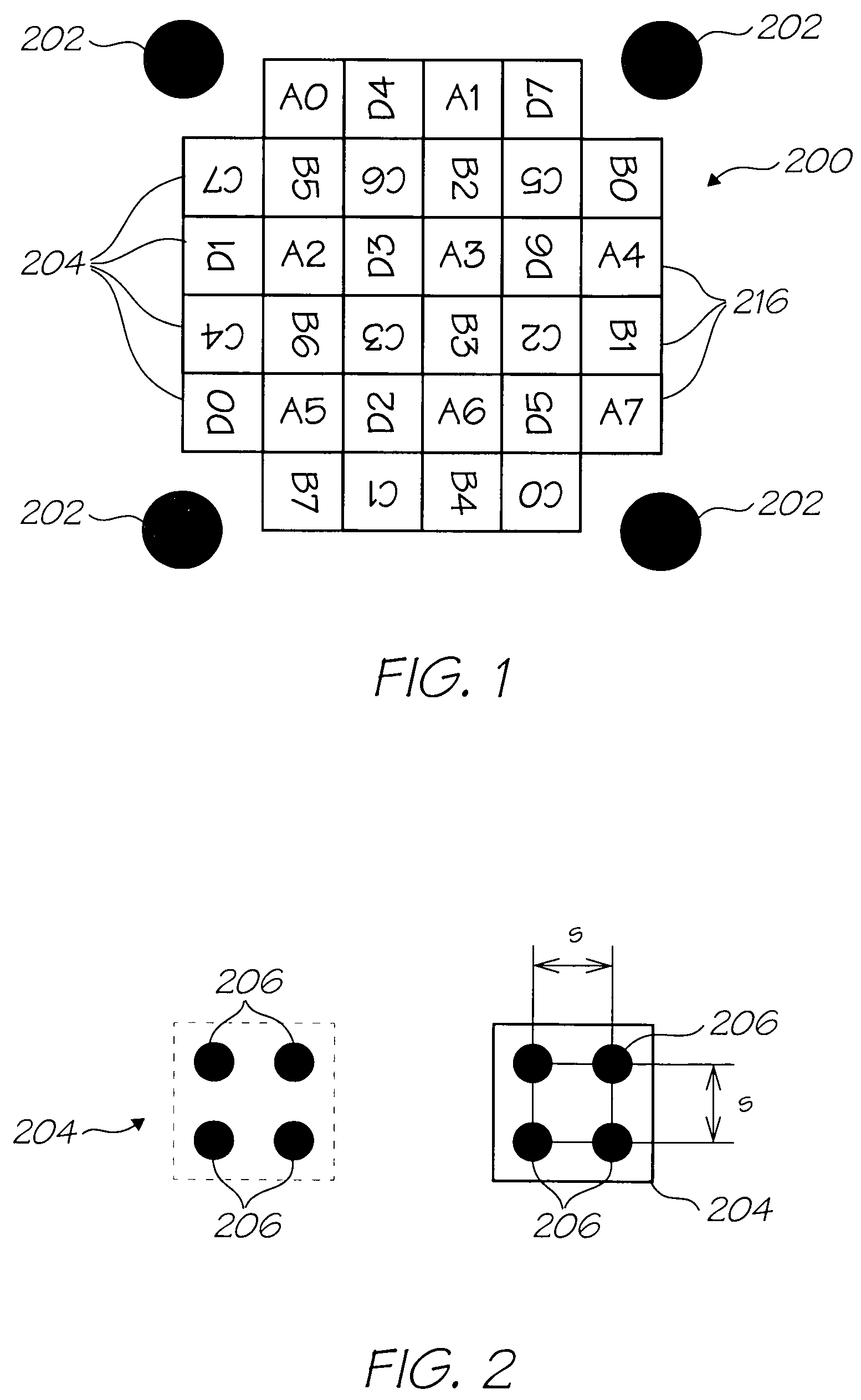

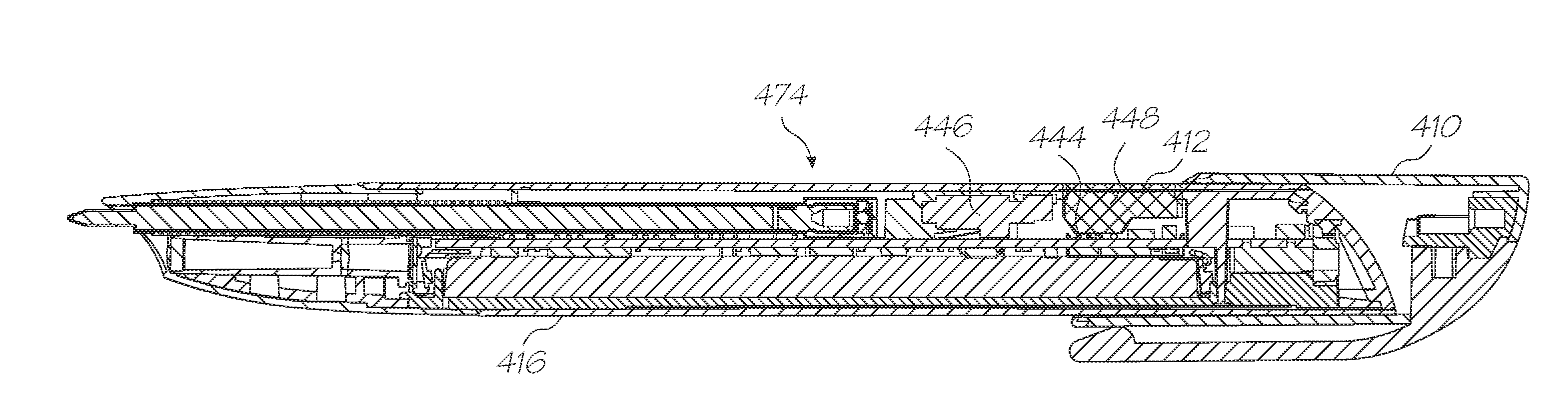

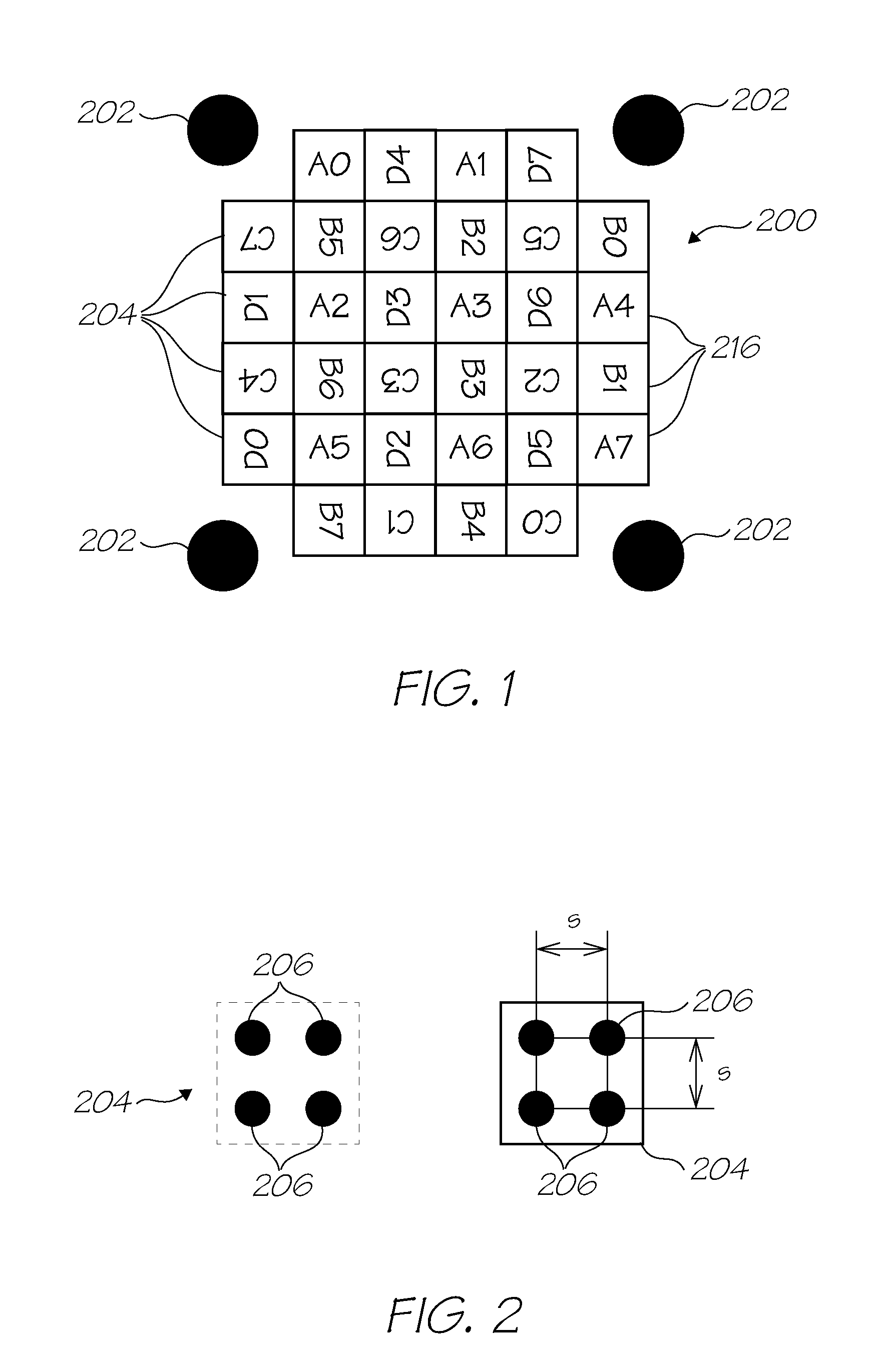

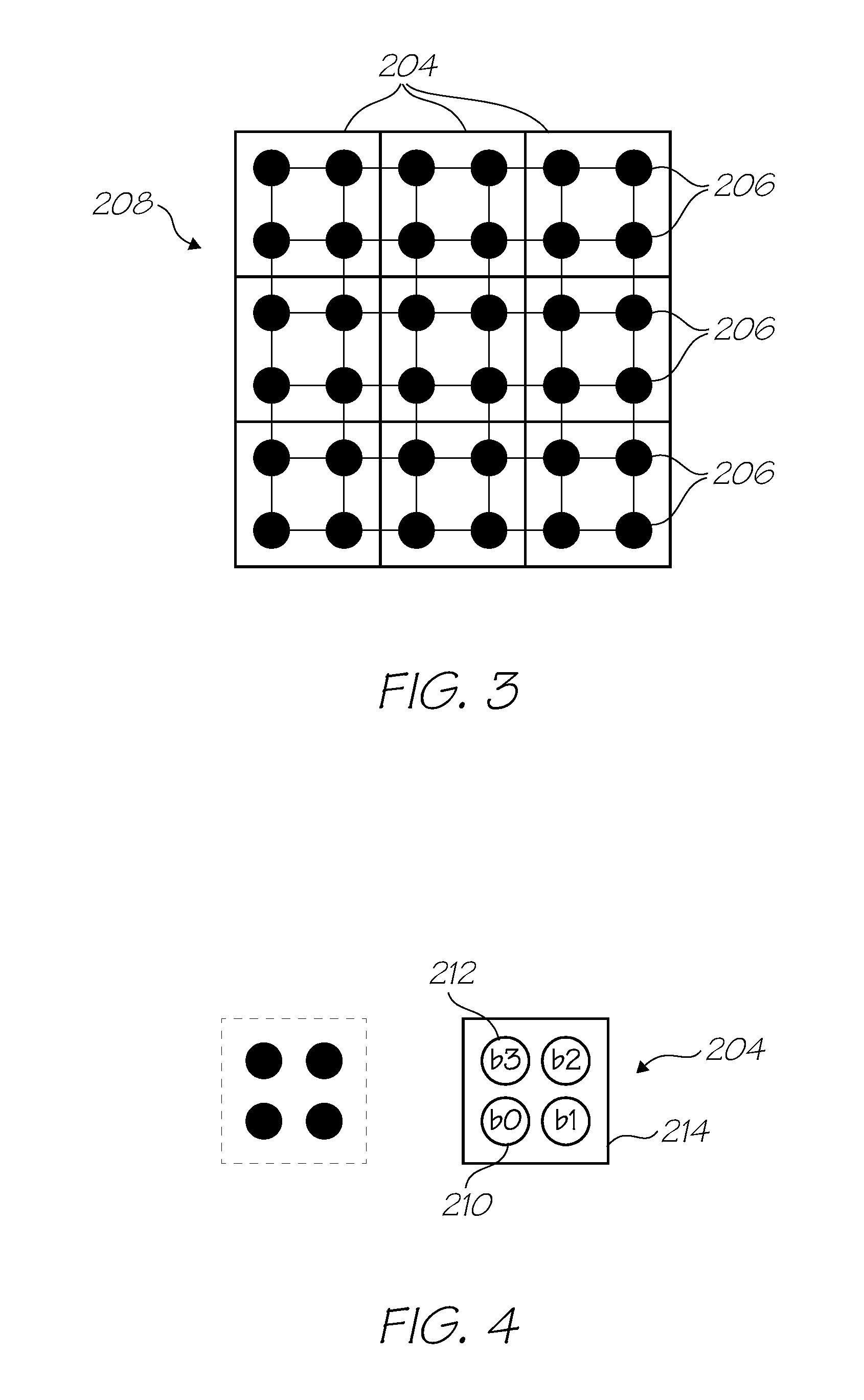

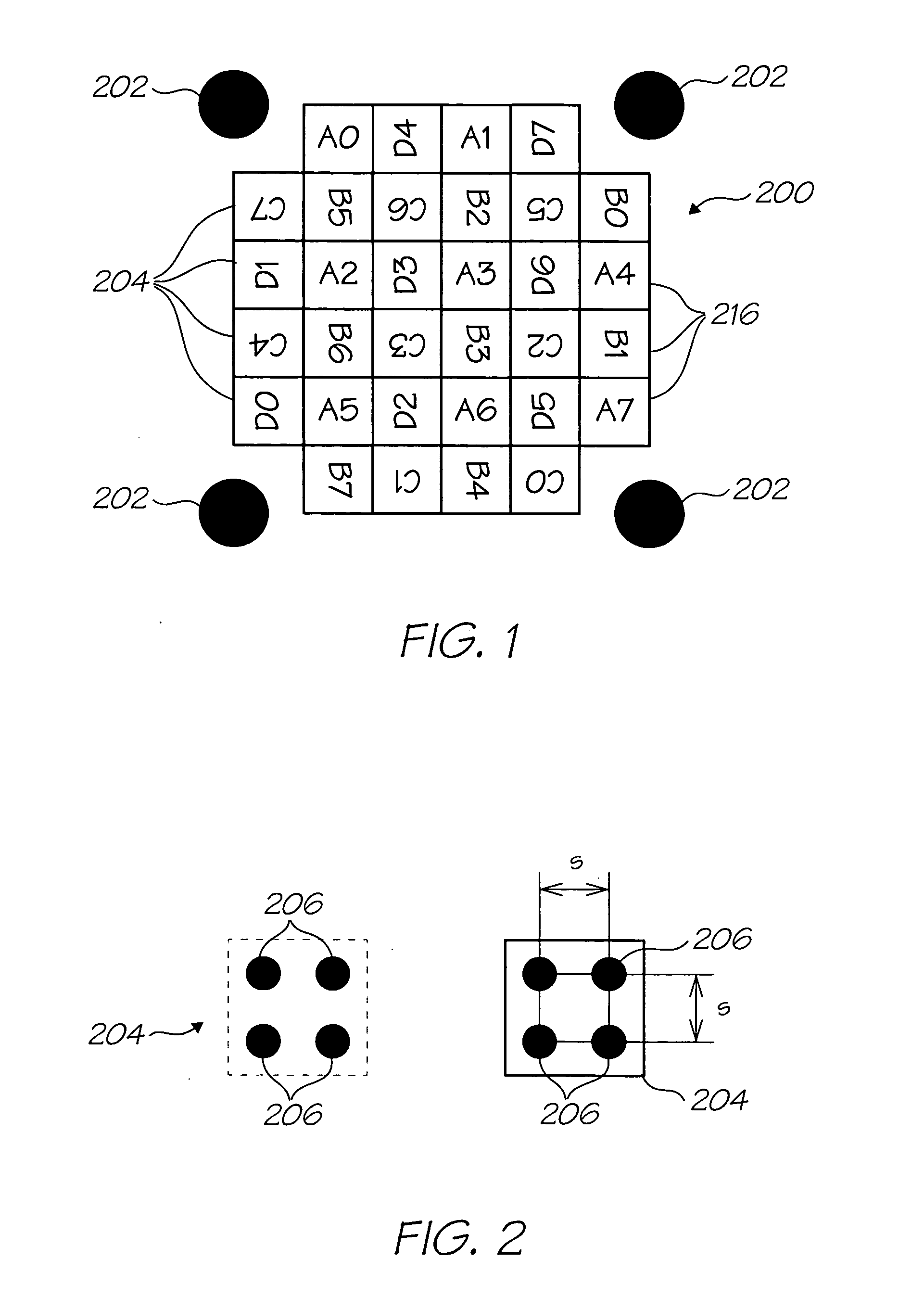

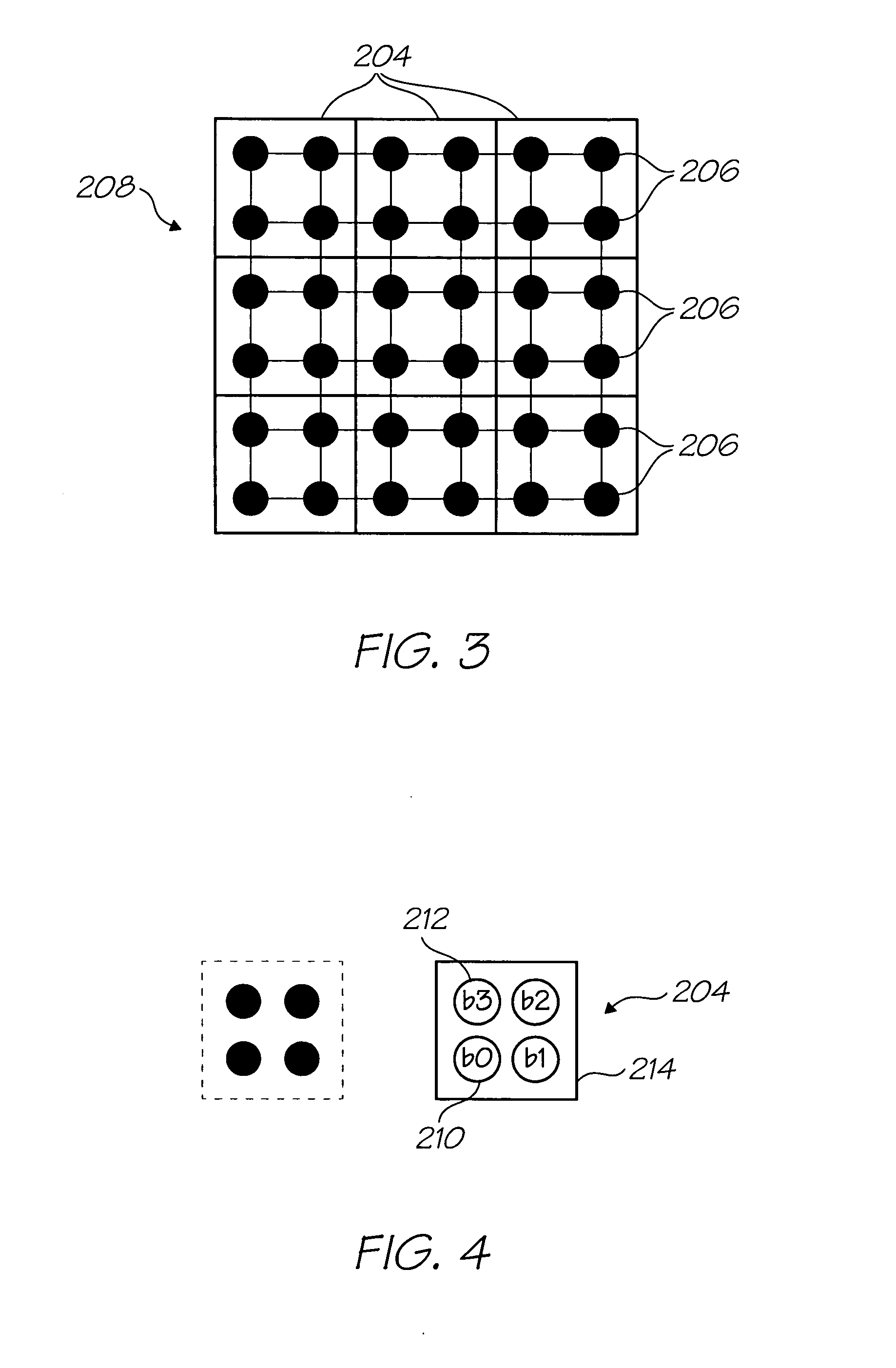

Optical force sensor

InactiveUS20070014490A1Less potential damageReduce contact frictionForce measurementCharacter and pattern recognitionResistive sensorsEngineering

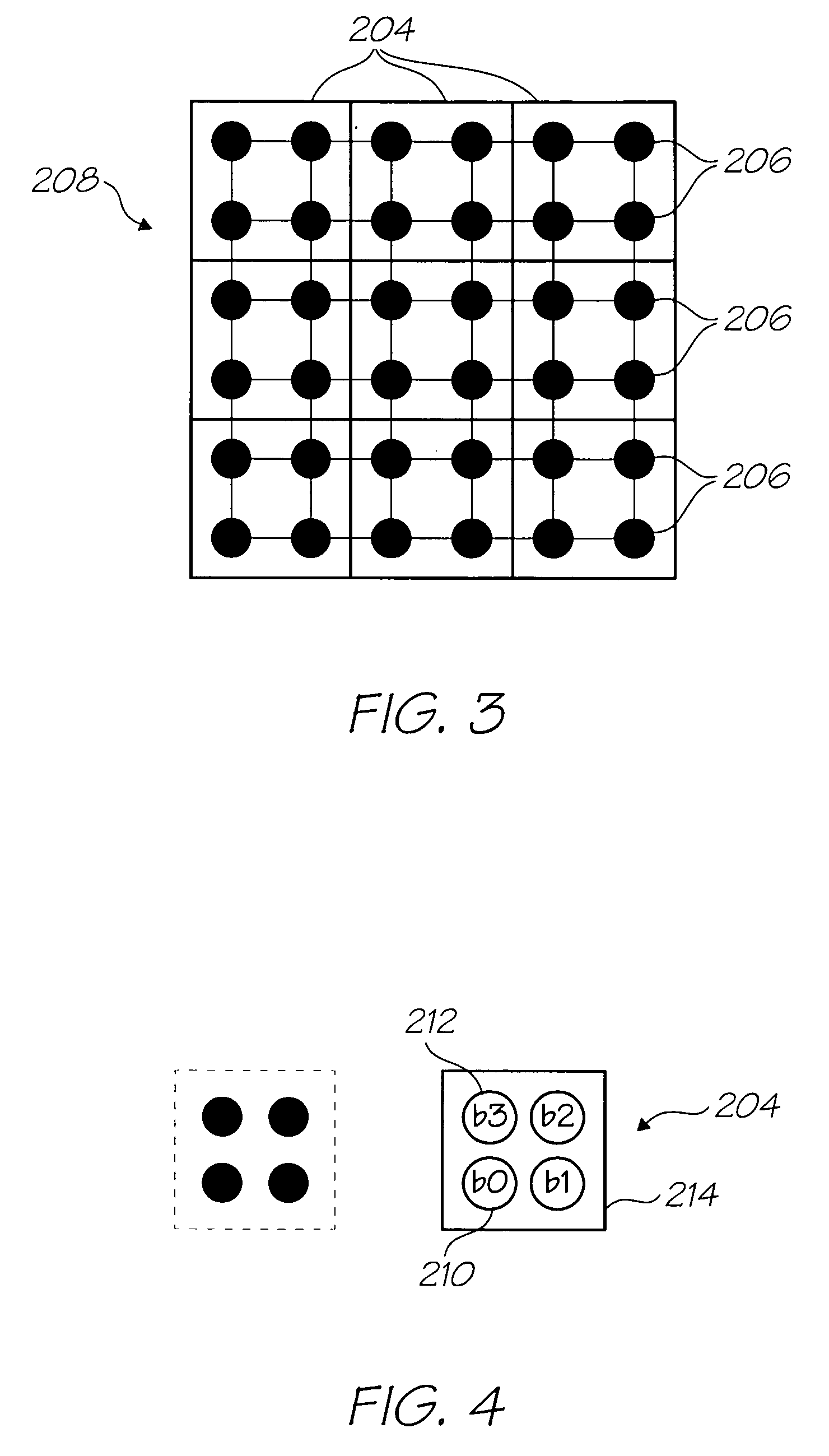

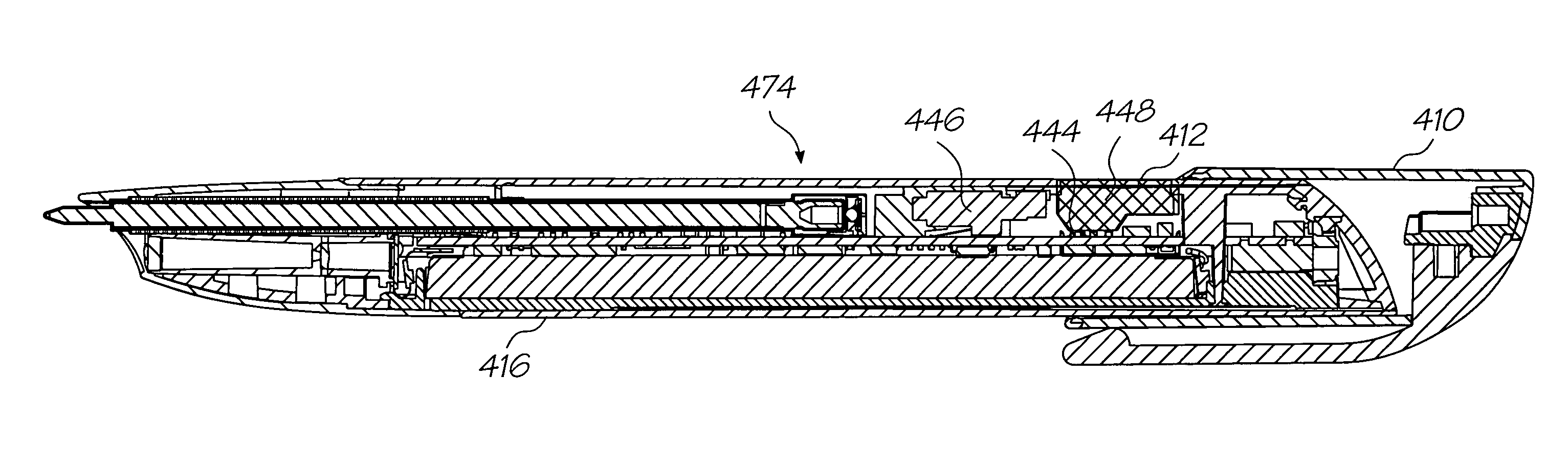

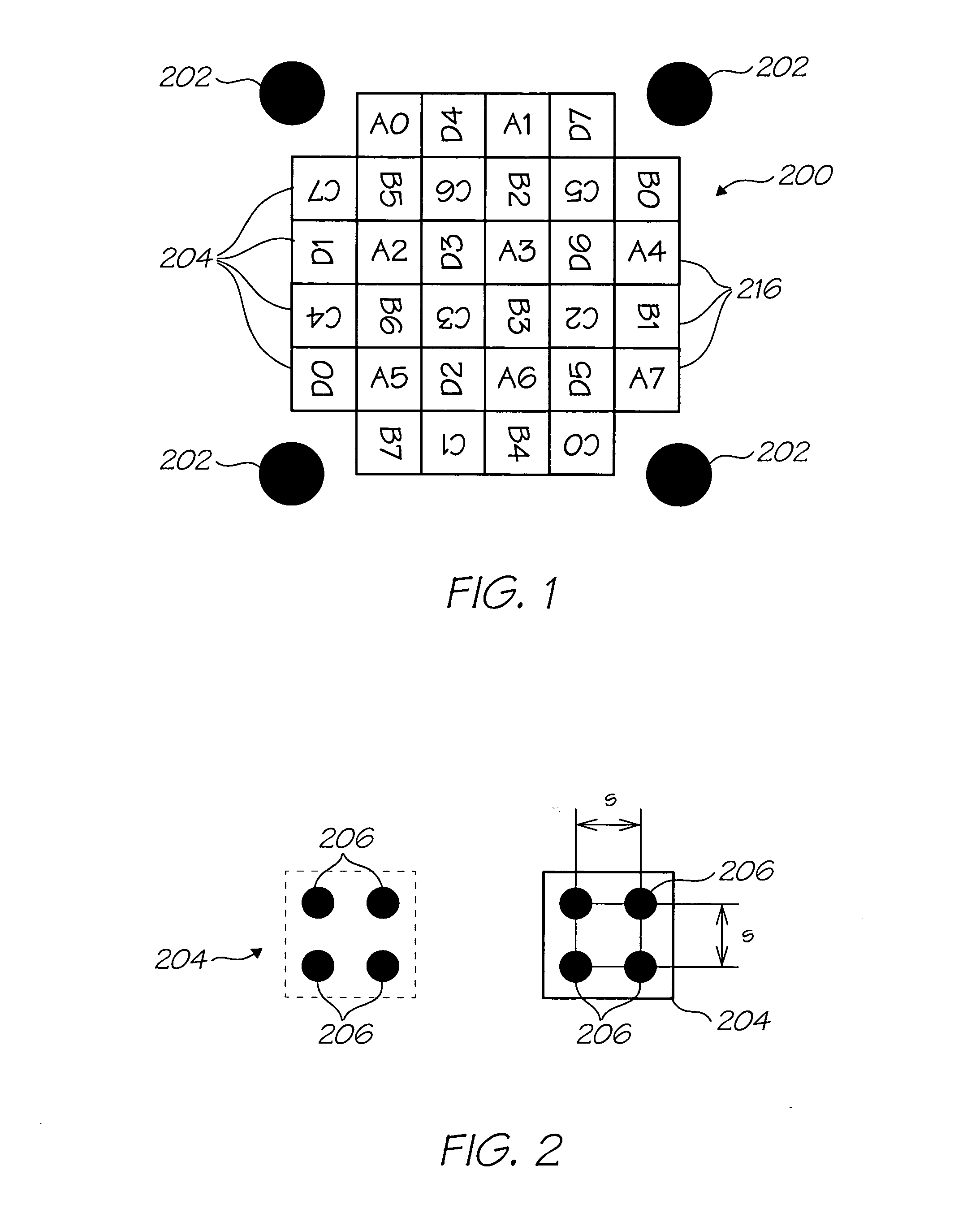

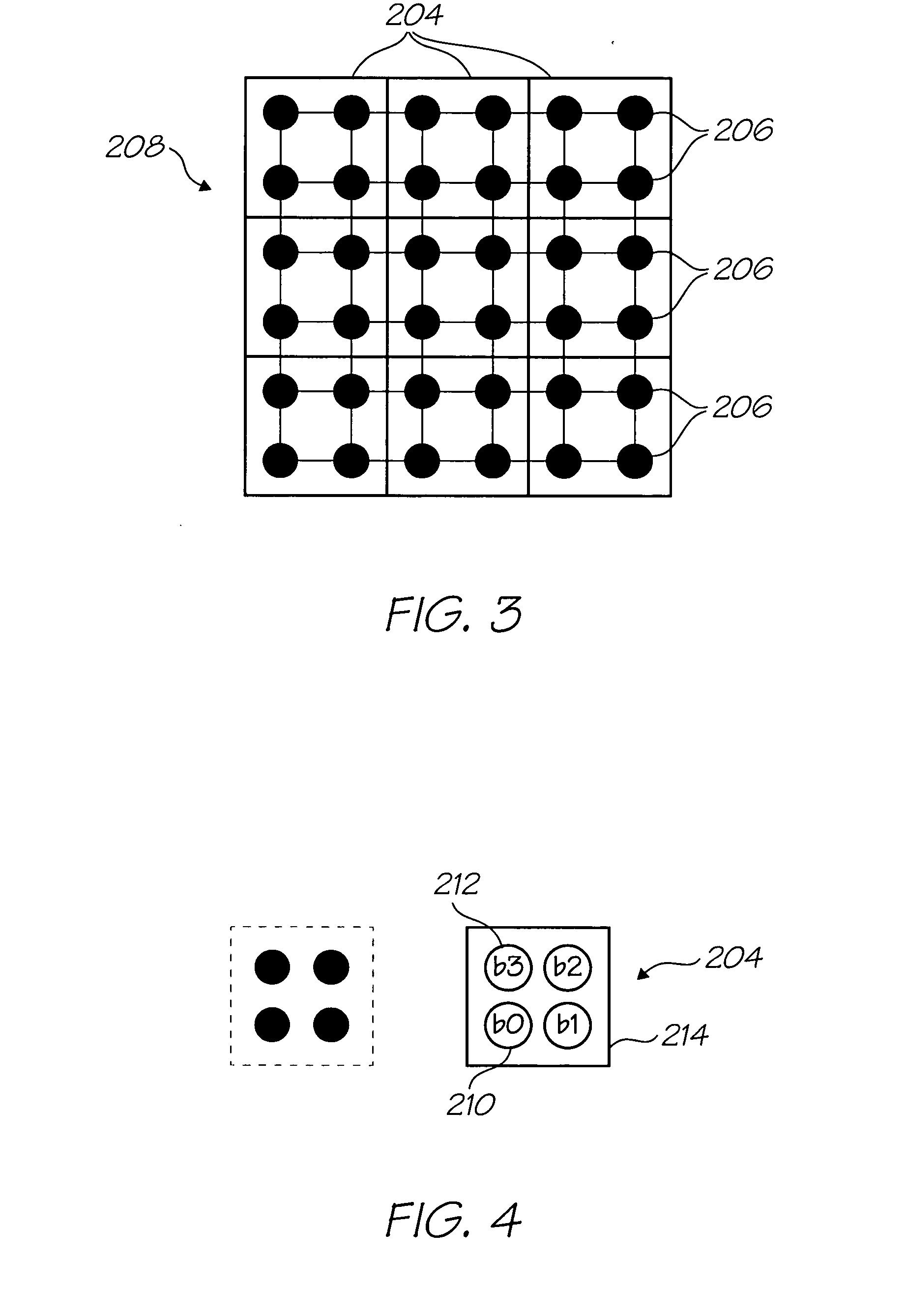

A force sensor particularly suited for use in an electronic stylus that senses the contact force on its nib for recording pen strokes and handwriting recognition. The sensor has a housing for a load bearing member for receiving an input force to be sensed and associated circuitry for converting the input force into an output signal indicative of the input force. The bearing member is movably mounted within the elongate body (up to 100 microns). The input force acting on the load bearing member is caused by contact on the nib. The load bearing member is biased against the direction of the input force. The force sensor also has a light source and photo-detector for sensing levels of illumination from the light source. Associated circuitry converts a range of illumination levels sensed by the photo-detector into a range of output signals, so that the illumination level sensed by the photo-detector varies with movement of the load bearing member within the elongate body such that the output signal from the circuitry is indicative of the input force. Using an optical sensor avoids the need to use a delicate piezo-resistive sensor that requires careful tolerancing during production.

Owner:LIVESCRIBE

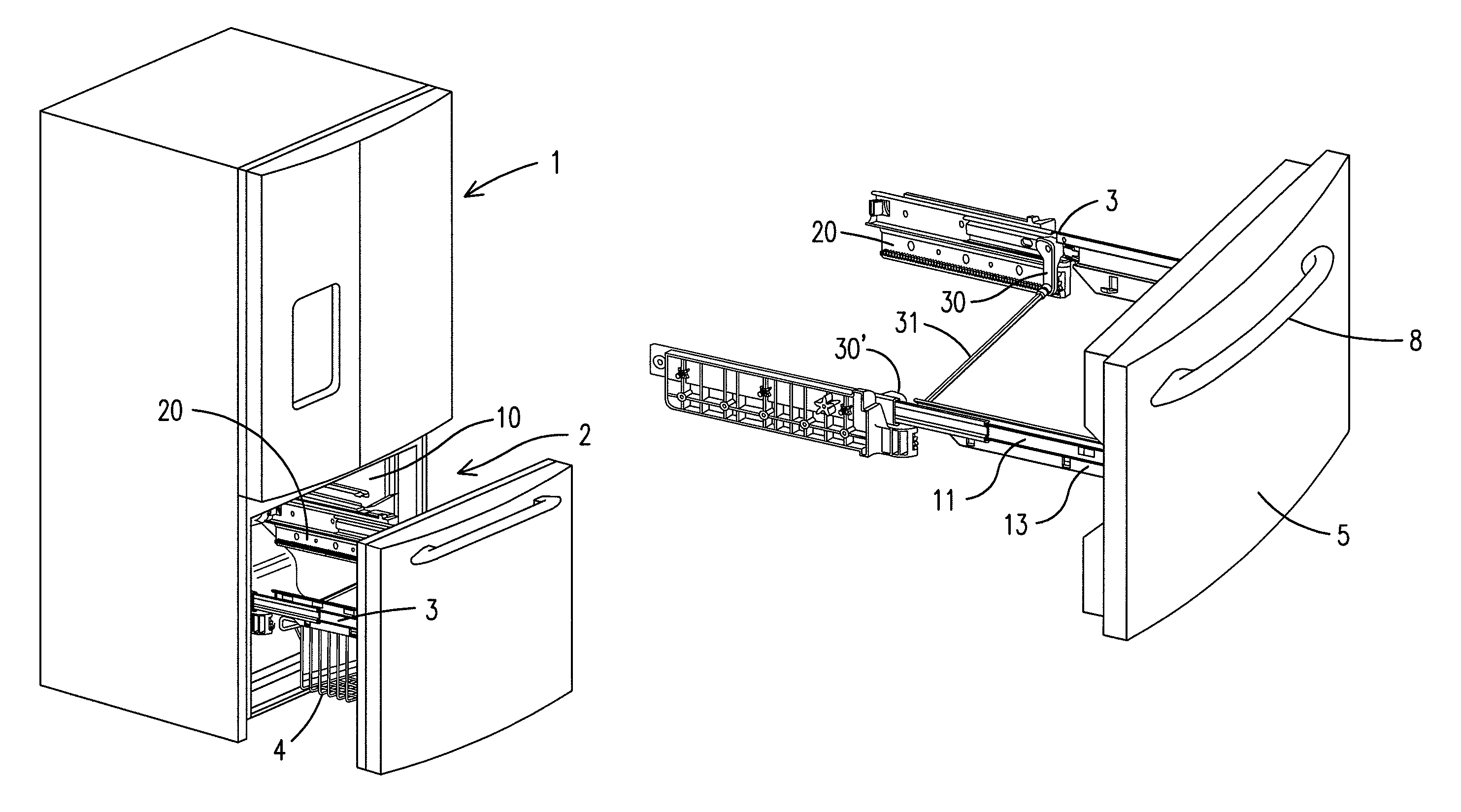

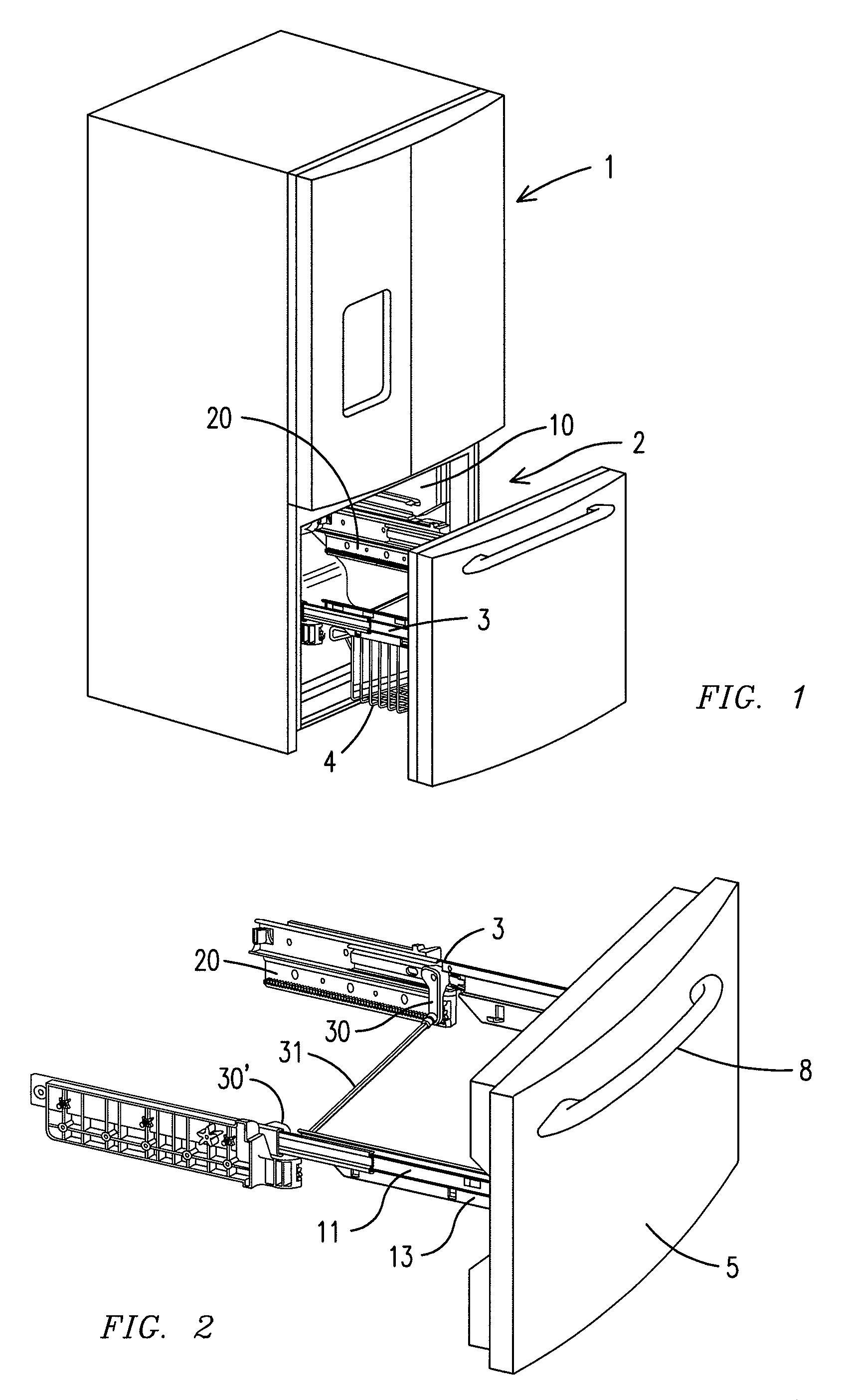

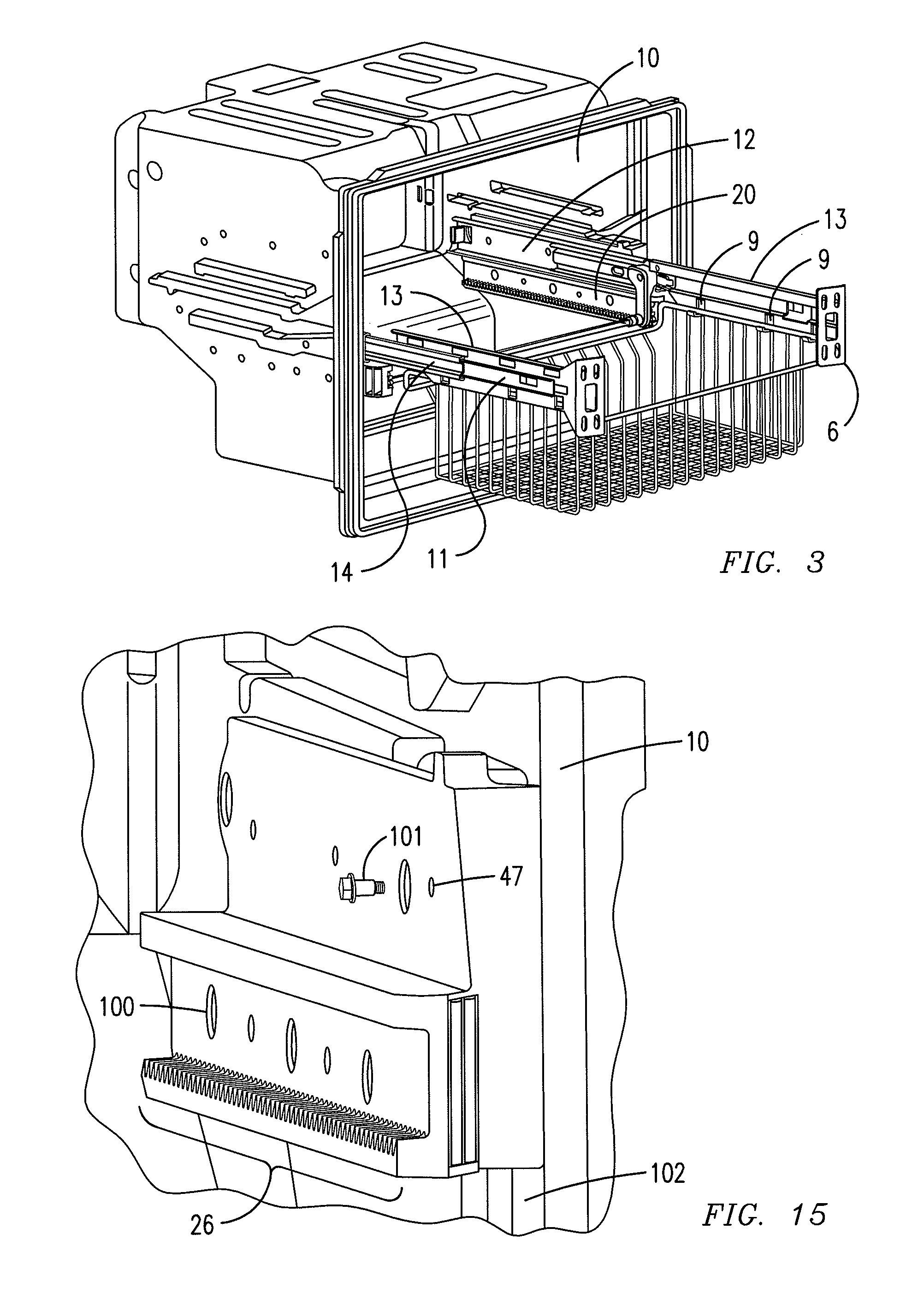

Support beam for a cabinet drawer

InactiveUS20090261698A1Easing extraction and introductionReduce contact frictionDrawersFittingGear wheelEngineering

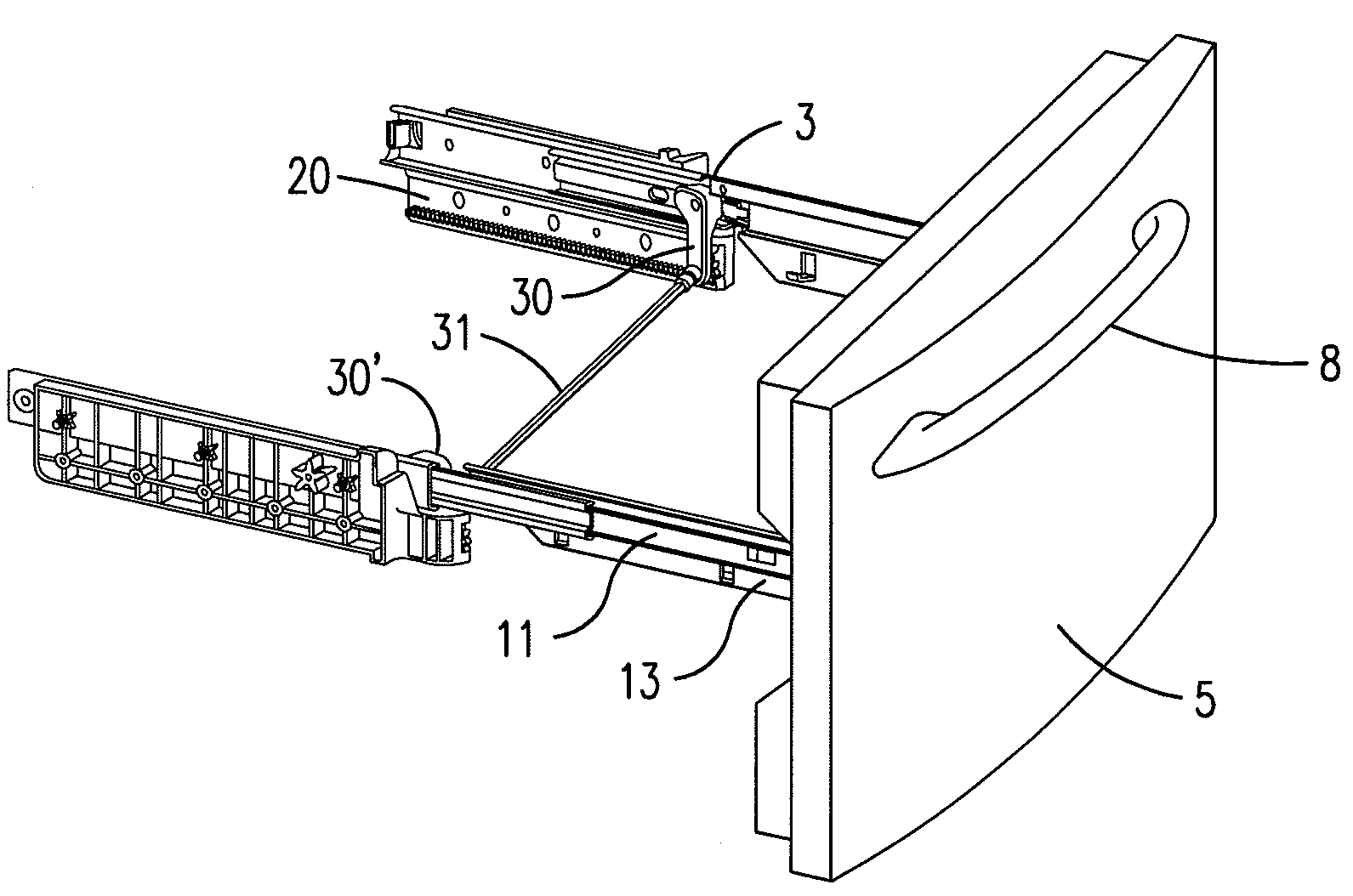

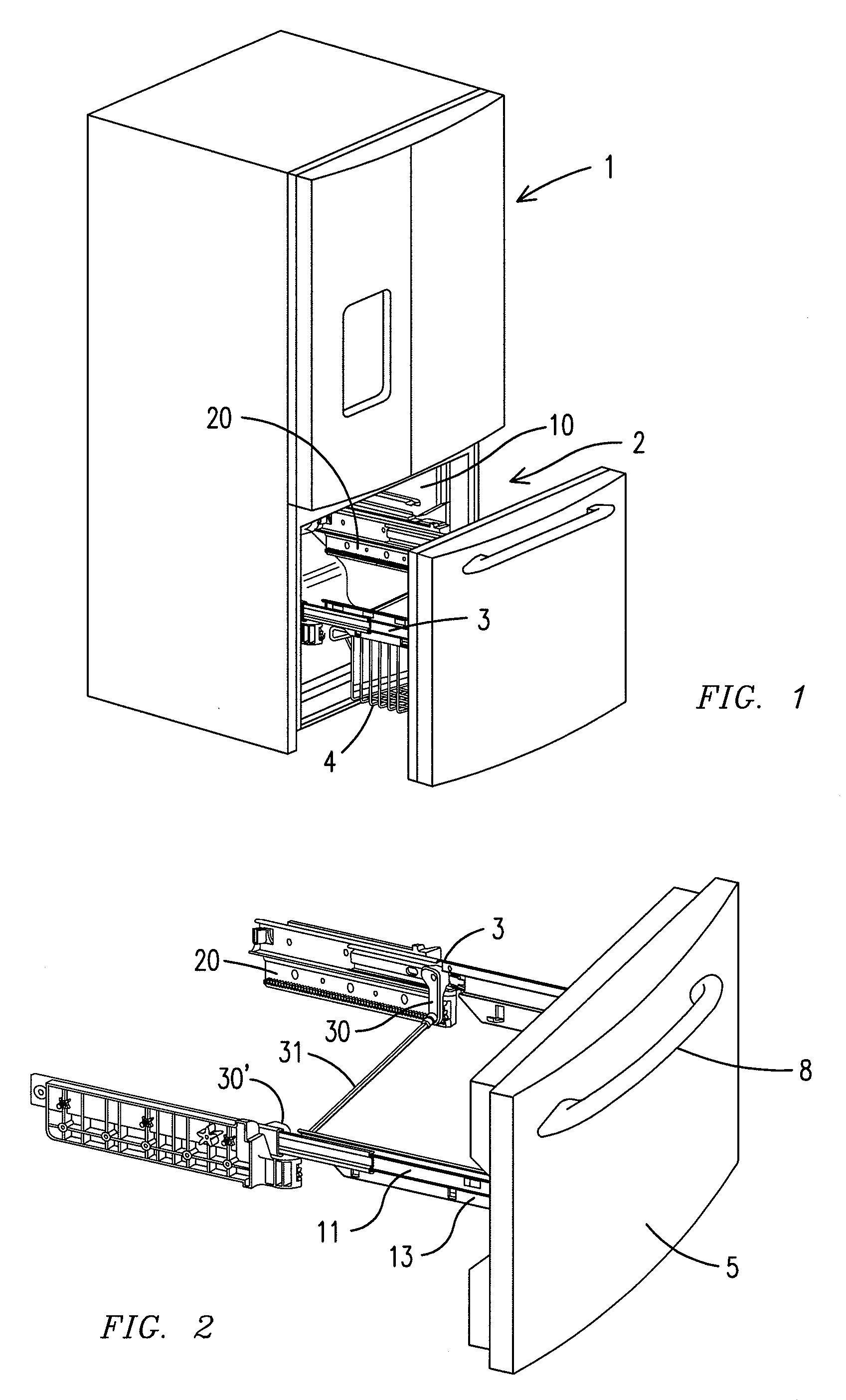

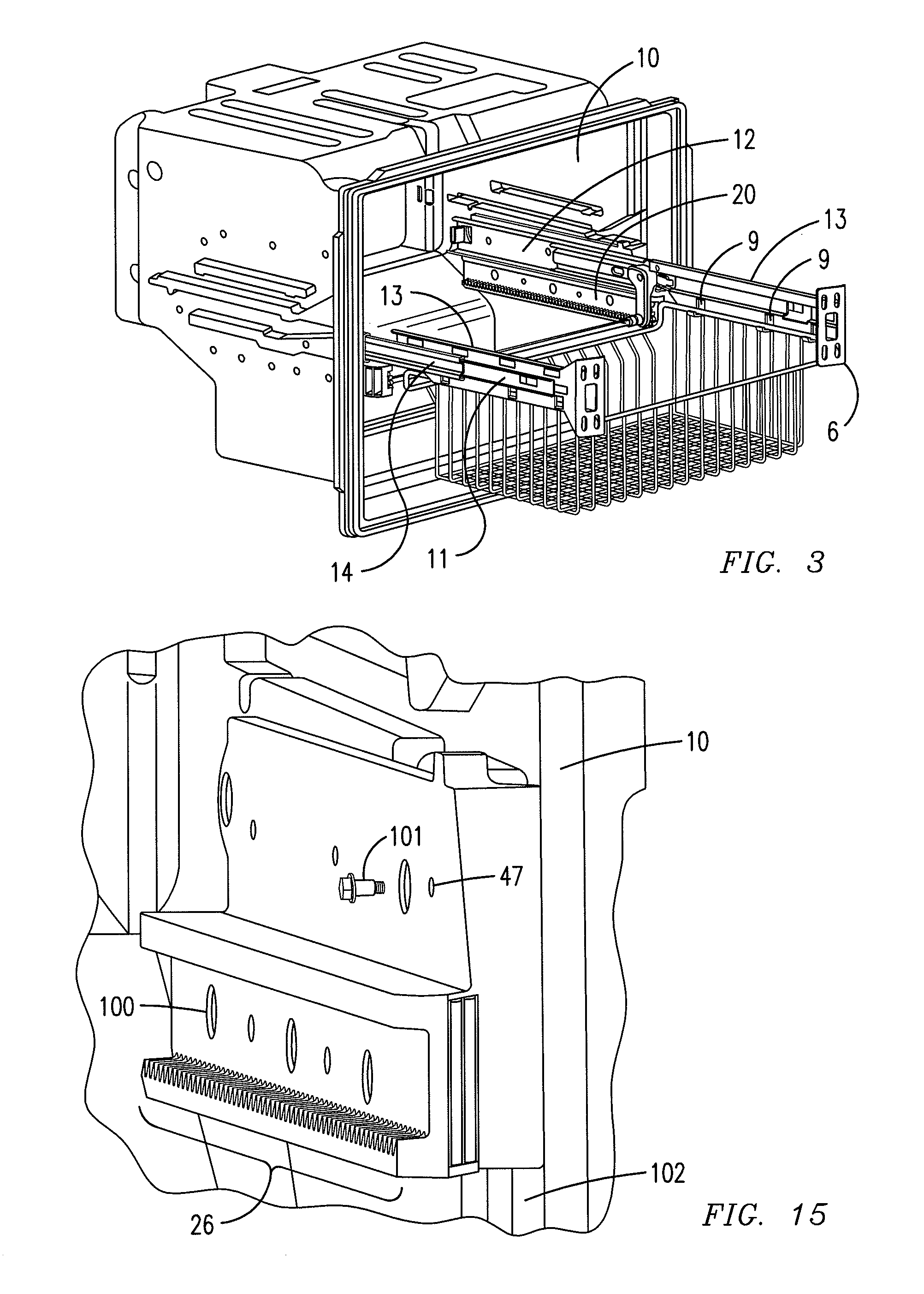

Cabinet drawer support beam is provided. An upper part of the beam may include a rail or longitudinal sliding mechanism and may further include an alignment mechanism fastened to the rail or longitudinal mechanism including a pinion that runs in the rack of the lower part of the support beam. The support beam may be fastened to the cabinet wall by means of barrels and fasteners. In one example implementation, at least two beams per cabinet may be found.

Owner:MABE SA DE CV

Pen with side loading cartridge

ActiveUS20070025805A1Less potential damageReduce contact frictionWriting connectorsForce measurementEngineeringChassis

Owner:LIVESCRIBE

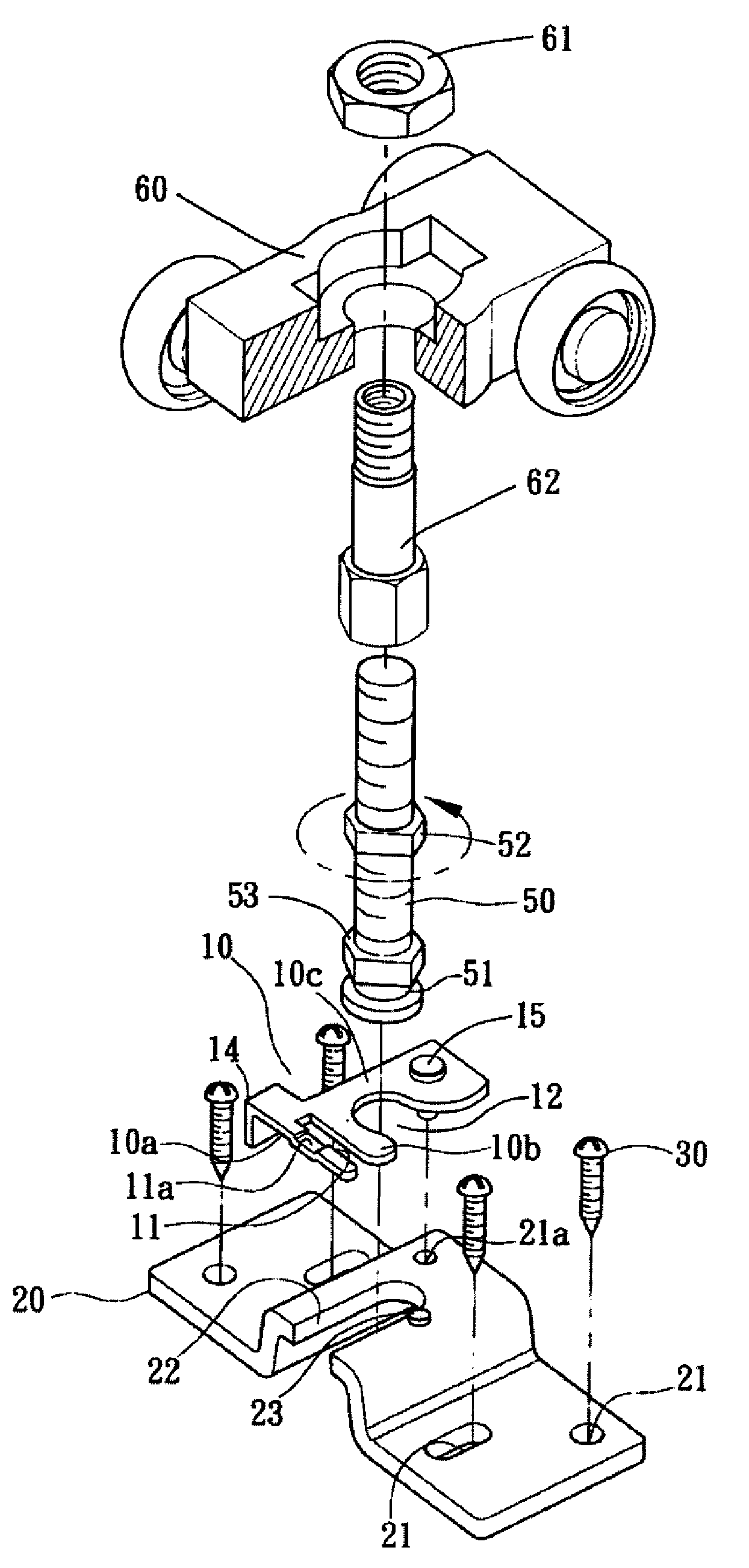

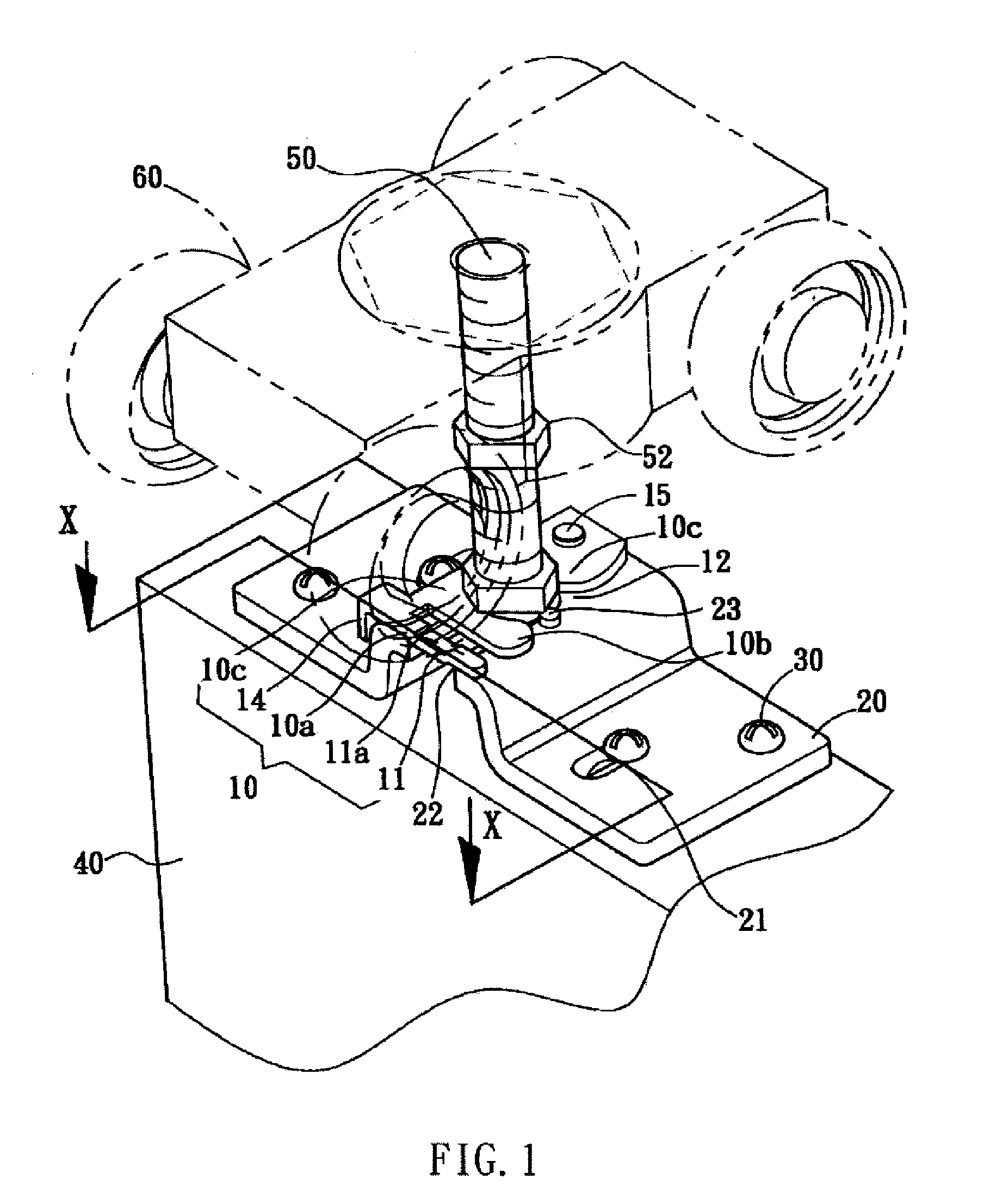

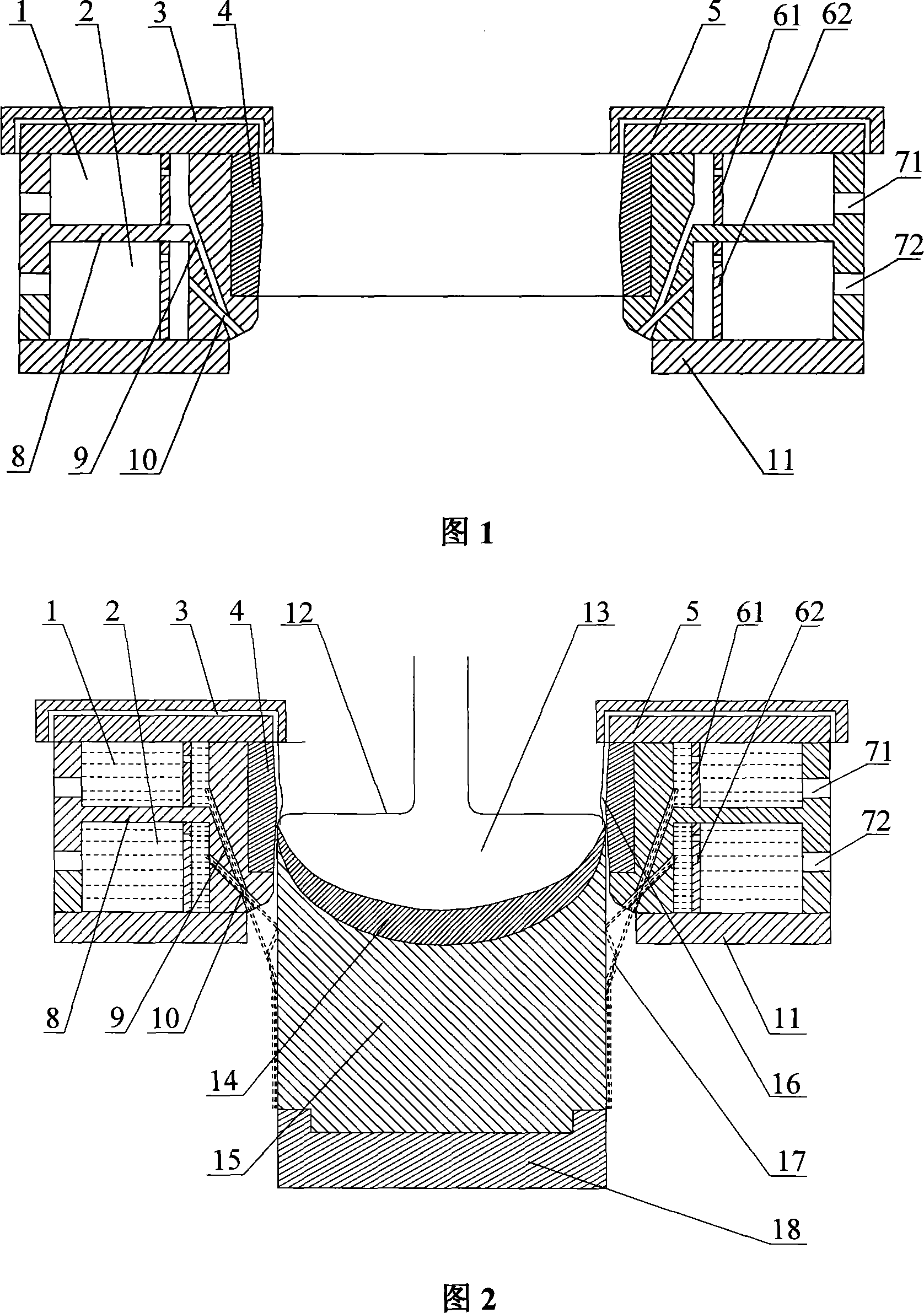

Positioning member for preventing detachment of axle

InactiveUS20090289463A1Prevent disengagementPrevent undesired separationBuilding locksWing suspension devicesRotational axisEngineering

A positioning member is coupled to a mounting plate, which defines a plurality of holes for receiving screws for connection with an end of an external object. An upper adjustment nut sets a distance between a roller seat and the mounting plate and to provide a securing function by cooperating with a roller seat nut and a roller seat bolt. The mounting plate forms in a central portion thereof an elongate slot for slidably receiving a neck of the axle therein. The positioning member includes a plate-like body forming a straight slot and an inclined slot for leading the neck therein and is provided with a rivet or a resilient fork-like fastener at one side of the inclined slot opposite to the straight slot to be fit into the a positioning hole defined beside the elongate slot for serving as a rotational axis of the positioning member.

Owner:ONLY INDAL CORP

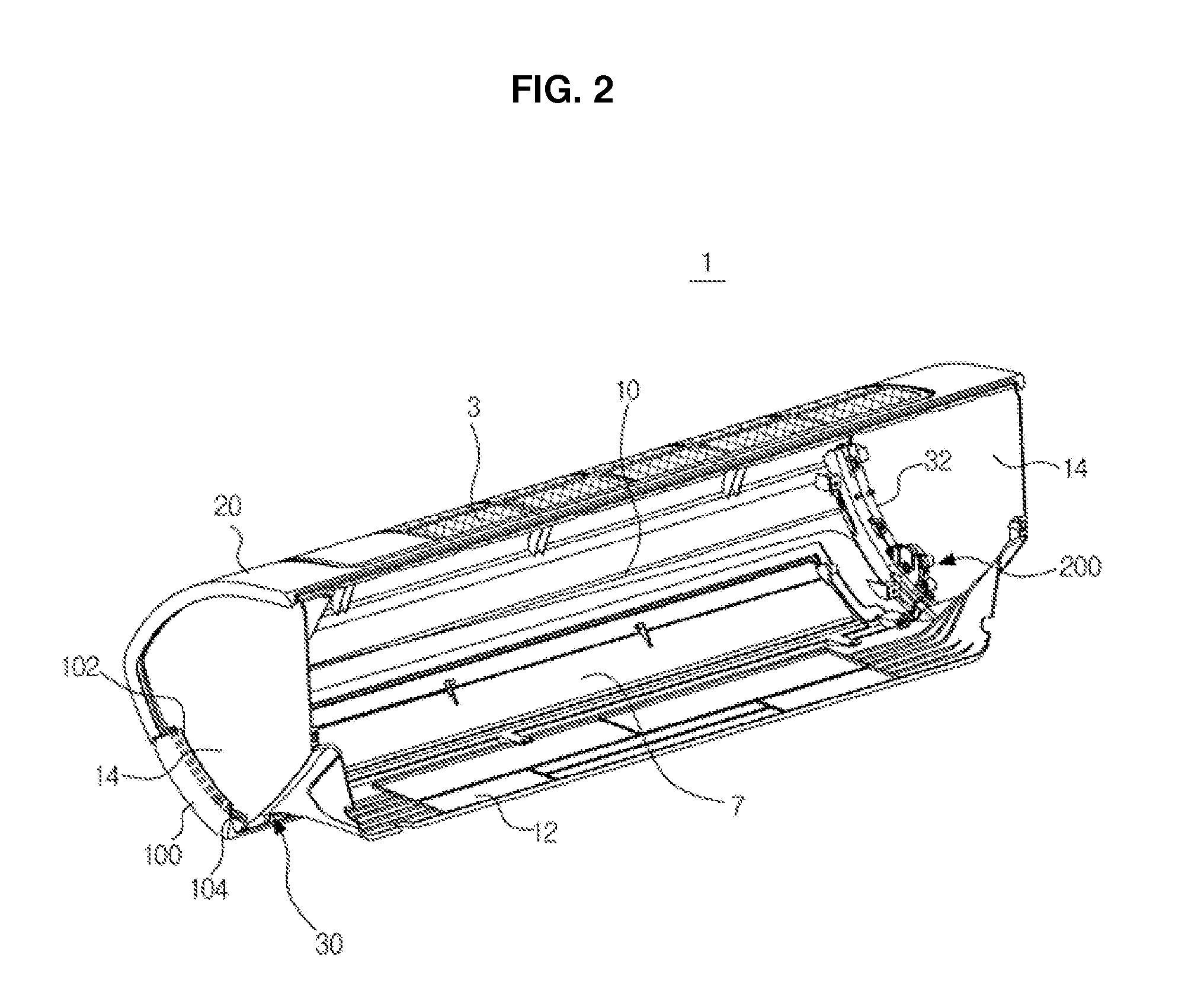

Air conditioner

InactiveUS20150075201A1Reduce contact frictionDucting arrangementsLighting and heating apparatusFront panelElectrical and Electronics engineering

An air conditioner including a door installed in order to provide a smooth appearance by hiding an outlet is provided. The air conditioner is installed on a wall and includes a front panel including a first panel part provided with an inlet and a second panel part connected to a lower portion of the first panel part and provided with an outlet; a lower panel connected to the second panel part of the front panel and extended toward the wall; and a door installed on a front surface of the second panel part so as to open and close the outlet while being slid, wherein the door is slid along a curved movement trajectory toward the lower panel, and a curvature of the movement trajectory is changed. A clean and smooth appearance may be formed using a door slid along a curved path and a slim appearance may be formed even in the state in which the door is opened.

Owner:SAMSUNG ELECTRONICS CO LTD

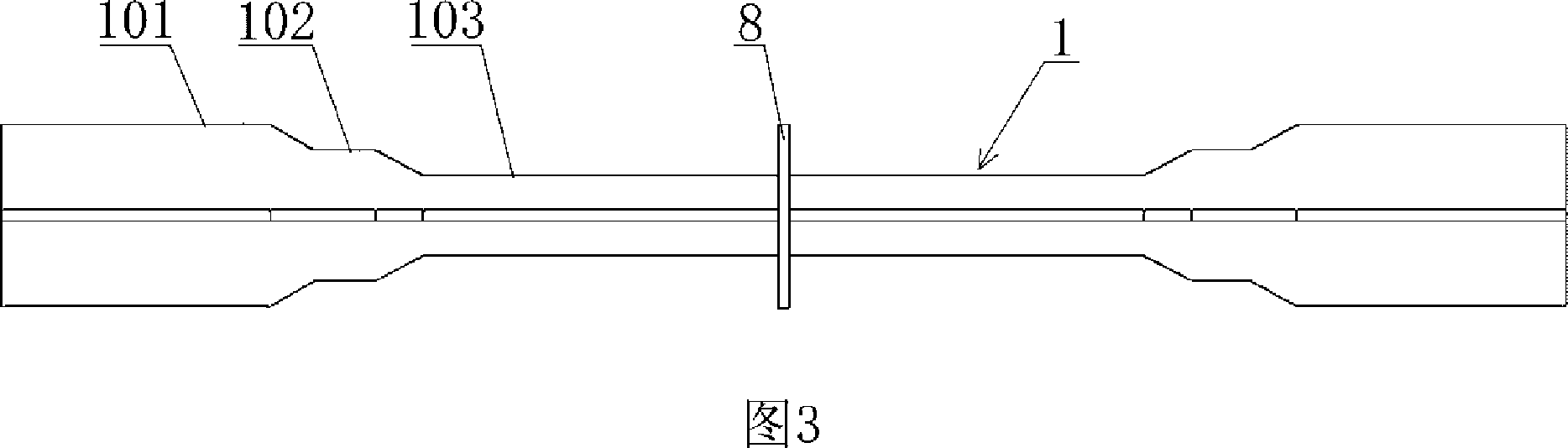

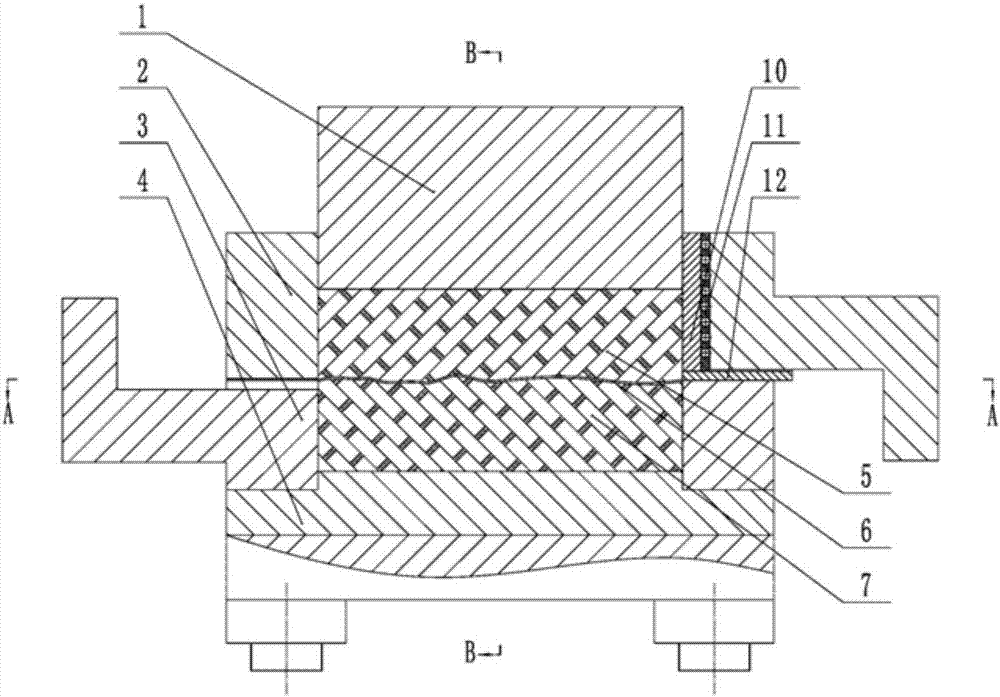

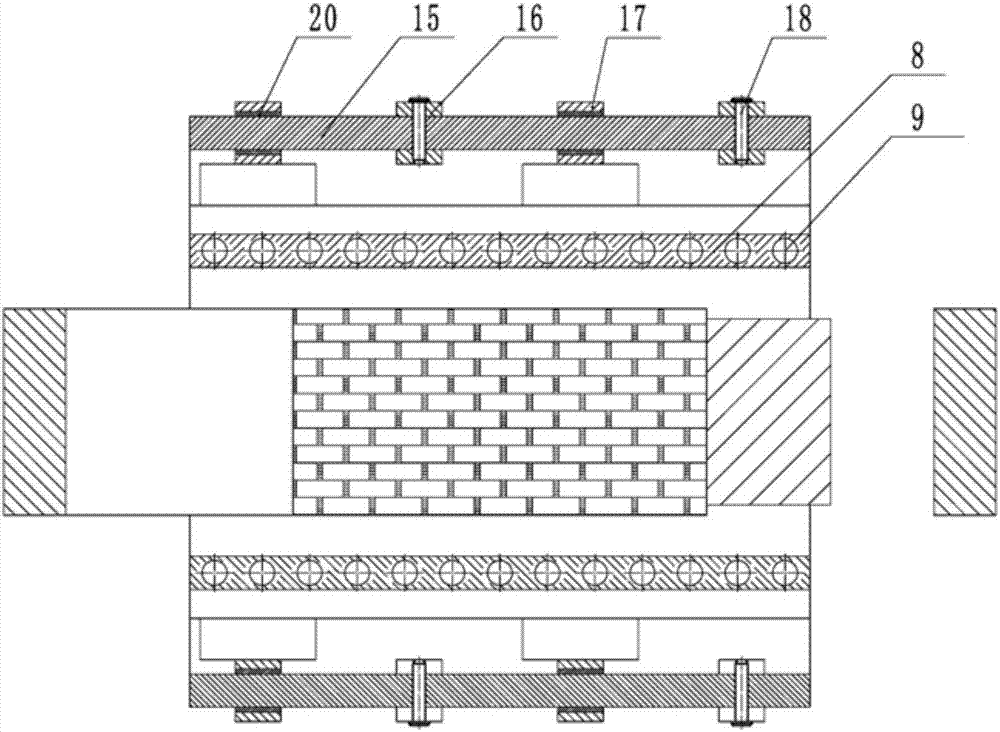

Double-layer bushing crisscross flexuosity restriction support with transverse diaphragm

InactiveCN101105054ASolve the problem of limited lateral expansionPossibility to avoid low-order bucklingShock proofingCruciformCompressible material

A cruciform buckling restrained brace with transverse partition double-layered bushing is provided. The core steel brace has a cruciform cross section, and comprises a middle segment (buckling segment) as major body with a smaller width, two distal end segments (extension segments), a transition segment between the buckling segment and the extension segment, and a transverse partition arranged in the middle of the buckling segment. Outer restraining steel bushings are positioned respectively at two sides of the transverse partition. An inner steel bushing is arranged between the outer restraining steel bushing and the core steel brace and has a cruciform cross section. The space between the inner steel bushing and outer restraining steel bushing is packed with fillers. An anti-adhesion material is coated tightly on the surface of the buckling segment and transition segment of the core steel brace, with a gap between the anti-adhesion material and the inner steel bushing and filled with a compressible material. The invention has the advantages of simple structure, low fabrication cost, suitability for streamline production, and wide application in high-rise buildings, towering buildings, and highway and railway bridges. The invention helps to increase the structural rigidity, improve the capacity of energy dissipation of the whole structure, and prevent earthquake disaster.

Owner:CHINA ACAD OF BUILDING RES +2

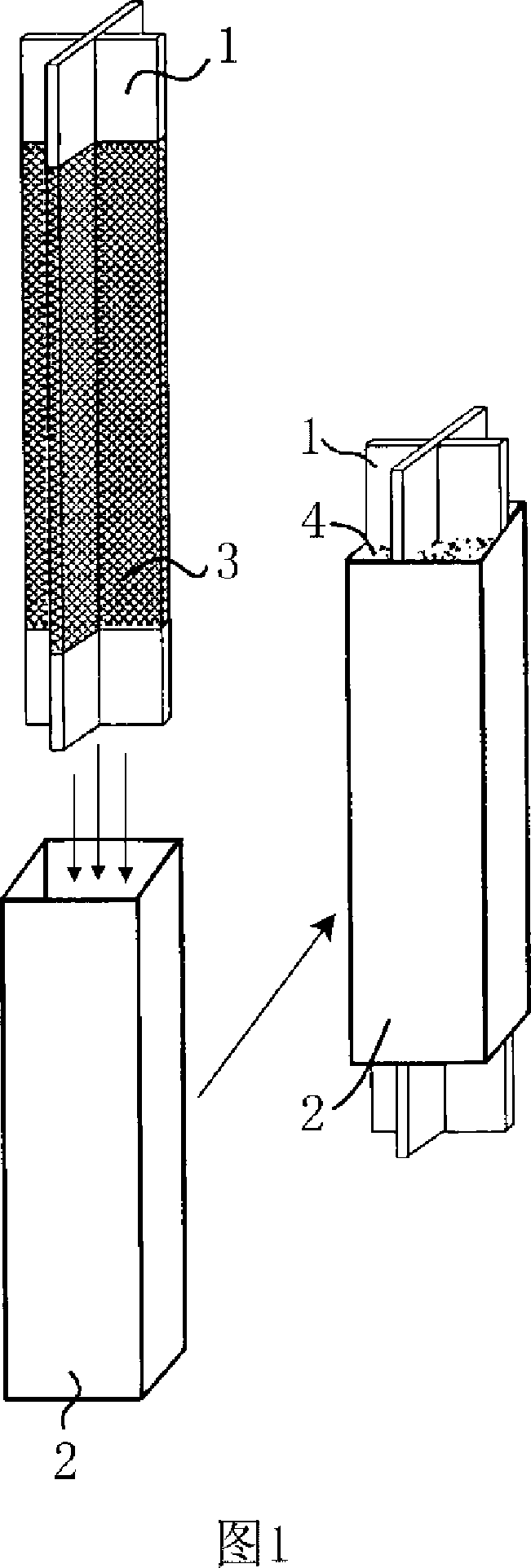

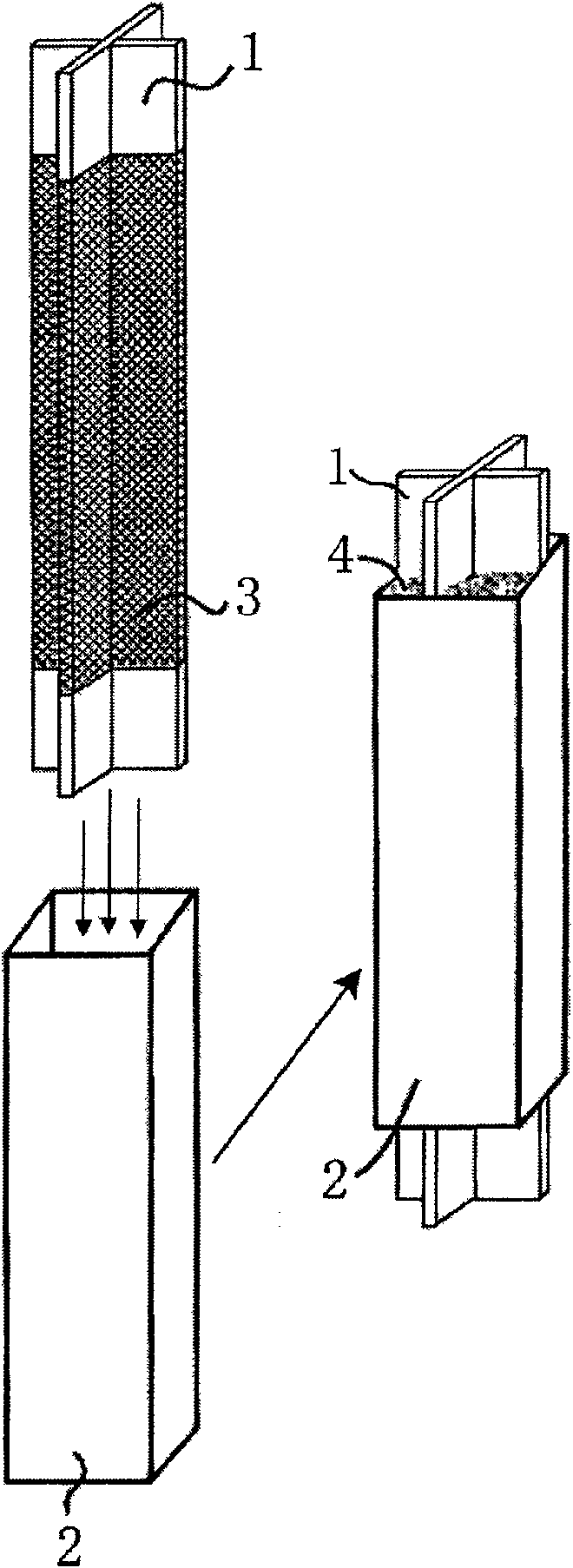

Continuous lubricating crystallizer for aluminum alloy semi-continuous casting

The invention relates to a continuous lubrication crystallizer used for casting aluminum alloy semi-continuously, wherein the inner wall of the crystallizer is inlaid with a graphite lining, a top cover of the crystallizer is internally provided with an independent oil cavity, the graphite lining presents up-down symmetric construction with a taper, a body of the crystallizer is provided with a top water cavity and a lower cavity which are independent, the top water cavity and the lower cavity are respectively opened with an independent water inlet and are respectively provided with a splash plate, the bottom of the top water cavity is provided with a row of water passing ports, the bottom of the lower water cavity is also provided with a row of water passing ports, the angel of the water passing ports of the top water cavity is different from and presents interlaced shape with the water passing ports of the lower water cavity's, when casting, a layer of continuous oil film forms via infiltrating oil forming the oil cavity to the graphite lining, which has effects of heatproof, reducing once cooling of ingot casting at the same time when improving graphite lubricating oil effects, two independent water cavities realize the independent or double water-cavity water supply, which improves the aftercooling effect on the premise of ensuring heat cracks not to appear at the early stage of aluminum alloy ingot casting, thereby realizing a low liquid level on the inner portion of the crystallizer, and distinctively improving surface quality of the ingot casting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Support beam for a cabinet drawer

InactiveUS8141968B2Easing extraction and introductionReduce contact frictionDrawersFittingEngineeringPinion

A cabinet drawer support beam is provided, and may include on an upper part of such beam, a rail or longitudinal sliding mechanism. An alignment mechanism may be fastened to the rail or longitudinal mechanism. The alignment mechanism may include a pinion that runs in the rack of the lower part of the support beam, and the support beam may be fastened to the cabinet wall by way of barrels and / or fasteners. At least two beams per cabinet may be included.

Owner:MABE SA DE CV

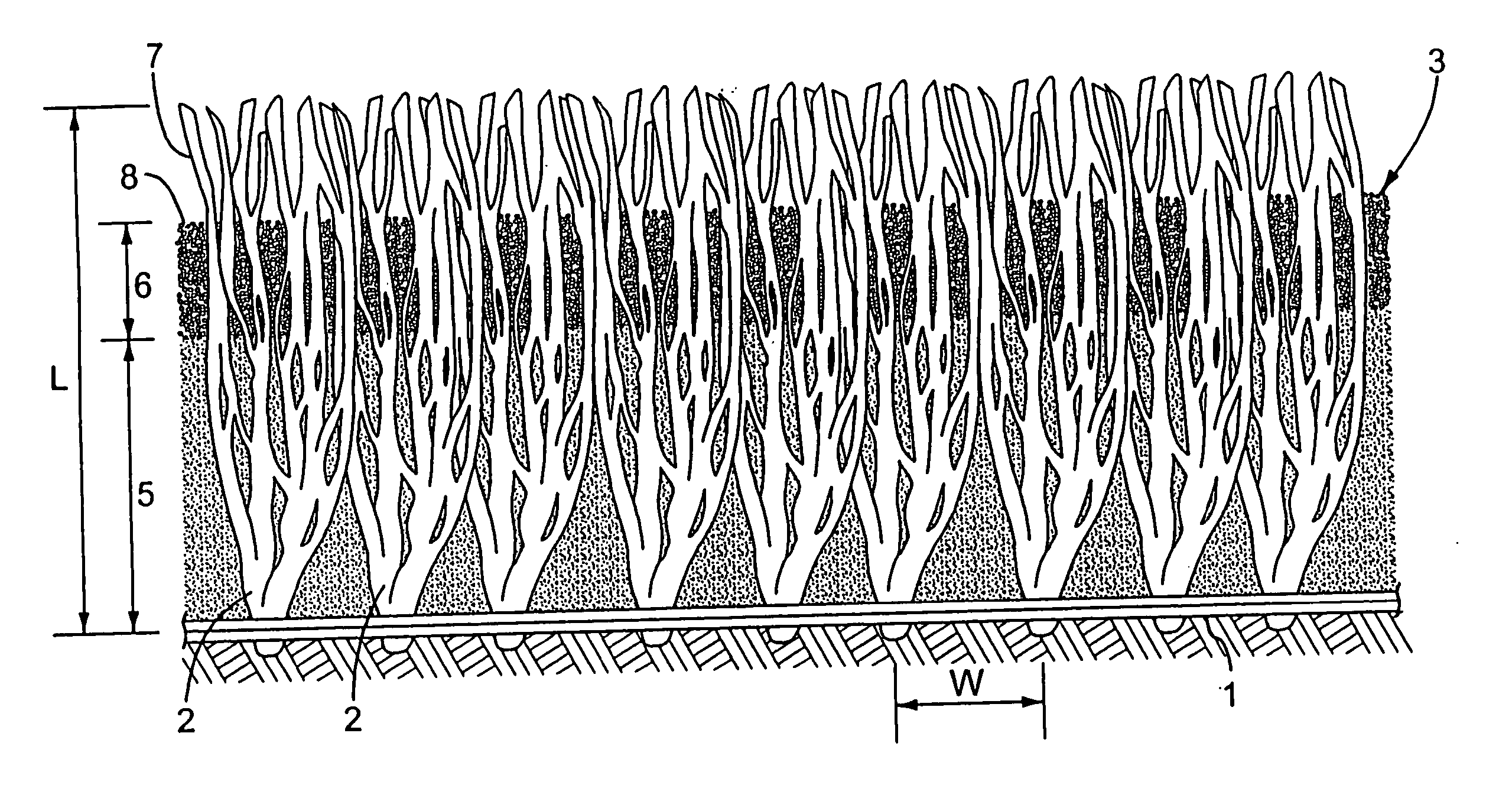

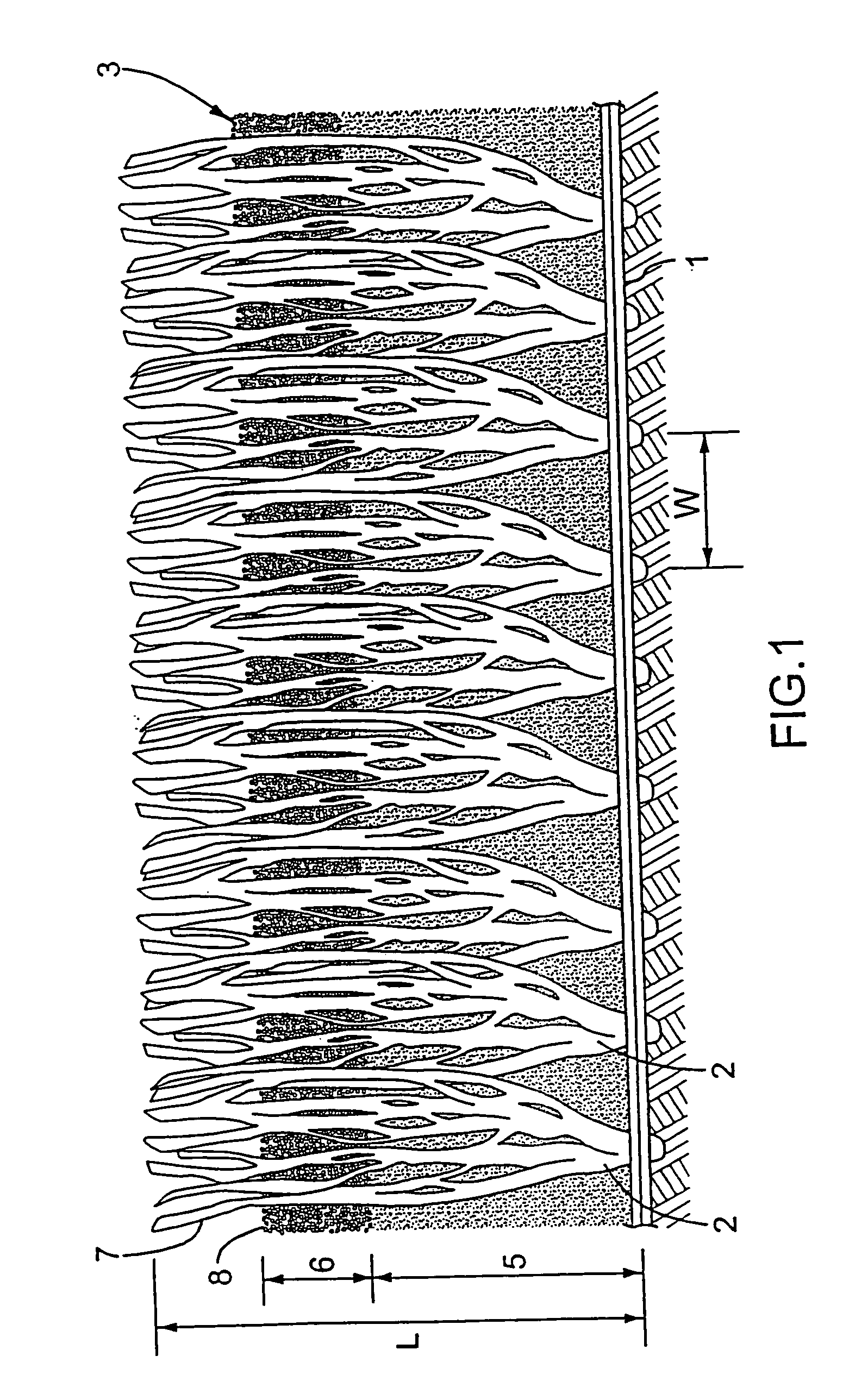

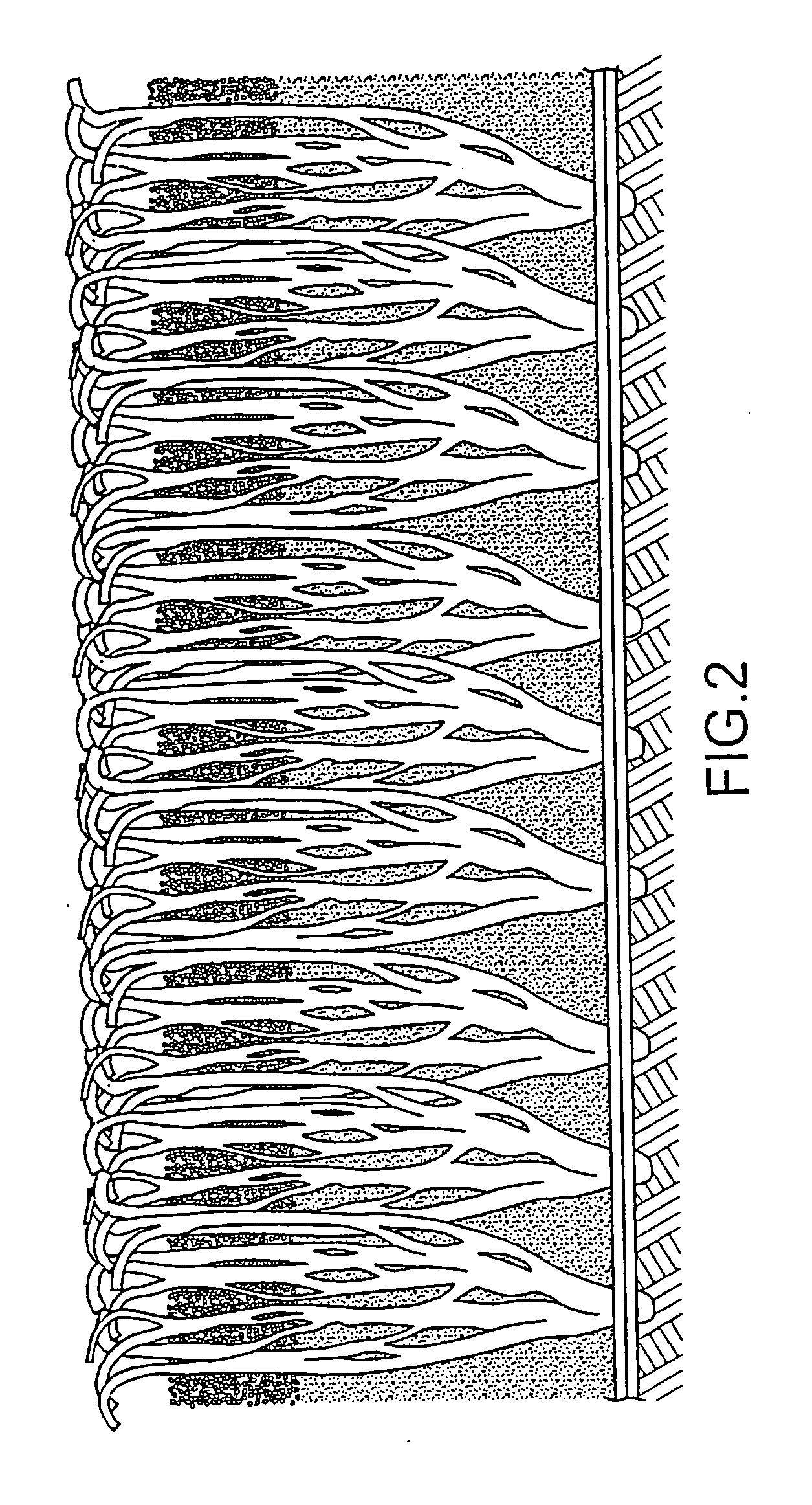

Synthetic grass with resilient granular top surface layer

InactiveUS20050008793A1Reduce contact frictionEasy to drainAgricultural articlesDead plant preservationSurface layerInfill

A synthetic grass assembly for installation on a supporting soil substrate includes a pile fabric with a flexible sheet backing and rows of upstanding synthetic ribbons representing grass blades, extending upwardly from an upper surface of the backing. An infill layer of two distinct graded courses of particulate material is disposed interstitially between the upstanding ribbons upon the upper surface of the backing and of a depth less than the length of the ribbons. A bottom course of intermixed hard sand and resilient rubber granules with substantially identical particle size distribution characteristics is installed upon the backing and a top course exclusively of resilient rubber granules is placed upon the bottom course.

Owner:FIELDTURF (IP) INC

Fixing Holder for Vibration Generating Device

InactiveUS20070253178A1Reduce thicknessEasy to changeResilient/clamping meansMechanical energy handlingElectrical and Electronics engineering

[PROBLEMS] To provide a fixing structure capable of adjusting the dimensions in the vertical direction of a vibration generating device including a circuit board in combination with the circuit board without reducing the size or the diameter of the vibration generation device. [MEANS FOR SOLVING PROBLEMS] A fixing holder in a holder shape for holding or including at least a part of the outer circumference of a vibration generating device has an inner circumferential surface substantially identical to the external shape of the vibration generating device. Groove-like rail parts are provided partially in the outer circumferential surface of the holder at the opposite ends thereof in the same linear direction, and the side end part of a notched circuit board or a part on the housing side of the apparatus is inserted into each of the groove-like rail parts, thus holding and securing the vibration generating device at an arbitrary vertical position against the surface of the circuit board in the apparatus.

Owner:NAMIKI PRECISION JEWEL CO LTD

Synthetic grass with resilient granular top surface layer

InactiveUS20060121236A1Reduce contact frictionEasy to drainAgricultural articlesLiquid surface applicatorsInfillSurface layer

A synthetic grass assembly for installation on a supporting soil substrate includes a pile fabric with a flexible sheet backing and rows of upstanding synthetic ribbons representing grass blades, extending upwardly from an upper surface of the backing. An infill layer of two distinct graded courses of particulate material is disposed interstitially between the upstanding ribbons upon the upper surface of the backing and of a depth less than the length of the ribbons. A bottom course of intermixed hard sand and resilient rubber granules with substantially identical particle size distribution characteristics is installed upon the backing and a top course exclusively of resilient rubber granules is placed upon the bottom course.

Owner:FIELDTURF TARKETT

Optical force sensor

InactiveUS7657128B2Prevent removalIncrease capacityForce measurementCharacter and pattern recognitionResistive sensorsContact force

Owner:LIVESCRIBE

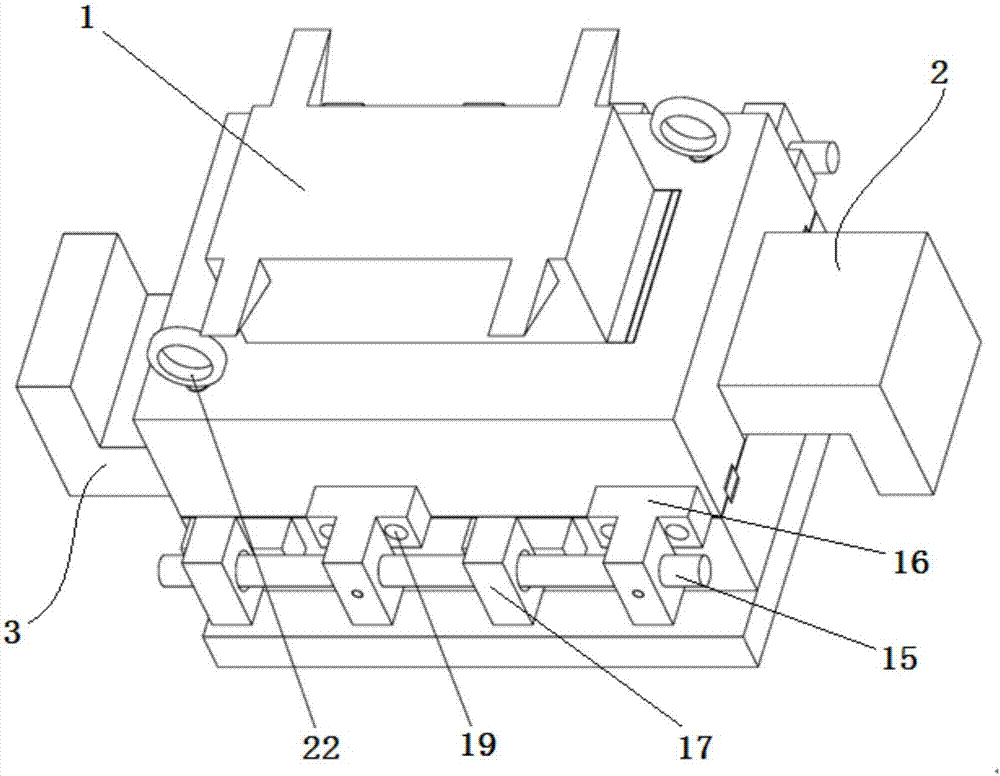

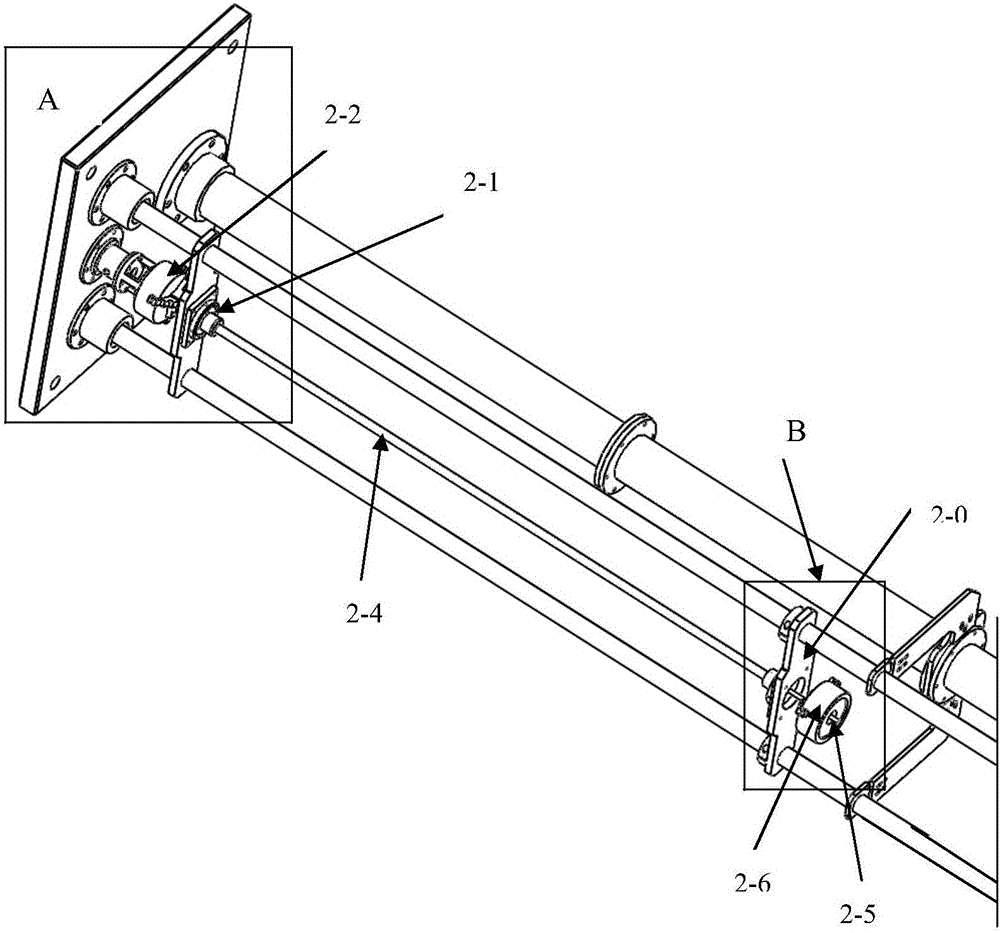

Rock joint sample direct shearing test box

InactiveCN107036906AStudy Dilatation PropertiesFreedom of movementMaterial strength using steady shearing forcesUpper jointEngineering

The invention relates to a rock joint sample direct shearing test box. The test box comprises a base, an upper shearing box and a lower shearing box which are used for placing a rock joint sample and a normal loading cushion block presses upon an upper joint block of a rock. A fixing support arranged downward is installed on the upper shearing box, a bearing support arranged upward is installed on the lower shearing box, a guiding rod is inserted into the fixing support and the bearing support in a penetrating mode, pin holes are formed in the fixing support, the guiding rod and the fixing support are fixed through a locating pin, and a linear motion bearing used for connecting the guiding rod with the bearing support is arranged in the slot of the bearing support. Compared with the prior art, by means of the test box, not only can free motion of the lower shearing box in the shearing direction in the rock joint sample shearing process be guaranteed, but also the problem that the upper shearing box is reversed upward is effectively solved; contact friction between the upper and lower shearing boxes in the rock joint sample shearing process and friction between the upper shearing box and the upper joint block of the rock are effectively reduced, so that the shearing process is more in line with the real condition.

Owner:TONGJI UNIV

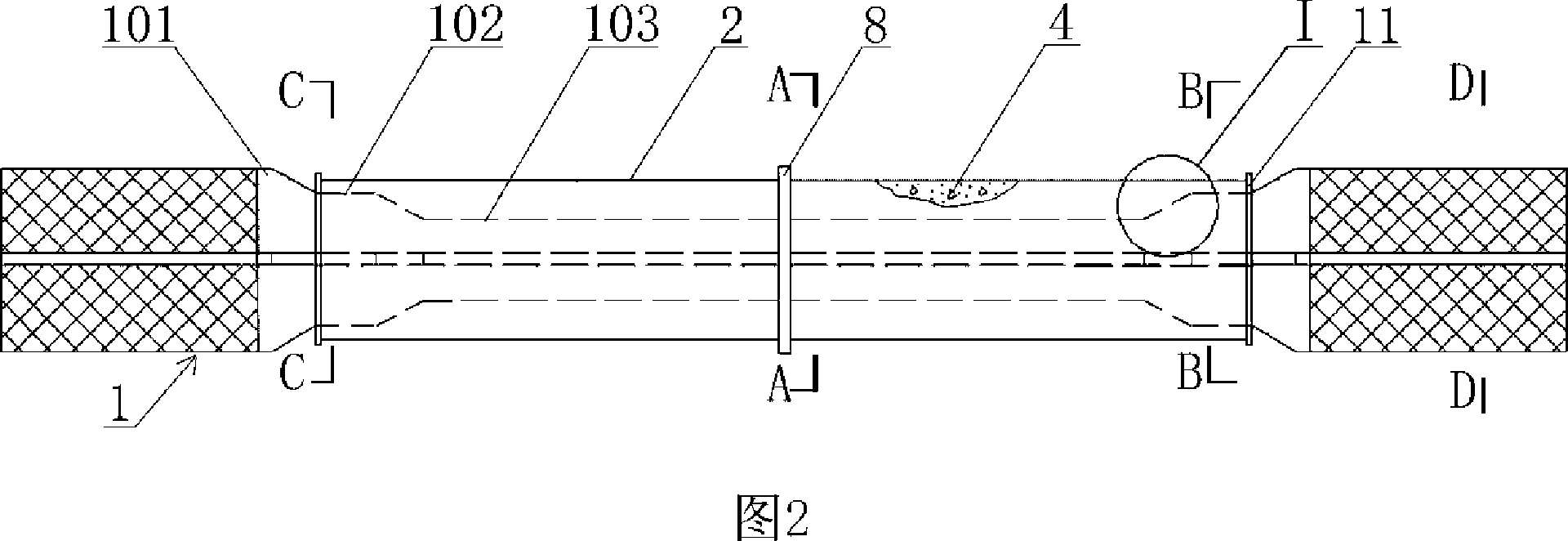

Double-layer bushing straight-line flexuosity restriction support with transverse diaphragm

InactiveCN100560884CSolve the problem of limited lateral expansionEliminates the problem of limited lateral expansionShock proofingCompressible materialCruciform

A linear buckling restrained brace with transverse partition double-layered bushing is provided. The core steel brace comprises a middle segment (buckling segment) as major body with a smaller width, two distal end segments (extension segments), and a transition segment between the buckling segment and the extension segment. The cross section of the buckling segment is shaped like the Chinese character 'Yi'. The cross sections of the transition segment and extension segment are cruciform. A transverse partition is welded in the middle of the buckling segment and provided outside with outer restraining steel bushings at two sides. An inner steel bushing is arranged between the outer restraining steel bushing and the core steel and has a linear cross section with respect to the buckling segment and a cruciform cross section with respect to the transition segment. The space between the inner steel bushing and outer restraining steel bushing is packed with fillers. An anti-adhesion material is coated on the surface of the core steel brace, with a gap between the anti-adhesion material and the inner steel bushing and filled with a compressible material. The invention has the advantages of simple structure, low fabrication cost, suitability for streamline production, and wide application in high-rise buildings, towering buildings, and highway and railway bridges.

Owner:CHINA ACAD OF BUILDING RES +2

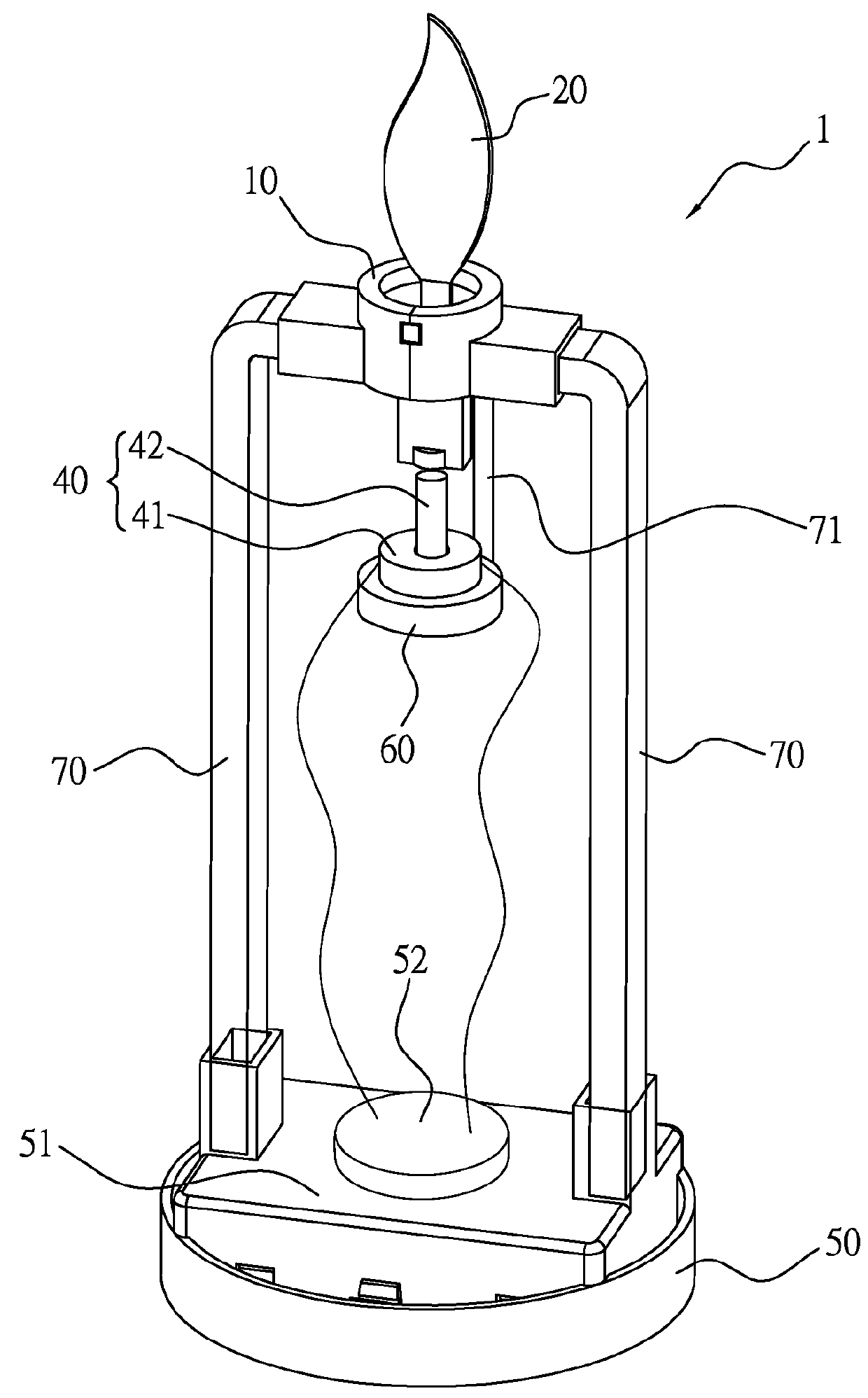

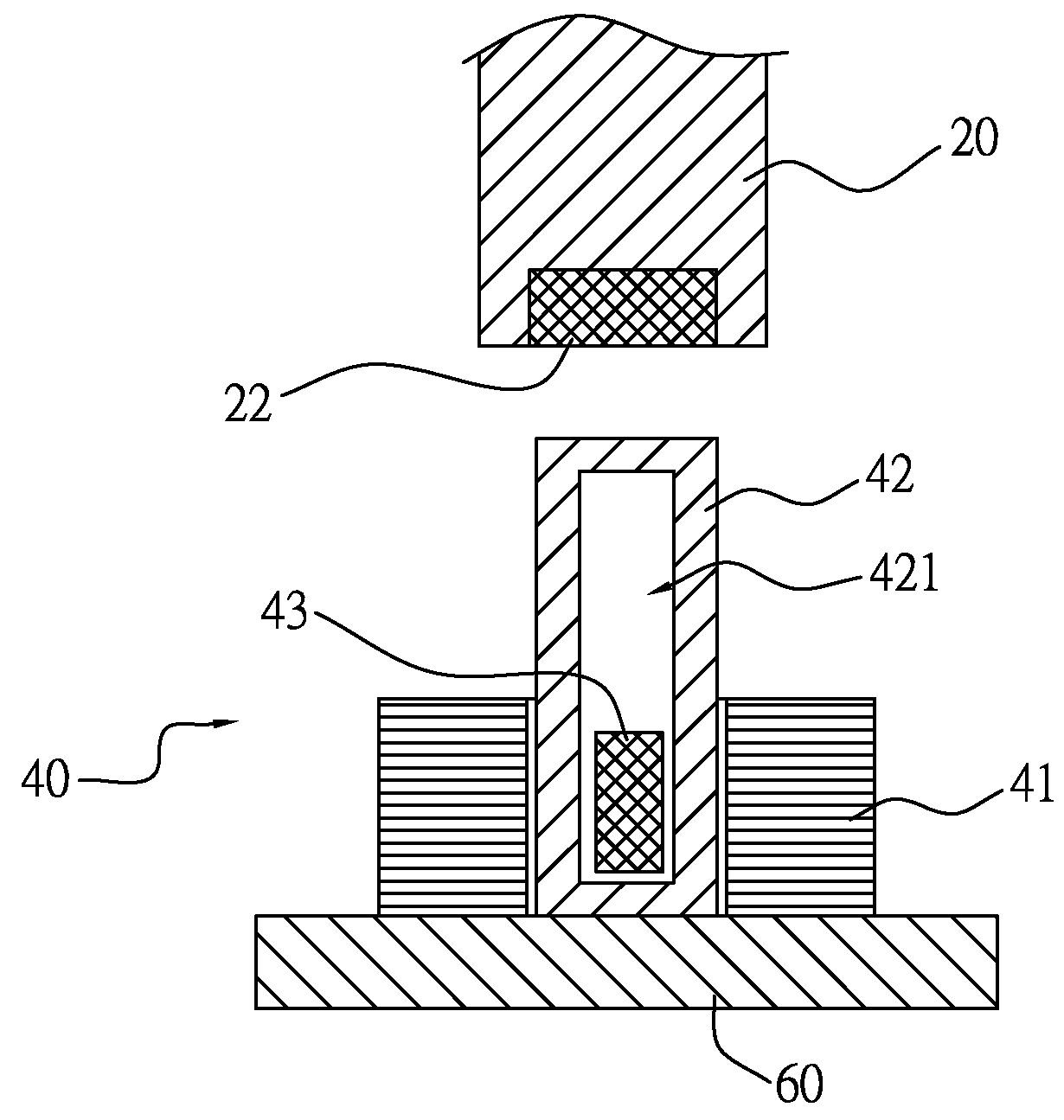

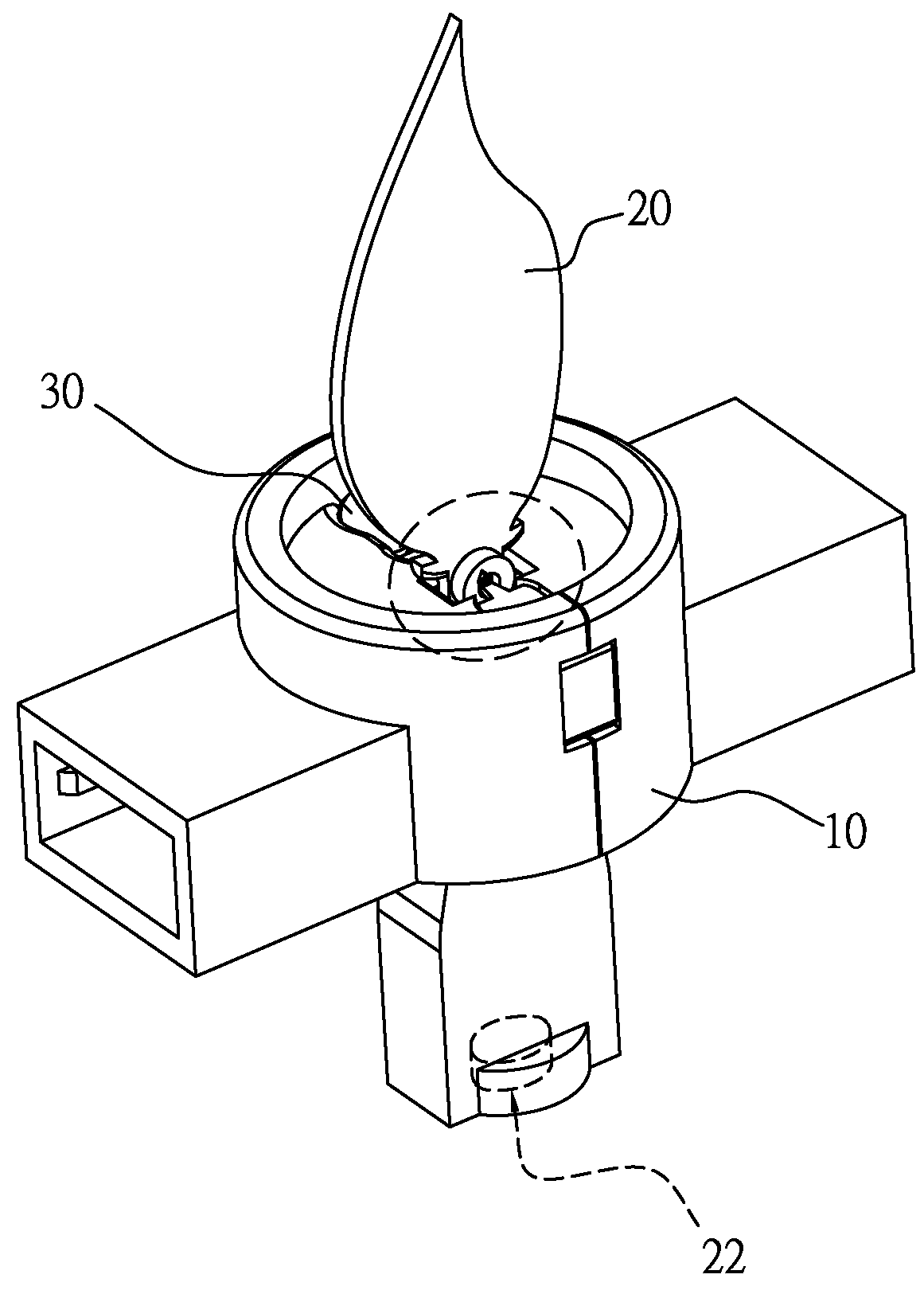

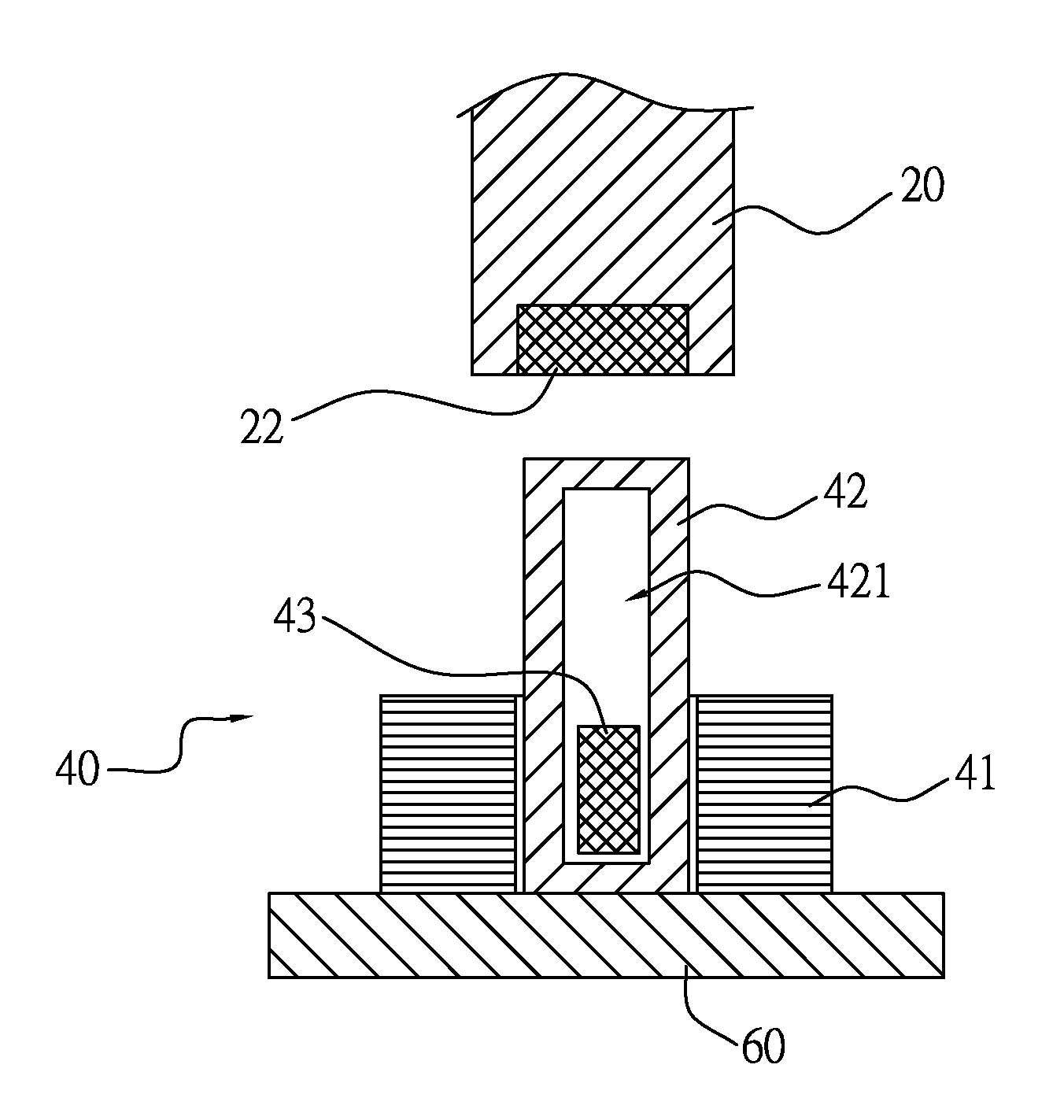

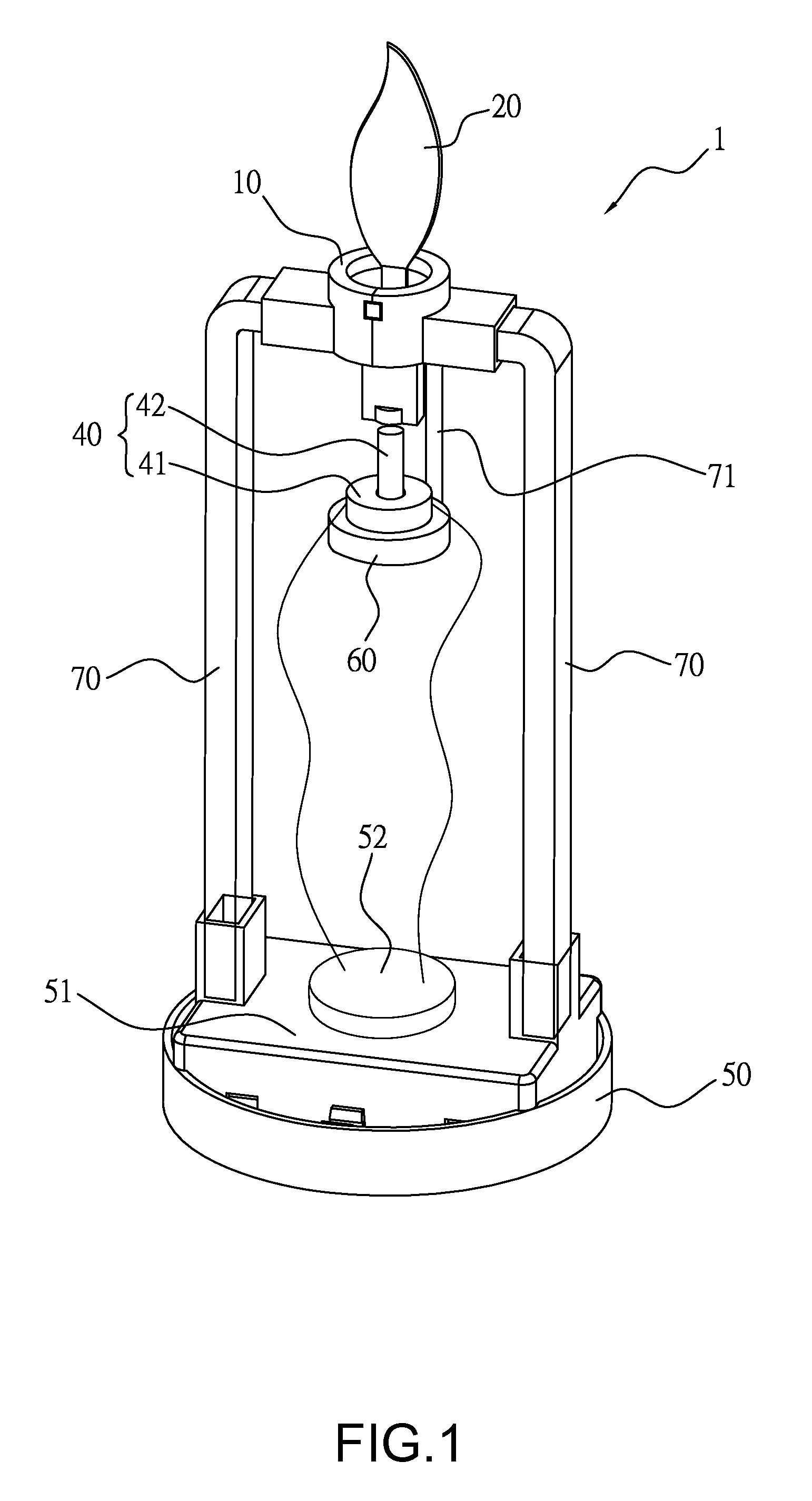

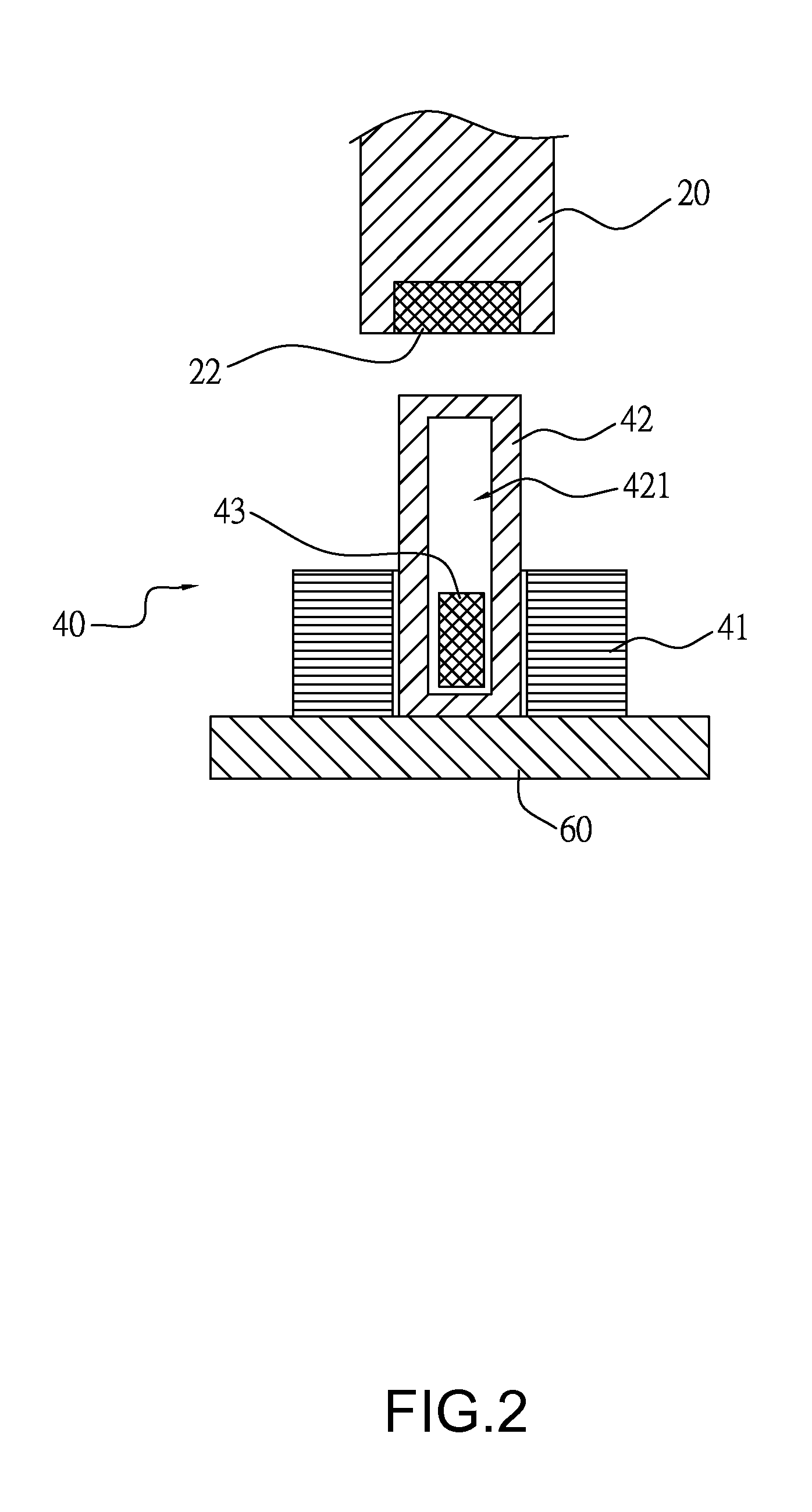

Dynamic flame simulating device

ActiveUS20160053954A1Not be restrictImprove problemElectric circuit arrangementsLight effect designsEngineeringLight source

A dynamic flame simulating device mainly comprises an upper base, a flame element suspended from the upper base, a light source providing light rays, and a driving assembly below the flame element. The driving assembly further comprises an electromagnetic coil and a second magnetic element, wherein the electromagnetic coil is powered on to drive the second magnetic element to bounce toward a first magnetic element on the bottom end of the flame element to generate repellent magnetic acting forces to make the flame element swing naturally and achieve the dynamic visual effect of the natural beating of the burning flame.

Owner:GLOBAL RICH INVESTMENT CO LTD

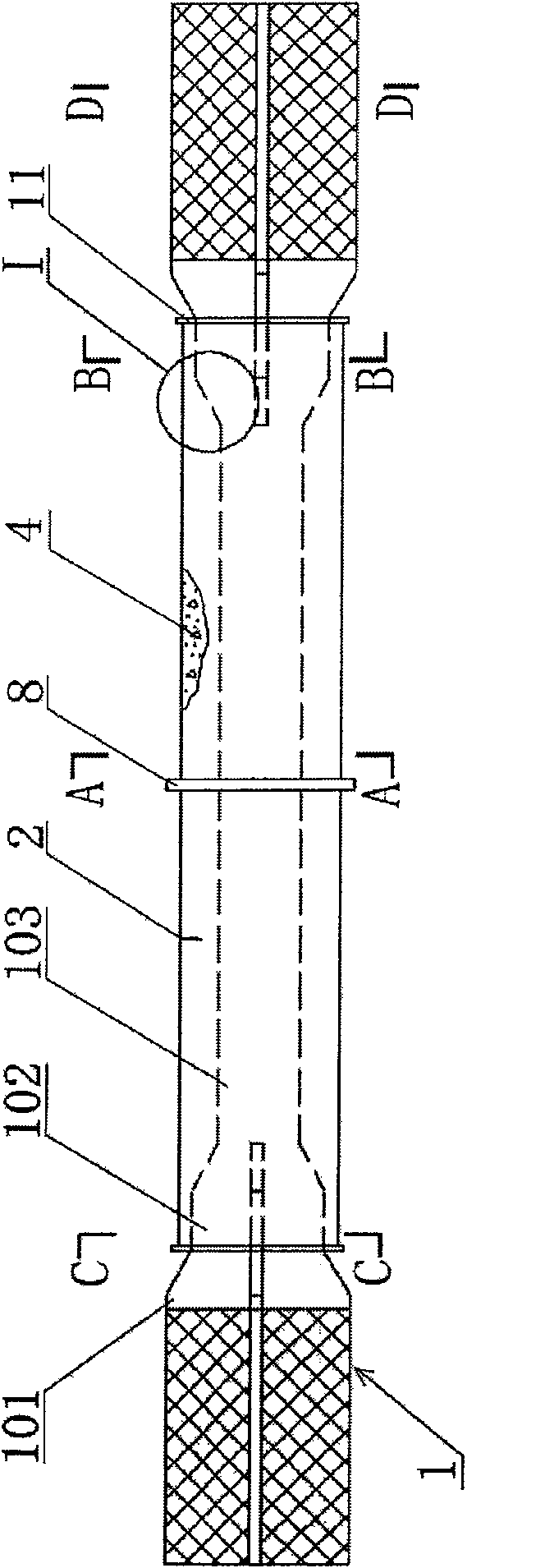

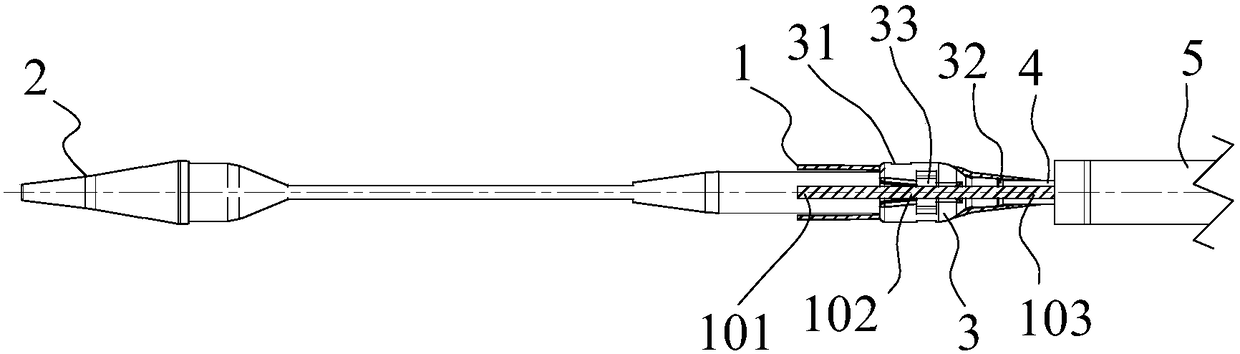

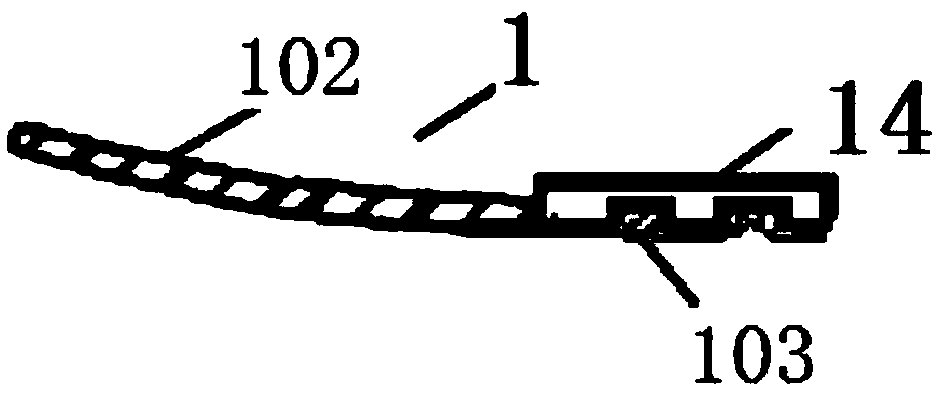

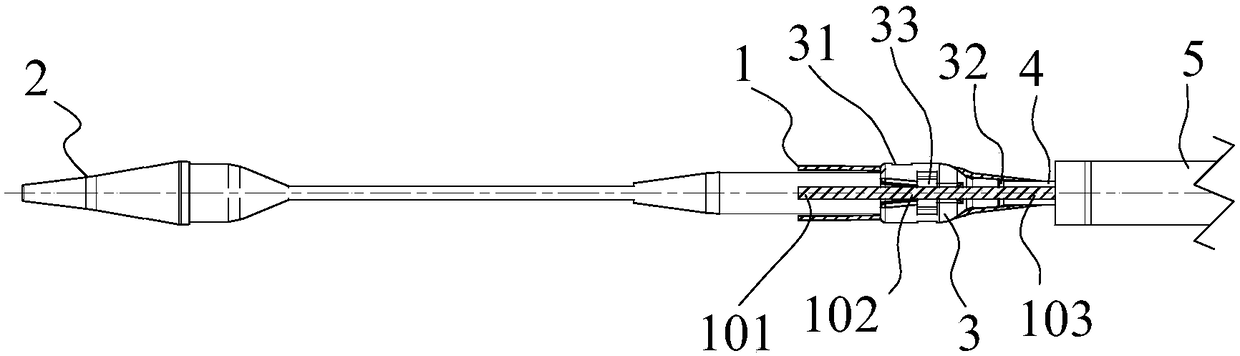

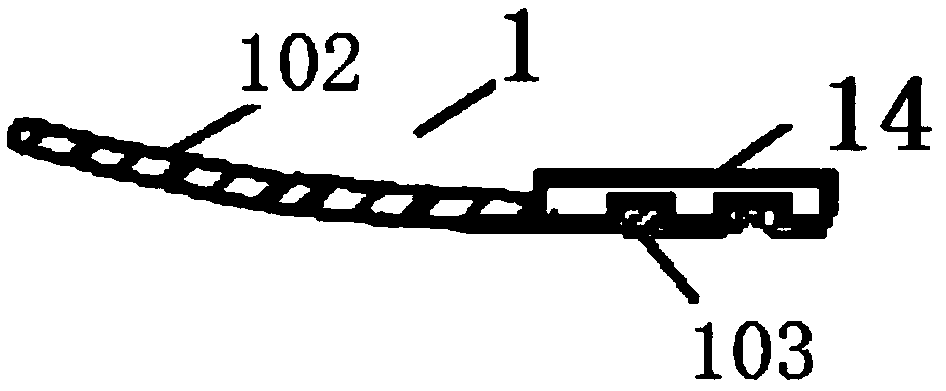

Bending-adjustable conveying system for interventional cardiac valve

The invention discloses a bending-adjustable conveying system for an interventional cardiac valve. The system comprises an outer sheath tube, an core tube assembly which is arranged in the outer sheath tube and can relatively slide in the axial direction and an operation handle connected with the proximal ends of the outer sheath tube and the core tube assembly; a tube body of the outer sheath tube is provided with a distal end and the proximal end, the handle is connected with a traction wire for pulling the distal end of the tube body to bend, a distal end of the traction wire is connected with the tube body, the connection part is located at the distal end of the tube body or is adjacent to the distal end of the tube body, and at least one section of the traction wire is a free sectionwhich is free outside the tube body; the system is further provided with floating limit strips, proximal ends of the floating limit strips are starting ends fixedly arranged opposite to a fixing heador the core tube assembly, and the floating limit strips float between a mounting portion of the interventional cardiac valve and the outer sheath tube; the outer wall of the fixing head is provided with a positioning part used for being matched with a connecting lug of the interventional cardiac valve, the connecting lug is completely released in front of the outer sheath tube, and the floating limit strips are bound by the outer sheath tube to keep the cooperation between the connecting lug and the positioning portion.

Owner:VENUS MEDTECH (HANGZHOU) INC

Optoelectronic Force Sensor

InactiveUS20100116564A1Prevent removalIncrease capacityTransmission systemsForce measurementResistive sensorsEngineering

A force sensor particularly suited for use in an electronic stylus that senses the contact force on its nib for recording pen strokes and handwriting recognition. The sensor has a load bearing member movably mounted for receiving an input force to be sensed, the load bearing member being biased against the direction of the input force. The sensor also has a light source, a photo-detector for sensing levels of illumination from the light source and circuitry for converting a range of illumination levels sensed by the photo-detector into a range of output signals. During use, the illumination level sensed by the photo-detector varies with movement of the load bearing member such that the output signal from the circuitry is indicative of the input force. Using an optical sensor avoids the need to use a delicate piezo-resistive sensor that requires careful tolerancing during production.

Owner:LIVESCRIBE

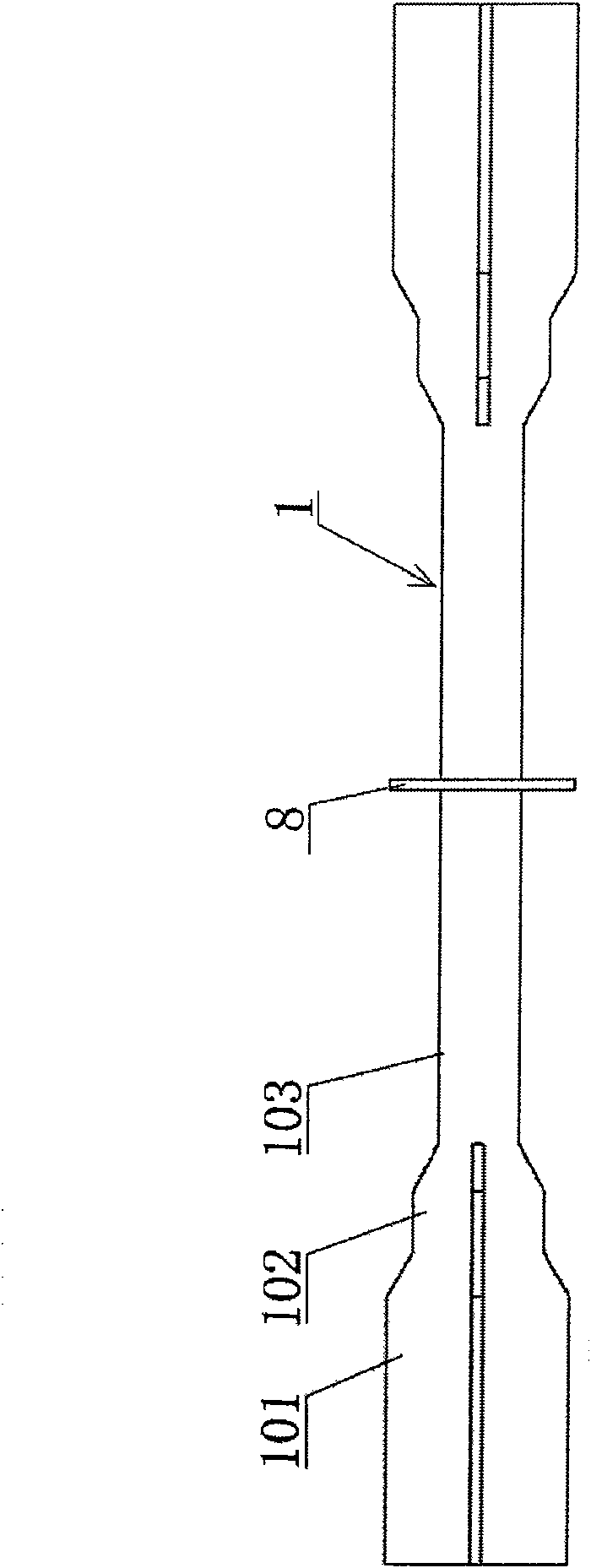

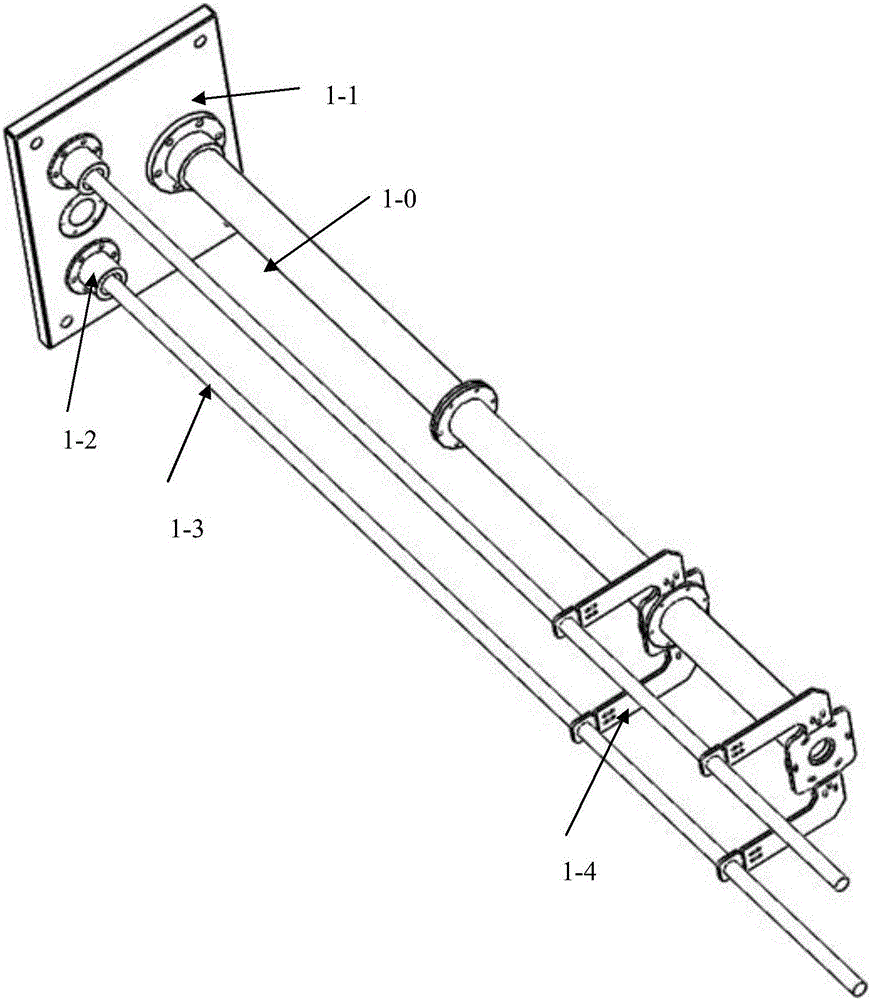

Indoor available comprehensive tubing string mechanics experiment platform

ActiveCN105928789AReduce cost and scaleLow driving torqueMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMutual influenceEngineering

The invention discloses an indoor available comprehensive tubing string mechanics experiment platform to solve the problem of unable accurate synchronous application of pulling, pressing, bending, twisting and other loads of present indoor experiment devices. The platform integrates loading and test mechanisms of pulling, pressing, bending, twisting and other different loads, and eliminates mutual influences of pulling and twisting combination load in a bearing isolation manner, and a test terminal collects and processes a pulling and twisting load signal in a double-sensor merging output mode. The platform can realize synchronous loading and testing of pulling, bending, twisting and other loads, and allows the real deformation of an oilfield tubing string under a given load condition to be obtained through scaling all parts of the oilfield tubing string in the practical use process.

Owner:NORTHEAST GASOLINEEUM UNIV

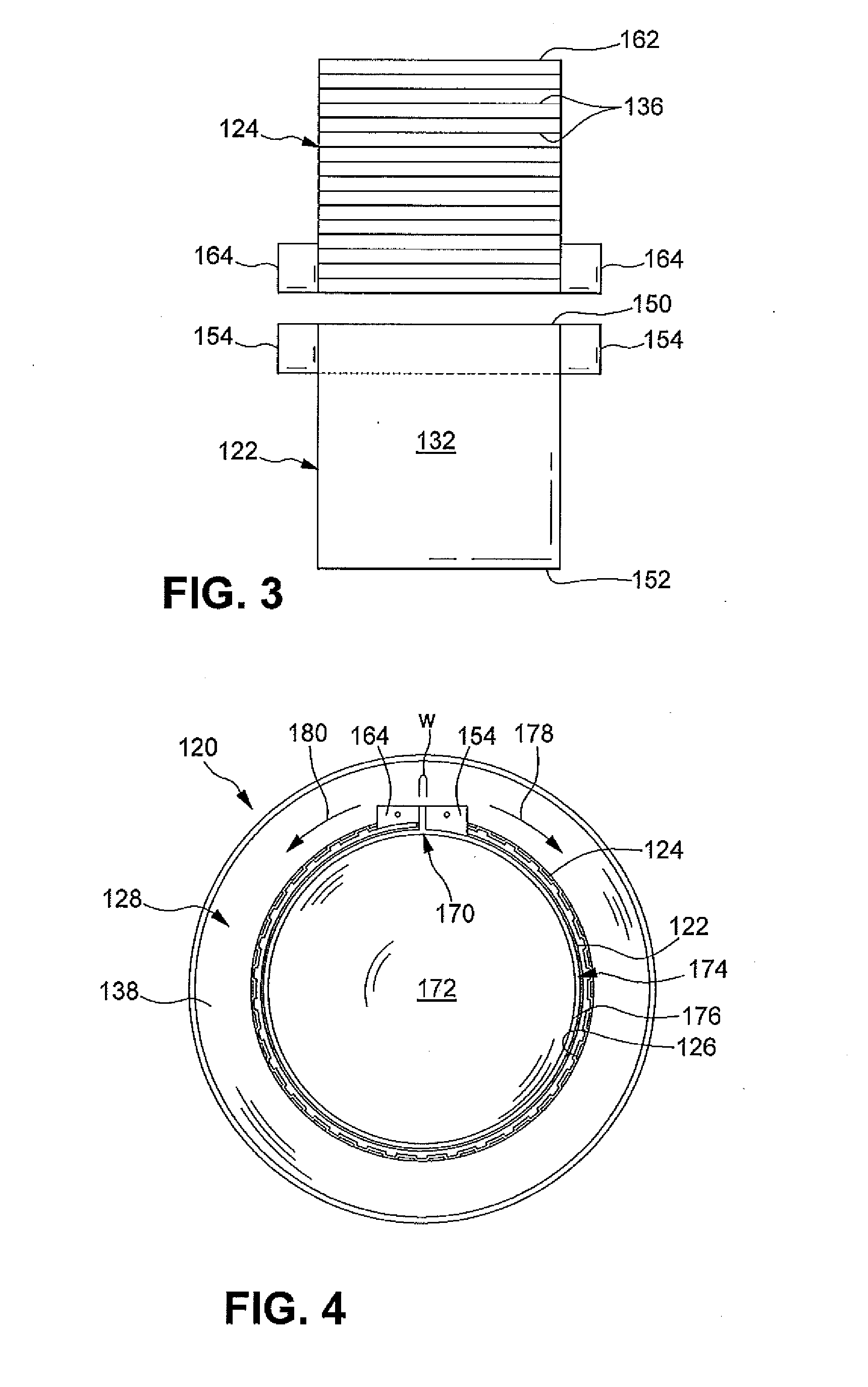

Keyless/grooveless foil bearing with fold over tab

InactiveUS20110229065A1Reduce contact frictionGas cushion bearingsBearing componentsEngineeringMechanical engineering

An improved air foil bearing assembly is disclosed. The air foil bearing assembly includes a bearing housing having an axially extending bore therein and a shaft arranged within the bore for relative coaxial rotation with respect to the bearing housing. The shaft cooperates with the bearing housing to define an annular gap therebetween. A foil assembly is disposed in the annular gap, including at least one foil having at least one laterally extending tab. The tab is adapted to be received in and extend axially from the annular gap and is further adapted to be bent into frictional contact with an outer surface of the bearing housing to militate against axial movement of the foil.

Owner:GM GLOBAL TECH OPERATIONS LLC

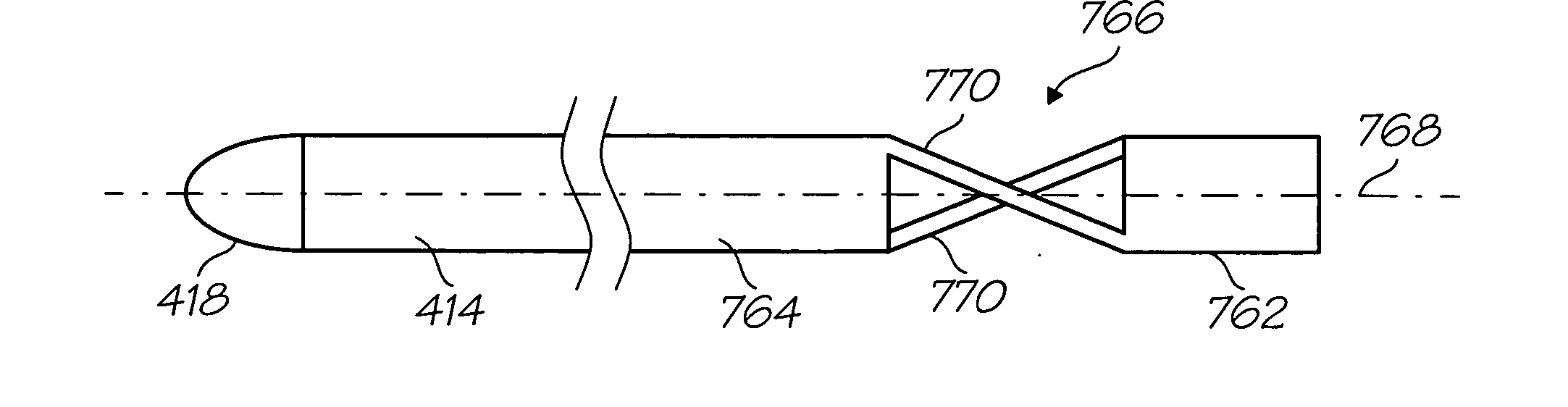

Collapsible force sensor coupling

InactiveUS20070042620A1Prevent removalIncrease capacityEngagement/disengagement of coupling partsWriting connectorsCouplingEngineering

A force sensor particularly suited for use in an electronic stylus that senses the contact force on its nib for recording pen strokes and handwriting recognition. The sensor has a housing for a load bearing member for receiving an input force to be sensed and associated circuitry for converting the input force into an output signal indicative of the input force. A coupling transmits the input force to the load bearing member. The coupling has an inner section for transmitting the input force to the load bearing member, an outer section for receiving an applied contact force and a collapsible section for allowing the outer section to move relative to the inner section when the contact force exceeds a threshold. This protects the force sensor from damage by sharp impact loads such as dropping the stylus on its nib.

Owner:LIVESCRIBE

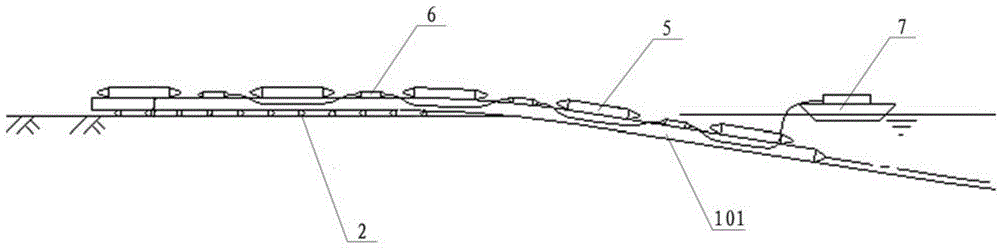

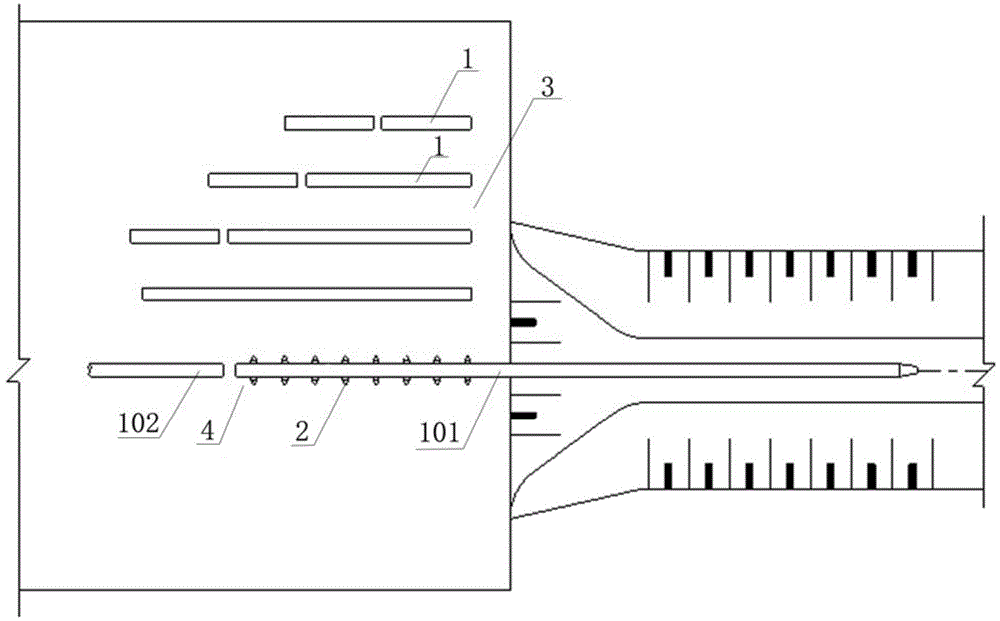

Designing method for sea-crossing steel sinking pipeline

The invention discloses a designing method for a sea-crossing steel sinking pipeline. The designing method for the sea-crossing steel sinking pipeline comprises the following steps: (1) determining the arrangement of a pipeline route according to the terrain of a seabed, wherein the sea-crossing steel sinking pipeline comprises two upwards-bent sections and two downwards-bent sections, which are on the same plane and have the same curvature radius; (2) calculating a design curvature radius: calculating the design curvature radius according to the strength and the stress characteristics of a pipeline material and a specification, and determining the arc lengths of the upwards-bent and downwards-bent sections according to the arrangement of the pipeline route and the design curvature radius; (3) digging a foundation trench matched with the pipeline route in the seabed on the basis of the arrangement of the pipeline route and the design curvature radius; (4) constructing and dragging the pipeline, and ensuring that the curvature radius of the sinking pipeline is equal to the design curvature radius. According to the designing method for the sea-crossing steel sinking pipeline, the shortcomings of a conventional bottom towing method are overcome, and the designing method for the sea-crossing steel sinking pipeline is safer and more suitable.

Owner:广东省水利电力勘测设计研究院有限公司

Recyclable conveying system for interventional heart valves with stable operation function

PendingCN108371570AControls are easy to holdEasy to useHeart valvesEngineeringMechanical engineering

The invention discloses a recyclable conveying system for interventional heart valves with a stable operation function. The recyclable conveying system comprises a core pipe assembly, an outer sheathing pipe, a handle and a floating limiting strip, wherein the outer sheathing pipe is arranged at the periphery of the core pipe assembly; the handle is used for controlling the core pipe assembly andthe outer sheathing pipe and is relatively slide along the axial direction of the outer sheathing pipe; a first control mechanism and a second control mechanism are arranged along the axial directionof the handle and are used for respectively adjusting the axial positions of the outer sheathing pipe and the core pipe assembly; a guide head and a fixed head are fixedly arranged on the outer pipe assembly, the guide head is fixedly arranged at the far end of the core pipe assembly, the near end of the core pipe assembly extends out of the fixed head, and an interventional heart valve installation position is formed between the guide head and the fixed head; the near end of the floating limiting strip is used as a starting end which is fixed corresponding to the fixed head or the core pipe assembly; the floating limiting strip is floated between the interventional heart valve installation position and the outer sheathing pipe; the outer wall of the fixed head is provided with a positioning part which is matched with a connecting lug of the interventional heart valve.

Owner:VENUS MEDTECH (HANGZHOU) INC

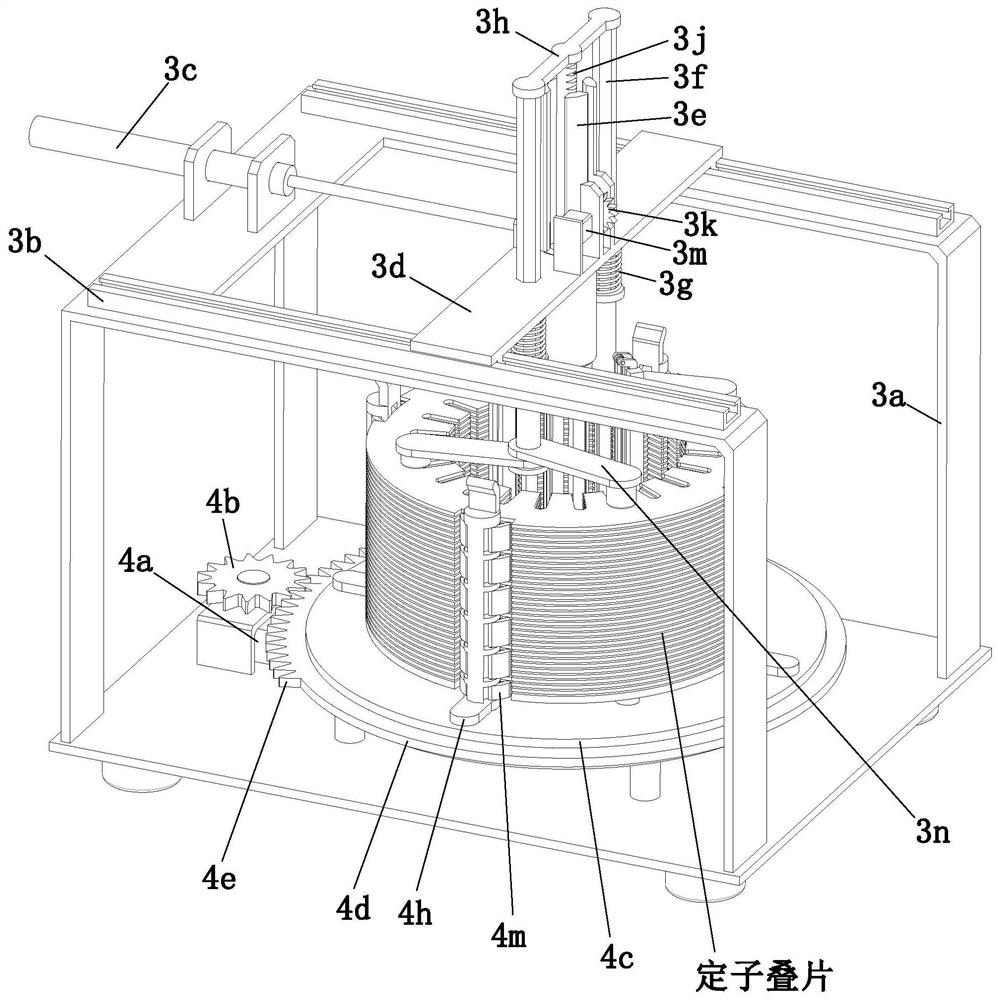

Motor stator punching sheet processing system

ActiveCN113098210AAvoid Rotation SkewImprove accuracyMetal-working feeding devicesManufacturing stator/rotor bodiesPunchingElectric machine

The invention provides a motor stator punching sheet processing system. The system comprises a mounting bottom plate, supporting legs, a positioning mechanism, an assembling mechanism and a supporting mechanism,solves the problem that the inner side and the outer side of a positioning punching sheet are difficult to support and abut synchronously during the lamination operation of the motor stator punching sheet, so that the concentricity of the positioning punching sheet is ensured, but the stator punching sheets which are stacked one by one are difficult to clamp and limit, avoids situations that the stator punching sheets are prevented from rotating and deflecting, the stacked positioning punching sheets are difficult to uniformly and repeatedly extrude, gaps between the motor stator punching sheet laminations are eliminated, and the motor stator punching sheet laminations are difficult to integrally move upwards, and avoids the problems of separation, fault and the like of the motor stator punching sheet lamination in the taking-out process.

Owner:佛山市顺德区致翔金属制品有限公司

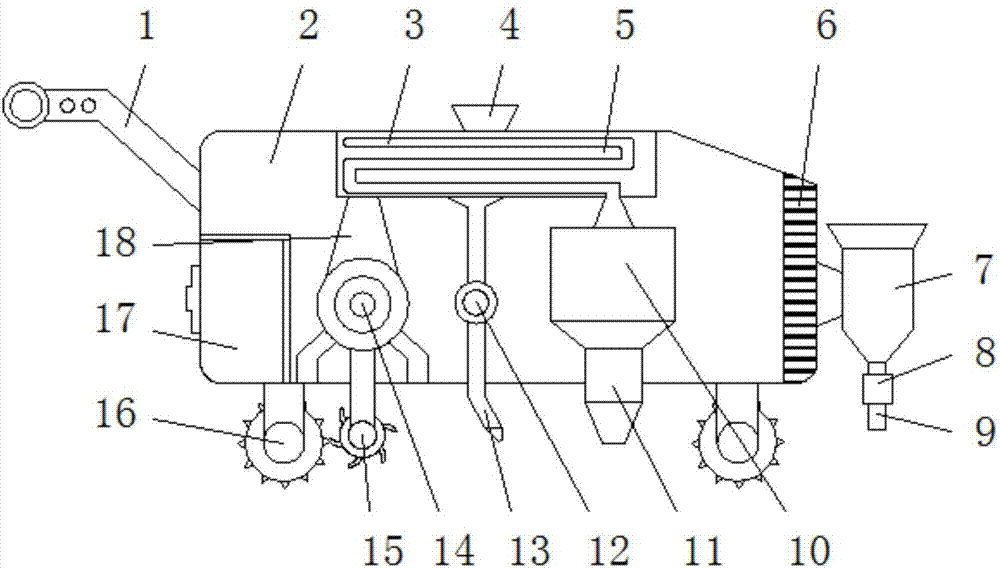

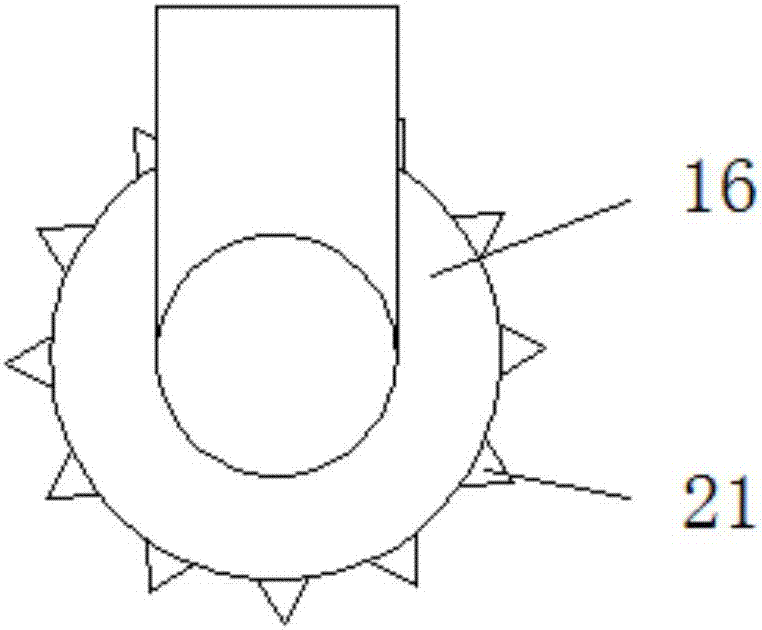

Road ice melting machine

InactiveCN107299616AIncrease the crushing rateImprove work efficiencySnow cleaningIce storageEngineering

The invention discloses a road ice melting machine, which comprises a main body of the ice melting machine, a handle is welded on one side of the ice melting machine body, a water storage tank is arranged on the inner top of the ice melting machine body, and an inlet Water outlet, the water storage tank is connected to the heater through a heating pipe, and a heat outlet pipe is welded at the bottom of the heater, a heat conduction pipe is welded on one side of the bottom of the water storage tank, and a motor is welded at the bottom of the heat conduction pipe, and the motor is connected to the ice breaker through a rotating shaft. The outer surface of the ice breaker is welded with an ice breaker, the motor is provided with a locker, the bottom of the salt storage tank is welded with a salt outlet pipe, and a flow meter is installed inside the salt outlet pipe. The bottom of the body is welded with a hub, and the outer surface of the hub is welded with sawtooth blocks. In the present invention, the overall structure design of the ice melting machine is simple and reasonable, the ice melting process is safe and simple, the heat utilization rate is high, and the ice melting work efficiency is strong.

Owner:CHENGDU YANXINGGUO TECH CO LTD

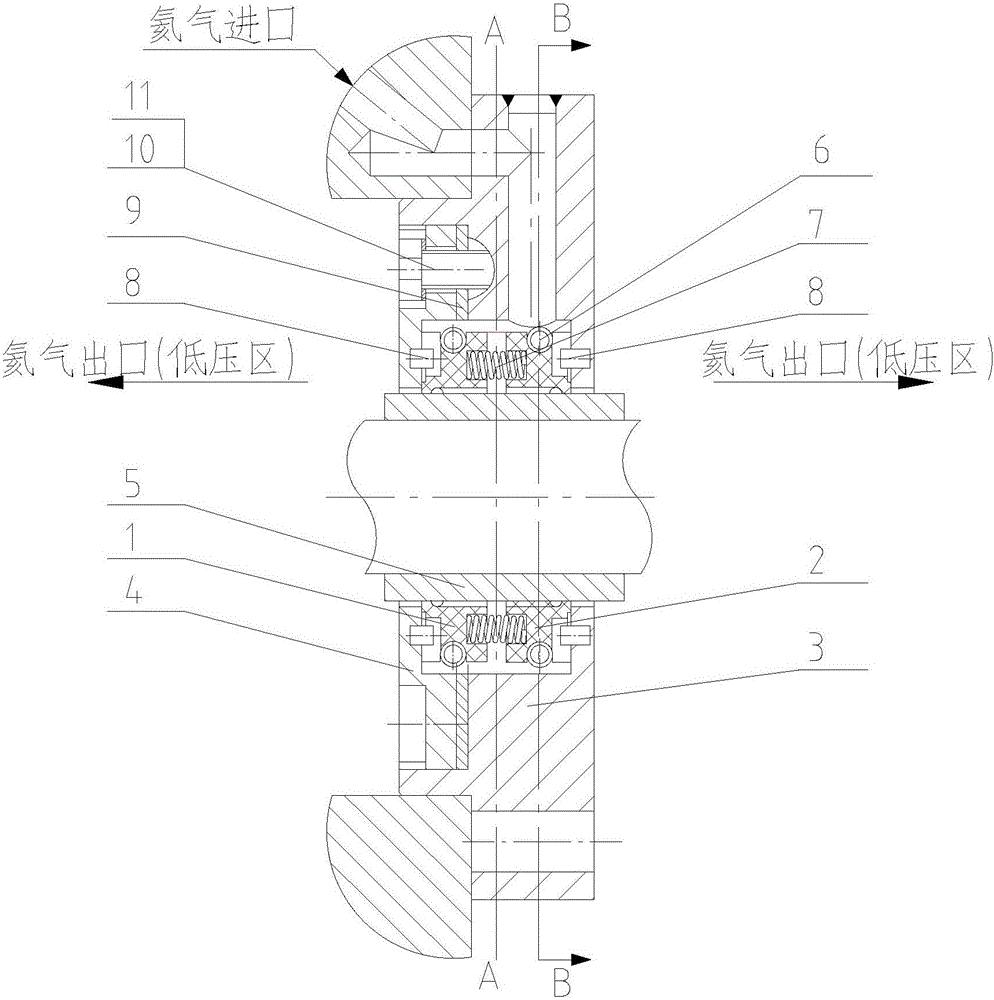

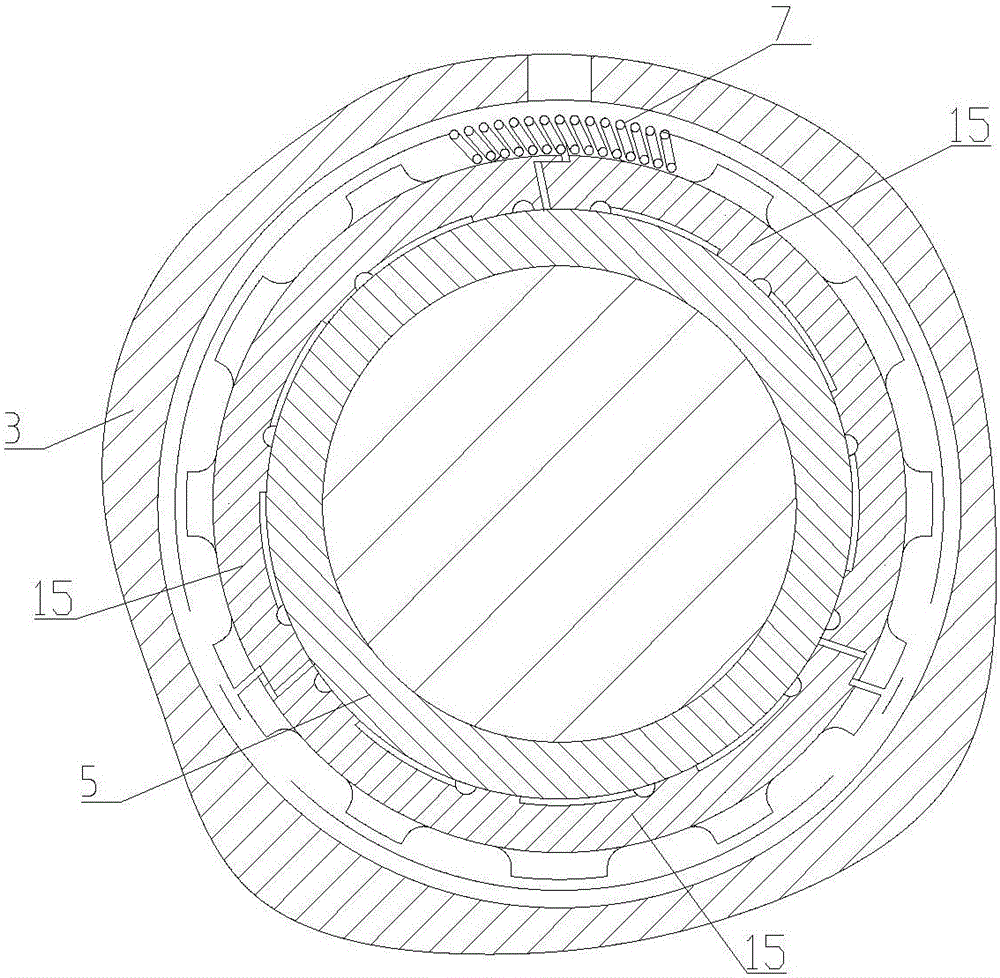

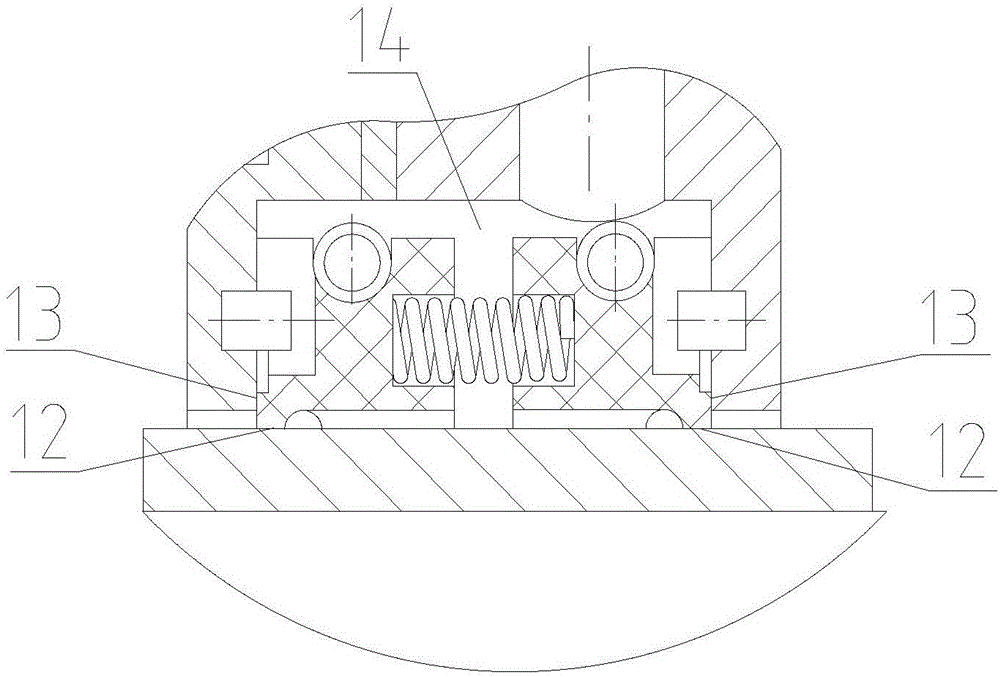

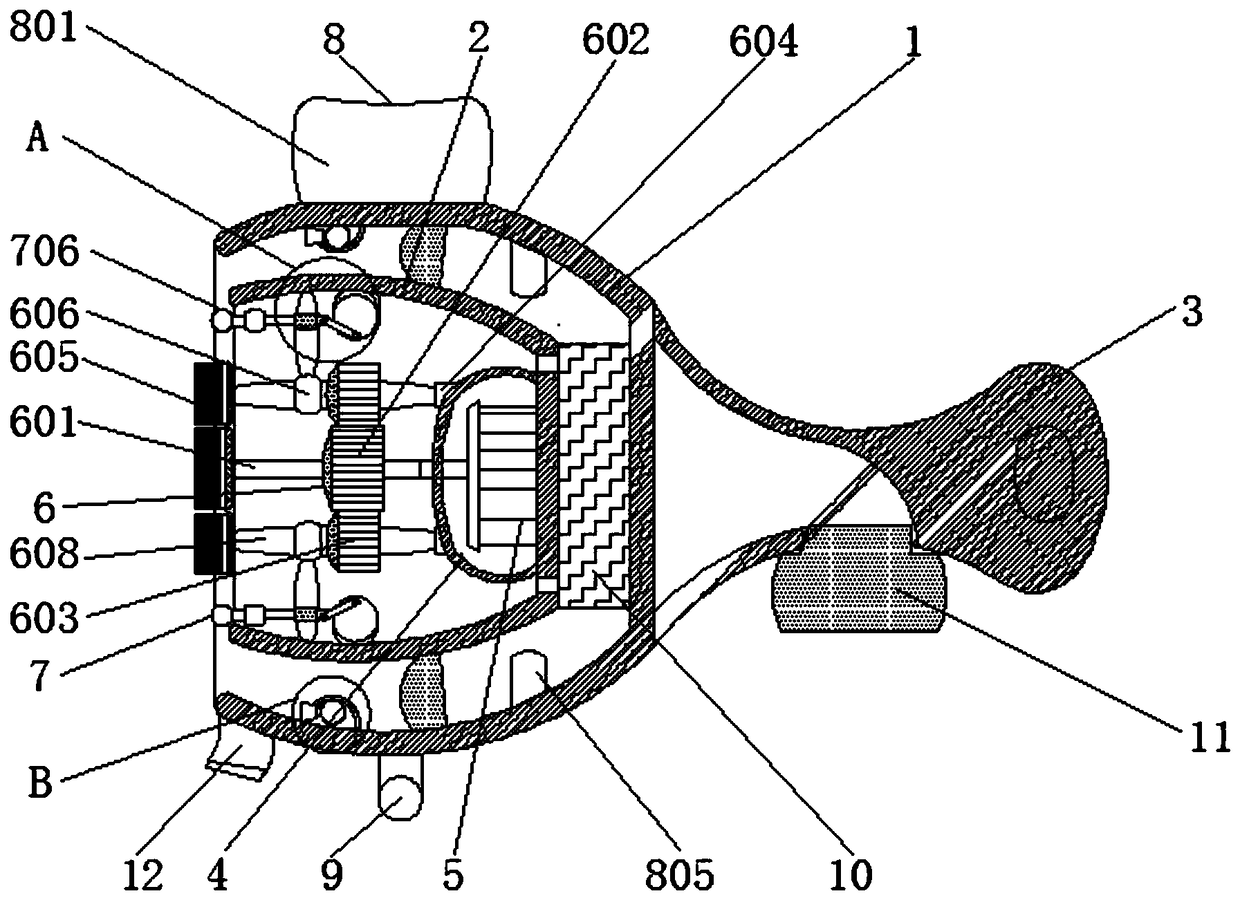

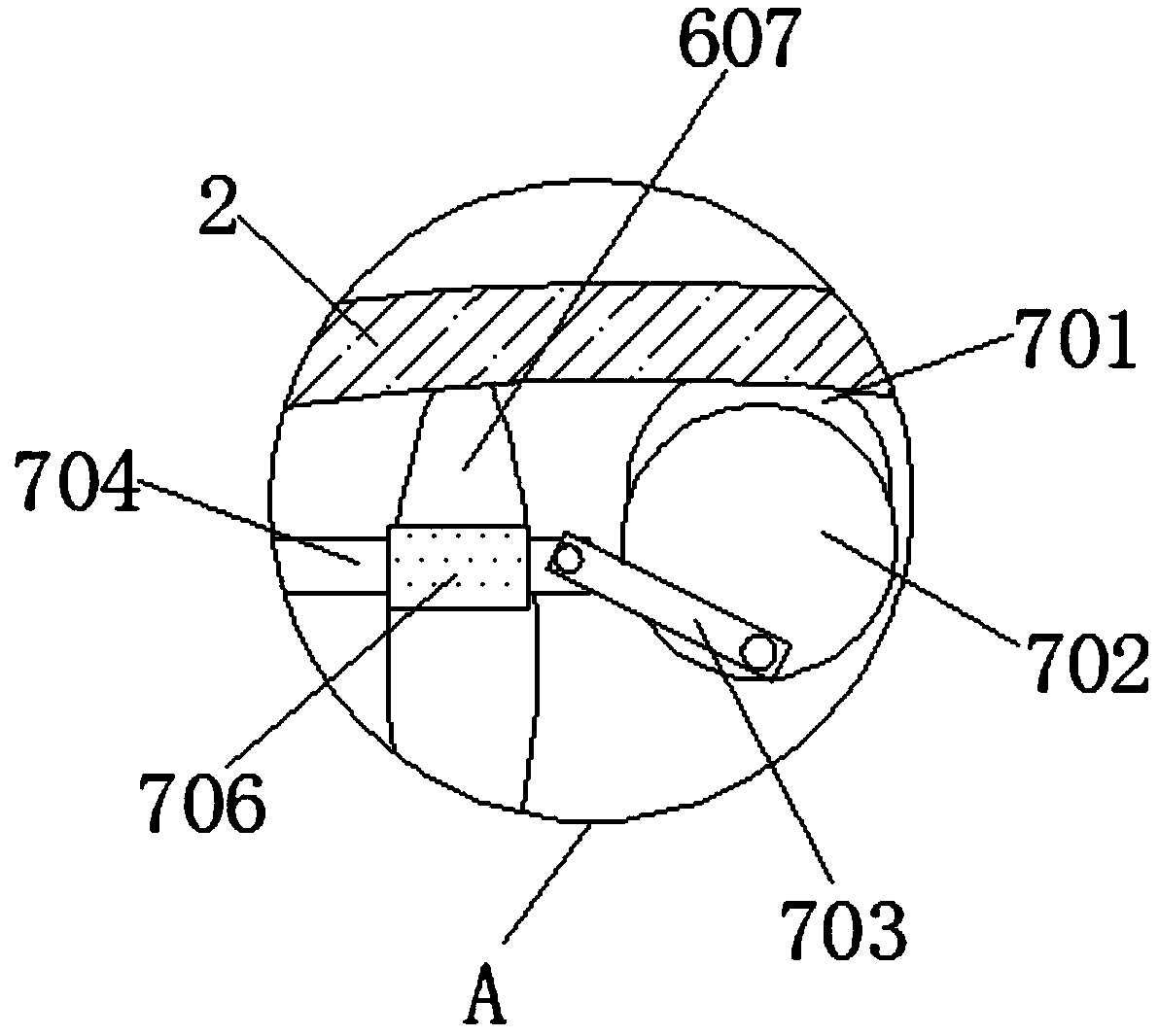

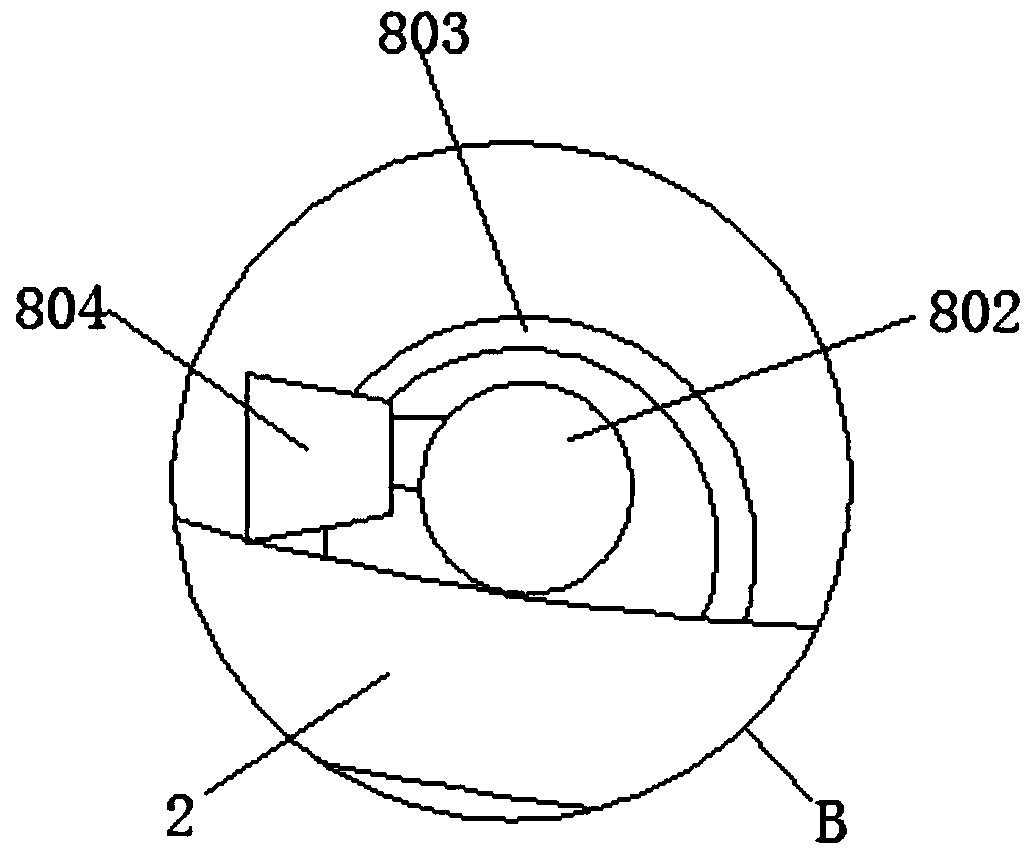

Circumferential sectioned helium sealing device for oxygen turbine pump of hydrogen oxygen engine

The invention discloses a circumferential sectioned helium sealing device for an oxygen turbine pump of a hydrogen oxygen engine. According to the circumferential sectioned helium sealing device, a circumferential sectioned sealing ring I and a circumferential sectioned sealing ring II are placed in a cavity formed by a cover plate and a sealing shell; sealing shaft sleeves are placed in rings of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II; the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II are oppositely placed and pre-tensioned by virtue of pre-tensioning springs; and each of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II is formed by connecting a plurality of fan-shaped arc sections with the same structure end to end, and constrained on an excircle surface through garter springs. According to the circumferential sectioned helium sealing device, each sealing ring is composed of the plurality of fan-shaped arc sections, a hydrodynamic groove structure is introduced, and a hydrodynamic effect of a sealing clearance fluid is adequately utilized, thus the helium sealing device reliably works under an extremely small clearance, and a low leakage amount is maintained.

Owner:BEIJING AEROSPACE PROPULSION INST

Dynamic flame simulating device

ActiveUS9388954B2Swinging of the flame element more realistic and naturalSimple structureElectric circuit arrangementsLight effect designsMagnetic tension forceEngineering

Owner:GLOBAL RICH INVESTMENT CO LTD

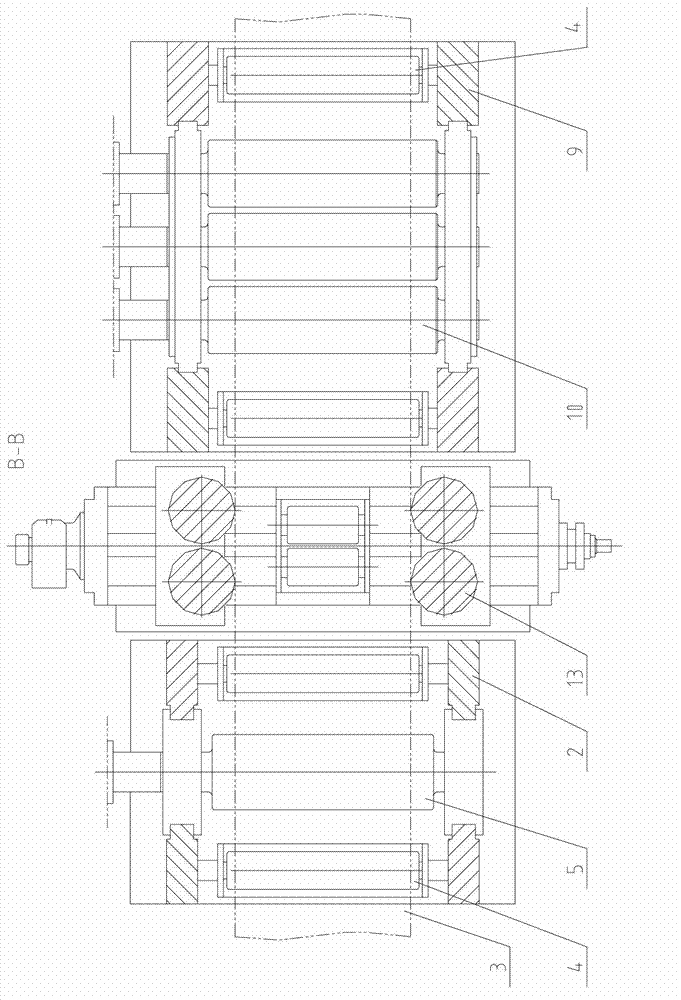

Roll gap adjusting device of plate-levelling machine

ActiveCN103084435AAvoid Scratching SituationsReduce contact frictionEngineeringMechanical engineering

The invention discloses a roll gap adjusting device of a steel plate-levelling machine and relates to the roll gap adjusting device of steel plate interrupted leveling equipment. The roll gap adjusting device of the steel plate-levelling machine is composed of rollers, a clamp sending device, a centering device, a leveling device and a base seat and characterized in that the clamp sending device and the levelling device are installed on the base seat, the centering device is installed between the clamp sending device and the levelling device, and the rollers are installed inside the clamp sending device and the levelling device. The roll gap adjusting device of the steel plate-levelling machine has the advantages of being novel in structure, easy and convenient to process, convenient to use, capable of improving surface quality of the steel plate, reducing loss of a roll, improving service life of the equipment, saving cost of maintaining and changing and the like. The invention belongs to a novel roll gap adjusting device of the steel plate-levelling machine with integrating economy and practicability together.

Owner:DALIAN SAGE GROUP

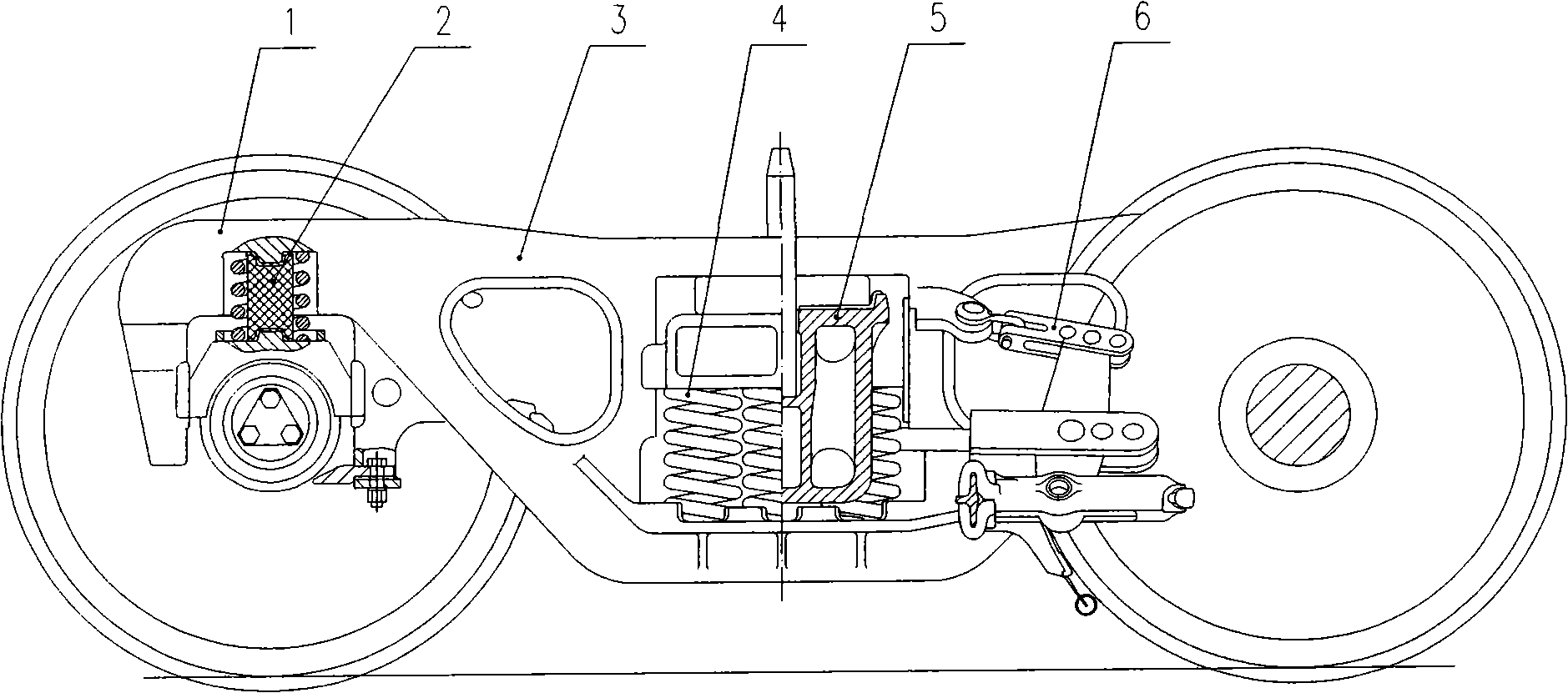

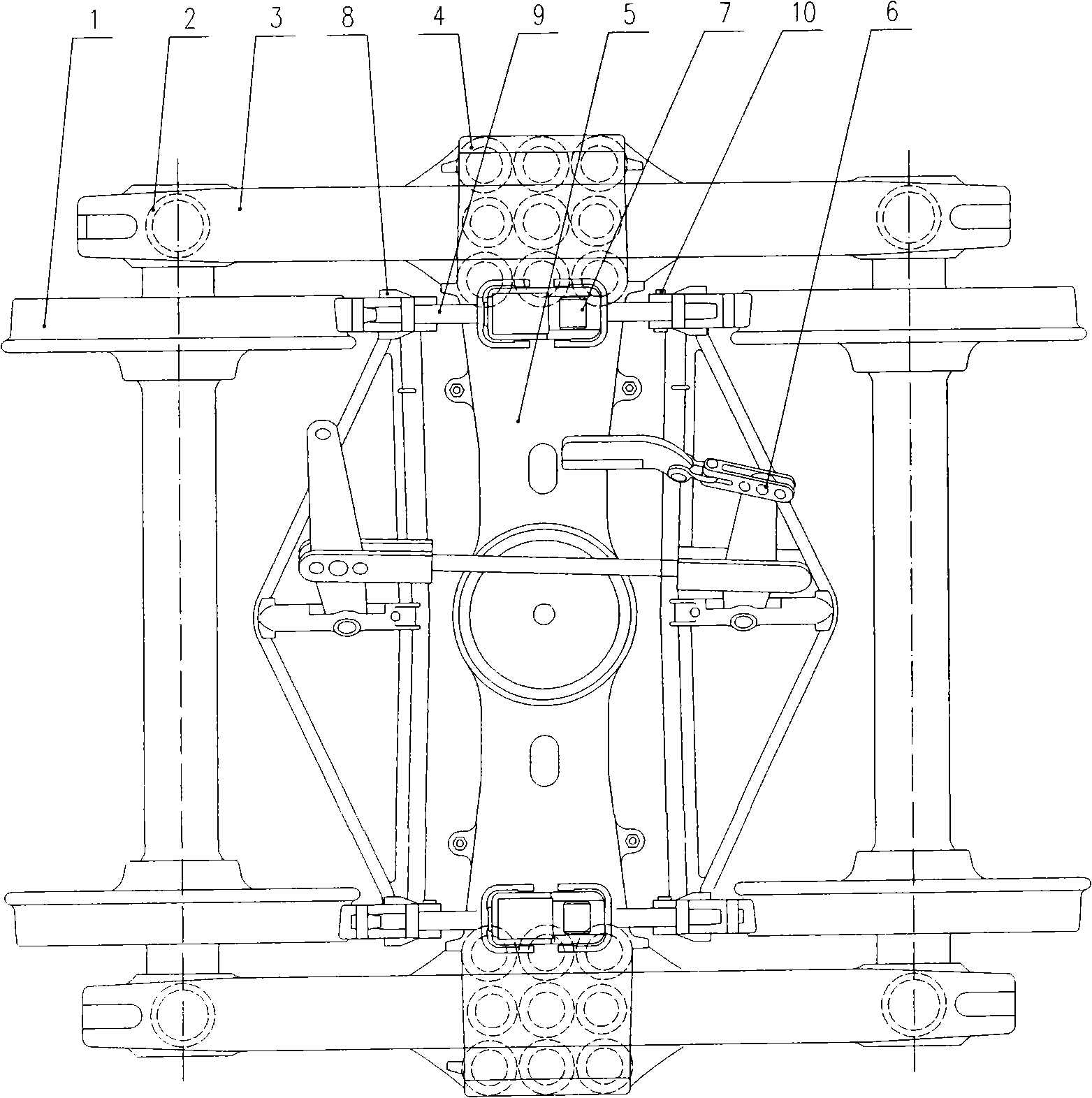

Bogie for goods train with large axle load and low dynamic action

ActiveCN101327801ASimple structureIncrease Strength ReserveBogie-underframe connectionsBogieSingle stage

The present invention provides a lorry bogie of large axle load and low power. The bogie comprises a wheel pair, a side frame, a swinging pillow, an axle box, a basic braking device, a single-stage suspension device, a two-stage suspension device and a side bearing. The side frame is arranged on the wheel pair through the single-stage suspension device, so that the side frame becomes the sprung mass; the swinging pillow is arranged on the side frame through the two-stage suspension device; the side bearing is arranged on the swinging pillow; the basic braking device is hanged on the swinging pillow, so as to become the sprung mass; the two-stage suspension device is a linking mechanism of a cylindrical rubber spring and a steel circular spring, and is arranged in the space which is formed by the bottom chord of the side frame and the lower part of the terminal of the swinging pillow; a pre-tightening rubber pad is arranged between the upper part of the terminal of the swinging pillow and the top chord of the side frame. The structure is simple; the strength reserve of the swinging pillow, the side frame and other key components is further improved; and the lorry bogie satisfies the requirement for increasing the axle load, reduces the unsprung mass, reduces the action of the wheel rail, realizes the low-power action, and improves the vehicle running quality.

Owner:CRRC SHANDONG CO LTD

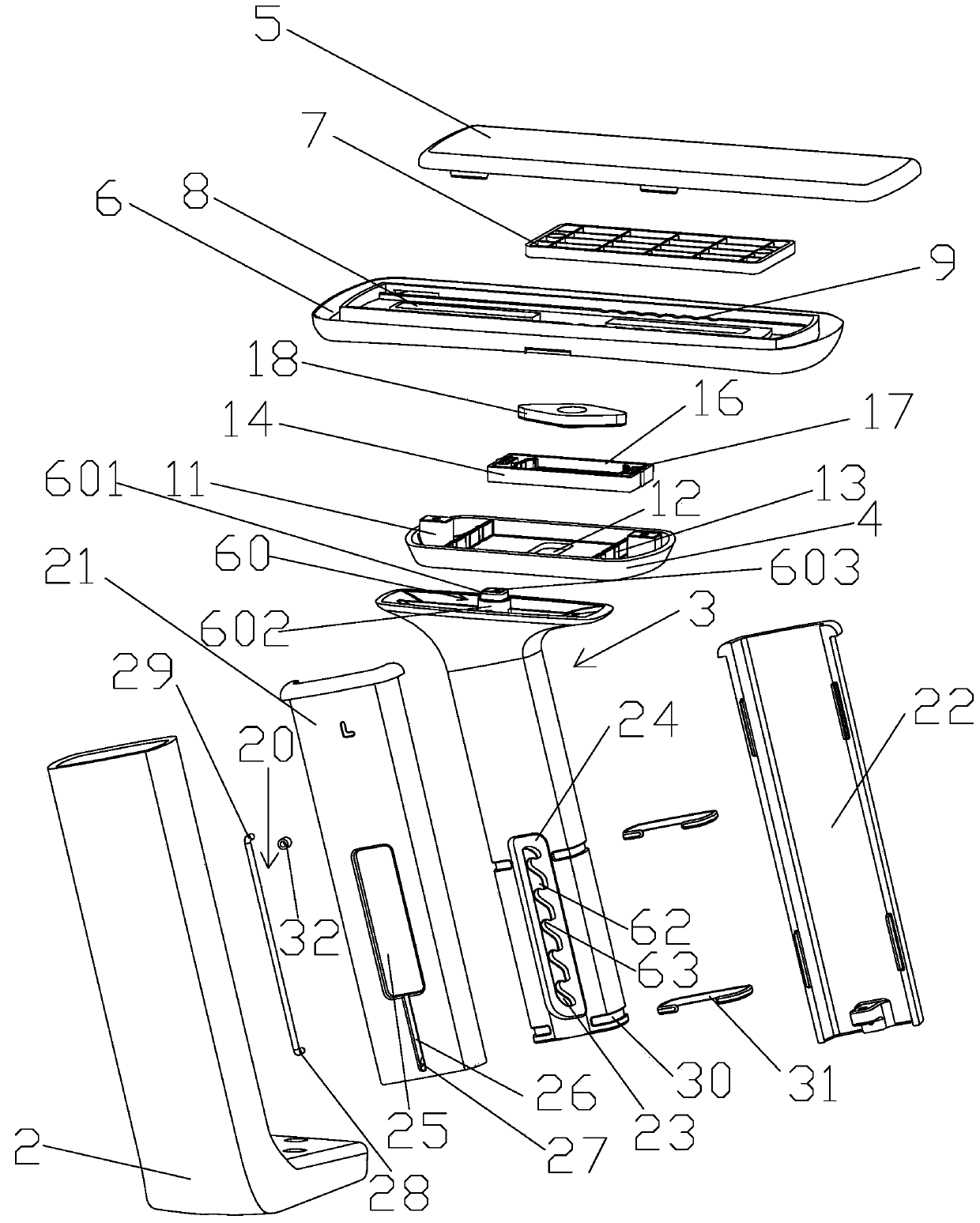

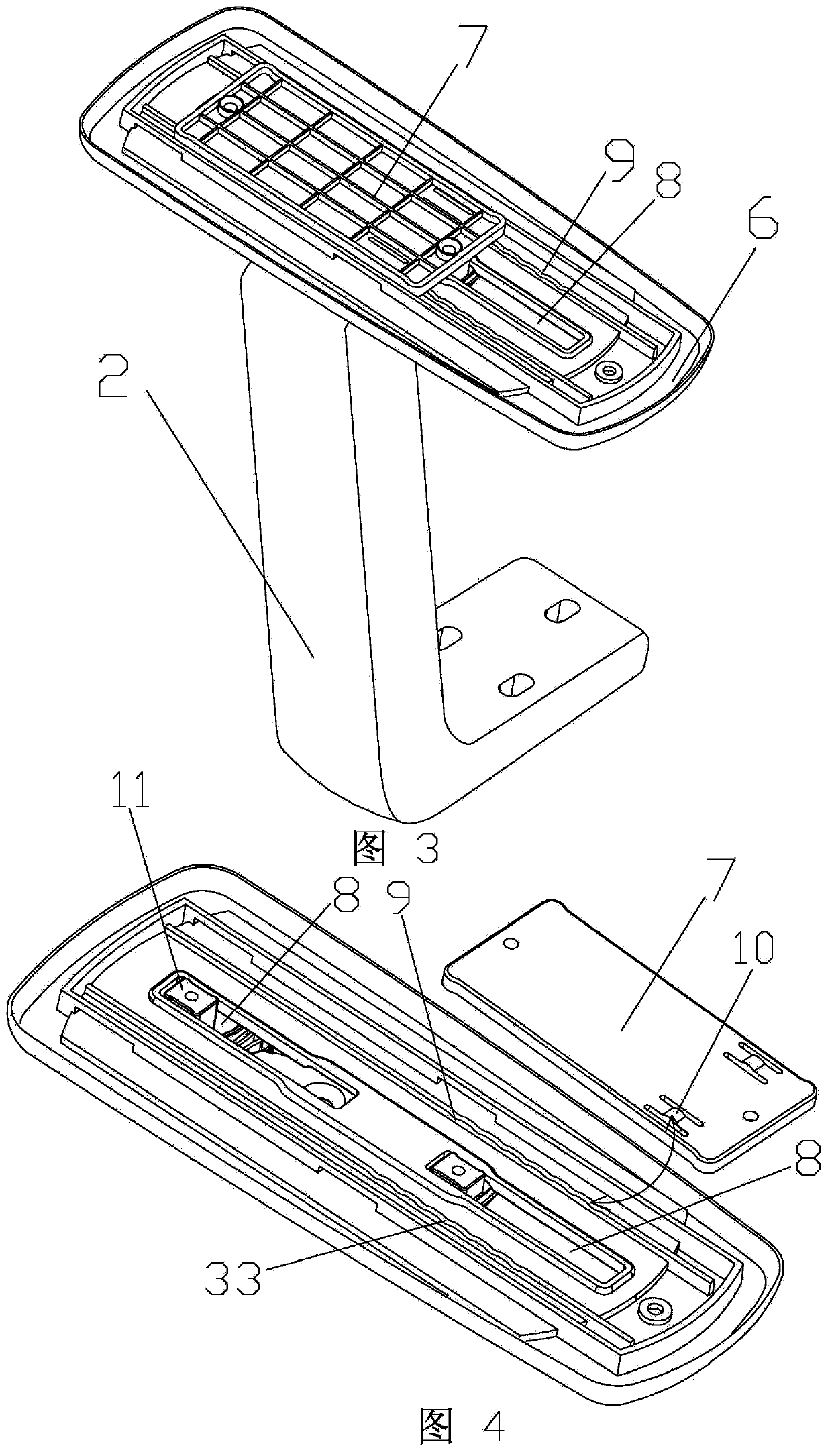

Multifunctional armrest

Owner:UE FURNITURE CO LTD

Household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction

The invention provides a household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction, relates to the mechanical field and solves the problem that an arranged screen window is hardly cleaned. The household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction comprises a fixed outer housing. A mounting inner shell is adhered to the fixed outer housing through a connecting block, a humidifying and deoiling mechanism is arranged between the fixed outer housing and the mounting inner shell, an opening is formed in the left end of the fixed outer housing, and a tail connecting protecting barrel is adhered to the right end of the fixed outerhousing. According to the household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction, a control motor controls cleaninghairbrushes on the end parts of a driving rotating rod and a driven rotating rod to rotate to clean dust on the surface of the screen window, so that the condition that the local part of the screen window is not cleaned as a result of unidirectional rotation is avoided. The motor controls a telescopic protecting part to beat the screen window continuously to simulate the action of flickering thewindow with a finger, so that dust is scattered effectively.

Owner:NANJING JONQUIL CONSTR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com