Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about How to "Easy to wet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

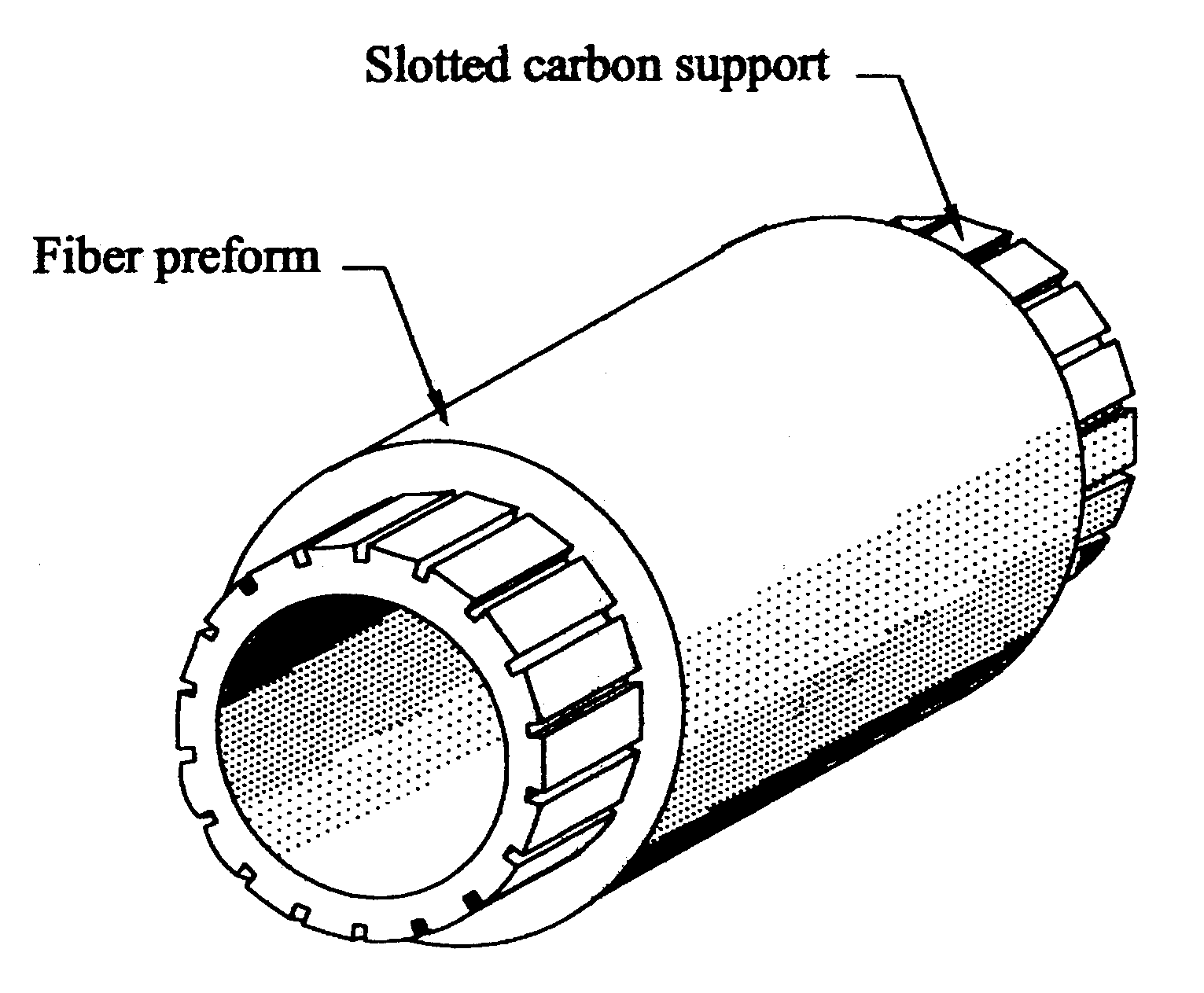

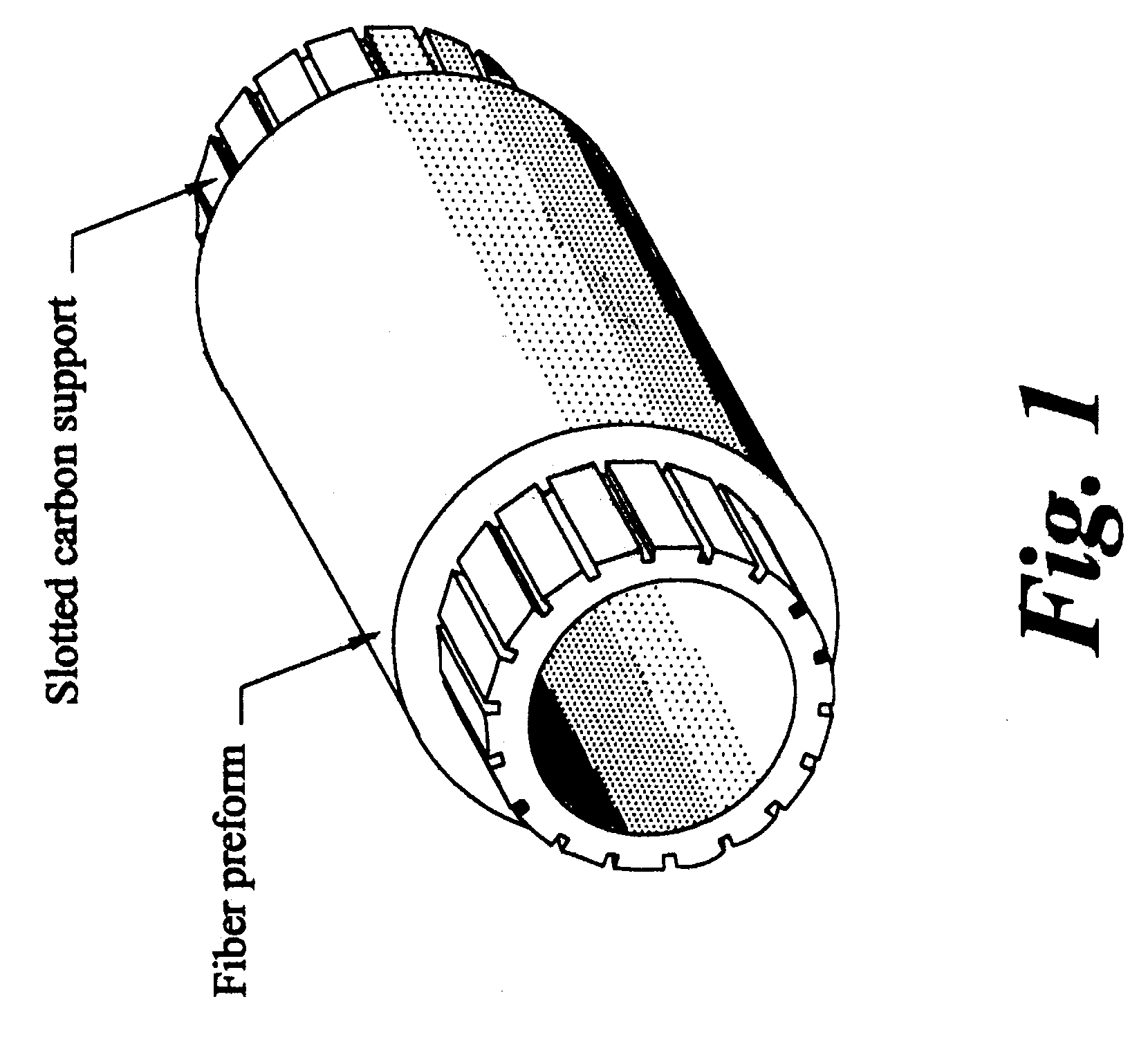

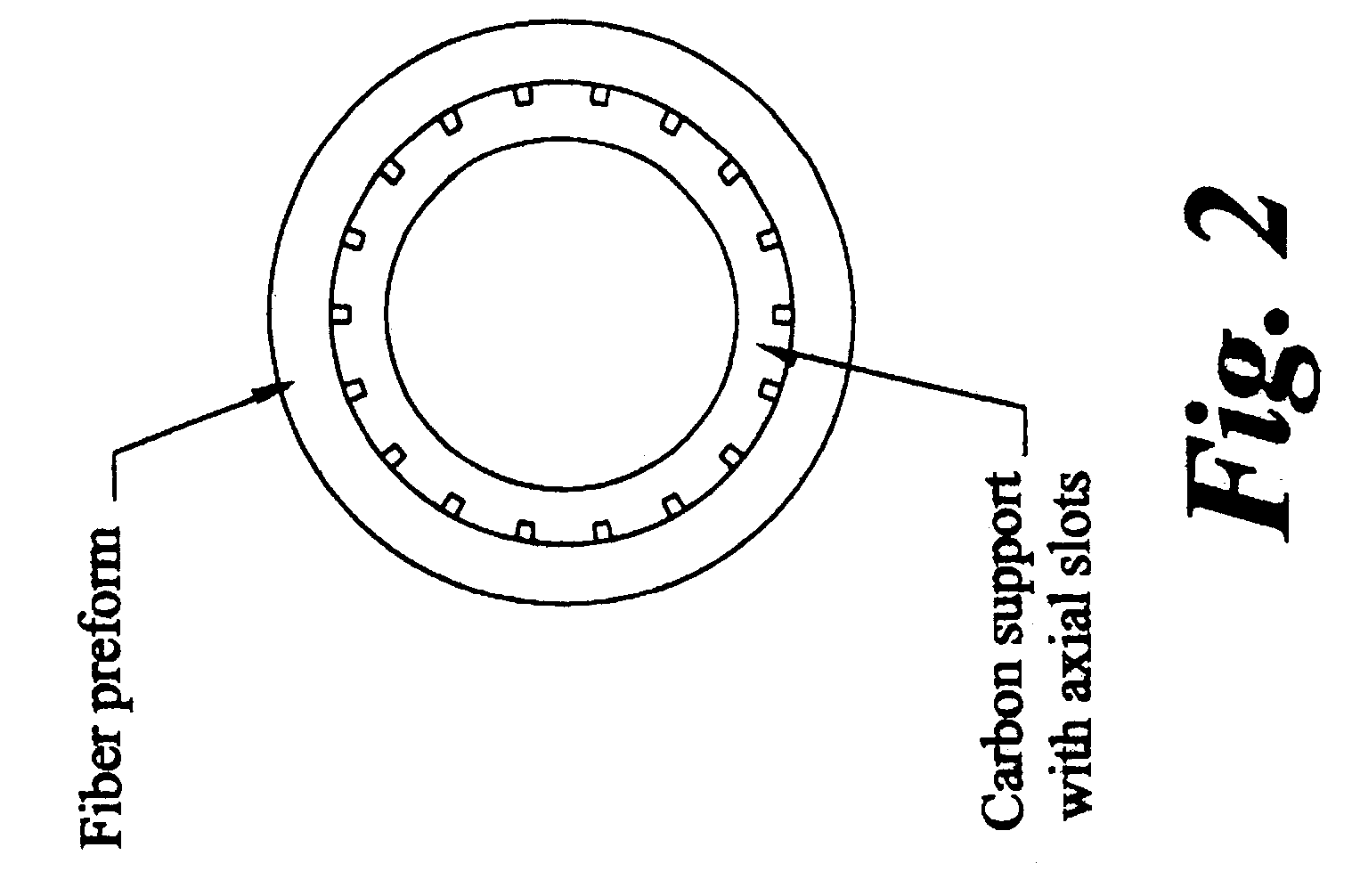

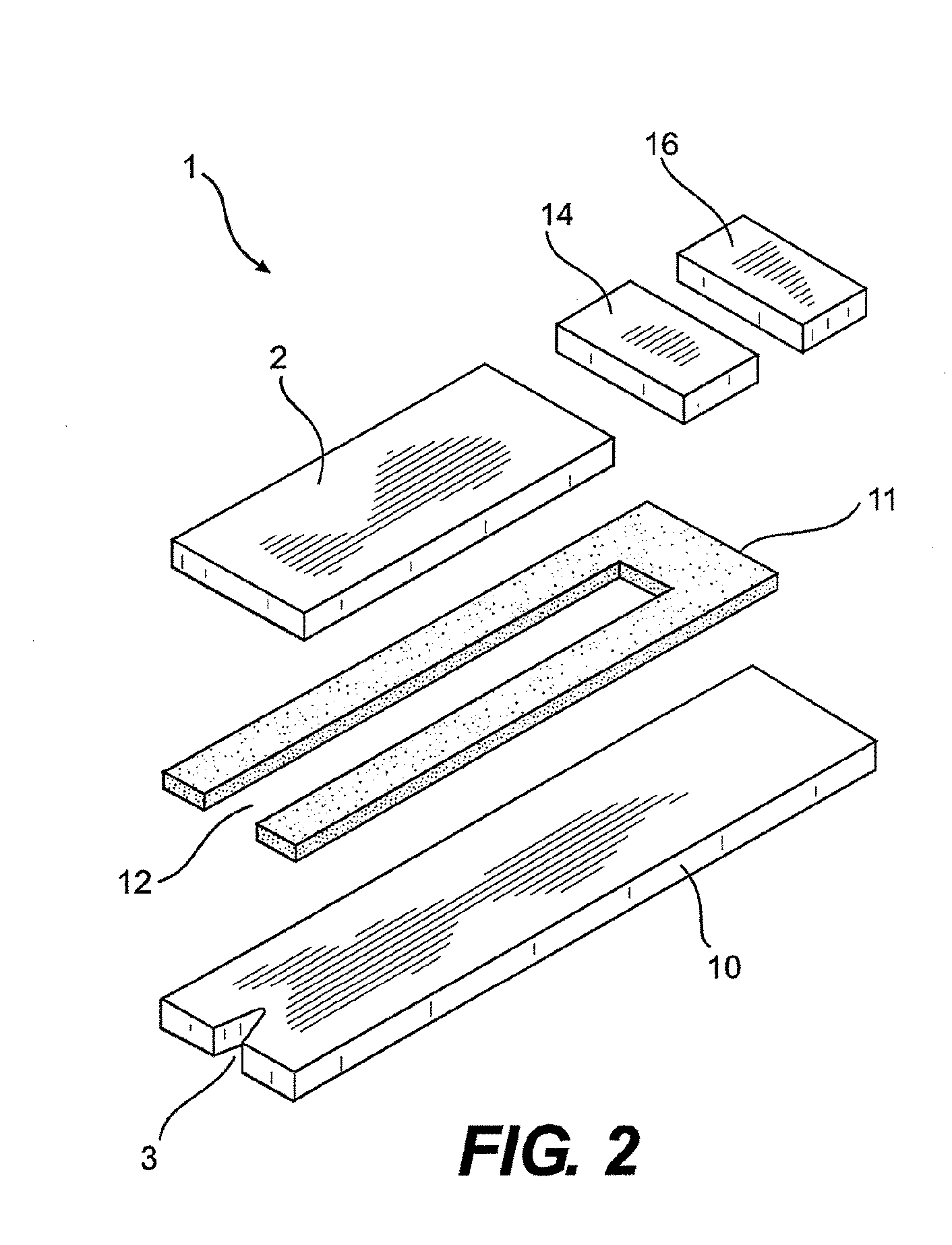

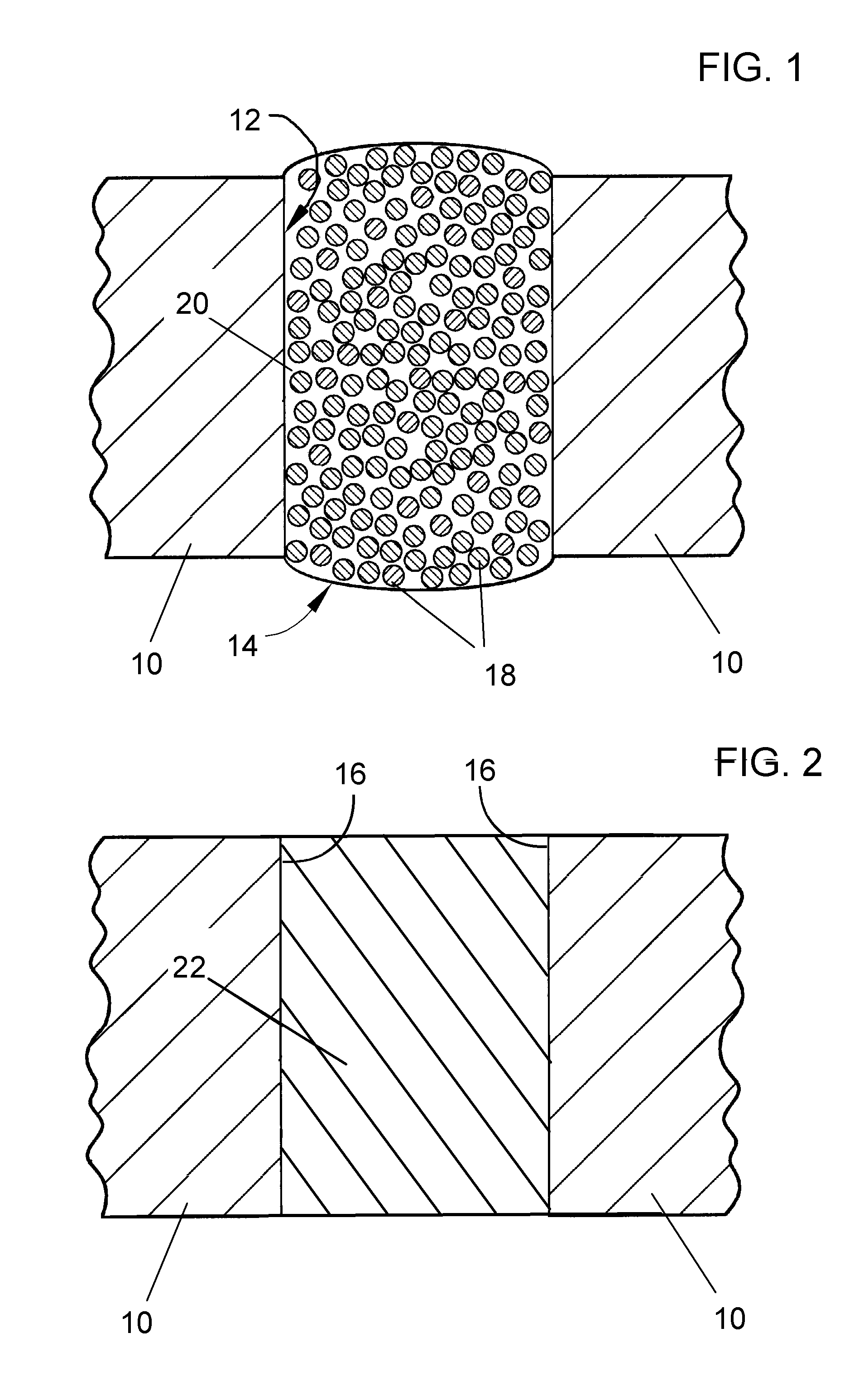

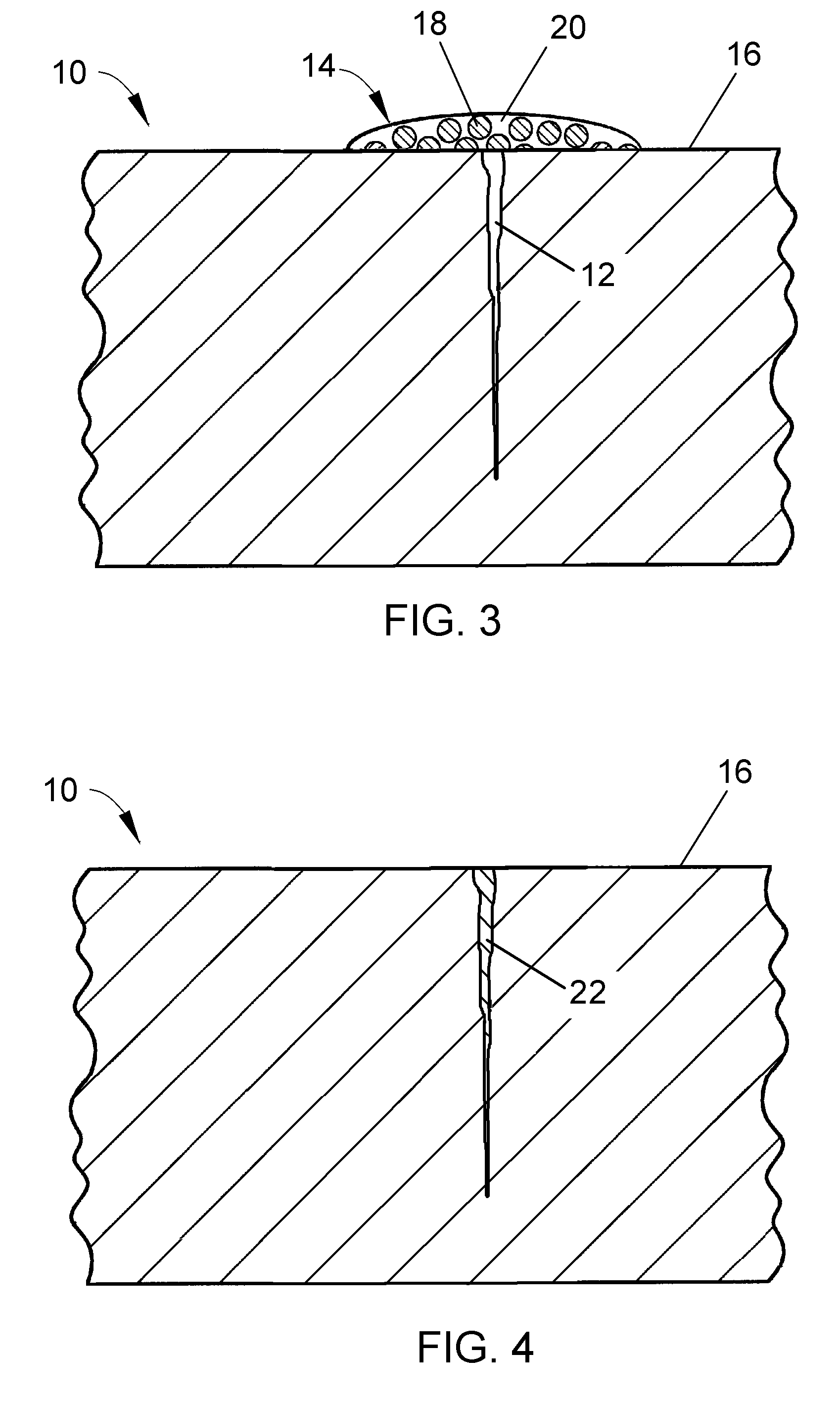

Method for producing melt-infiltrated ceramic composites using formed supports

InactiveUS6503441B2Avoid distortionEvenly distributedPretreated surfacesCeramic shaping apparatusCeramic compositeMetallurgy

A method for producing shaped articles of ceramic composites provides a high degree of dimensional tolerance to these articles. A fiber preform is disposed on a surface of a stable formed support, a surface of which is formed with a plurality of indentations, such as grooves, slots, or channels. Precursors of ceramic matrix materials are provided to the fiber preform to infiltrate from both sides of the fiber preform. The infiltration is conducted under vacuum at a temperature not much greater than a melting point of the precursors. The melt-infiltrated composite article substantially retains its dimension and shape throughout the fabrication process.

Owner:GENERAL ELECTRIC CO

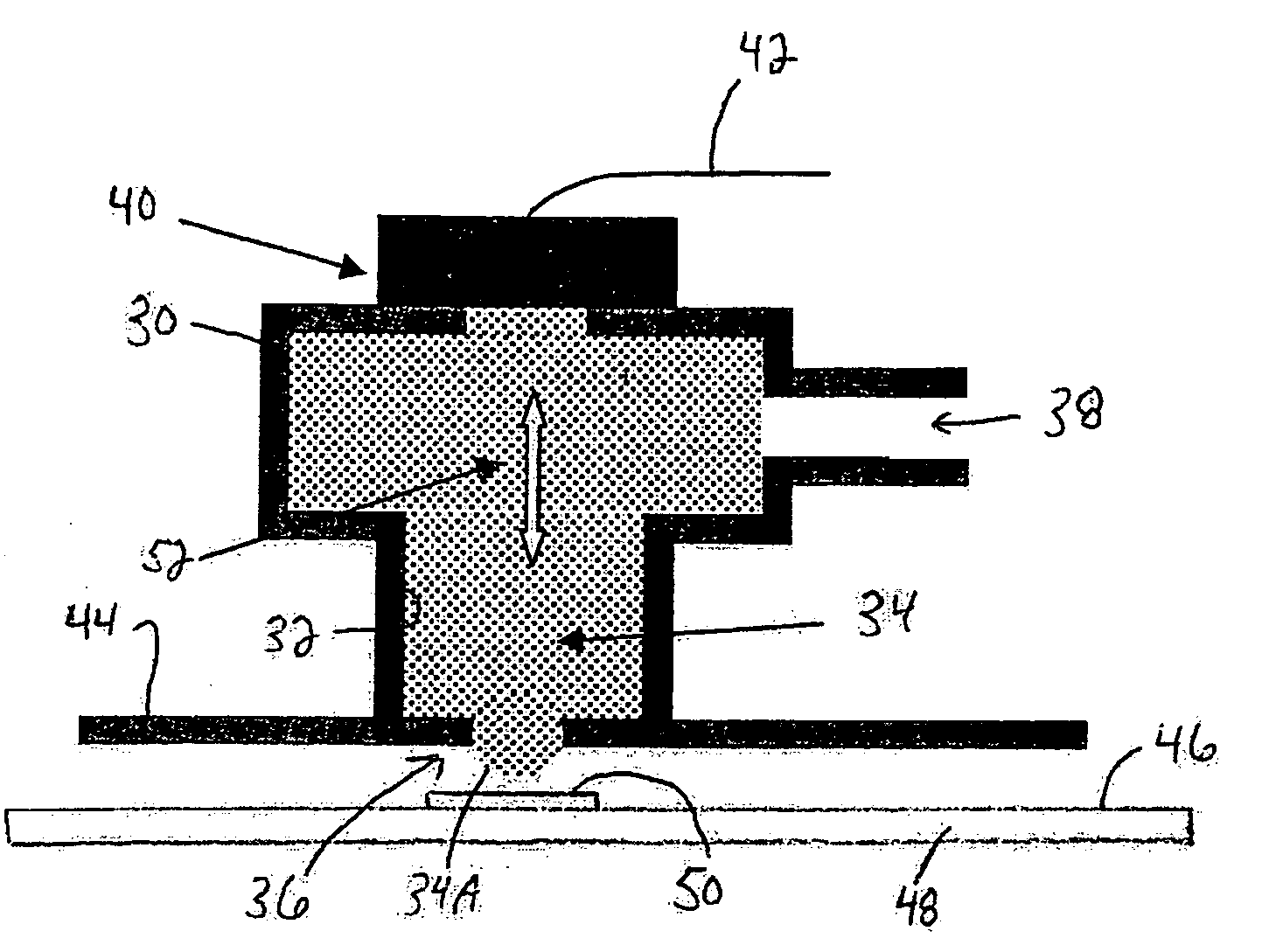

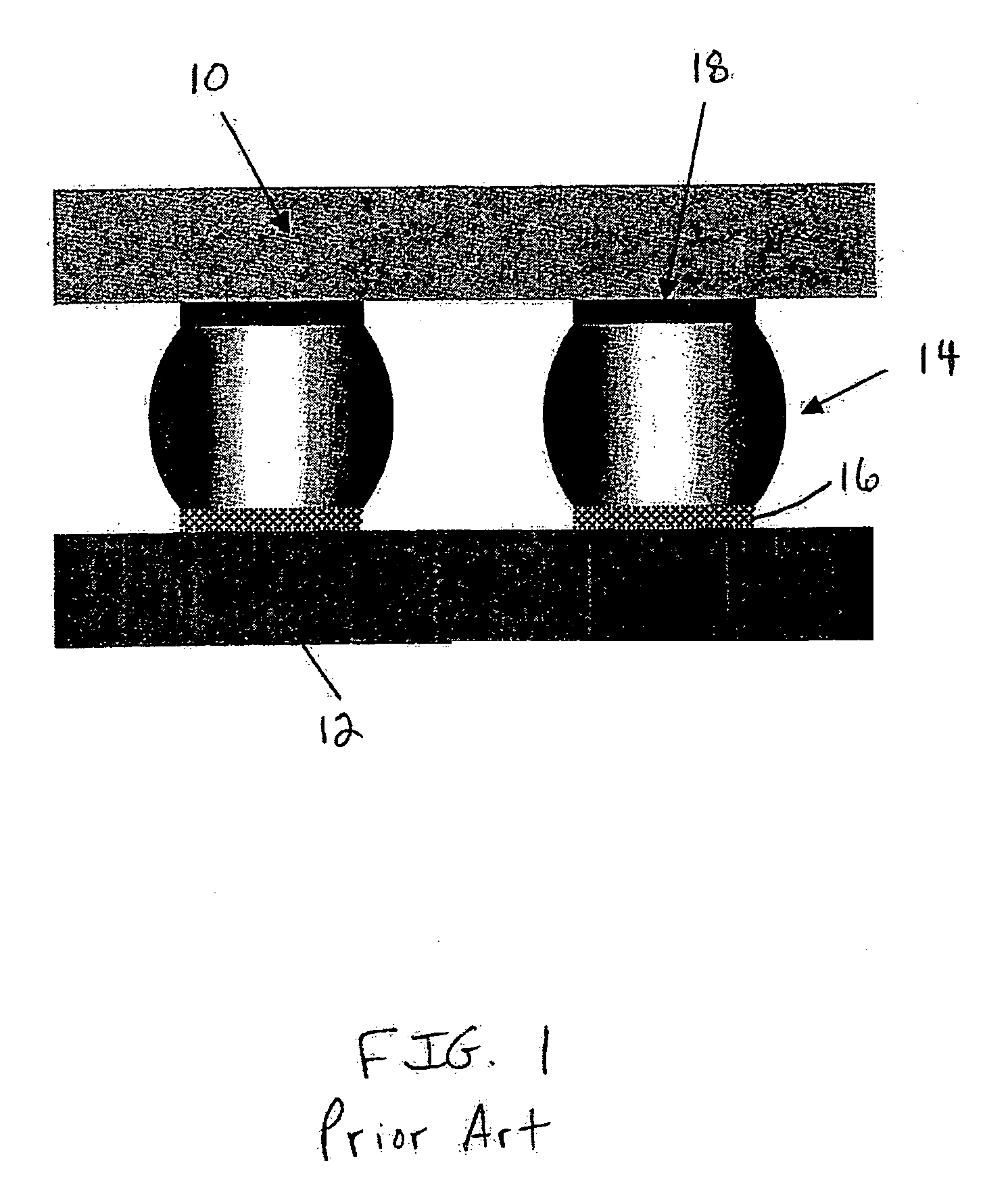

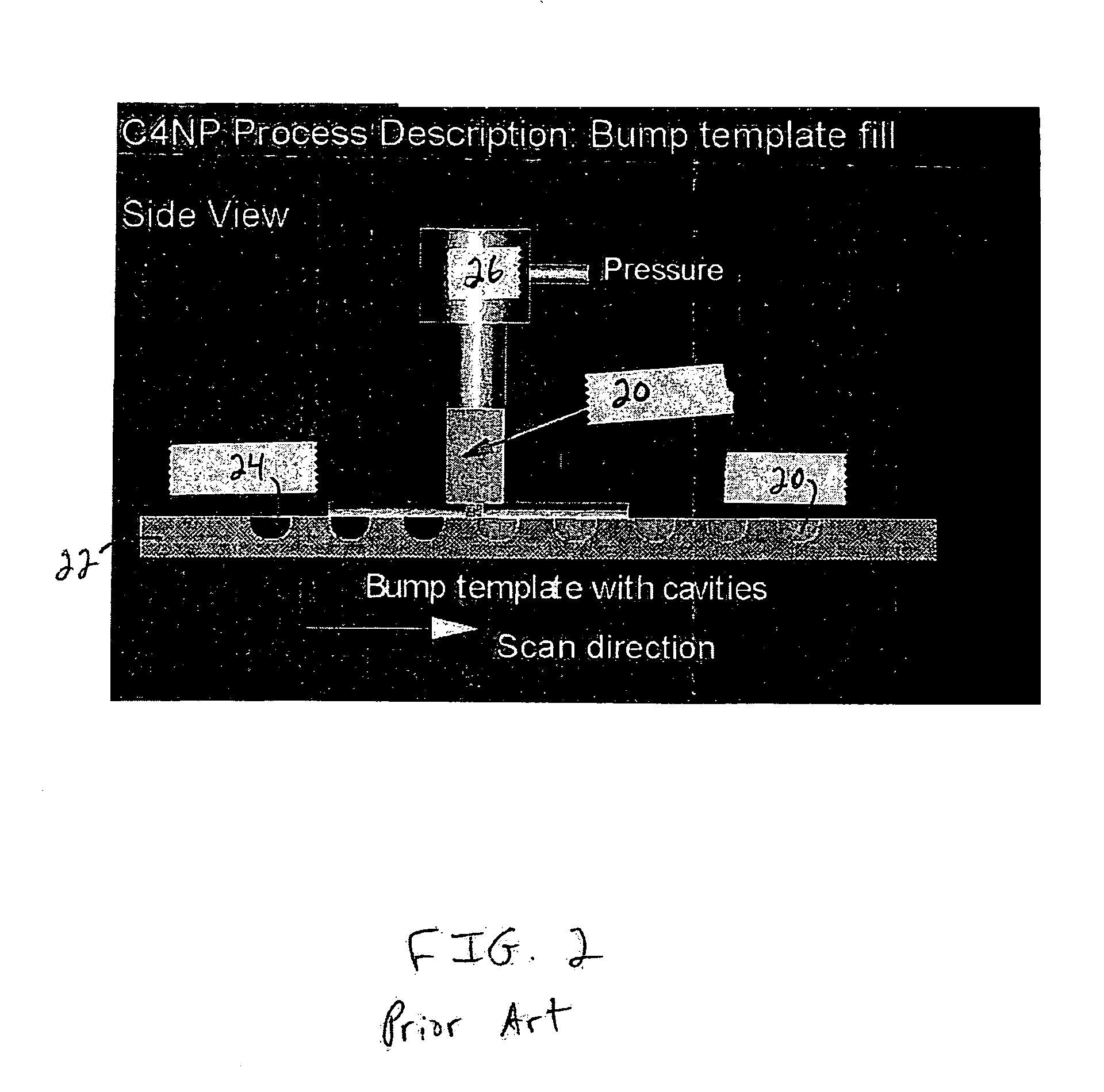

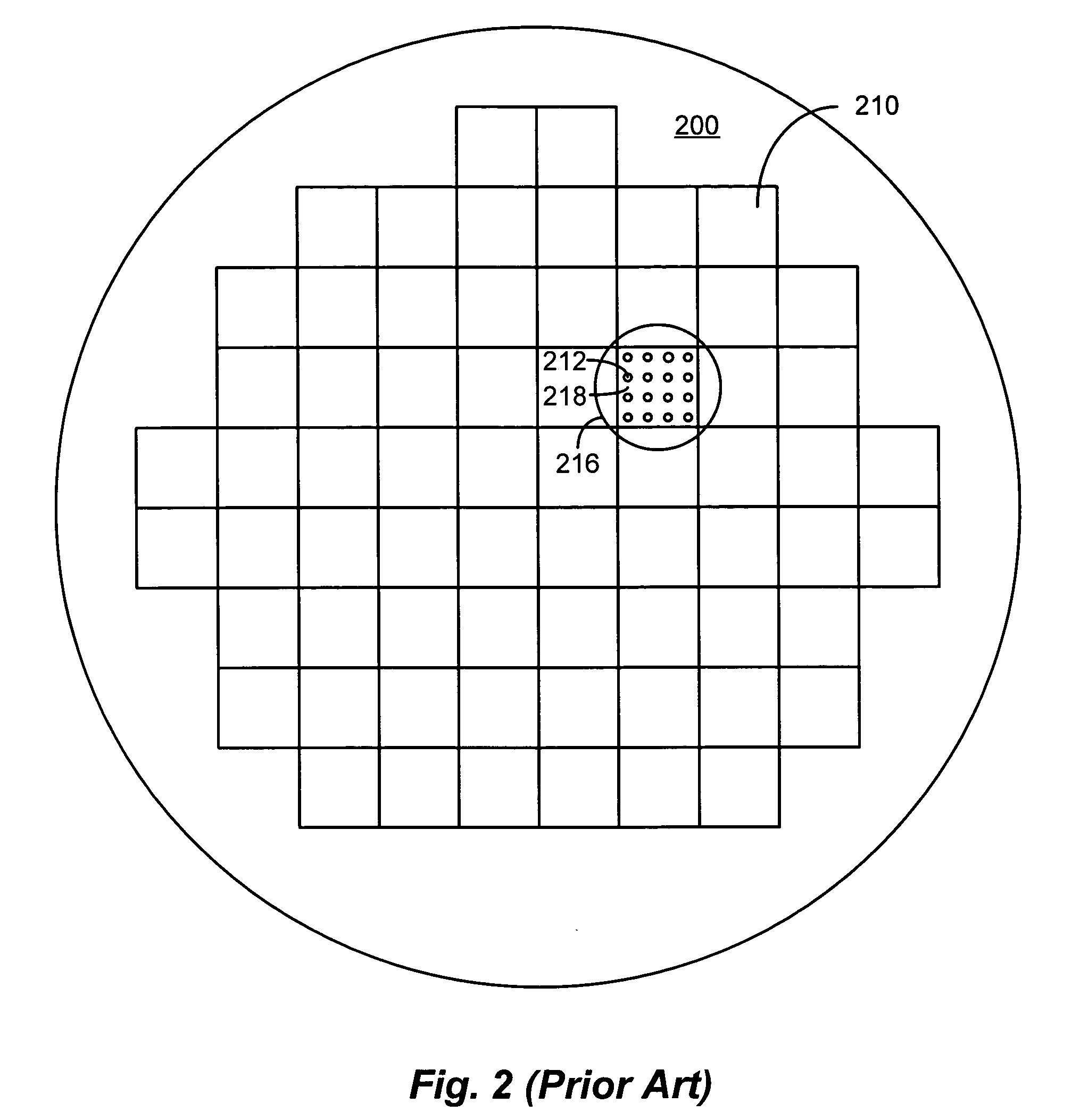

Tools and methods for forming conductive bumps on microelectronic elements

InactiveUS20060183270A1Easy to wetGood adhesionSolid-state devicesSemiconductor/solid-state device manufacturingContact padEngineering

A method of making a microelectronic assembly includes providing a microelectronic element having a front face and contact pads accessible at the front face, providing a dispensing tool containing a molten metal and having a discharge port for dispensing the molten metal, and aligning the discharge port of the dispensing tool with one of the contact pads of the microelectronic element. A mass of the molten metal is dispensed through the discharge port and onto the one of the contact pads of the microelectronic element; and ultrasonic waves are applied to the mass of molten metal during the dispensing step for facilitating wetting of the mass of molten metal with the one of the contact pads of the microelectronic element.

Owner:TESSERA INC

Test element for analyzing body fluids

ActiveUS20080060424A1Avoid polluting the environmentEasy to wetPreparing sample for investigationPretreated surfacesAnalyteMedicine

An analytical test element for determining an analyte in a body fluid comprises a detection area in which the analyte is detected and an application site at which the body fluid can be applied to the test element. The application site is spaced apart from the detection area, wherein at least some of the body fluid applied to the application site moves from the application site to the detection area. The test element also comprises a contamination area which at least partially adjoins the application site, wherein an adhesive substance is applied to at least part of the contamination area of the test element. The adhesive substance adheres to the contamination area of the test element and is able to interact with an excess amount of applied body fluid such that at least some of the body fluid adheres to the test element and thereby an excess amount of body fluid remains in the contamination area. An additional embodiment provides for test elements which, after use, can be stored in a storage container. Another embodiment provides for the production of the test elements.

Owner:ROCHE DIABETES CARE INC

Aerogel containing blanket

ActiveUS20060125158A1Low thermal conductivityEvenly distributedNon-fibrous pulp additionNatural cellulose pulp/paperFiberSlurry

A process of producing a blanket is described and can involve forming an aqueous slurry of hydrophobic aerogels, fibers, and at least one wetting agent, drying the aqueous slurry to form a substantially dried product, and calendaring the substantially dried product to form the blanket. The blanket can be used in a variety of applications, including windows.

Owner:CABOT CORP

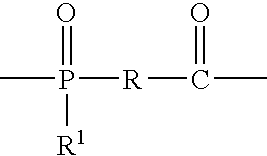

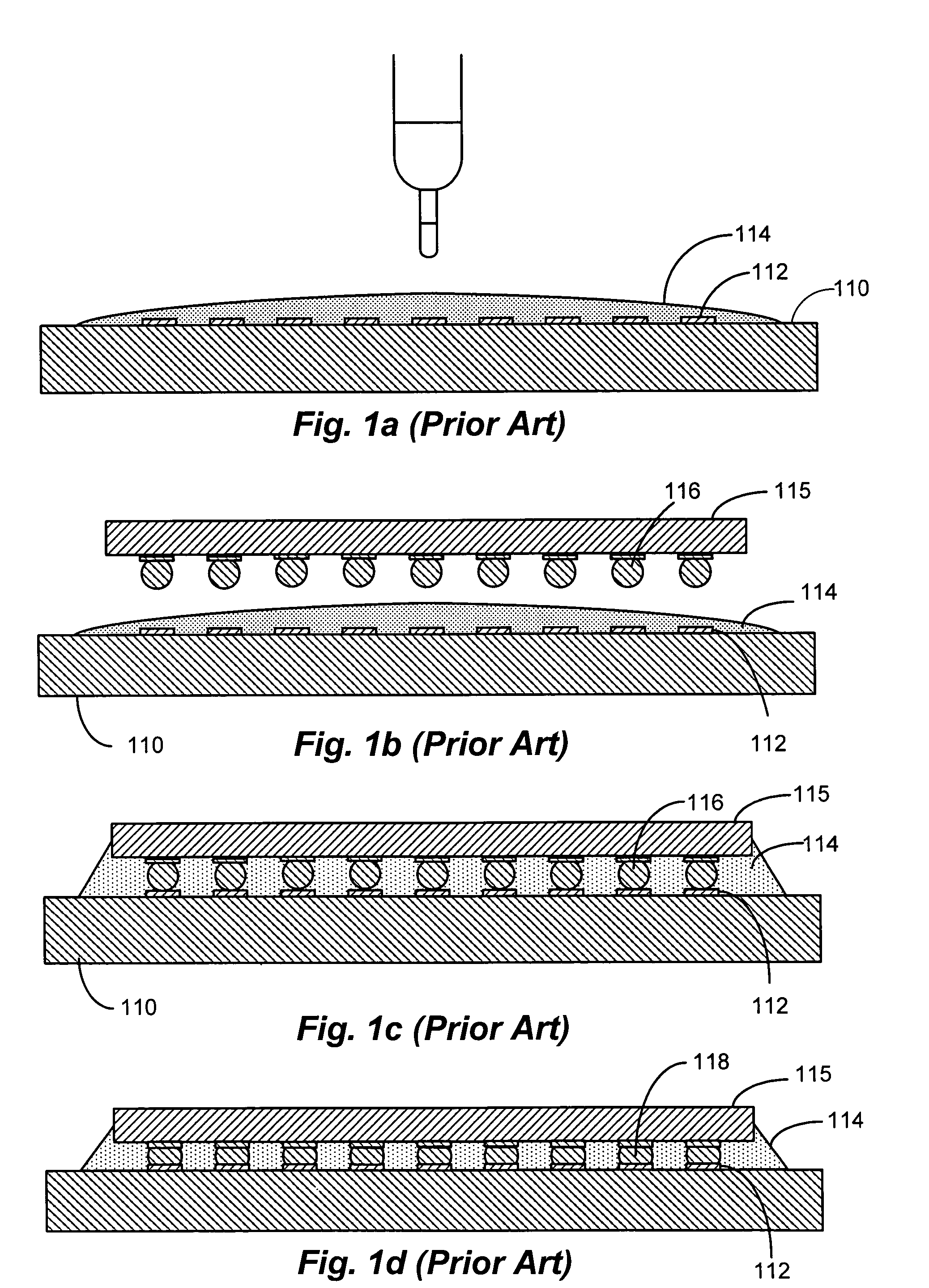

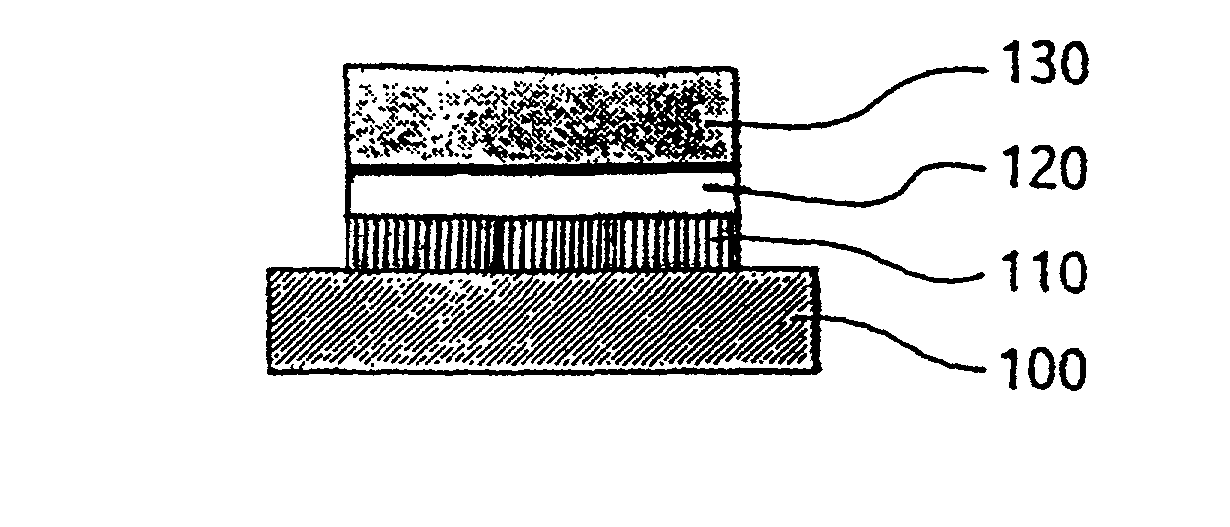

Integrated underfill process for bumped chip assembly

InactiveUS20050028361A1High yieldWeight increasePrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringThermal expansion

An integrated underfilling process for attaching a chip / die having conductive solder bump contacts to a substrate. The process involves B-staging filled underfill on the chip / die, depositing a fluxing unfilled underfill onto the surface of the substrate, mating the chip / die with the B-staged underfill to the substrate and reflowing the assembled chip / substrate. The B-staged filled underfill reduces the coefficient of thermal expansion of the underfill fillet and the fluxing unfilled underfill removes metal oxide from the surface of the solder bump contacts and bond pads to promote the formation of reliable metallurgical joints.

Owner:INDIUM CORPORATION

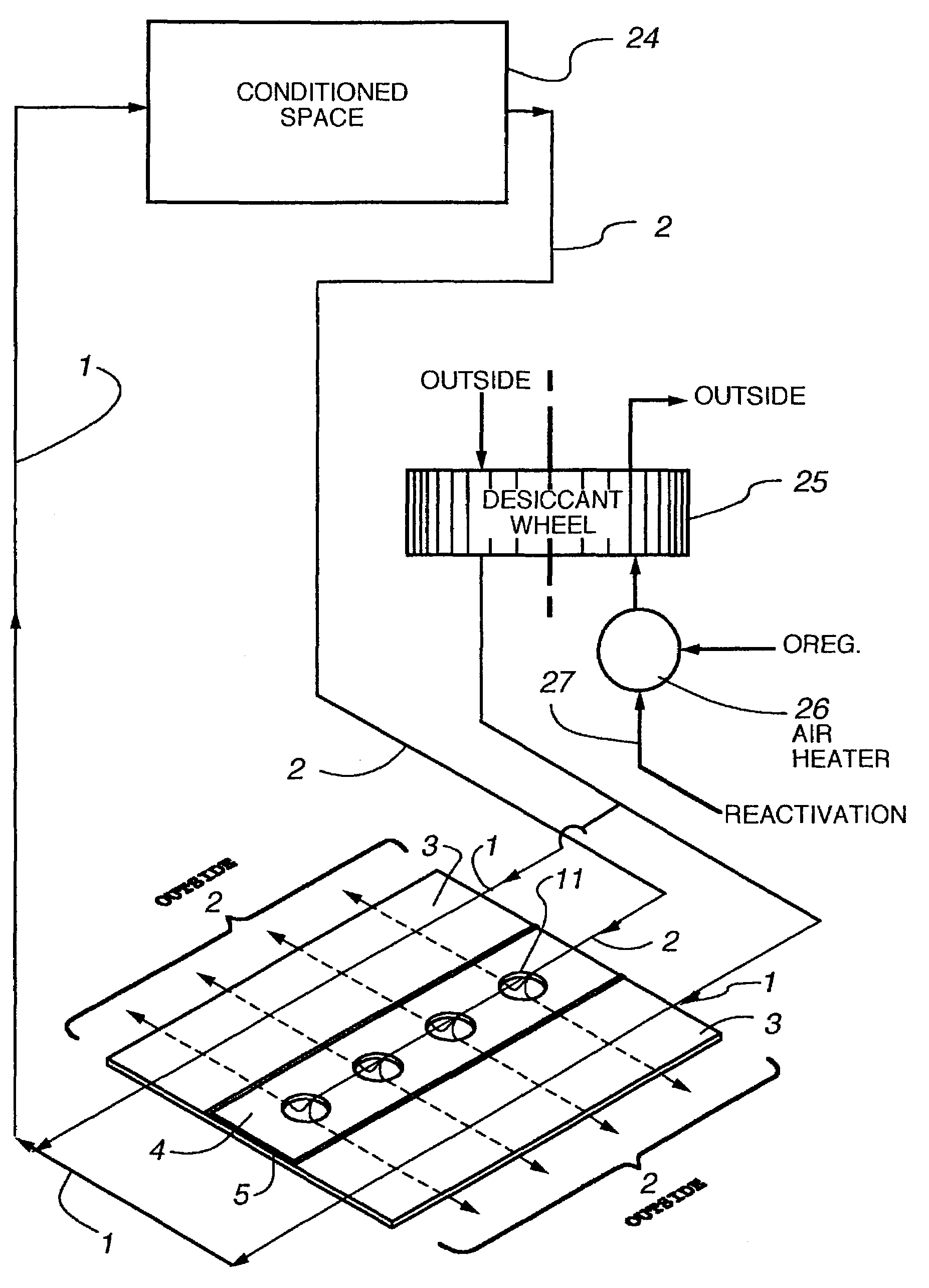

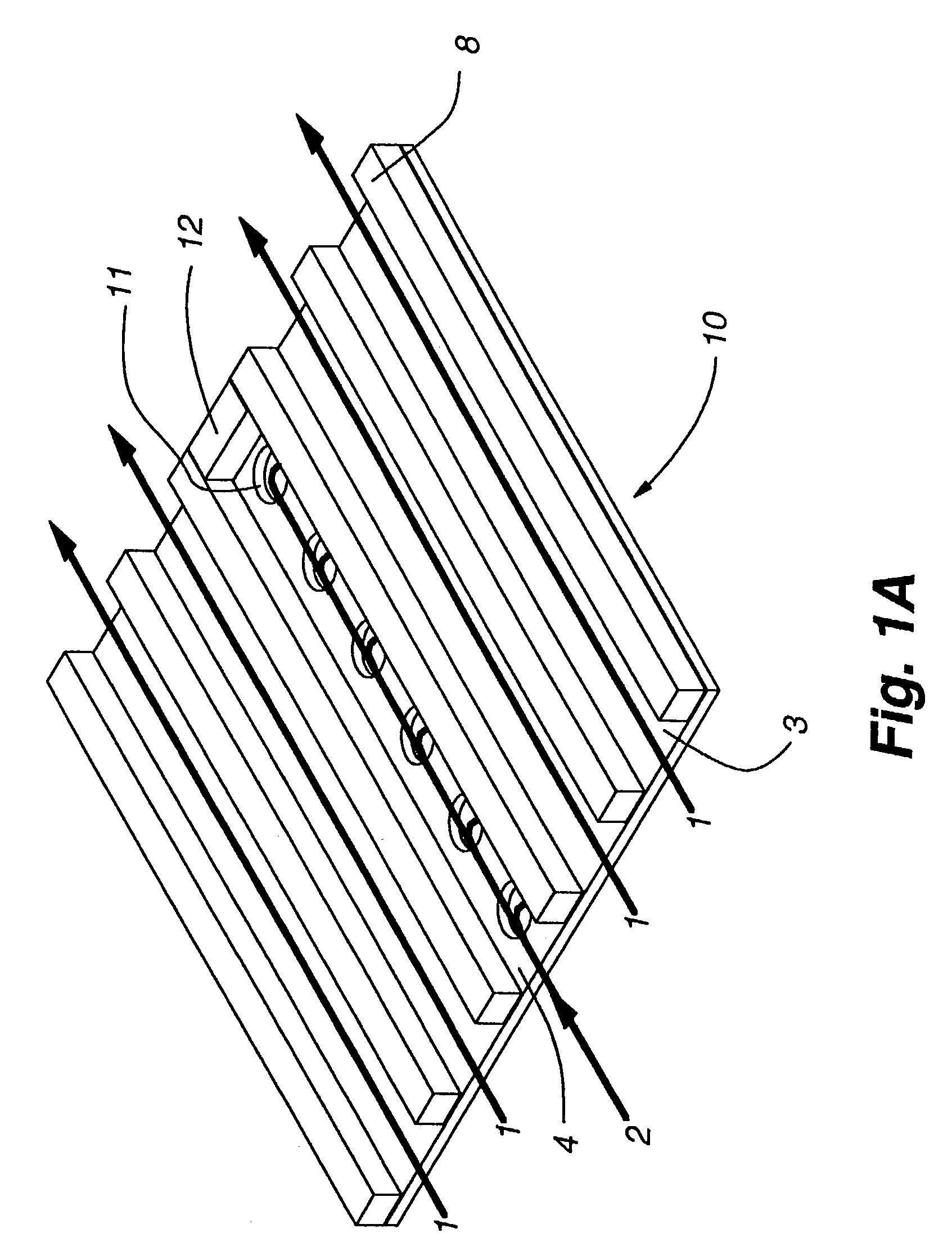

Method and plate apparatus for dew point evaporative cooler

InactiveUS7197887B2Small pressure dropReduce temperature differenceAir treatment detailsFree-cooling systemsEvaporative coolerFiber

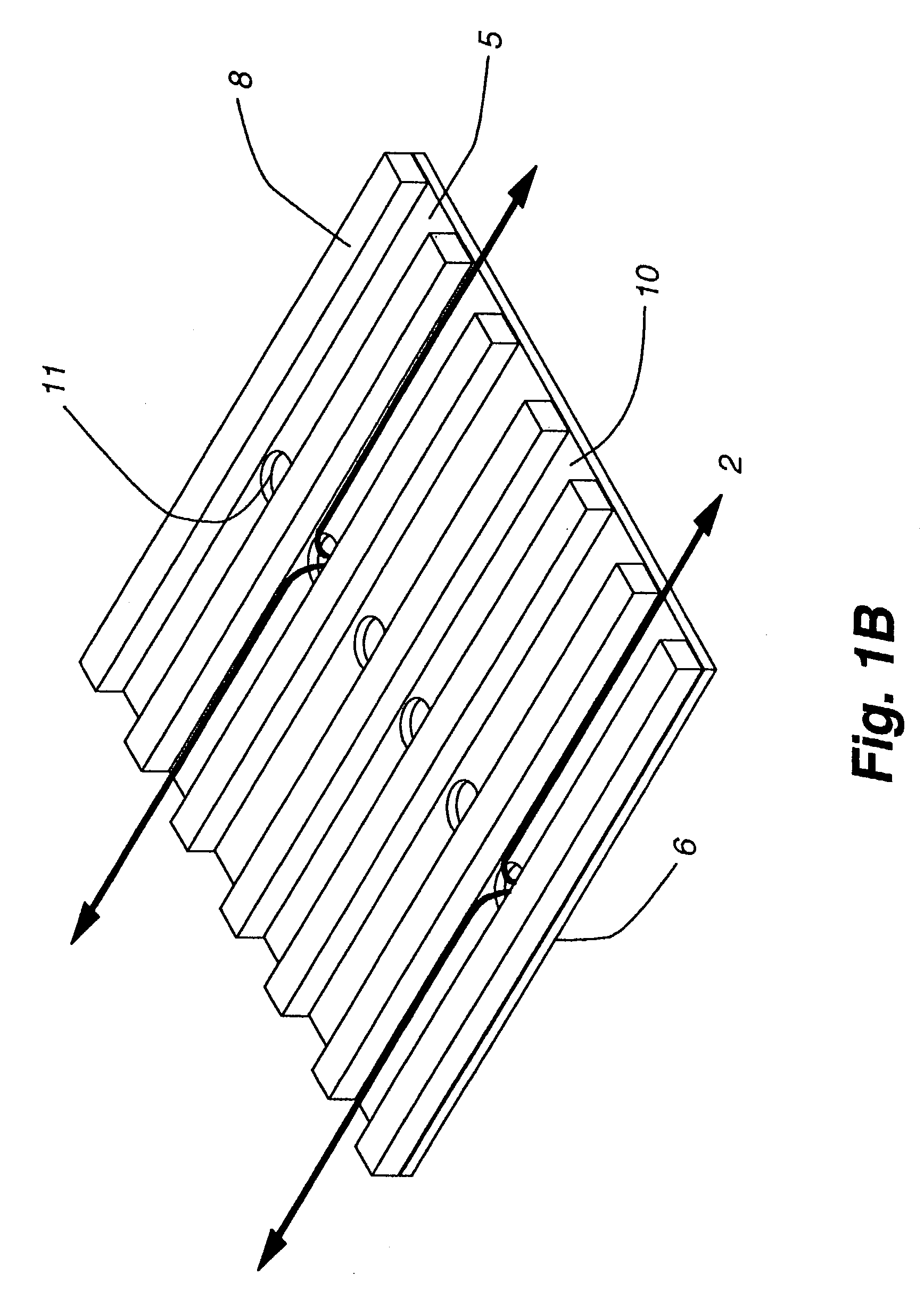

An improved method and apparatus for indirect evaporative cooling of a fluid stream to substantially its dew point temperature. Plate heat exchanger has perforations 11 and channels 3, 4 and 5 for gas or a low temperature for liquids on a dry side and wet side. Fluid streams 1 flow across the dry side 9, transferring heat to the plate. Gas stream 2 flows across the dry side and through perforations to channels 5 on wet side 10, which it then cools by evaporative cooling as well as conductive and radiative transfer of heat from plate. A wicking material provides wetting of wet side. In other embodiments, a desiccant wheel may be used to dehumidify the gas, air streams may be recirculated, feeder wicks 13 and a pump may be used to bring water from a water reservoir, and fans may be used to either force or induce a draft. The wicking material may be cellulose, organic fibers, organic based fibers, polyester, polypropylene, carbon-based fibers, silicon based fibers, fiberglass, or combinations of them. The device may be operated in winter months to scavenge heat from exhaust gases of a space and thus pre-heat fresh air, while simultaneously humidifying the fresh air.

Owner:F F SEELEY NOMINEES

Oxidation ceramic to metal braze seals for applications in high temperature electrochemical devices and method of making

InactiveUS7055733B2Improve sealingEasy to wetFinal product manufactureLayered productsElectrochemistrySuperalloy

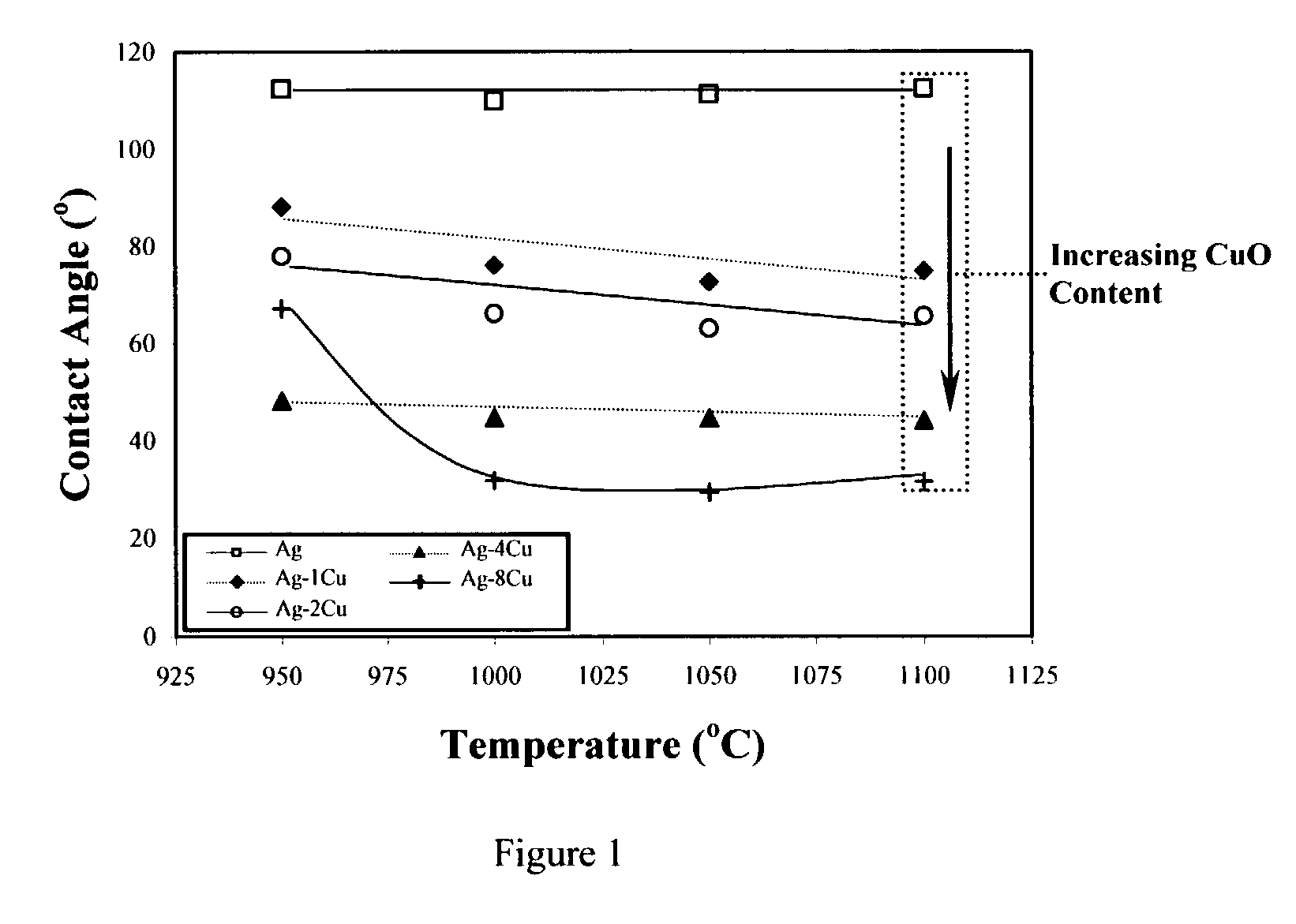

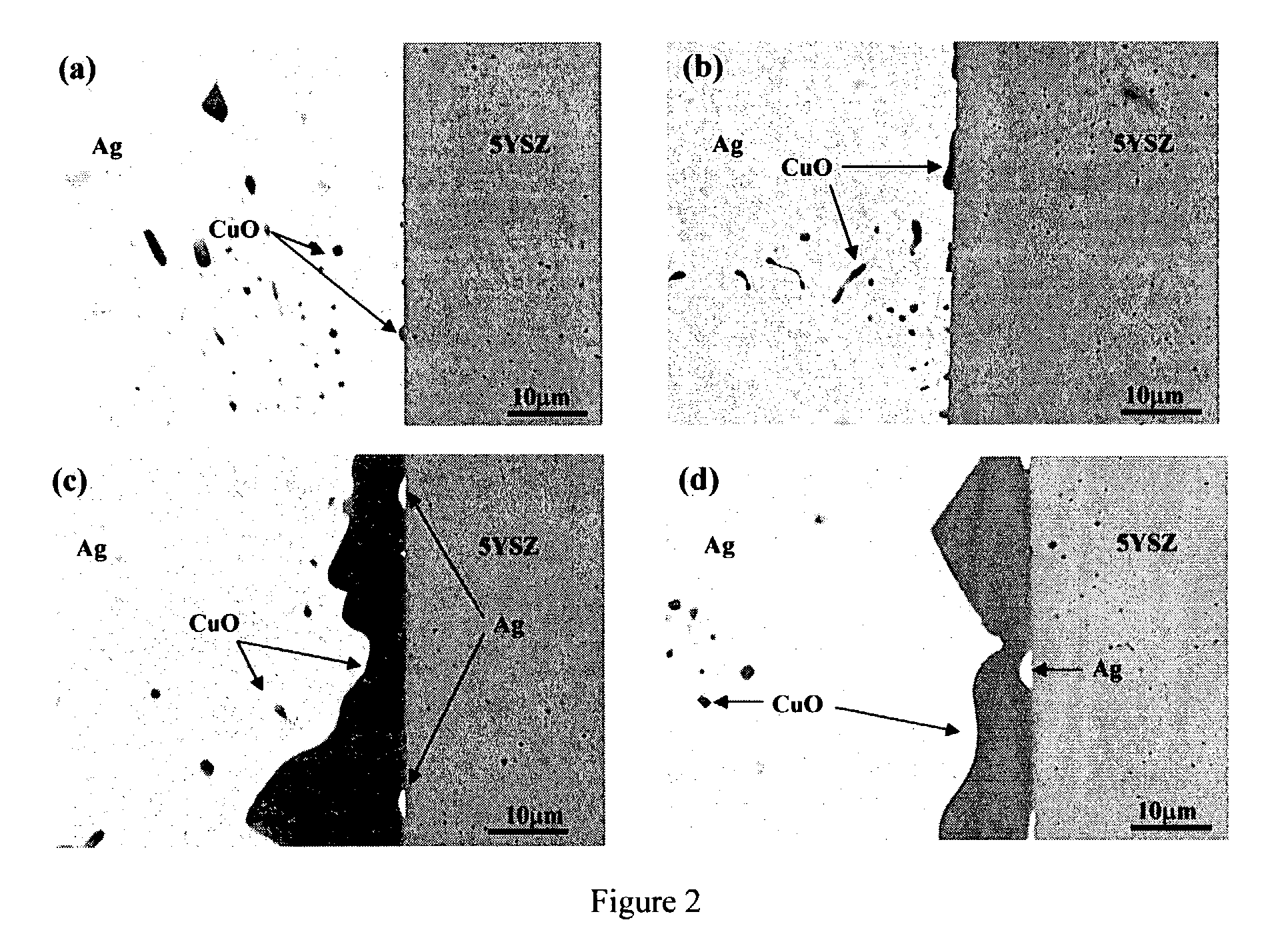

A method of joining metal and ceramic parts, wherein an alumina forming metal part and a ceramic part are provided. A braze material in placed between the alumina forming metal part and the ceramic part, and the combination is then heated in an oxidizing atmosphere, preferably in air at a temperature of between 500° C. and 1300° C. The alumina forming metal parts are selected from the group consisting of high temperature stainless steels, such as Durafoil (alpha-4), Fecralloy, Alumina-coated 430 stainless steel and Crofer-22APU, and high temperature superalloys such as Haynes 214, Nicrofer 6025, and Ducraloy. The braze material is selected as a metal oxide-noble metal mixture, preferably Ag—CuO, Ag—V2O5, and Pt—Nb2O5, and more preferably between 30.65 to 100 mole % Ag in CuO.

Owner:BATTELLE MEMORIAL INST

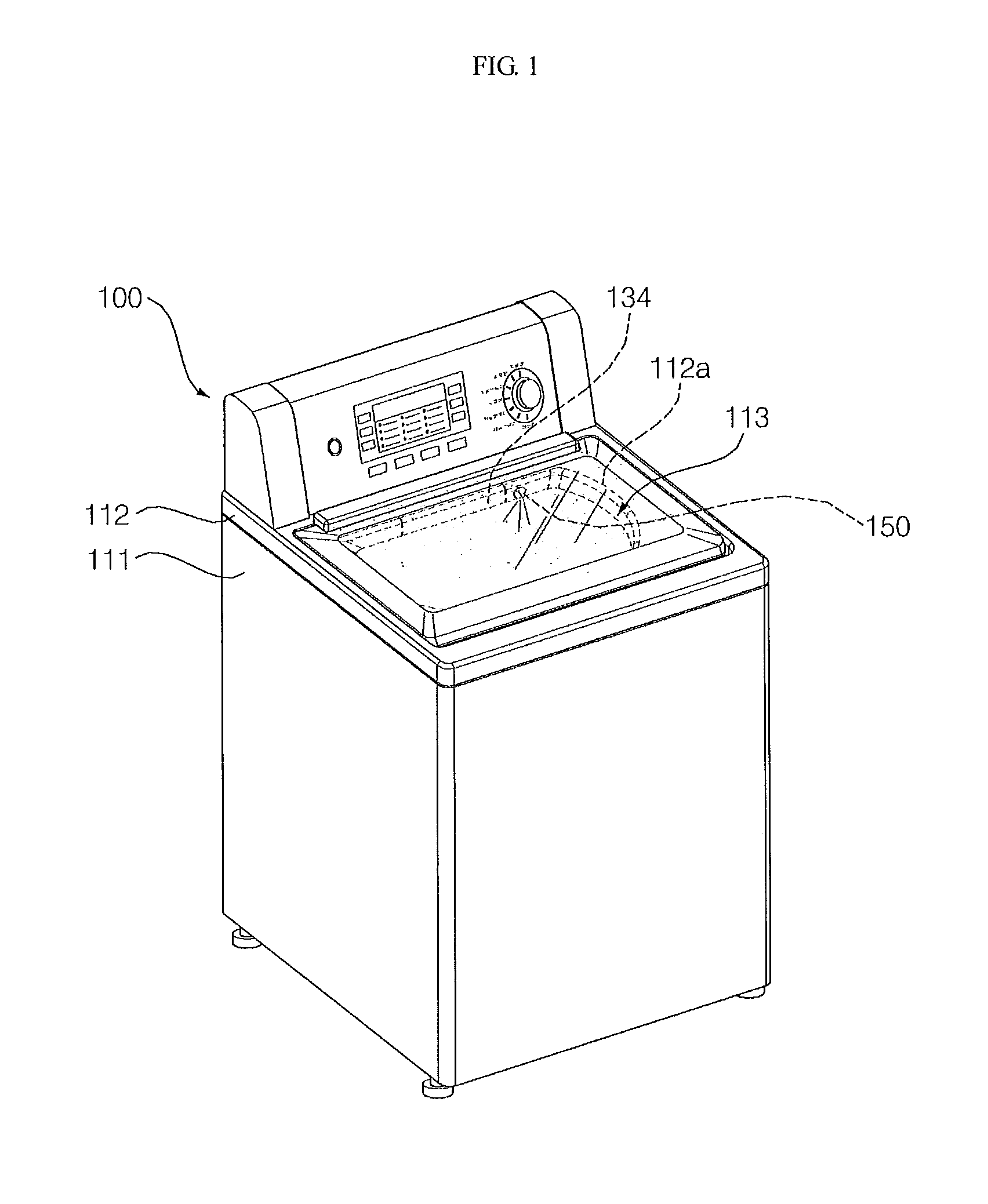

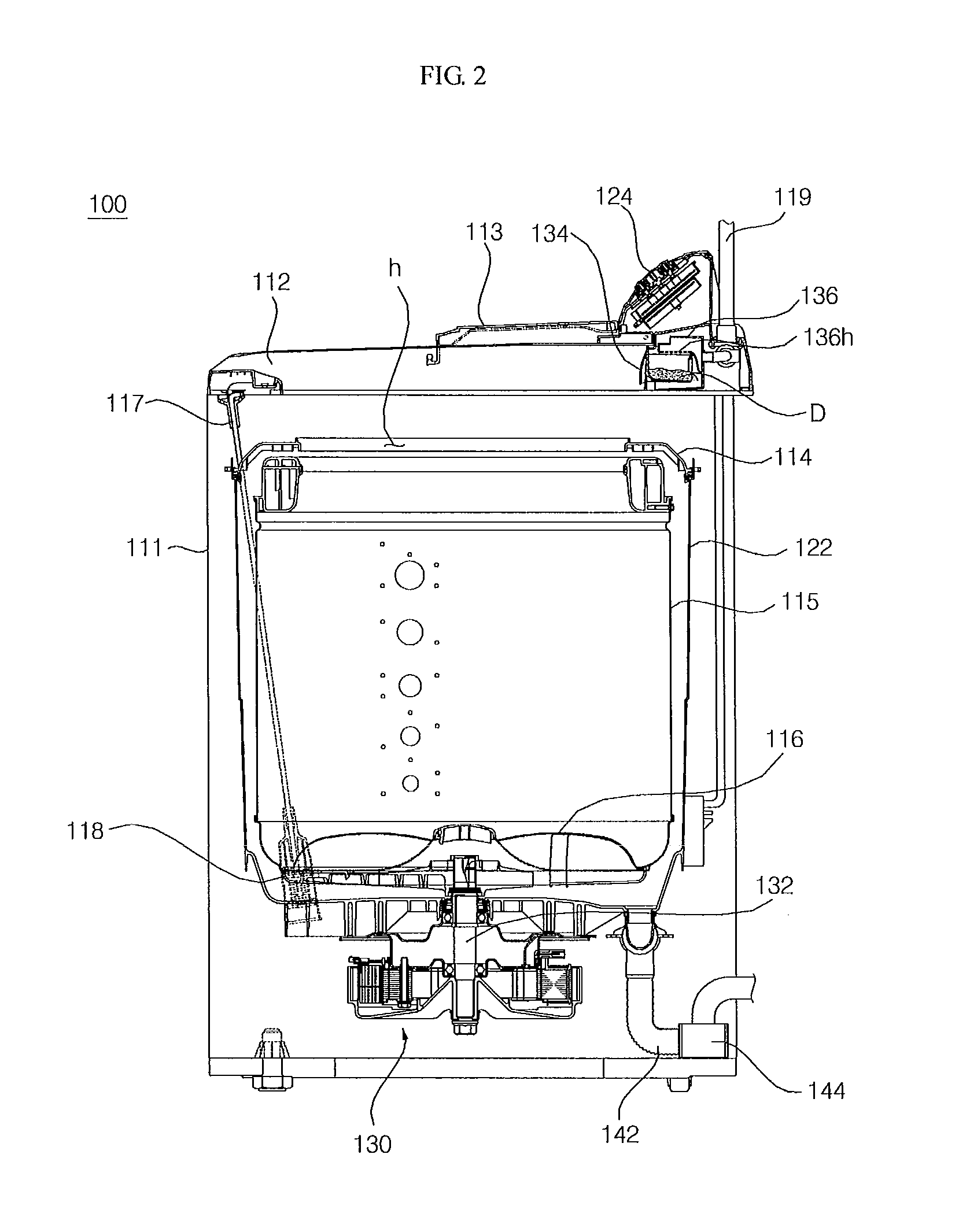

Washing machine

InactiveUS20100281927A1Spray speed be improveSpray range be secureOther washing machinesWashing machine with receptaclesSpray nozzleEngineering

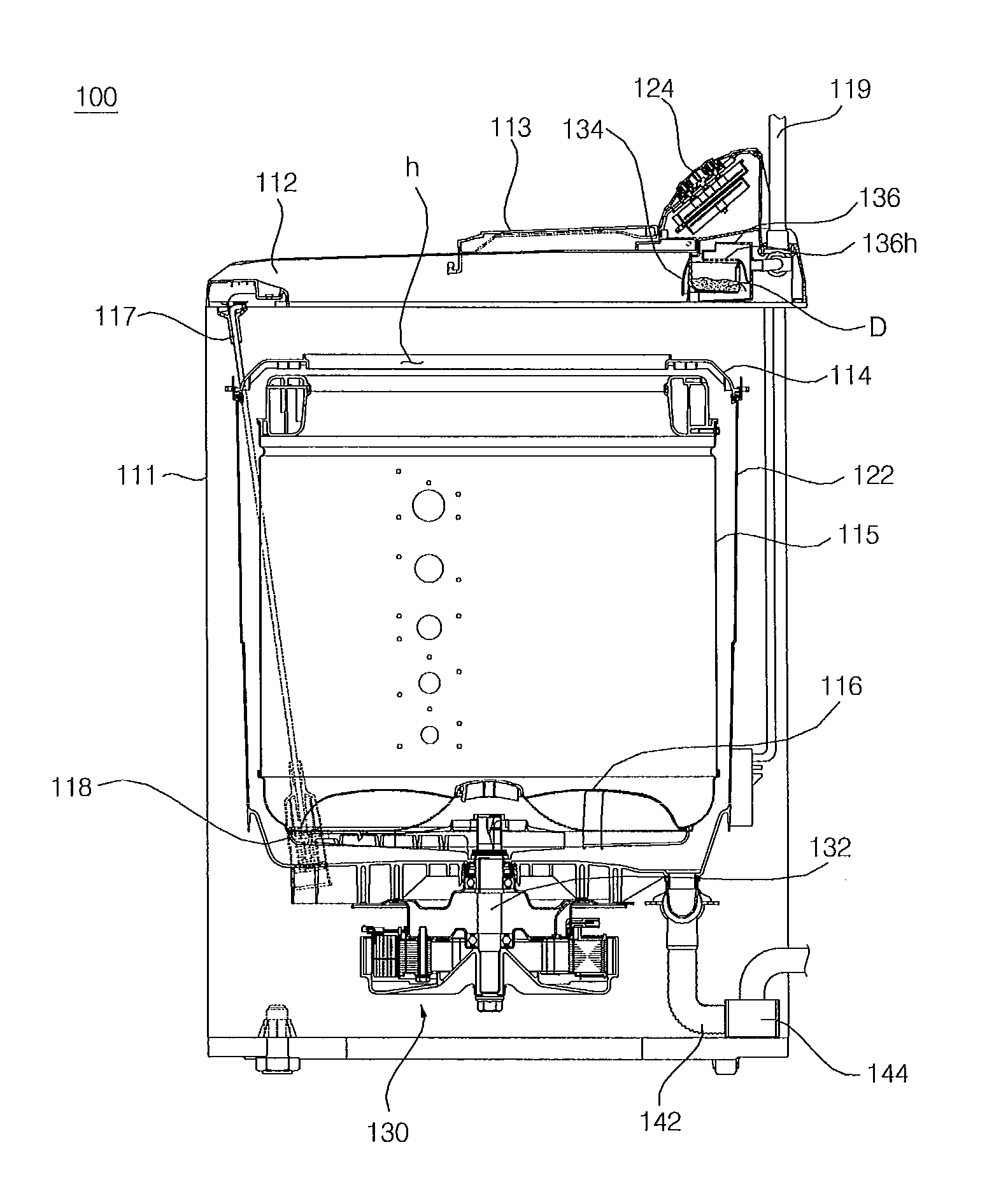

A washing machine includes: a cabinet forming an external appearance and having an open upper portion; a reservoir hanging within the cabinet and allowing washing water to be put therein; a washing tub rotatably disposed within the reservoir and accommodating the laundry; and a spray nozzle spraying washing water into the washing tub such that one boundary of sprayed washing machine reaches a side wall of the washing tub and the other boundary of the sprayed washing water reaches the bottom of the washing tub, wherein the spray nozzle includes: a tube part forming a passage along which washing water is introduced; and a spray part connected with the tube part to spray washing water and disposed such that a spray face against which washing water discharged from the tube part splashes is bent at a certain angle with respect to a discharge direction of the tube part. The laundry can be effectively wet by increasing a spray range of washing water.

Owner:LG ELECTRONICS INC

High-adhesion ultraviolet radiation polyurethane double-solidifying carpentry paint and preparation method thereof

InactiveCN101100583AImproves toughness and tensile strengthPrevent cracking of paint filmLiquid surface applicatorsPolyurea/polyurethane coatingsChemistryMagnesium silicate

A high-adhesive ultraviolet polyurethane dual curing woodenware coating consists of dual-component priming paint and finish; Priming paint A consists of polyurethane acrylic ester with -NCO group 30-50 proportion, modified nanometer silicon dioxide 10-20 proportion, superfine hydrated magnesium silicate 10-20 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion; Priming paint B consists of polyurethane acrylic ester with hydroxy-group 20-30 proportion, modified nanometer silicon dioxide 10-20 proportion, superfine hydrated magnesium silicate 10-20 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion; Finish consists of polyurethane acrylic ester 10-30 proportion, epoxy-acrylic ester 10-30 proportion, modified nanometer silicon dioxide 10-30 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion. It has better coating adhesion, mechanical strength and abrasive resistance. It can be used to coat large-area oily woods.

Owner:CHANGZHOU GUANGHUI CHEM +2

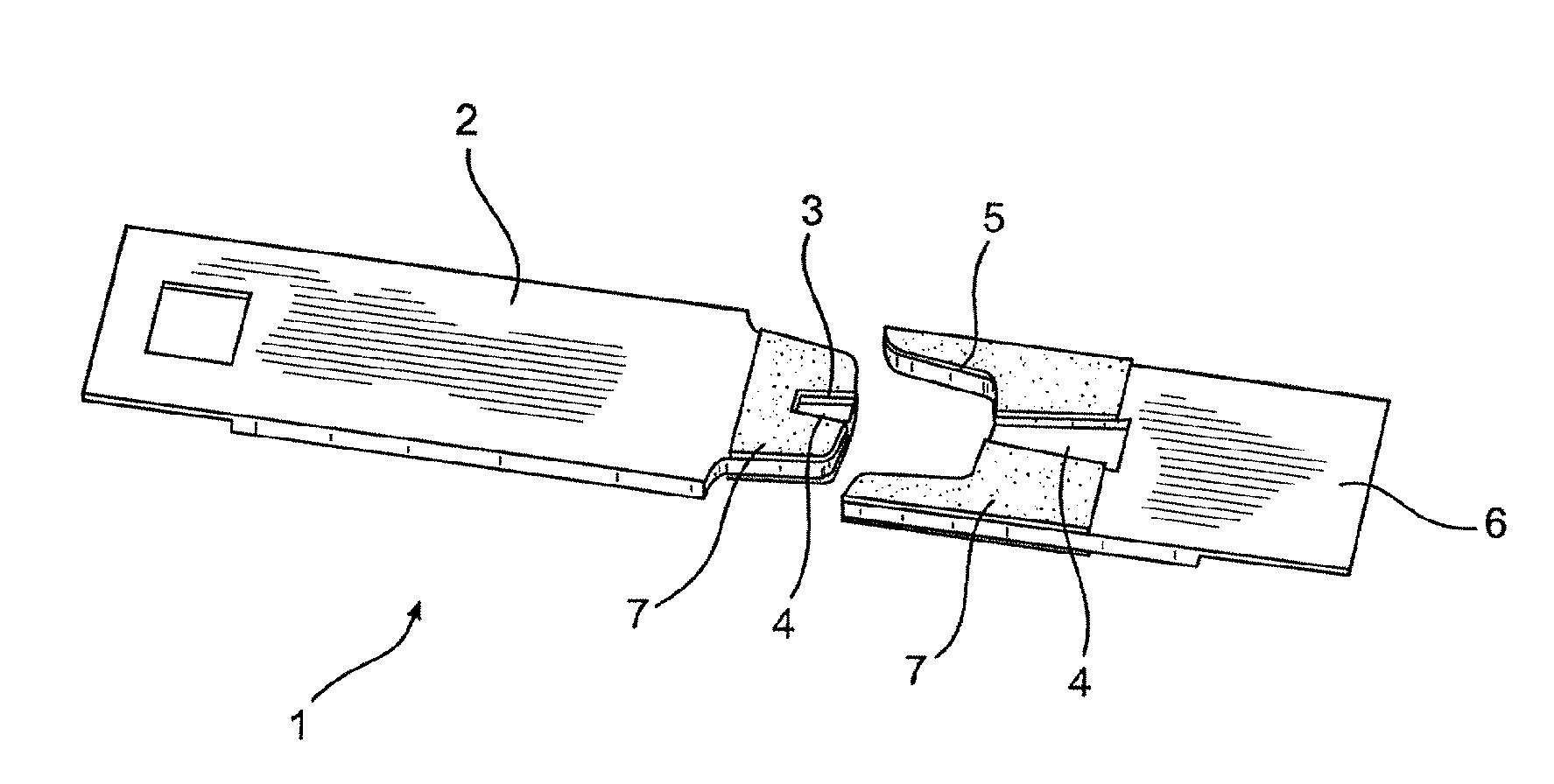

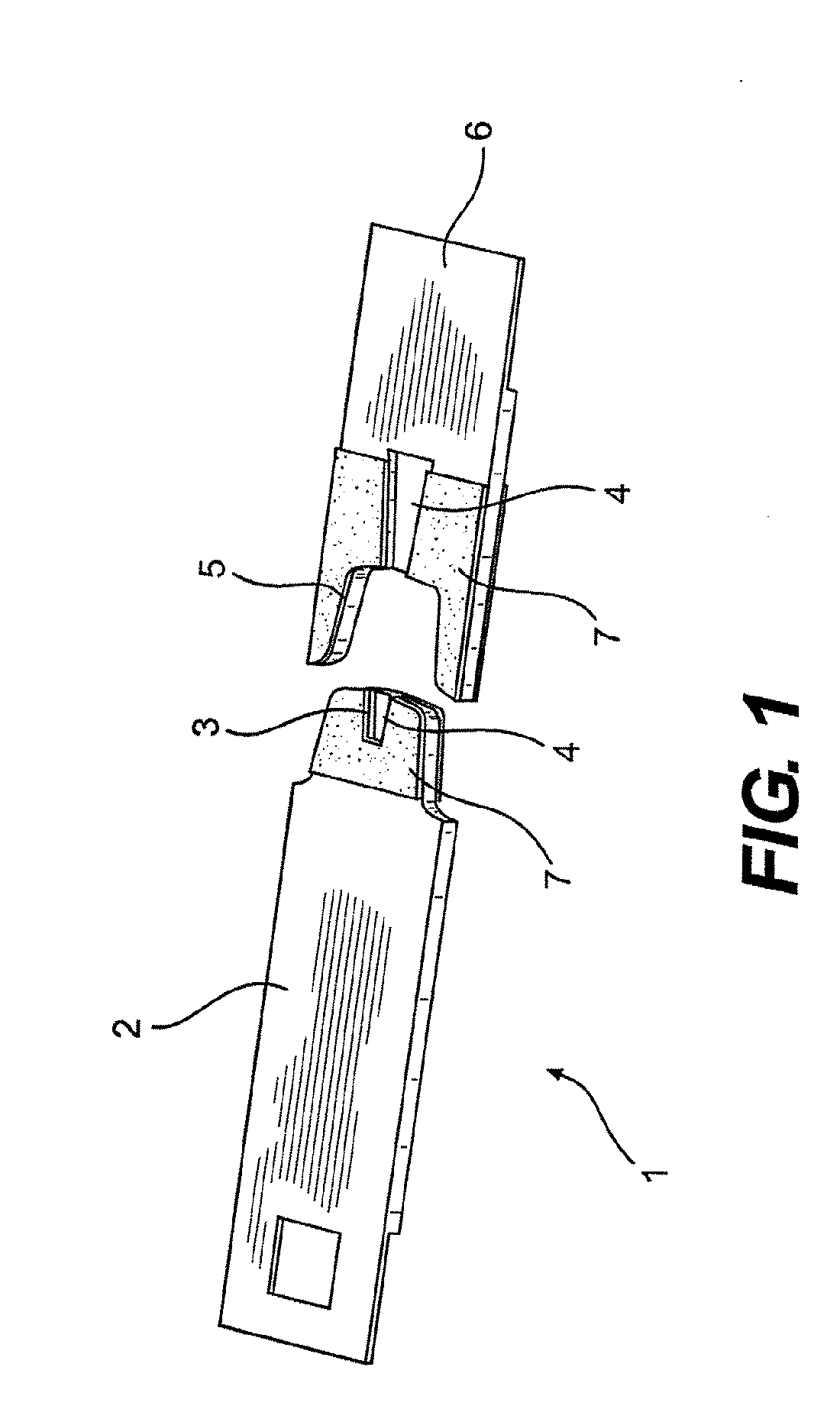

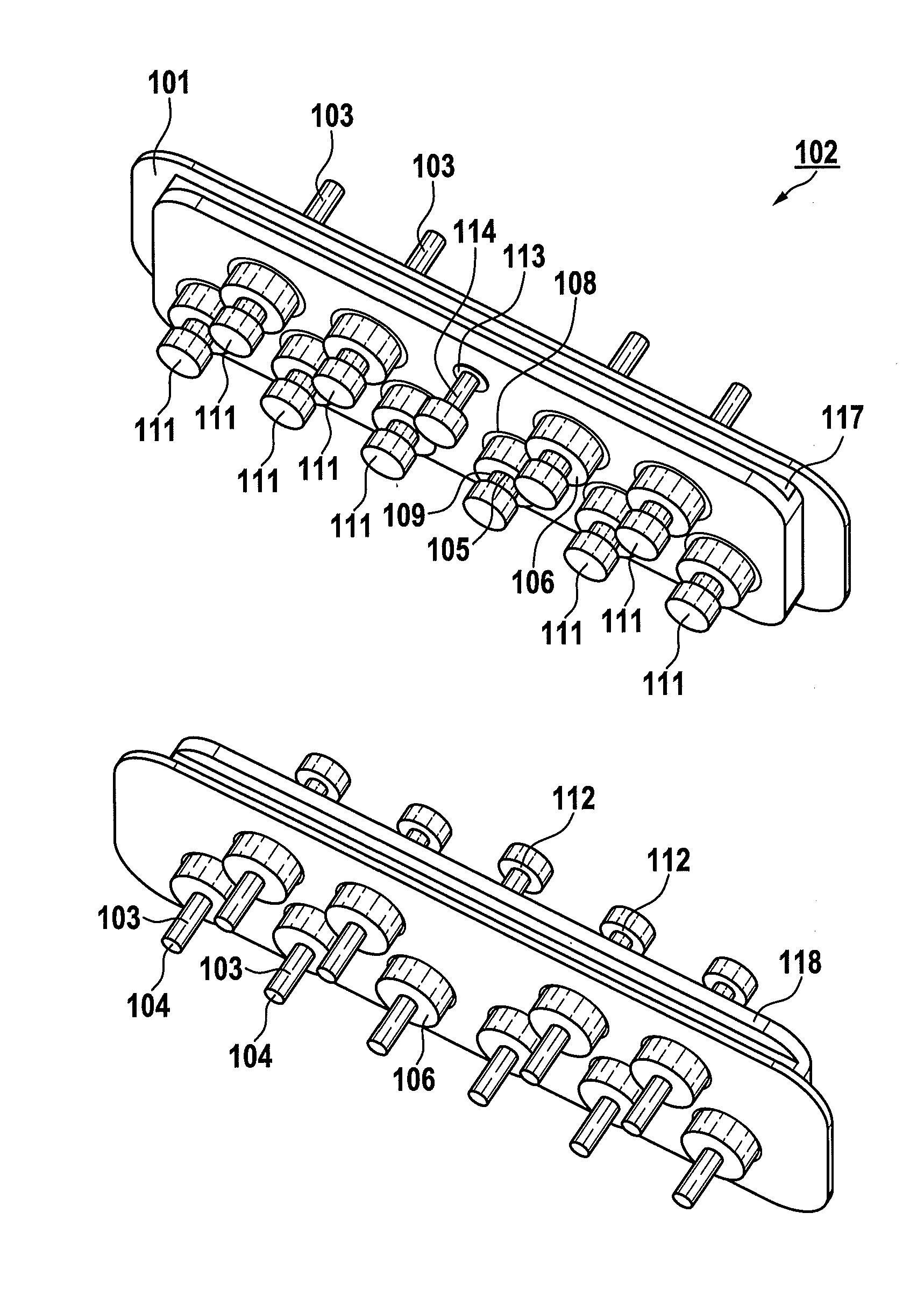

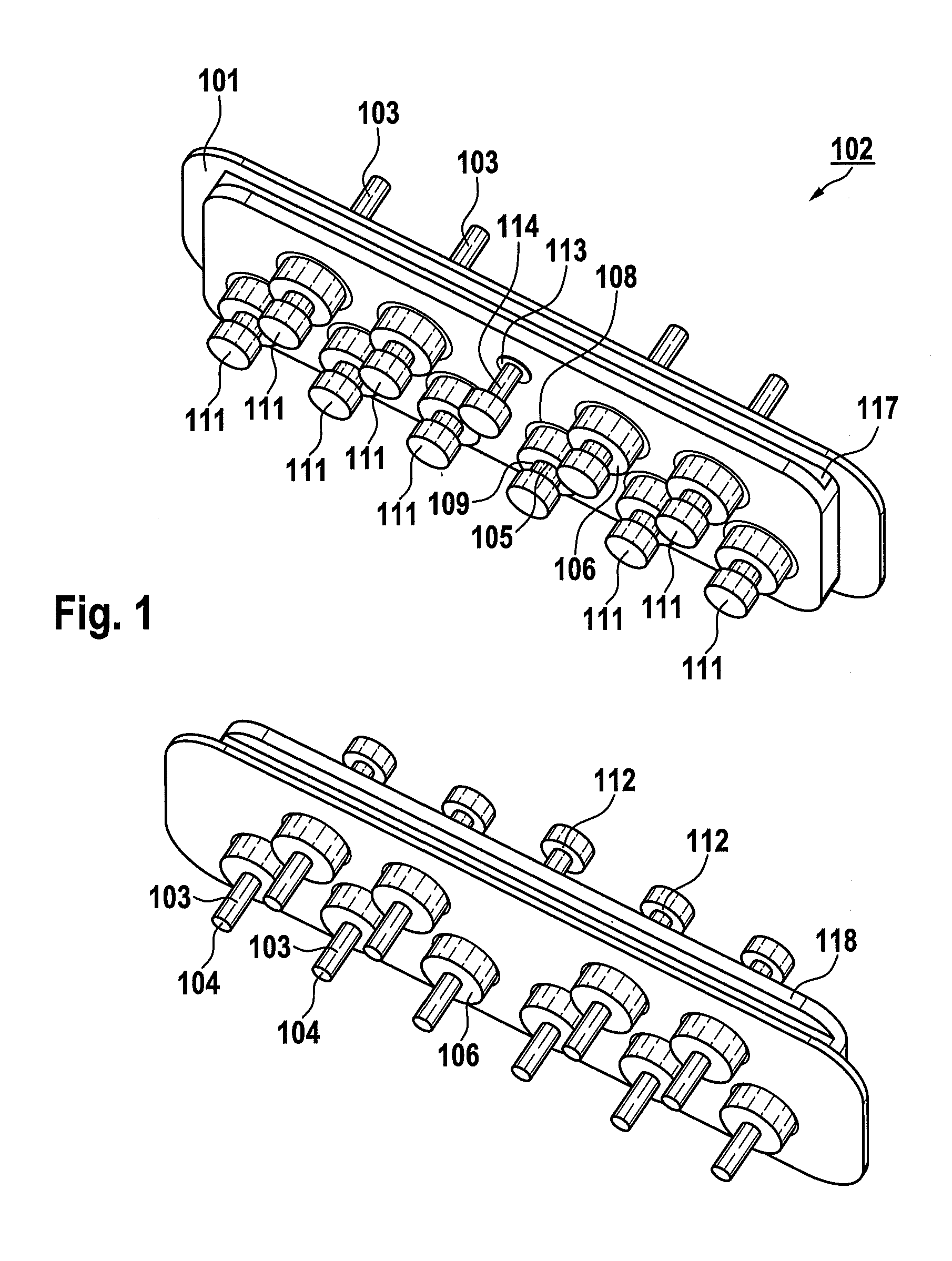

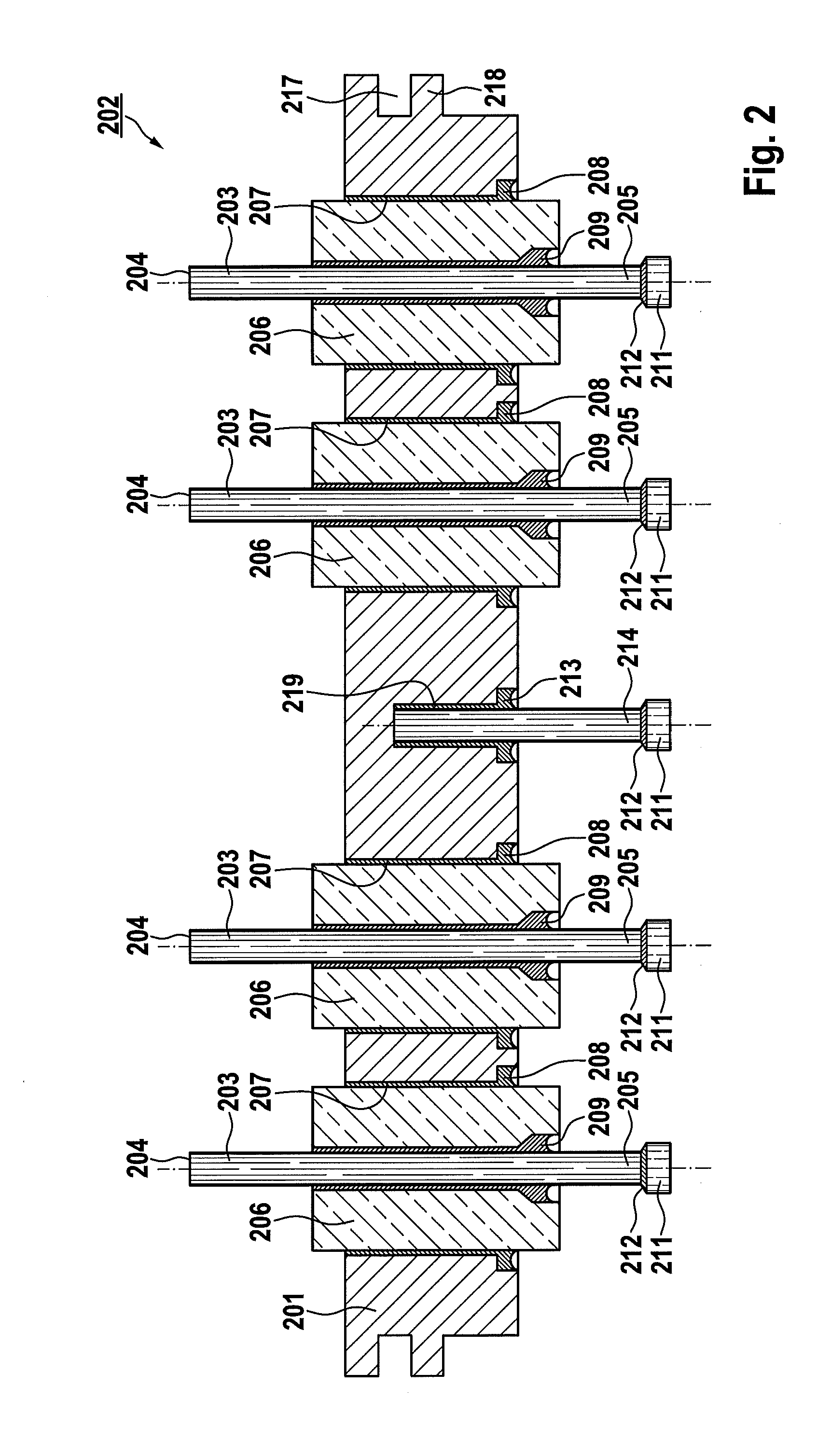

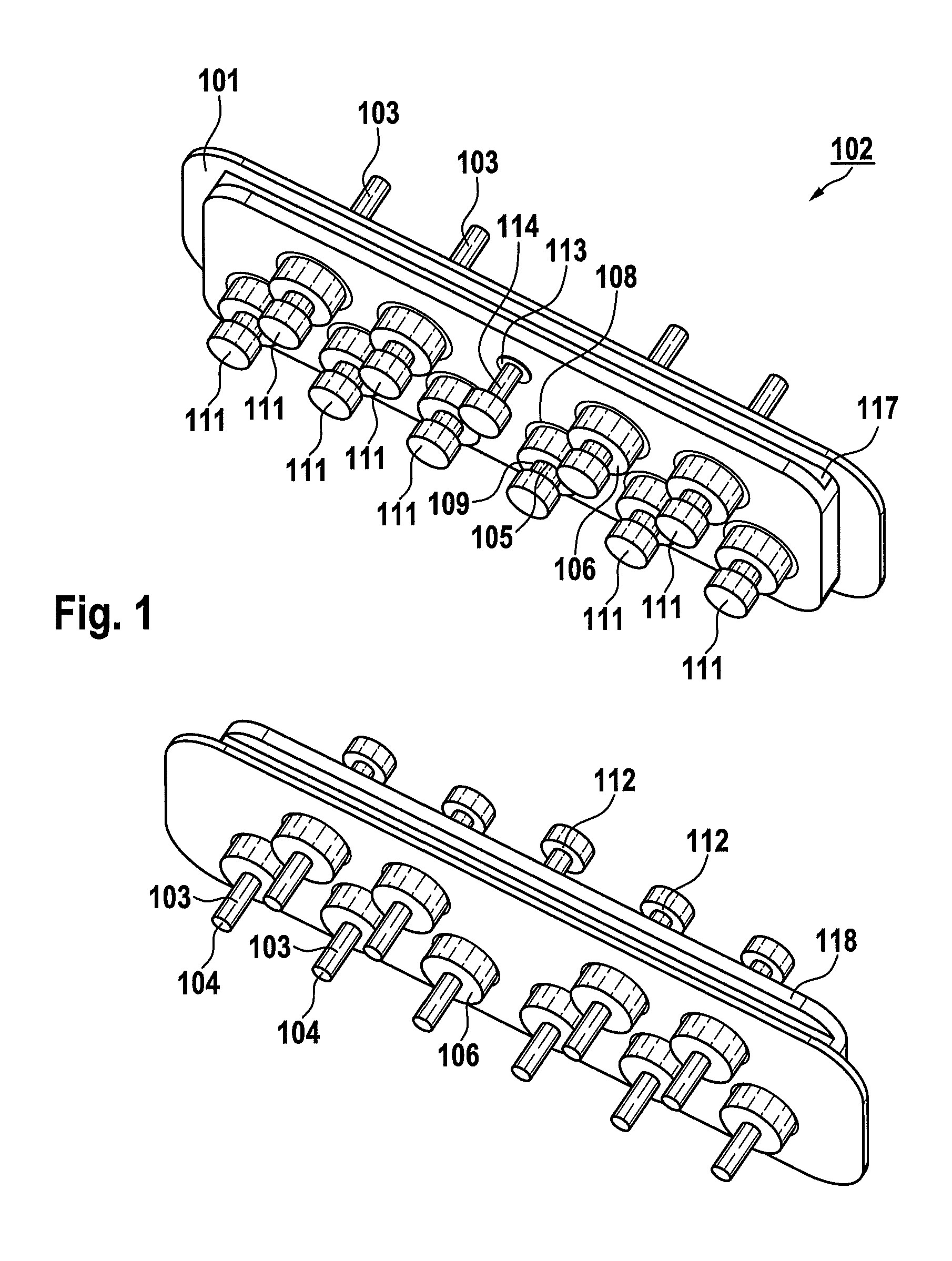

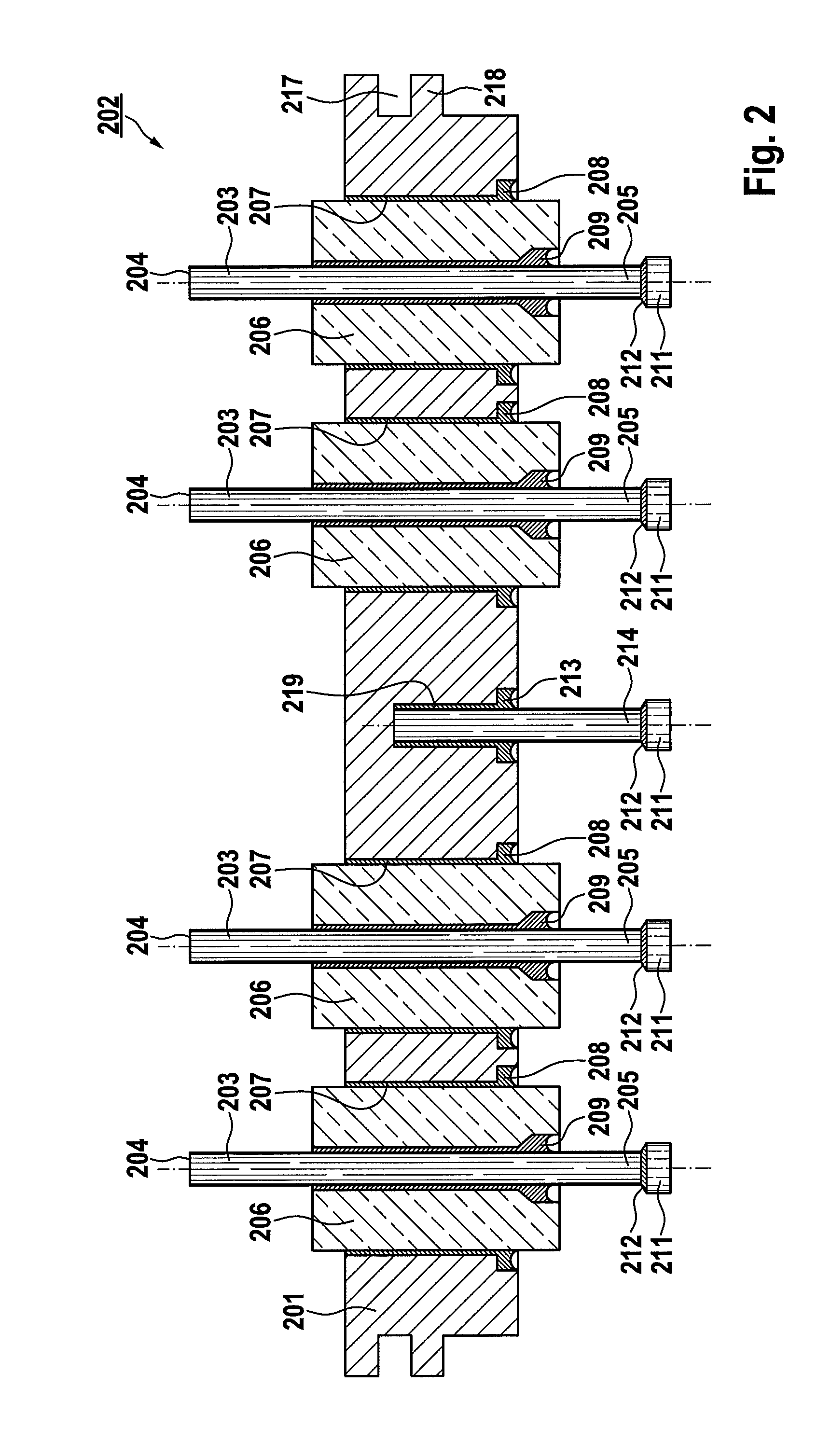

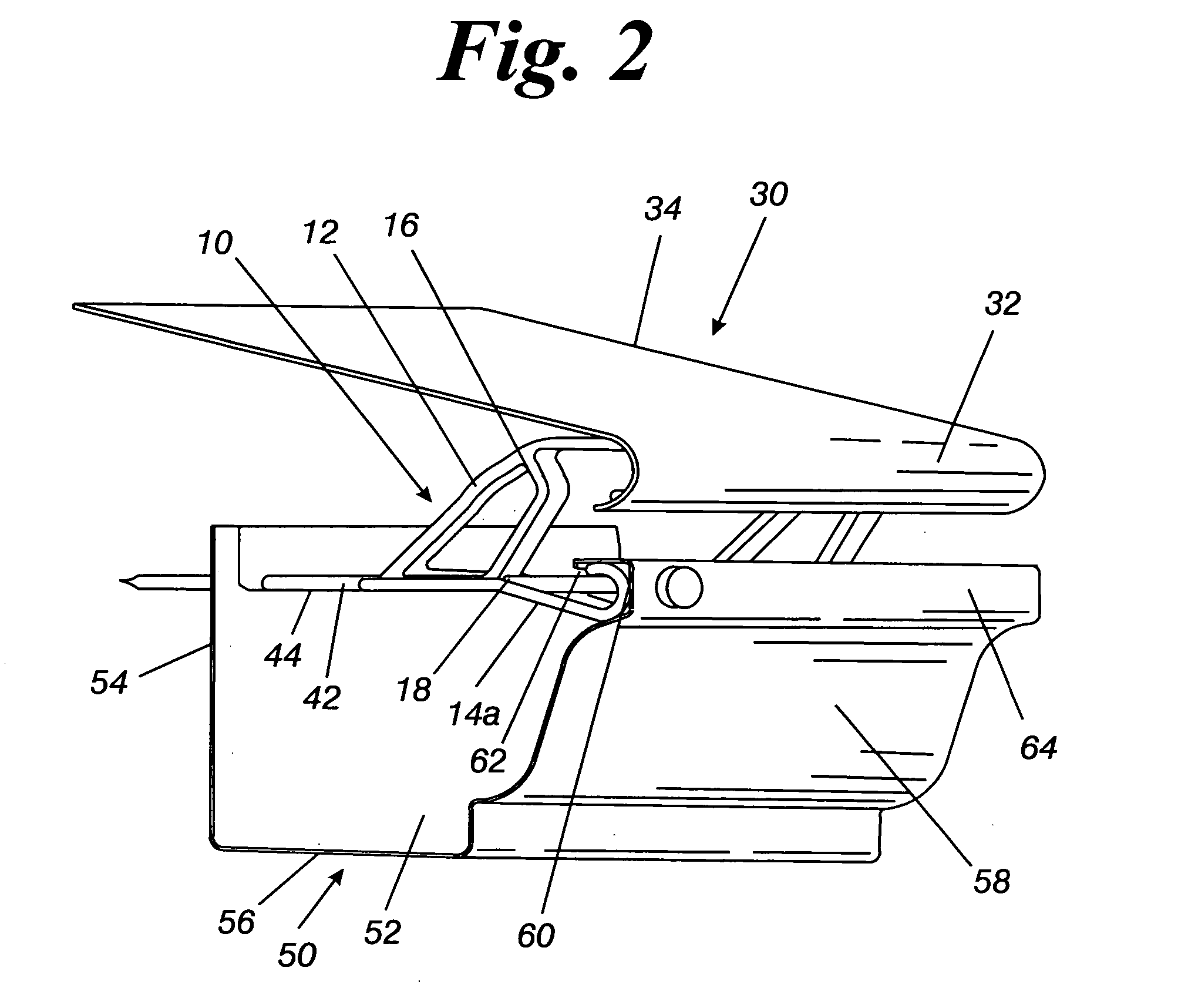

Electrical Feedthrough, in Particular for Medical Implants

ActiveUS20110232961A1Improve carrying capacityFirmly connectedAnti-noise capacitorsElectrotherapyBiomedical engineeringMedical treatment

An electrical feedthrough, in particular for use in an electro-medical implant, having a flange enclosing at least one feedthrough bushing and at least one terminal pin enclosed by the at least one feedthrough bushing, the terminal pin having at least one section which can be joined at a lower energy in the interior of the implant.

Owner:BIOTRONIK SE & CO KG

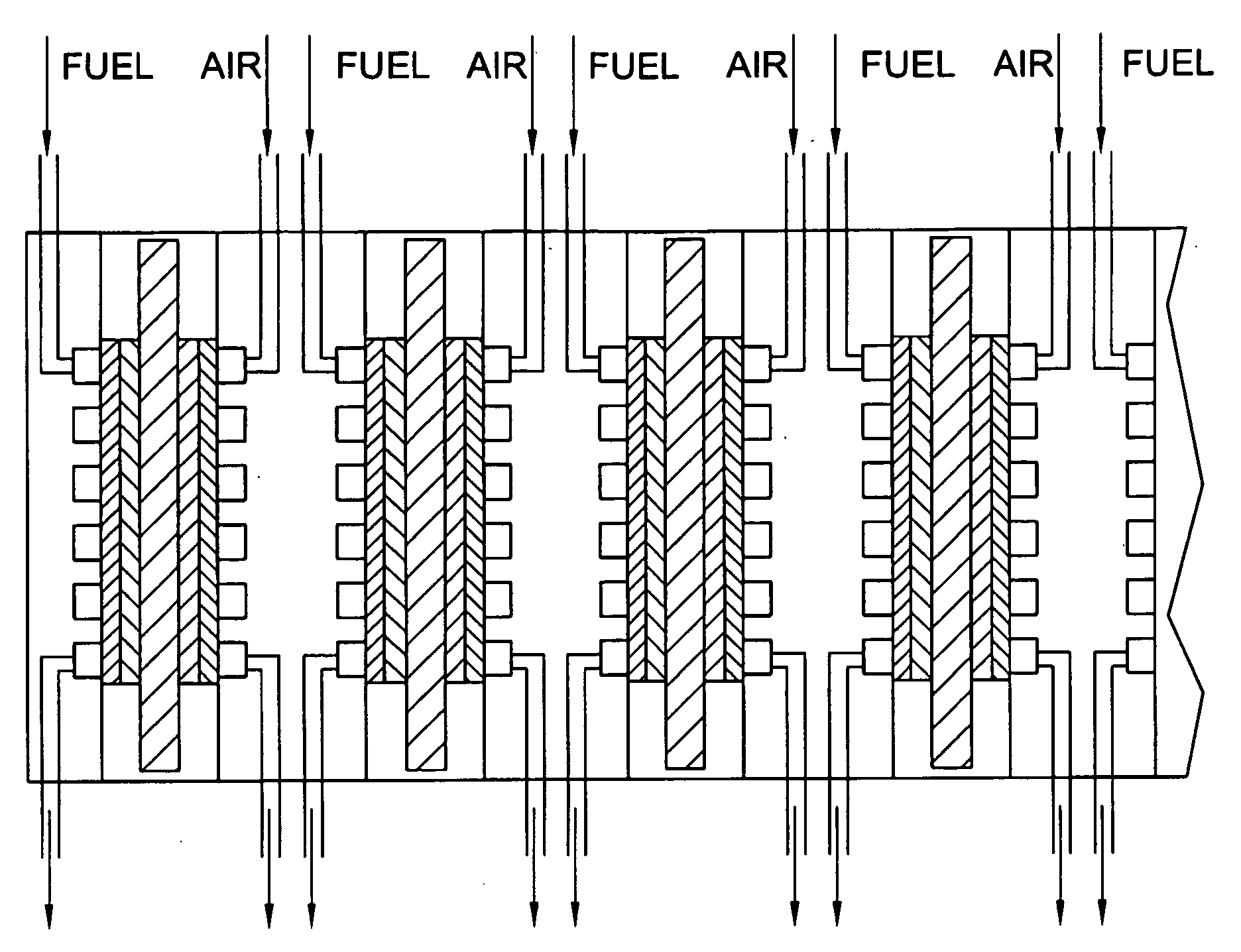

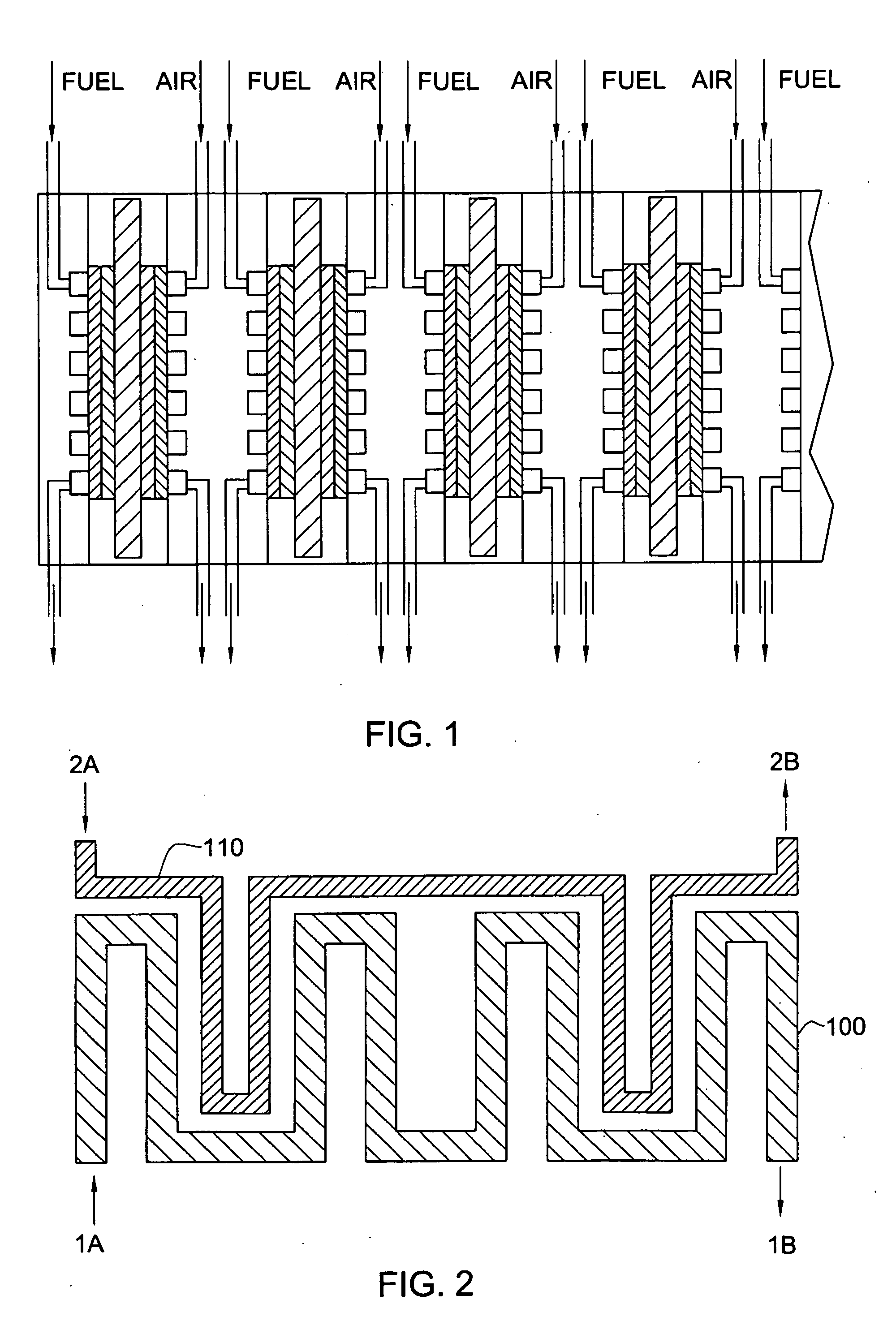

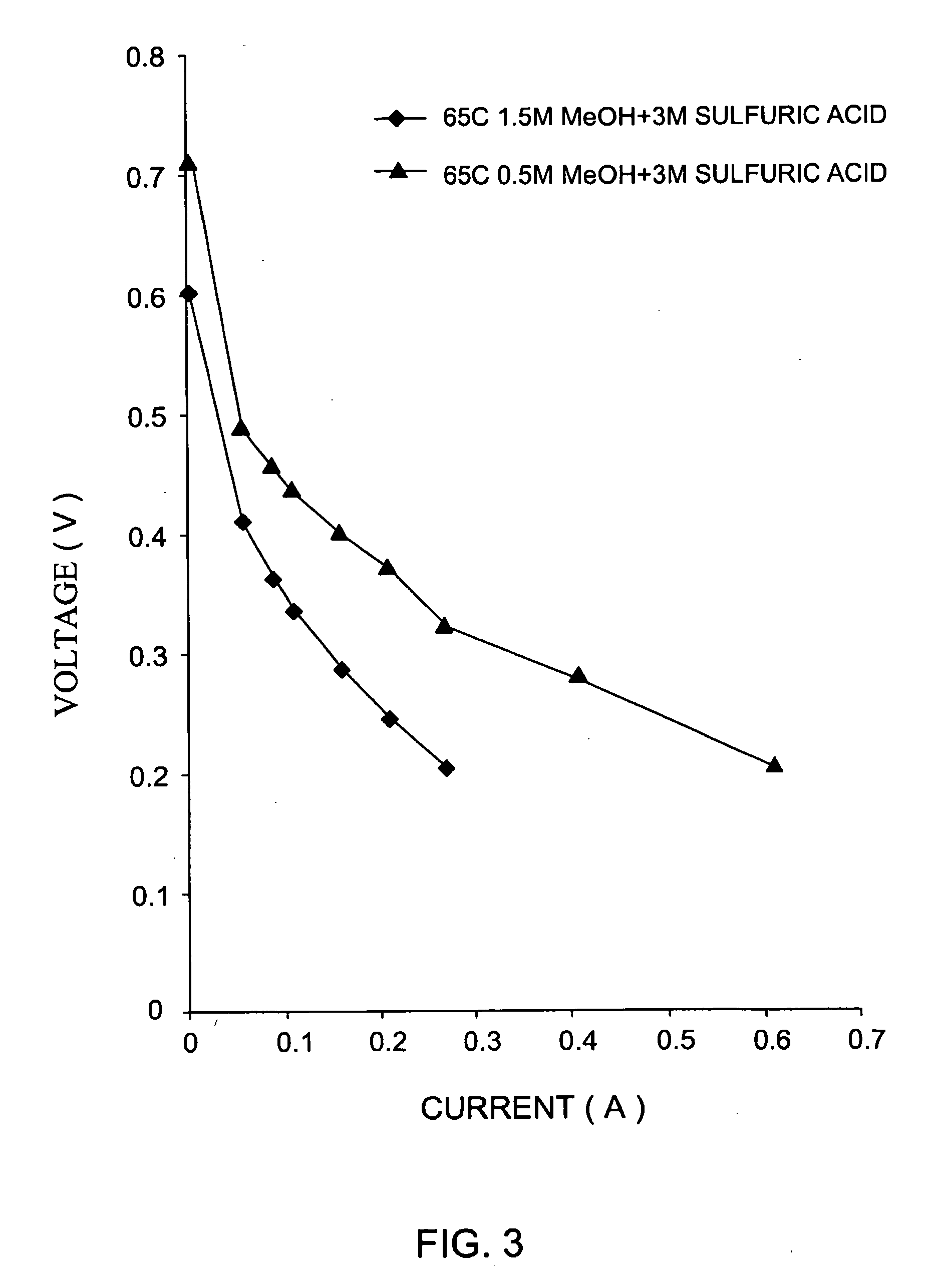

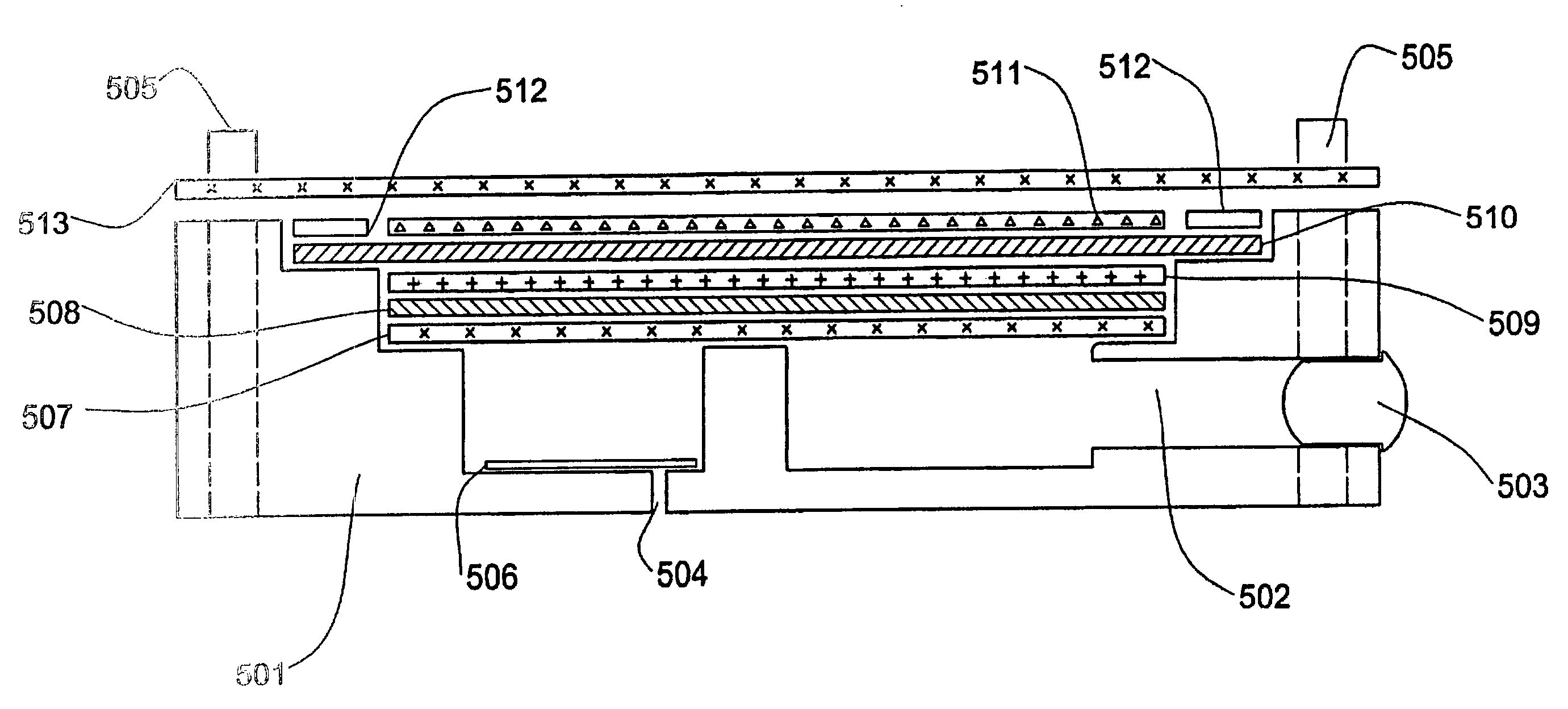

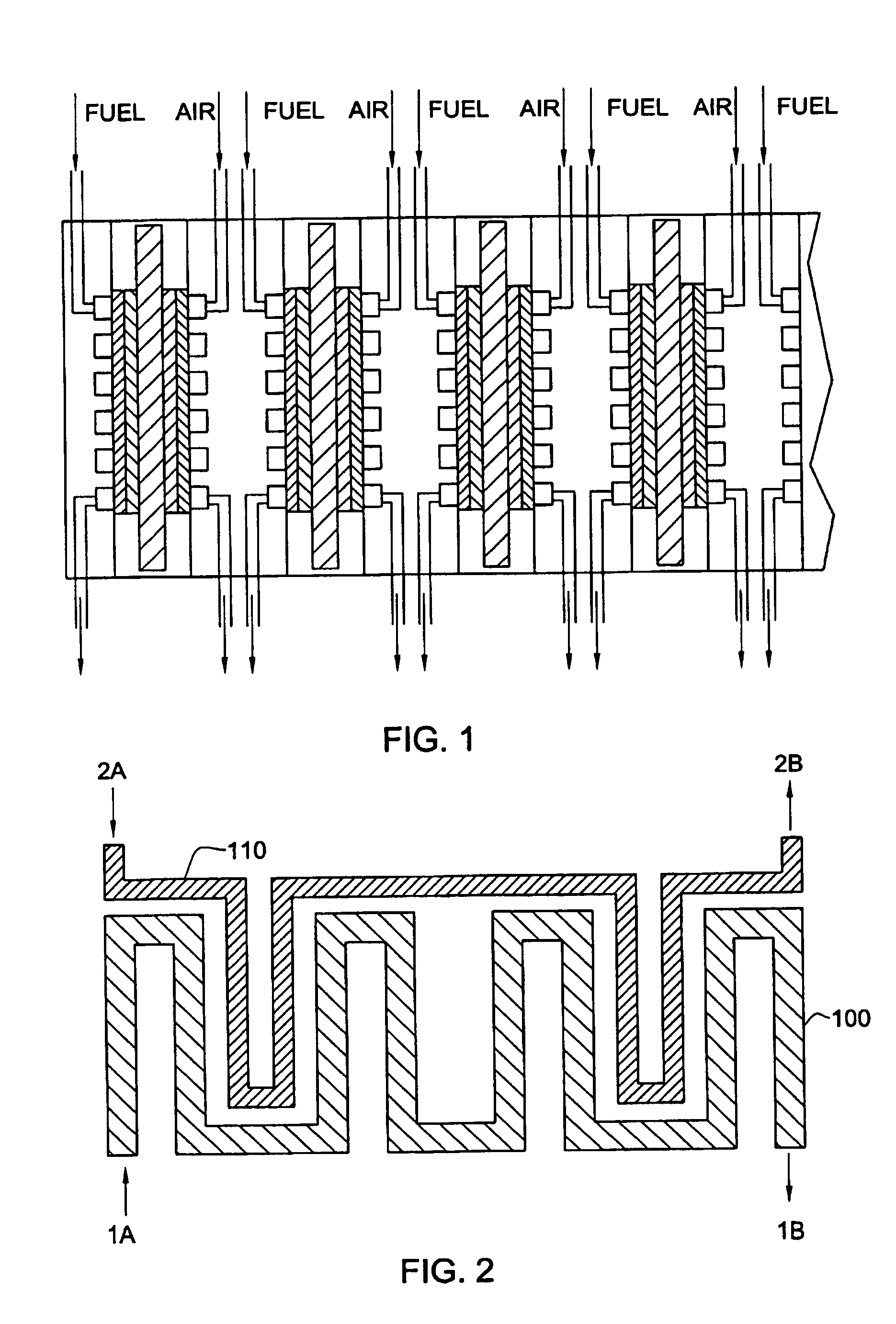

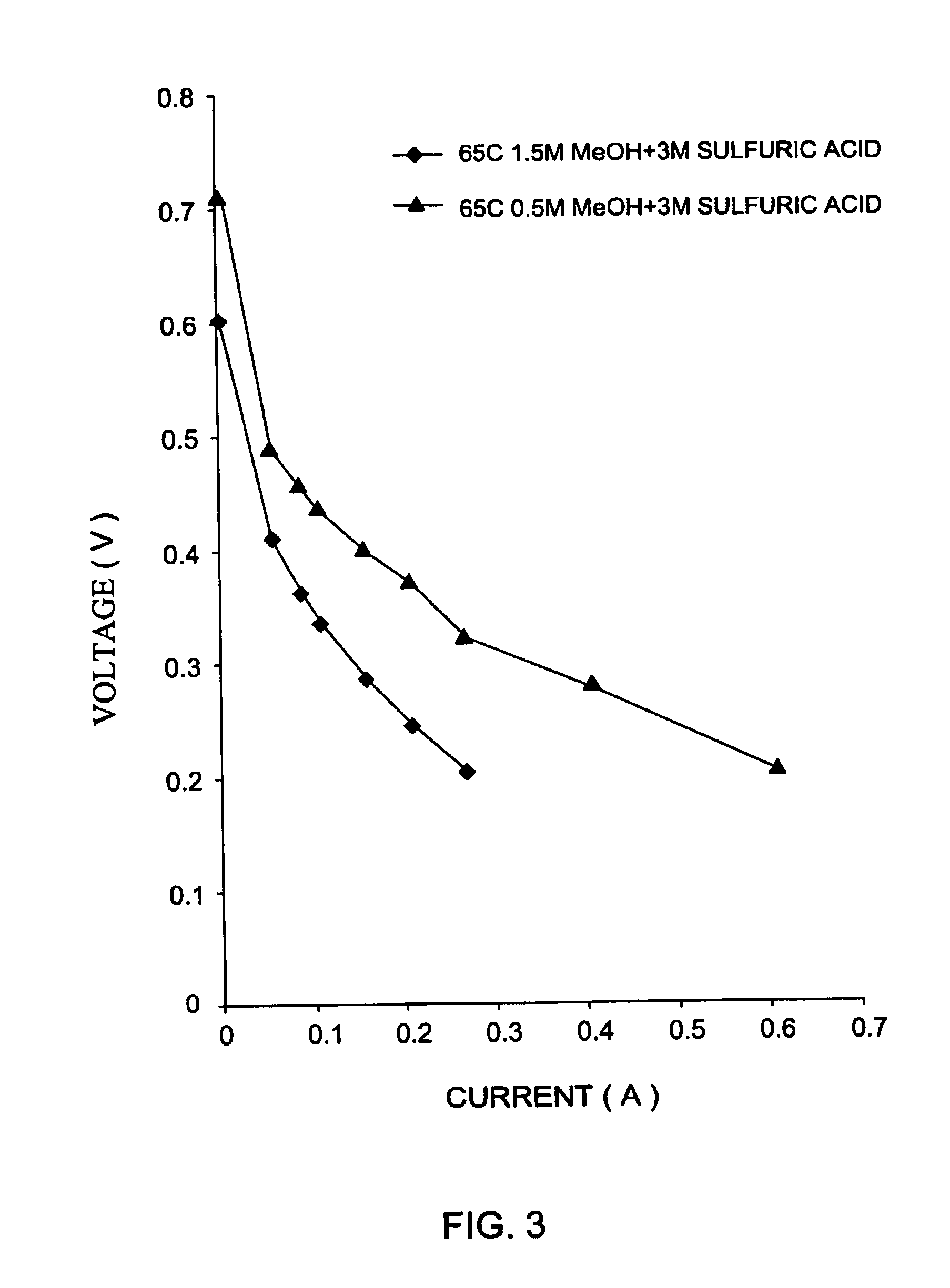

Fuel cell with proton conducting membrane

InactiveUS20080241629A1Reducing and avoiding needImprove performanceElectrolyte holding meansFuel cells groupingFuel cellsPtru catalyst

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

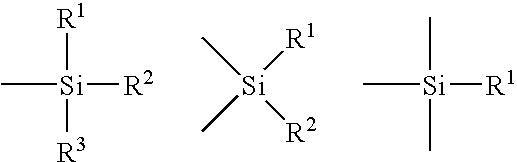

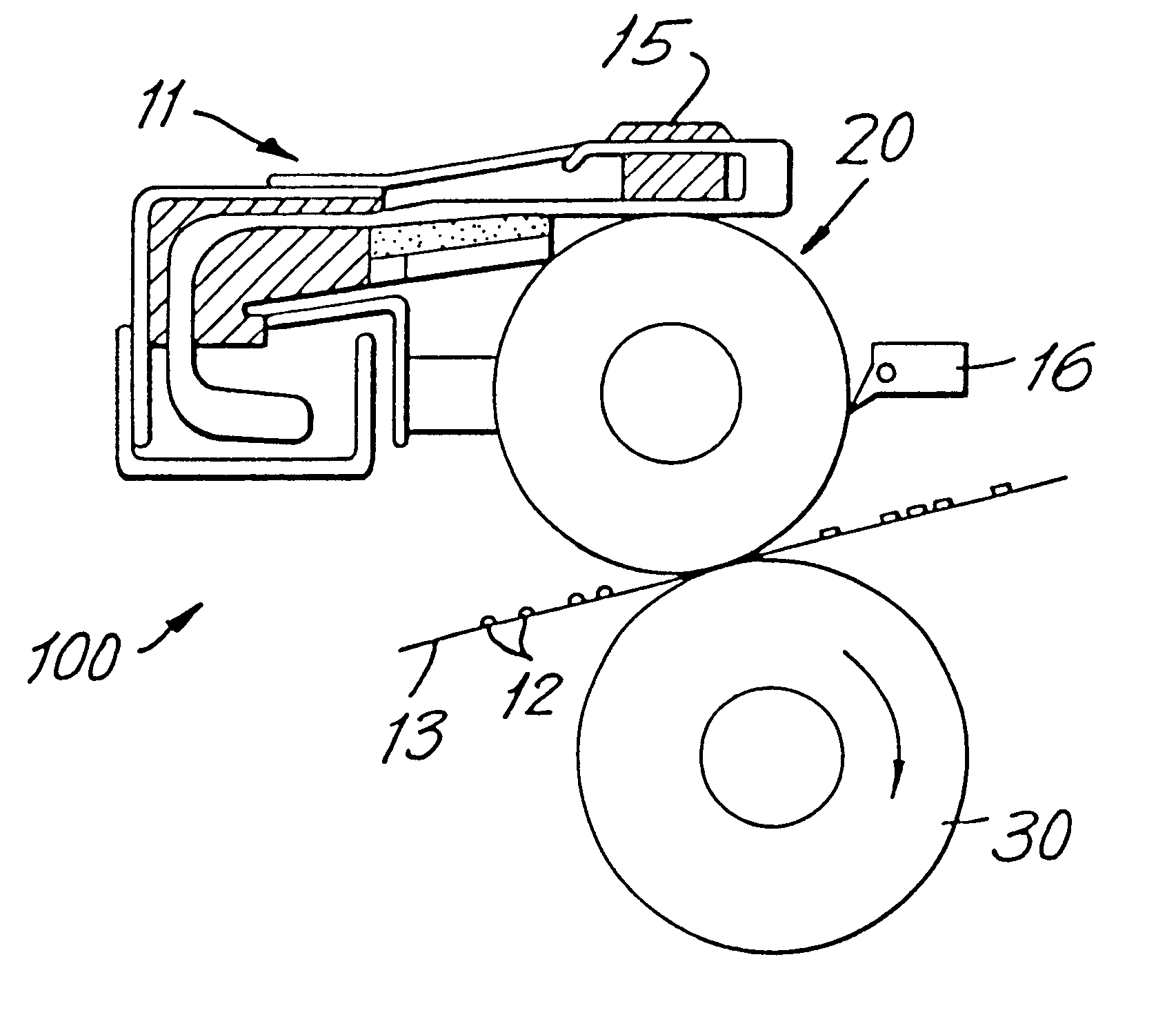

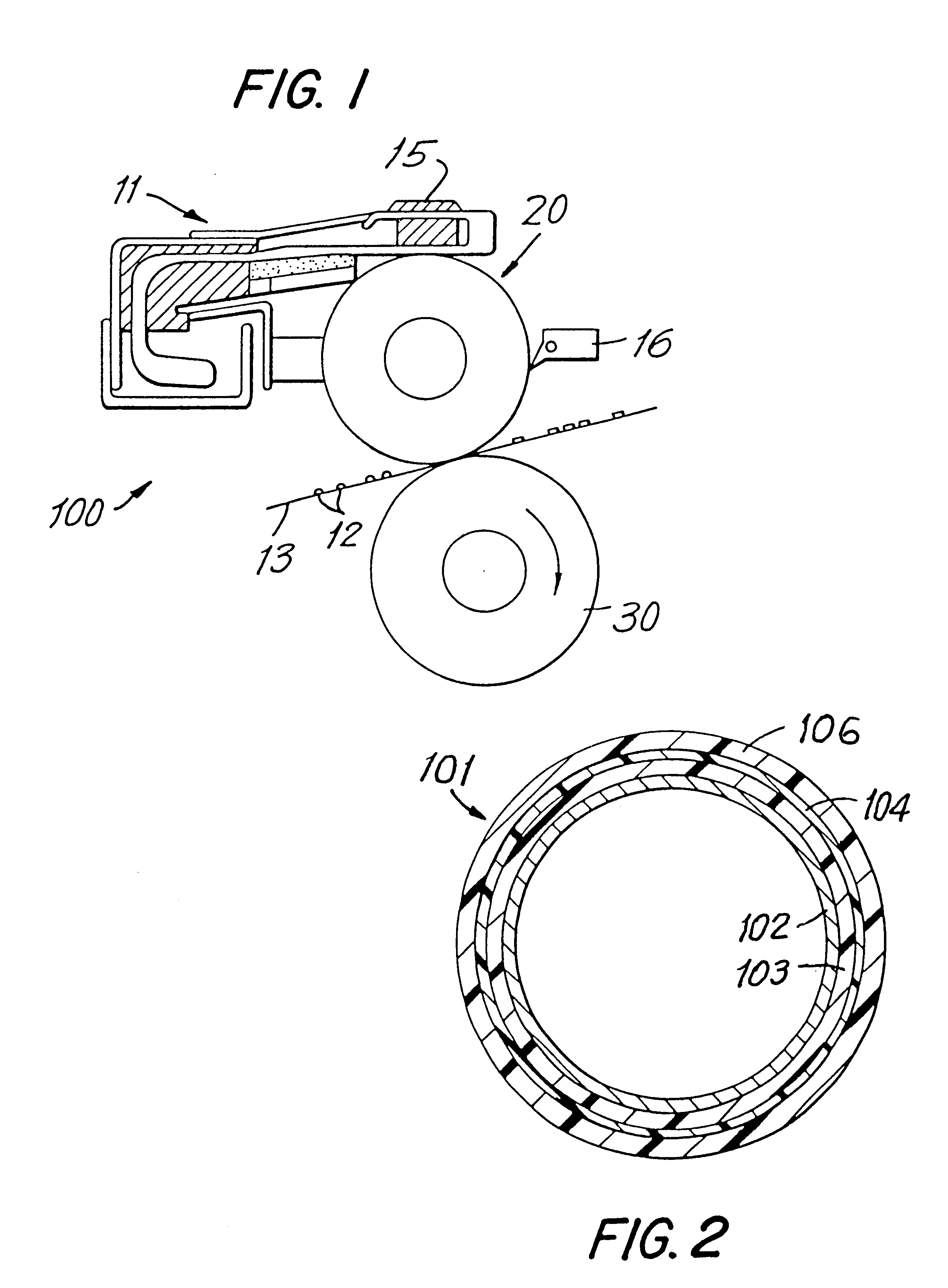

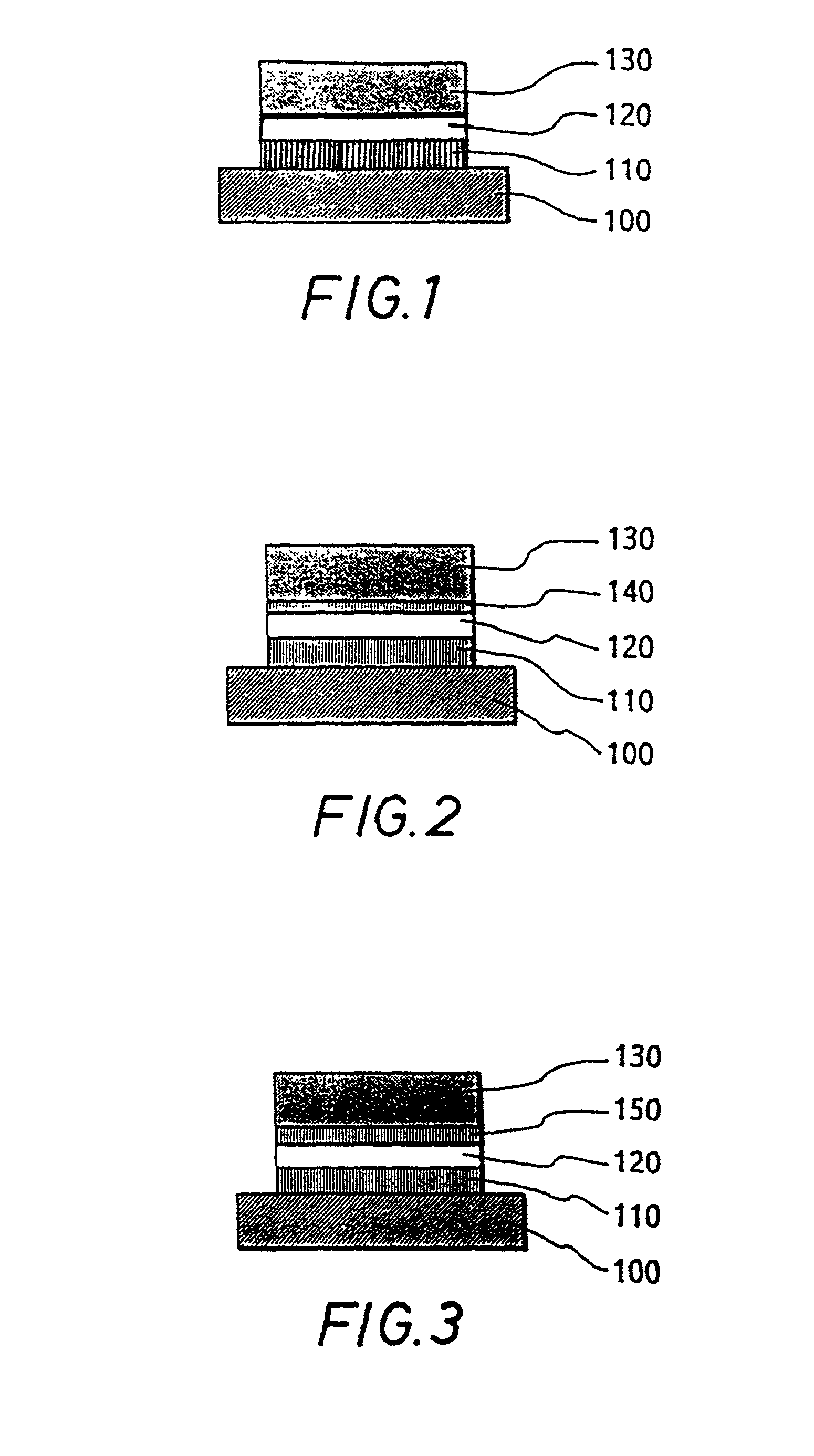

Multilayer fuser rolls having fluoropolymer coating on a compliant baselayer and method of forming

InactiveUS6596357B1Easy to wetAvoid insufficient bondingSynthetic resin layered productsFlexible pipesPolymer scienceSilanes

A fuser member for fixing toner to a recording medium having a fluoropolymer non-stick topcoat on a compliant silicone rubber baselayer bonded to a metallic insert is provided. The fluoropolymer is adhered to the silicone rubber baselayer using a primer of a blend of silane and a polyamide resin. The primed silicone baselayer is preheated in an infrared oven to remove low molecular weight fractions. A primer is applied to the prebaked rubber and completely dried before applying the fluoroelastomer topcoat by spraying,

Owner:AMES RUBBER CORP +1

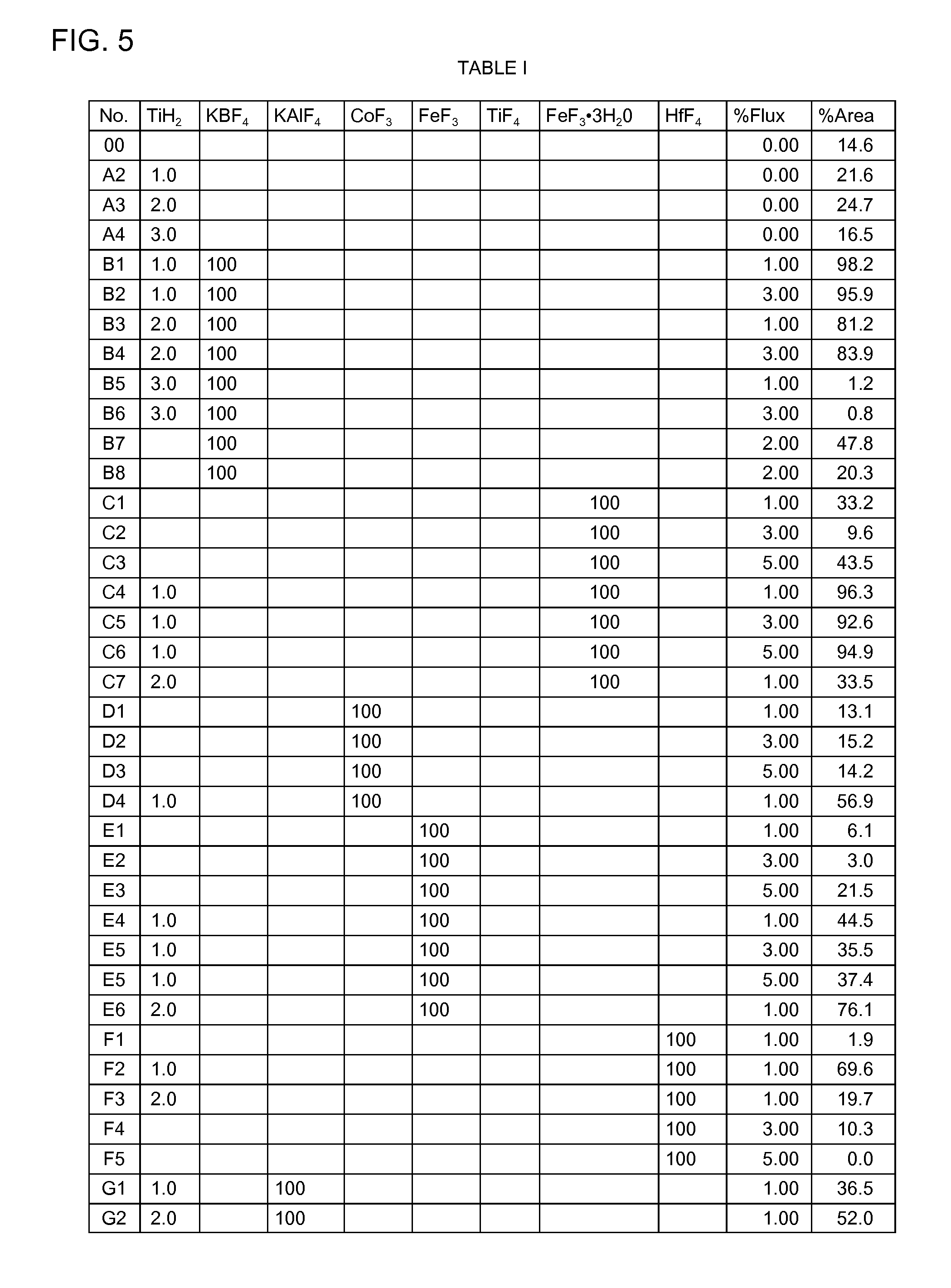

Braze compositions and methods of use

InactiveUS20090139607A1Easy to movePromoting brazingFurnace typesWelding/cutting media/materialsInorganic compoundBraze alloy

Braze compositions containing flux compositions and processes for using such braze compositions, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze composition contains an aqueous binder system, multiple inorganic compounds, titanium hydride, and a metallic braze alloy. The braze composition is useful when brazing superalloys that are prone to oxidation at elevated brazing temperatures.

Owner:GENERAL ELECTRIC CO

Direct oxidation fuel cell with a divided fuel tank having a movable barrier pressurized by anode effluent gas

InactiveUS7413824B2Reducing and avoiding needImprove performanceElectrolyte holding meansWater management in fuel cellsFuel cellsFuel tank

The present invention provides improved, low-cost fuel cells having reduced fuel crossover, reduced sensitivity to metal ion impurities and ability to operate under a broad range of temperatures. The invention further provides improved methods for catalyst preparation and a new integrated flow field system for use in H2 / O2 fuel cells.

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

Electrical feedthrough, in particular for medical implants

ActiveUS8536468B2Easy to manufactureWeaken energyAnti-noise capacitorsElectrotherapyBiomedical engineeringMedical treatment

An electrical feedthrough, in particular for use in an electro-medical implant, having a flange enclosing at least one feedthrough bushing and at least one terminal pin enclosed by the at least one feedthrough bushing, the terminal pin having at least one section which can be joined at a lower energy in the interior of the implant.

Owner:BIOTRONIK SE & CO KG

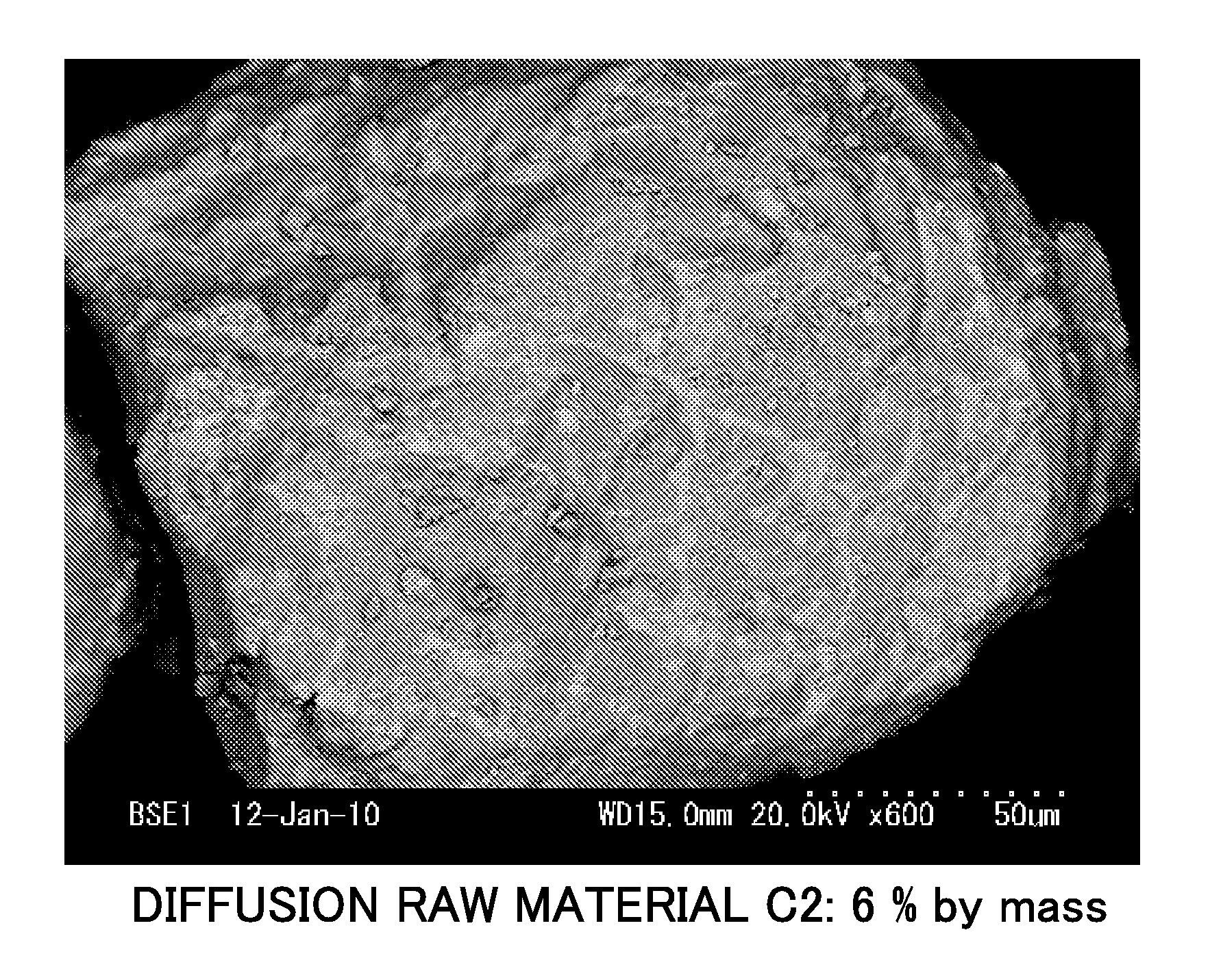

Anisotropic rare earth magnet powder, method for producing the same, and bonded magnet

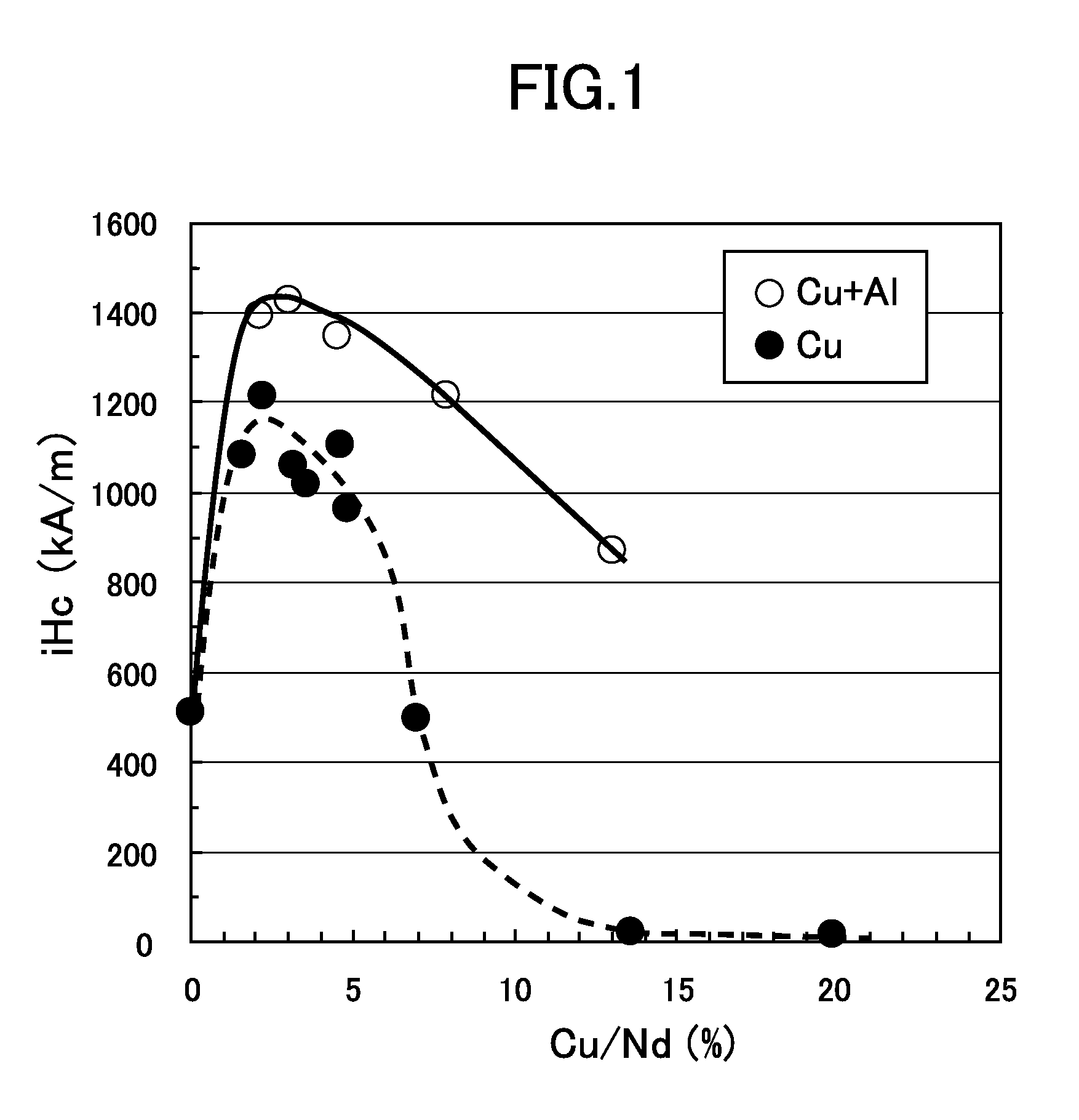

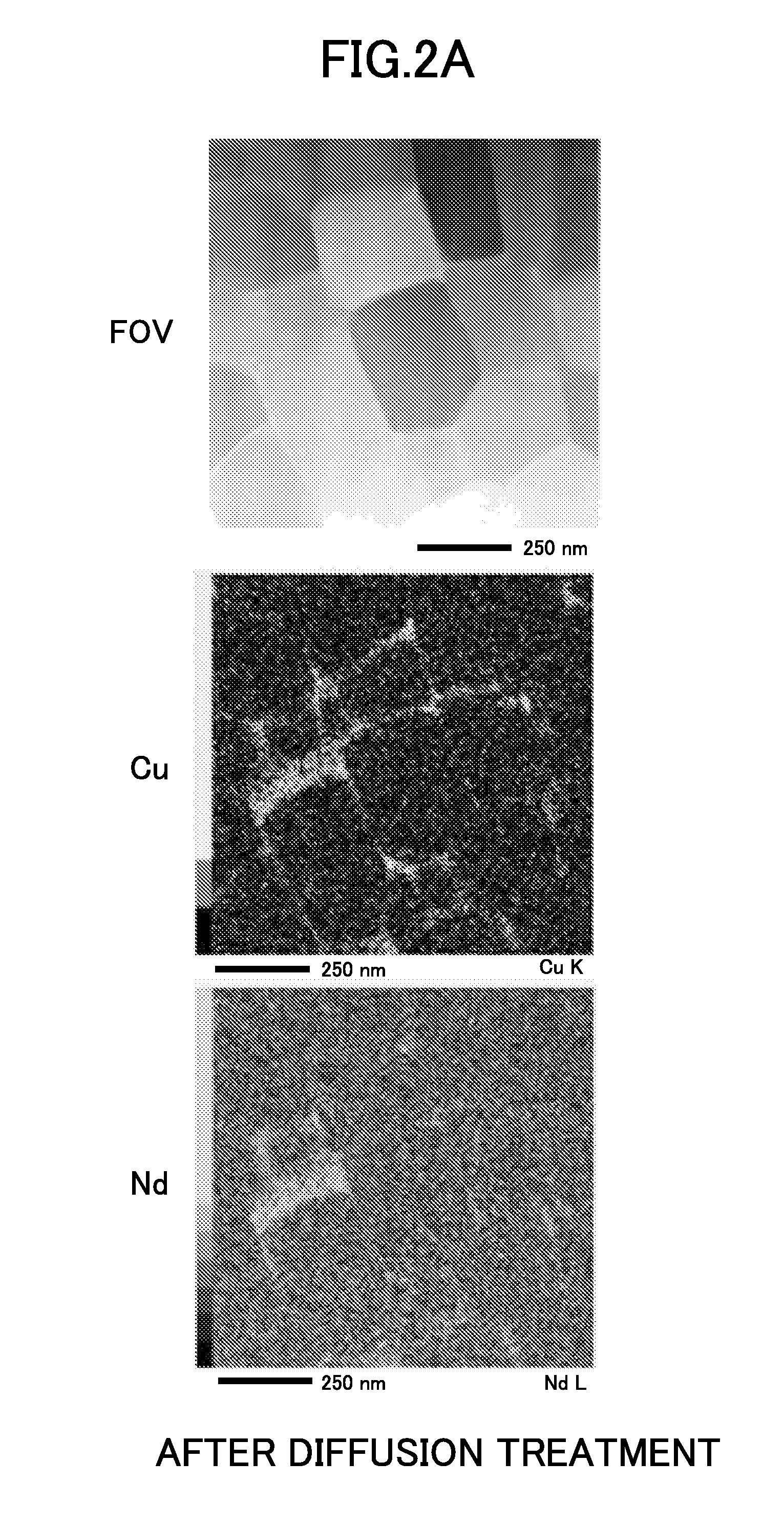

ActiveUS20130009736A1Low coercivityLow magnetic flux densityTransportation and packagingMetal-working apparatusRare-earth elementCrystallite

The anisotropic rare earth magnet powder of the present invention includes powder particles having R2TM14B1-type crystals of a tetragonal compound of a rare earth element (R), boron (B), and a transition element (TM) having an average crystal grain diameter of 0.05 to 1 μm, and enveloping layers containing at least a rare earth element (R′) and copper (Cu) and enveloping surfaces of the crystals. Owing to the presence of the enveloping layers, coercivity of the anisotropic rare earth magnet powder can be remarkably enhanced without using a scarce element such as Ga and Dy.

Owner:AICHI STEEL

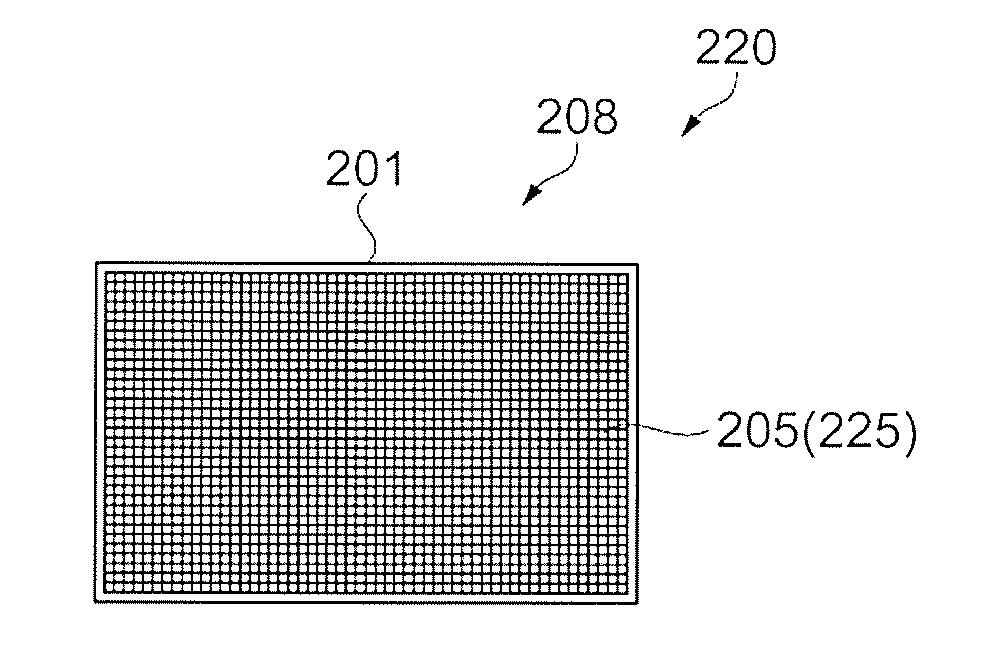

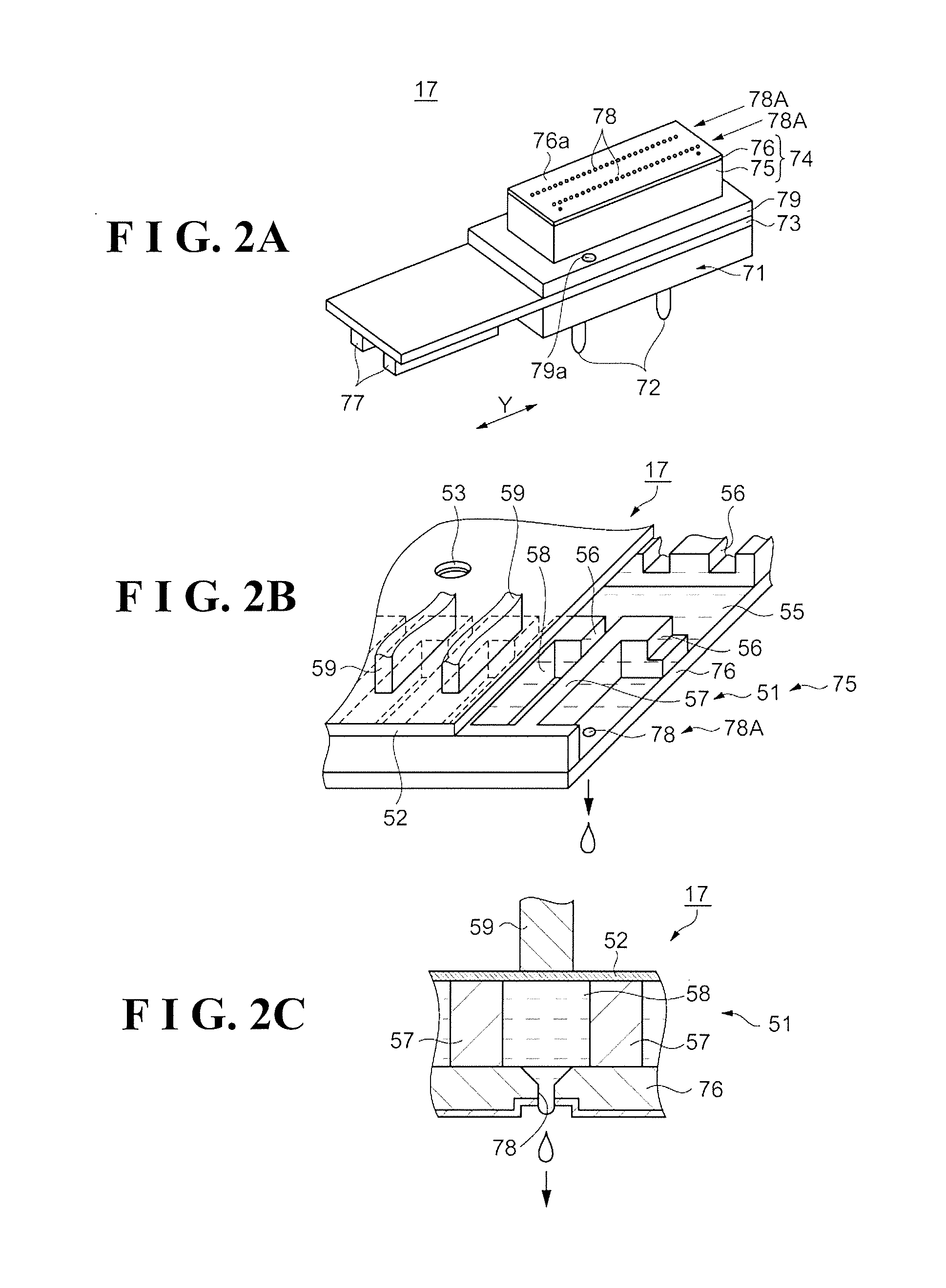

Film-formation method, method for manufacturing electro-optical device, electro-optical device, and electronic apparatus

InactiveUS20100062147A1Accurate shapeEasy to wetSolid-state devicesPretreated surfacesThin membraneFilm material

A film-formation method is a method for depositing a liquid containing a film material to form a film in a prescribed film formation area enclosed by a partition wall on a substrate. The film-formation method includes forming the partition wall using at least in part a wettability-variable material in which wettability with respect to the liquid is variable, depositing the liquid in the film formation area, varying the wettability of the wettability-variable material in the partition wall in a state in which the liquid is disposed within the film formation area so that liquid affinity of the wettability-variable material becomes higher than liquid affinity of the wettability-variable material before the liquid is deposited in the film formation area, and forming the film by solidifying the film material in the liquid.

Owner:KATEEVA

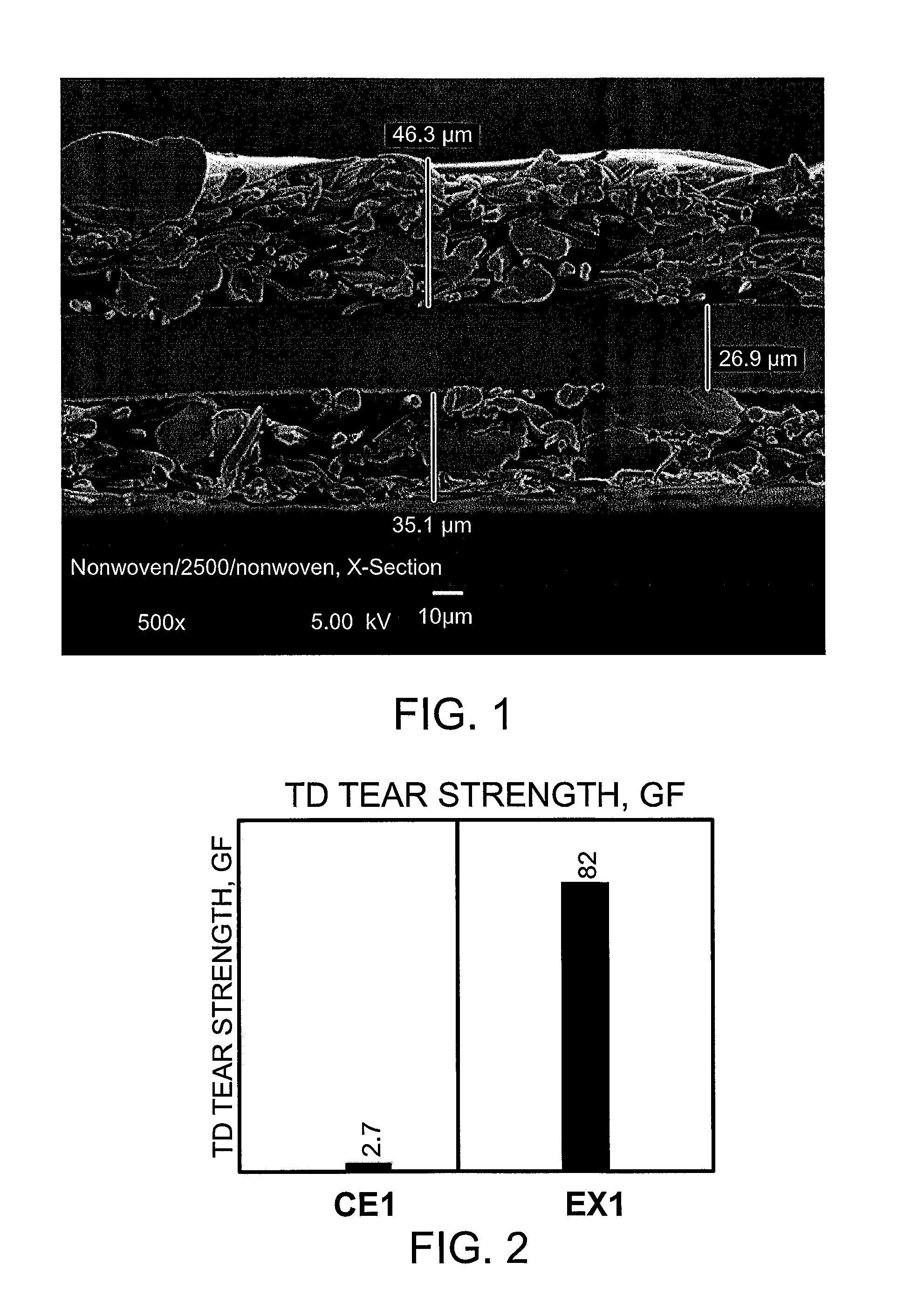

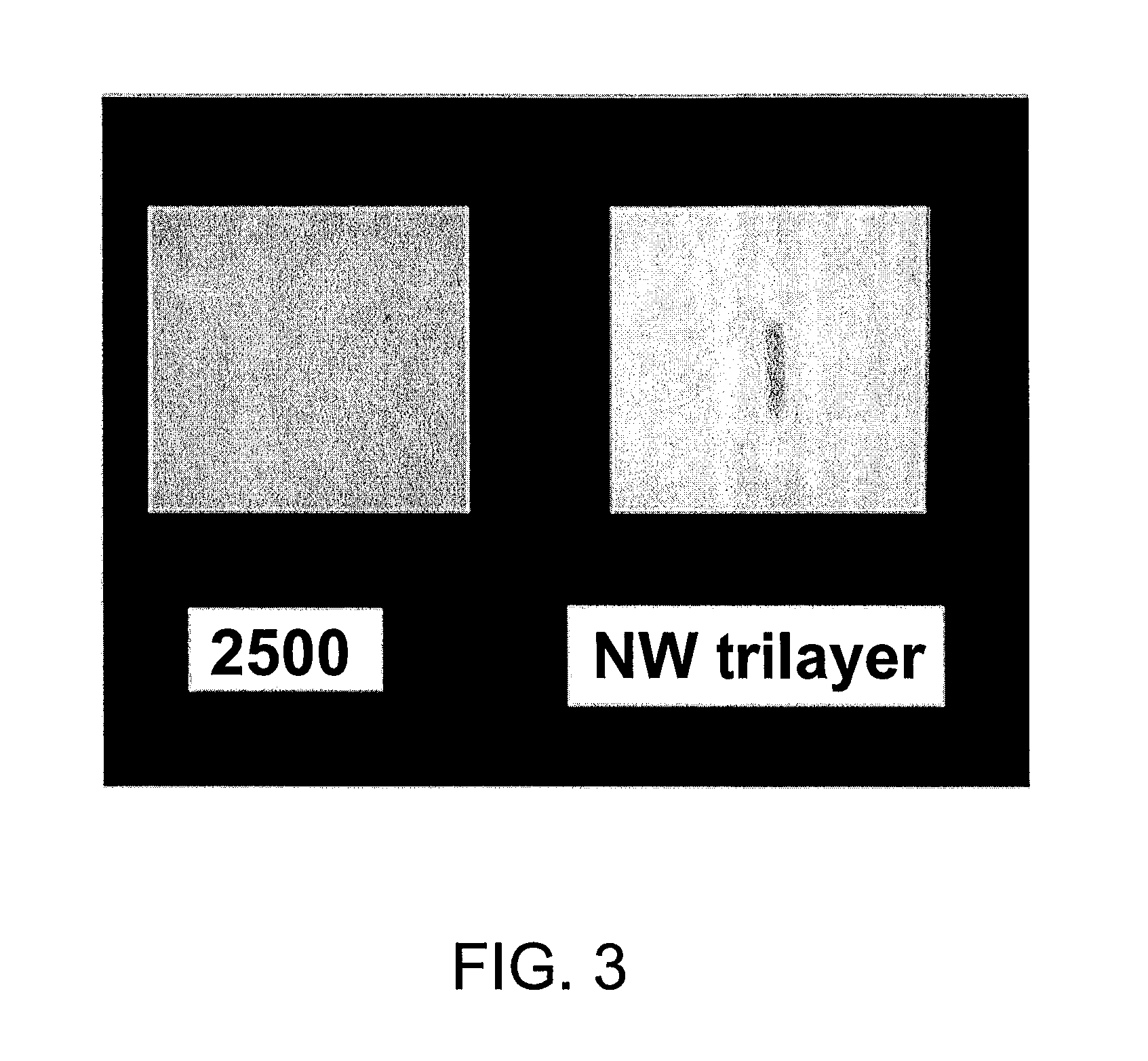

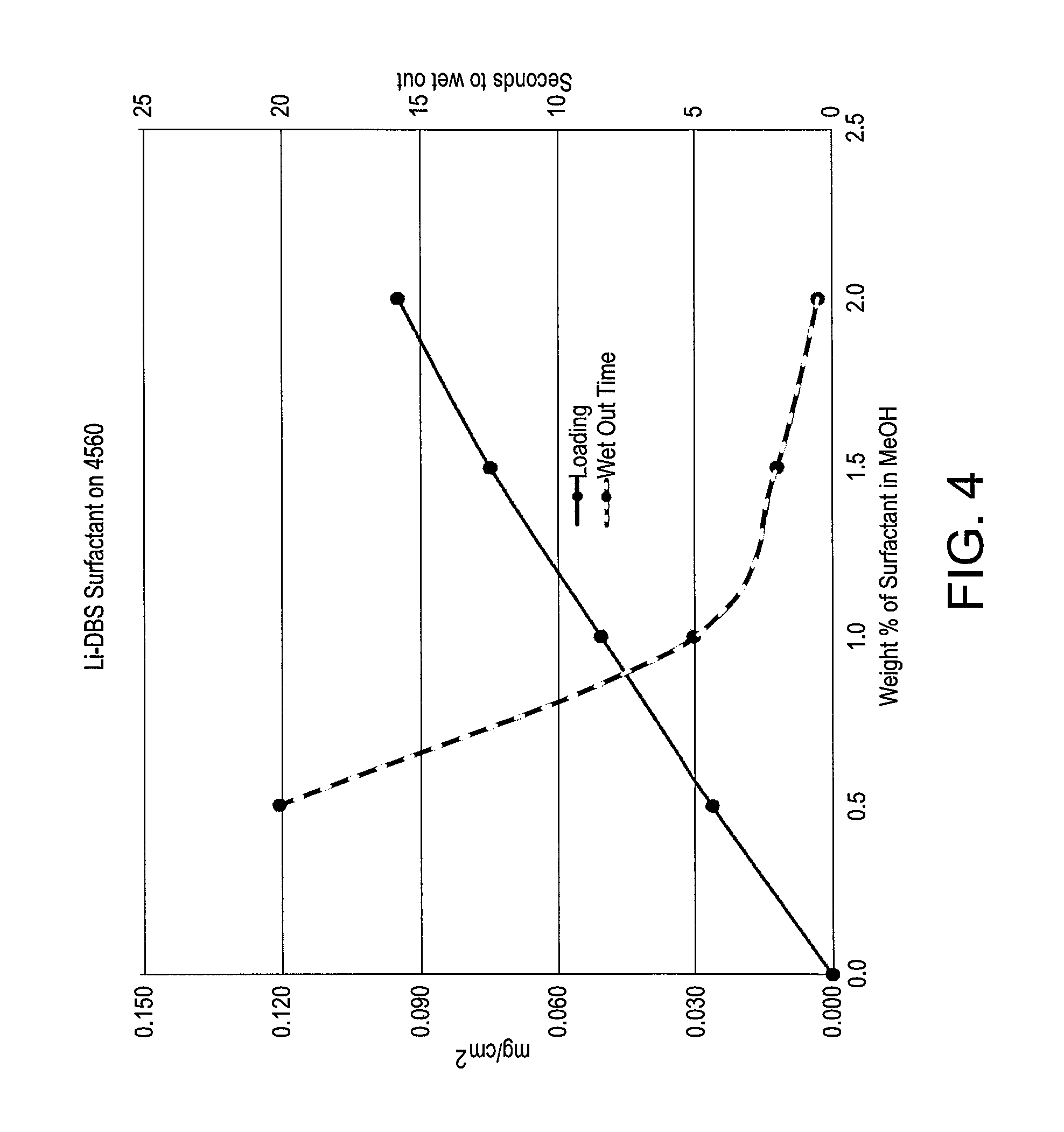

Coated or treated microporous battery separators, rechargeable lithium batteries, systems, and related methods of manufacture and/or use

ActiveUS20160329541A1Improve wettabilityIncrease capacityCell electrodesLi-accumulatorsPhysical chemistrySolvent

In accordance with at least certain embodiments, the present invention is directed to novel, improved, coated, or treated separator membranes, separators or membrane based separators for lithium batteries. The membranes or separators may include non-woven layers, improved surfactant treatments, or combinations thereof. The separators or membranes are useful for solvent electrolyte lithium batteries, especially rechargeable lithium ion batteries, and provide improved performance, wettability, cycling ability, and / or recharging efficiency.

Owner:CELGARD LLC

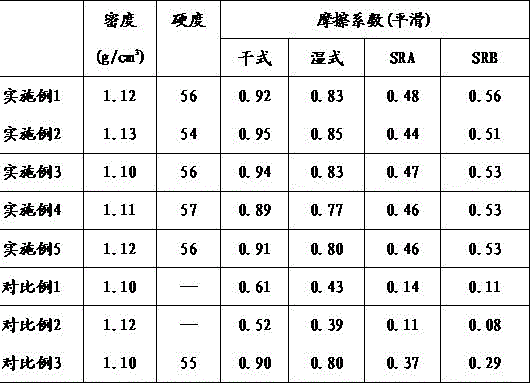

Anti-skid rubber sole and preparation method thereof

ActiveCN106832470AImprove skid resistanceIncrease polaritySolesDomestic articlesPolymer scienceVulcanization

The invention relates to a rubber sole, and provides an anti-skid rubber sole. The anti-skid rubber sole is prepared from the following raw materials: NBR / PVC emulsion co-precipitation alloy, low-melting point polyamide, natural rubber, soluble polymerized styrene-butadiene rubber, brominated butyl rubber, white carbon black, an anti-aging agent, polyethylene glycol, a silane coupling agent, polyethylene wax, diethylene glycol, zinc oxide, stearic acid, insoluble sulfur, a vulcanization accelerator D and a vulcanization accelerator DM. The anti-skid rubber sole is vulcanized and molded in a mold of a space aluminum material, the vulcanizing temperature is 170 DEG C, the pressure is 16.5MPa-17.5MPa, and the vulcanizing time is 210-250s.

Owner:MAOTAI FUJIAN SOLES CO LTD

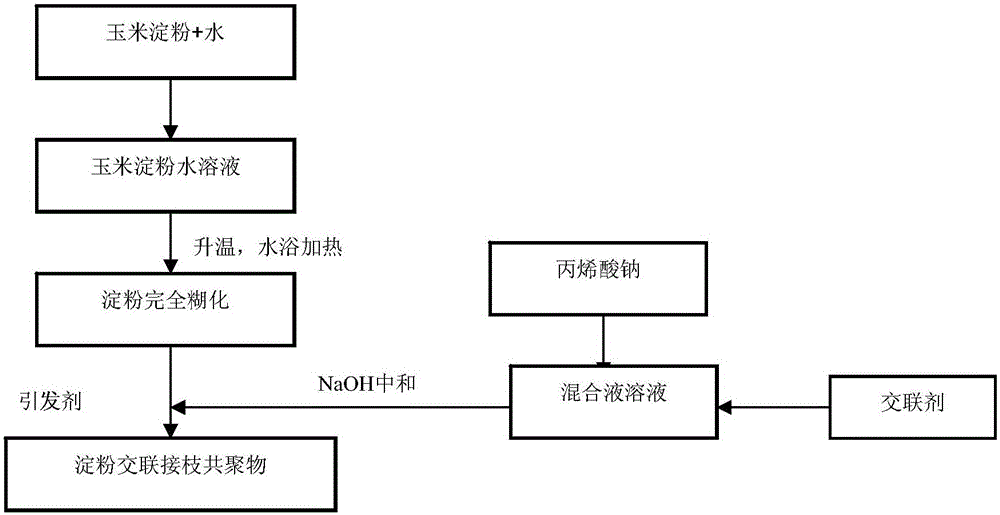

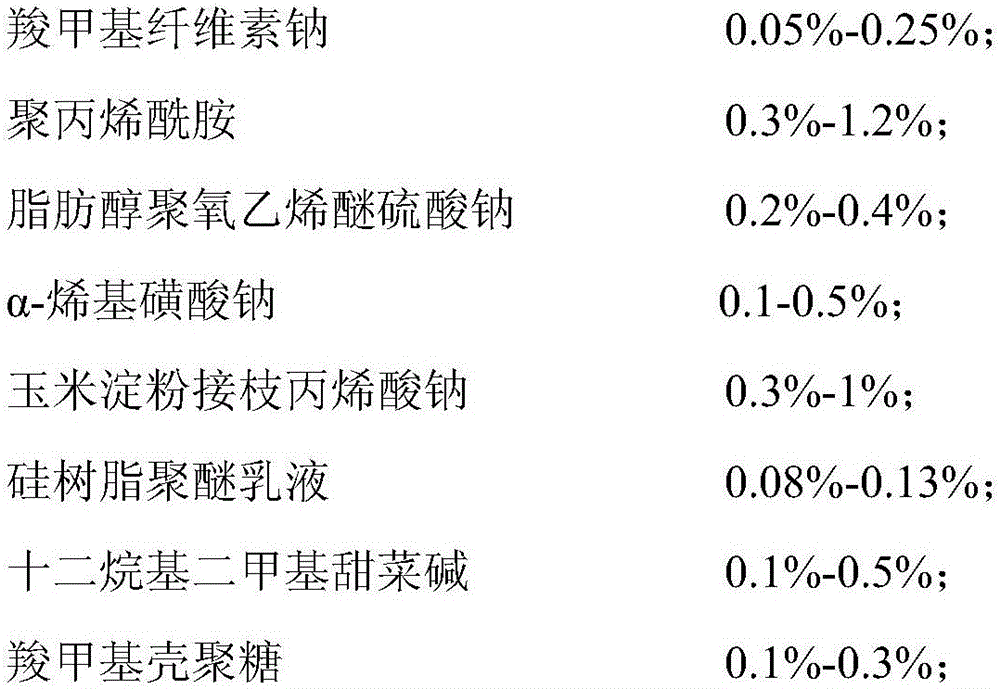

Wetting agent capable of inhibiting dust flying

ActiveCN105860933AReduce surface tensionImprove wettabilityOther chemical processesTransportation and packagingCorn starchSodium carboxymethylcellulose

The invention discloses a wetting agent capable of inhibiting dust flying. The wetting agent comprises 0.05-0.25% of sodium carboxymethyl cellulose, 0.3-1.2% of polyacrylamide, 0.2-0.4% of polyoxyethylene fatty alcohol sodium sulfate, 0.1-0.5% of sodium alpha-alkenylsulfonate, 0.3-1% of corn starch grafted sodium acrylate, 0.08-0.13% of silicone resin polyether emulsion, 0.1-0.5% of dodecyldimethylbetaine, 0.1-0.3% of carboxymethyl chitosan, 0.05-0.1% of dioctyl sodium sulphosuccinate, 0.4-0.6% of ethanediol, 0.2-0.4% of calcium chloride and the balance of water. The sprayed fog drops can quickly capture and wrap the dust particles, thereby increasing the particle settling speed. The sprayed fog drops can be covered on the dust on the coal rock surface and ground surface to prevent secondary flying dust, thereby enhancing the dust removal efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

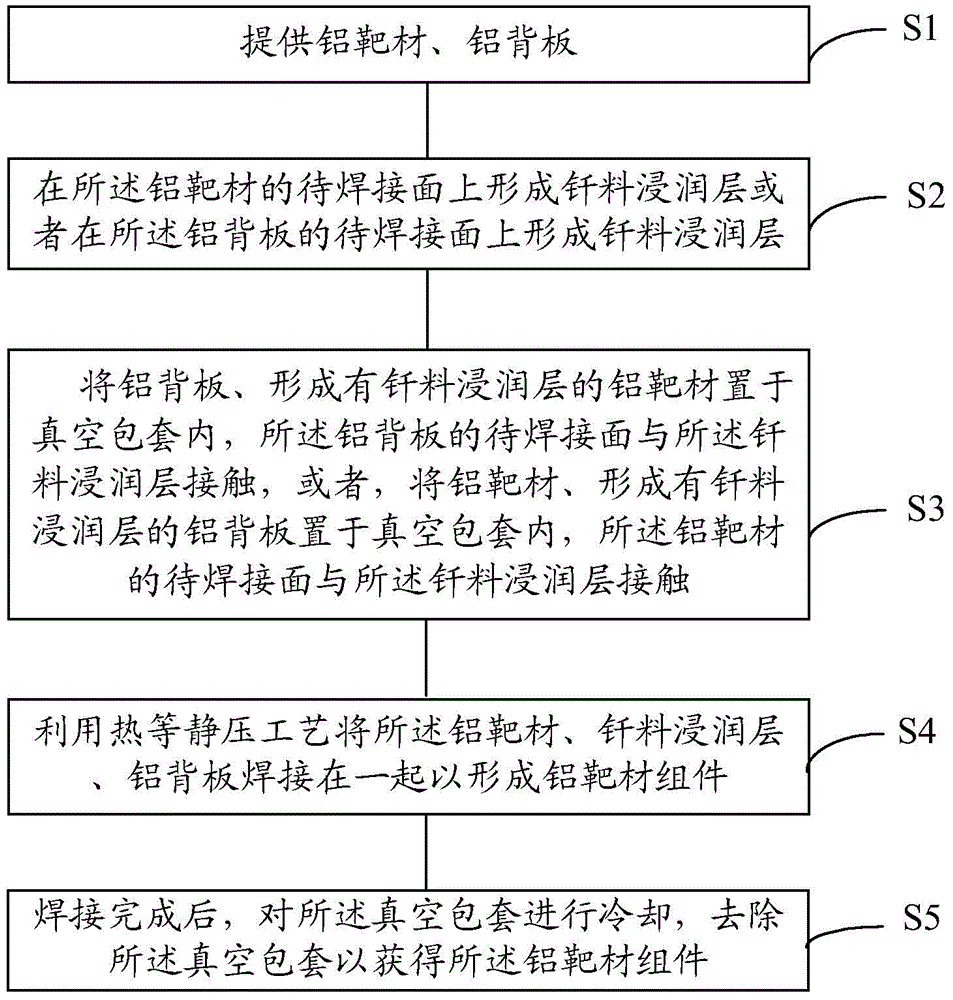

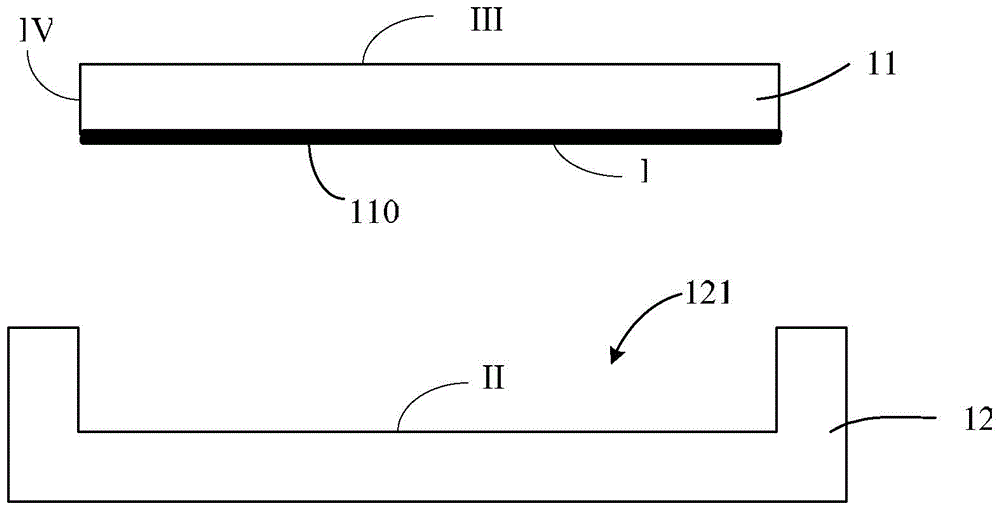

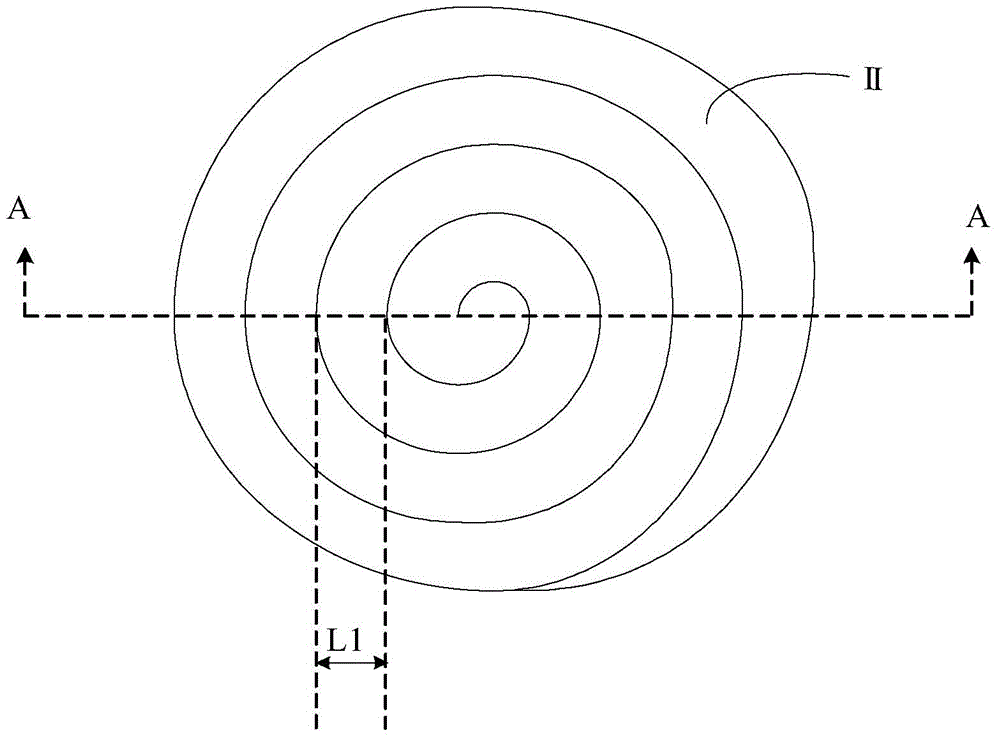

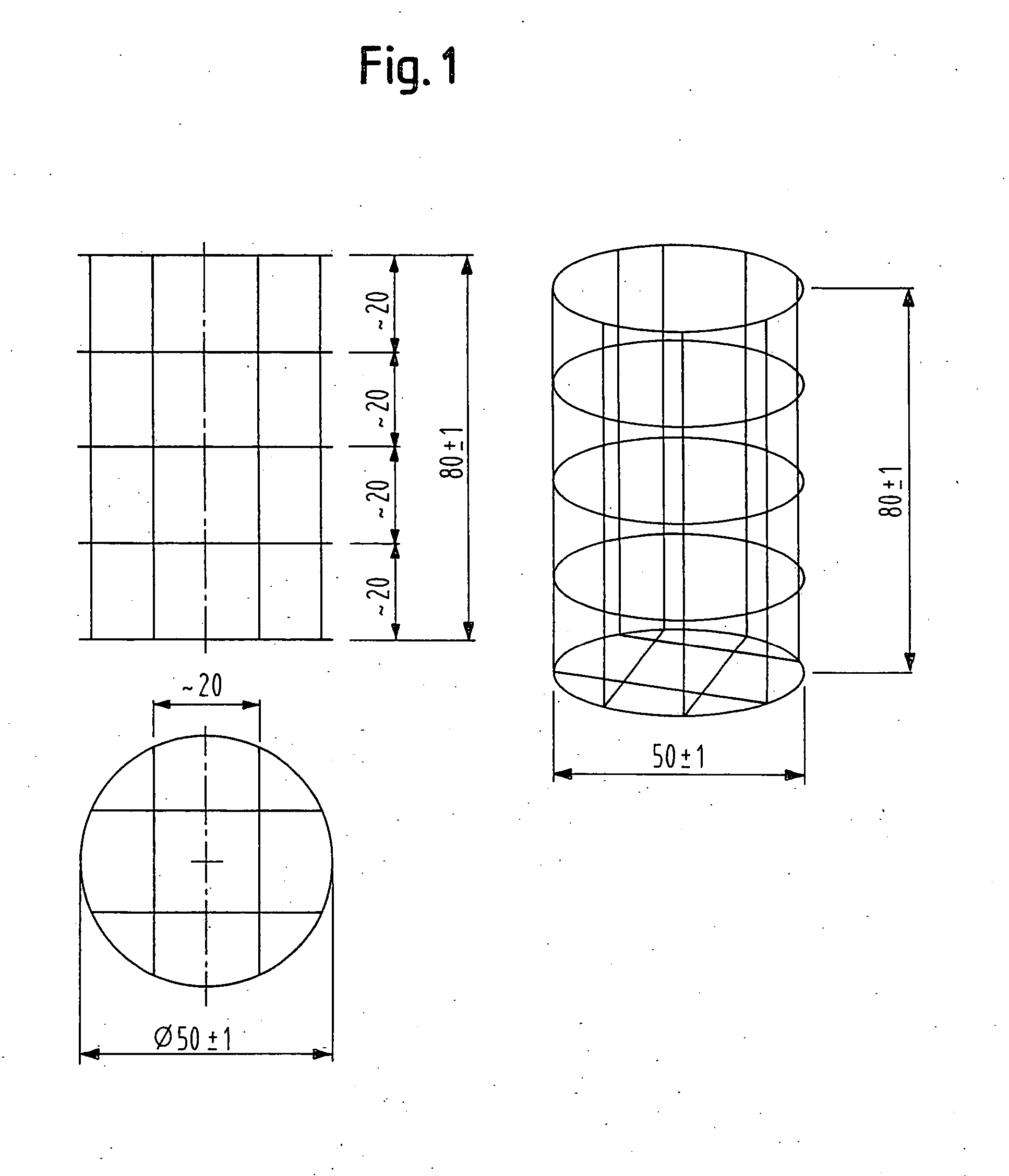

Welding method of aluminum target assembly

ActiveCN104588810AImprove welding efficiencyImprove welding strengthSoldering apparatusWelding/soldering/cutting articlesHot isostatic pressingAluminium

The invention provides a welding method of an aluminum target assembly. The welding method comprises the steps that an aluminum target and an aluminum back plate are provided; a brazing filler metal wetting layer is formed on the surface, to be welded, of the aluminum target or the surface, to be welded, of the aluminum back plate; the aluminum back plate and the aluminum target with the formed brazing filler metal wetting layer are placed in a vacuum packaging sleeve, and the surface, to be welded, of the aluminum back plate makes contact with the brazing filler metal wetting layer, or, the aluminum target and the aluminum back plate with the formed brazing filler metal wetting layer are placed in the vacuum packaging sleeve, and the surface, to be welded, of the aluminum target makes contact with the brazing filler metal wetting layer; the aluminum target, the brazing filler metal wetting layer and the aluminum back plate are welded together through a hot isostatic pressing technology so as to form the aluminum target assembly; after welding is accomplished, the vacuum packaging sleeve is cooled and removed to obtain the aluminum target assembly. By means of the welding method, welding between the aluminum target and the aluminum back plate can be achieved, the welding efficiency is high, the formed aluminum target assembly is high in welding strength and low in deformation, and the demand of long-term stable production and usage of targets can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Textile having water-repellent front surface and close-fitting-resistant back surface, and production method thereof

The present invention discloses a production method of a textile having a water-repellent front surface and a close-fitting-resistant back surface, wherein the production method comprises fabric pre-treatment, dyeing, hydrophilic shaping, and network making, the front surface of the fabric is coated with a waterproof slurry, the back surface is coated with a close-fitting-resistant slurry or forms local projections through a printing treatment, and the close-fitting-resistant slurry is a foaming slurry, a glue slurry or a water slurry. The present invention further provides the textile having the water-repellent front surface and the close-fitting-resistant back surface, wherein the outer layer of the textile has water repellency so as to make the textile outer layer be wetting resistance and always maintain dryness. According to the present invention, the local projections are formed in the inner layer of the textile to separate the human body and the textile, such that the surface contact of the human body and the textile is converted into the point contact, the air layer is formed in the middle, and the microclimate convection and circulation between the human body and the textile is enhanced so as to achieve hot eliminating, cool keeping, and improve wearing comfort of clothing.

Owner:ANTA CHINA

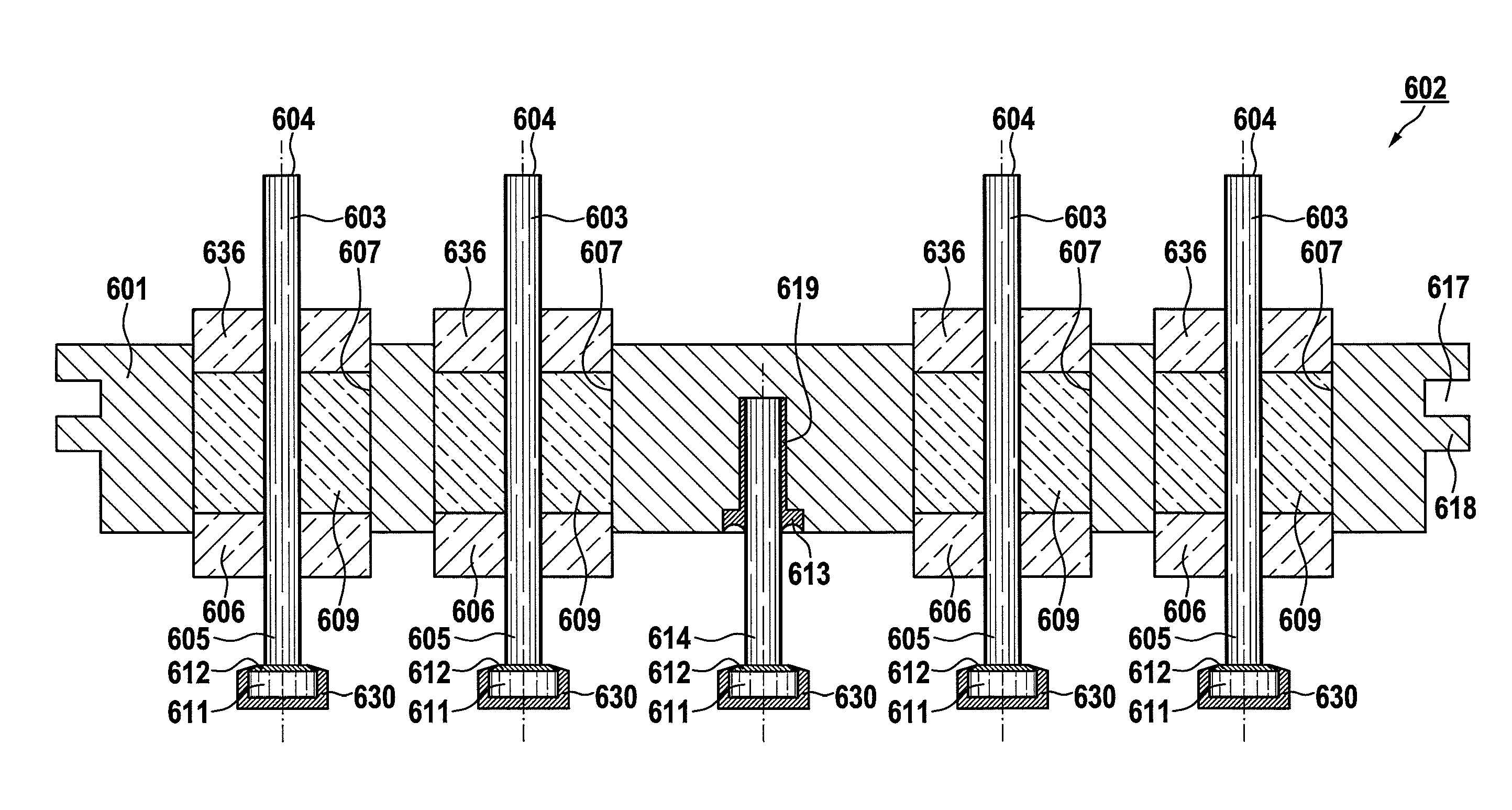

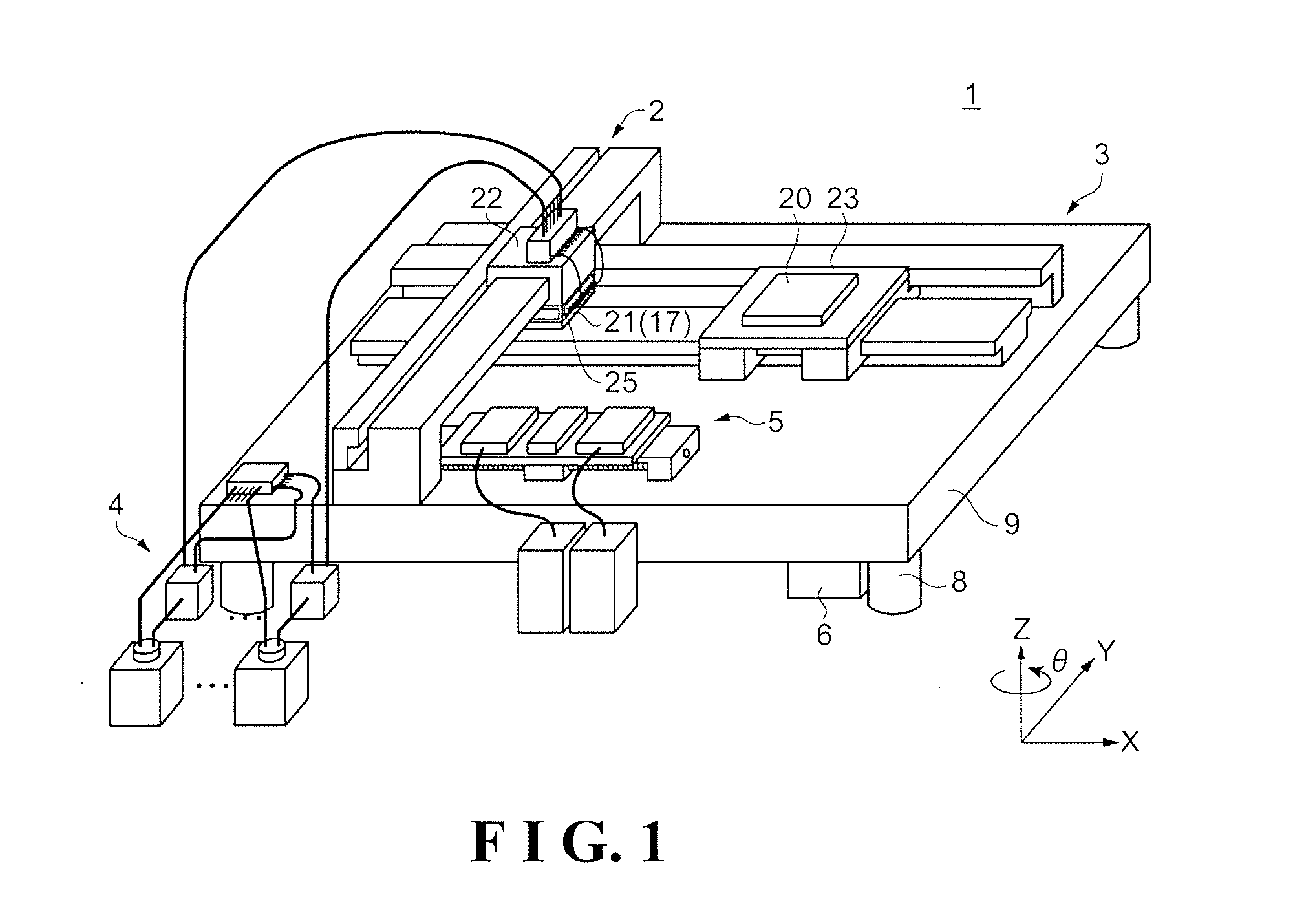

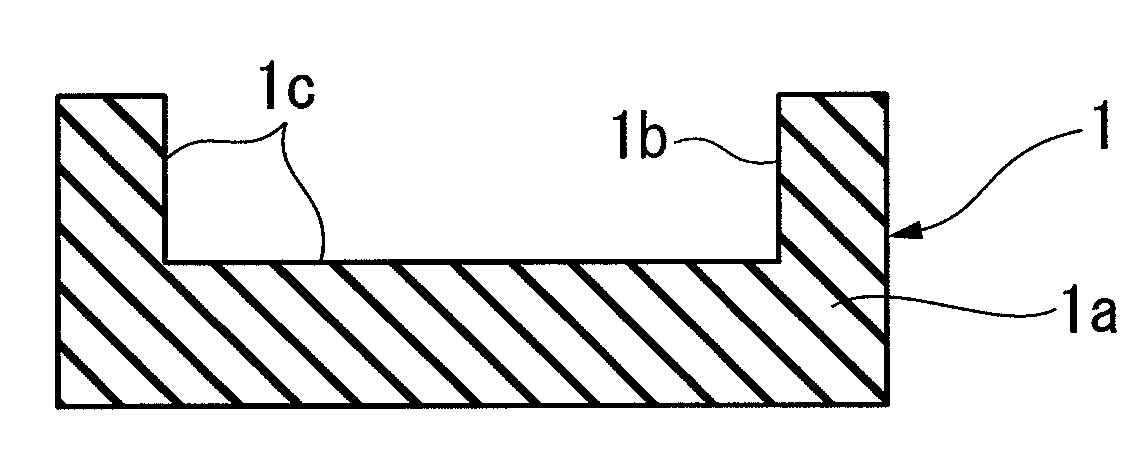

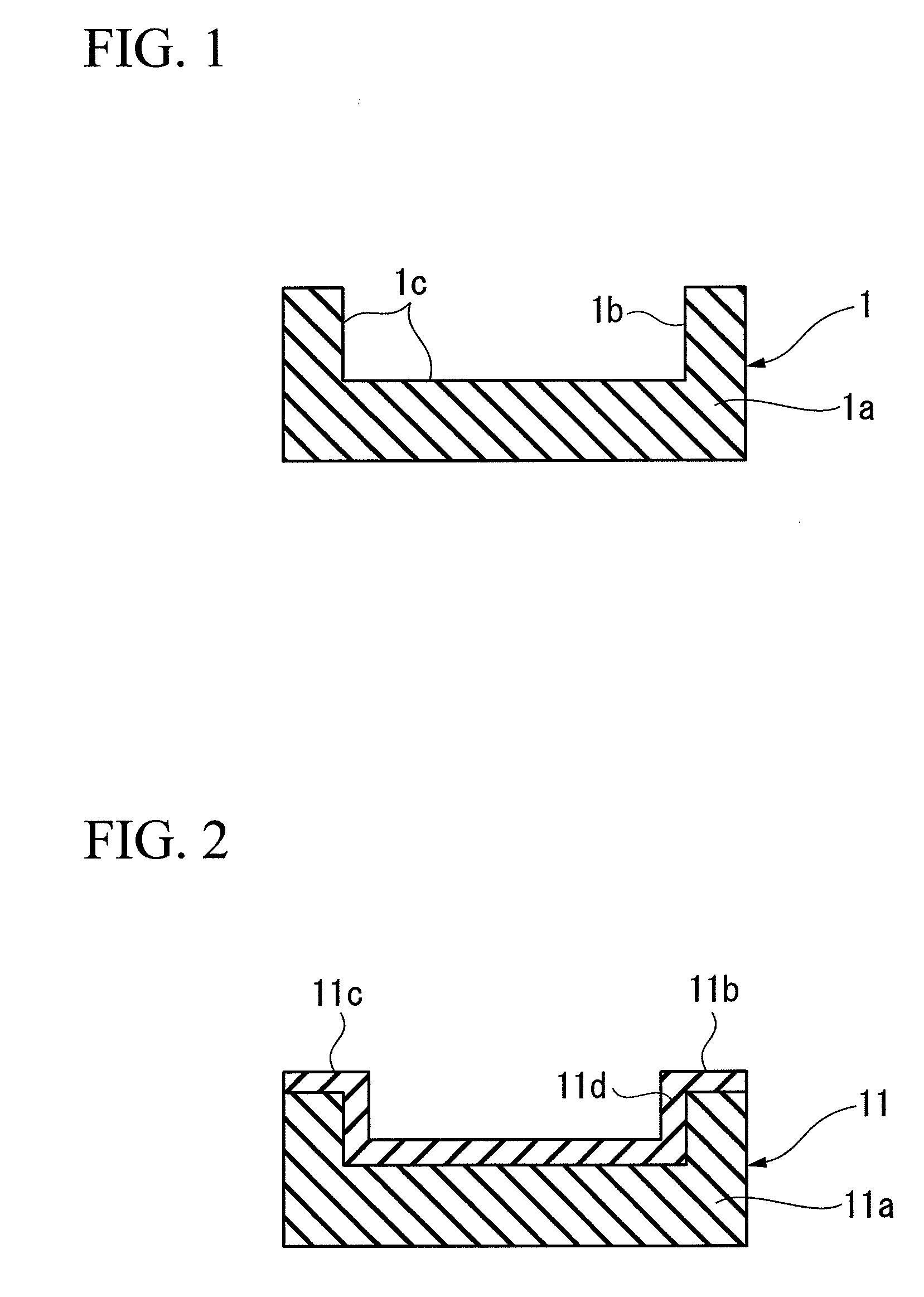

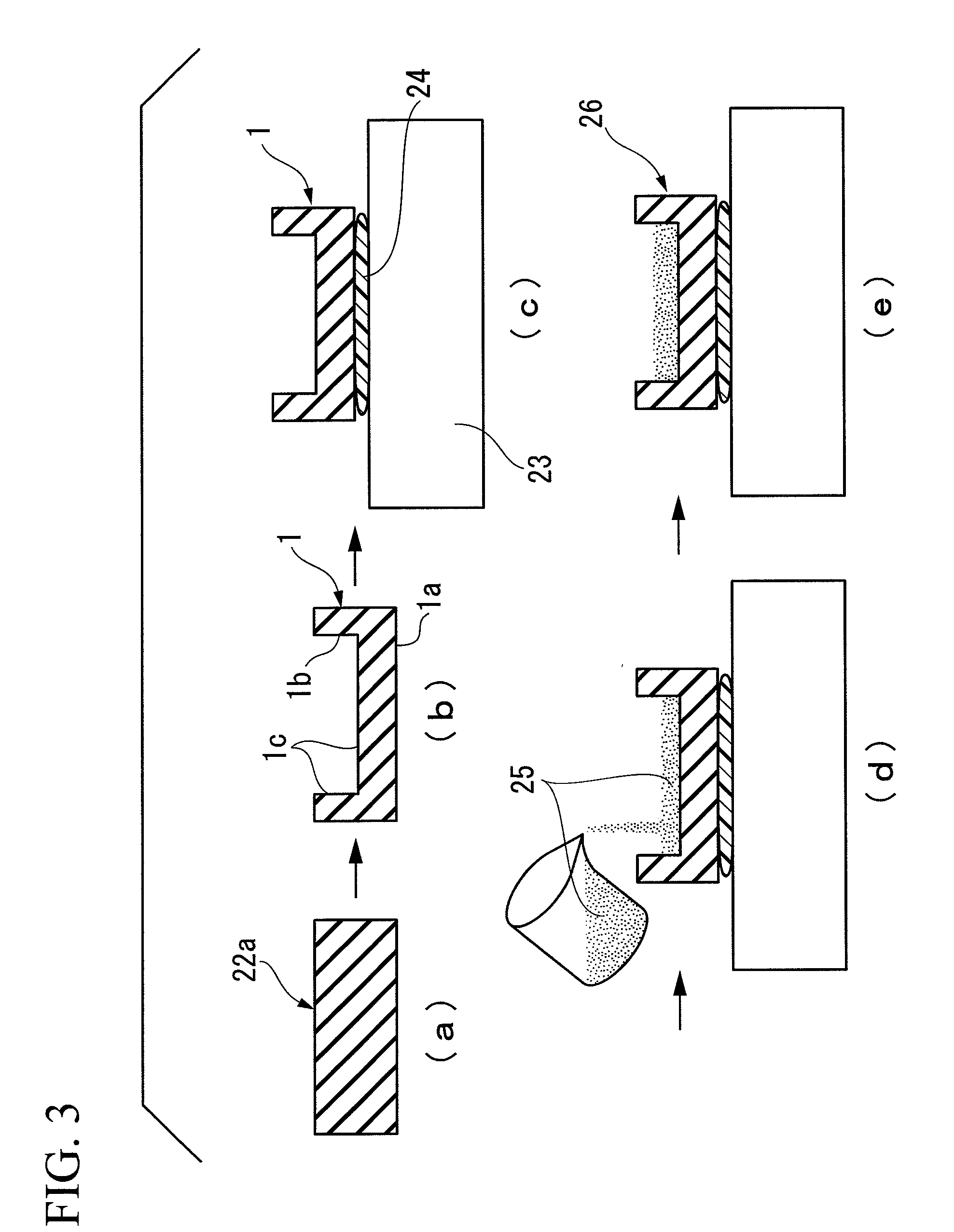

Sputtering deposition apparatus and backing plate for use in sputtering deposition apparatus

ActiveUS20100006430A1Stably holdEasy to wetCellsVacuum evaporation coatingSputter depositionMechanical engineering

A backing plate for use in a sputtering deposition apparatus being capable of stably holding Ga, and a sputtering deposition apparatus which is equipped with the backing plate are provided. Such a backing plate for use in a sputtering deposition apparatus is a backing plate for holding a target material which contains Ga, and at least a contact surface of which coming into contact with the target material is constituted from an easily wettable material having a contact angle to Ga in a liquid state of not more than 90°.

Owner:TOYODA GOSEI CO LTD

Developing degradable polymer stent and preparation method thereof

The invention provides a developing degradable polymer stent and a preparation method thereof. A plasma vapor deposition method is adopted to deposit a degradable developing material on the surface of a bracket; the prepared developing coating is not transmitted under X ray, so that the stent can be clearly seen under X ray, and therefore, some interferences of a metal developing material on MRI (magnetic resonance imaging) and CT (computed tomography) images are avoided, and problems that side effects are easily produced as biocompatibility of the metal developing material is poor, and the metal developing material cannot be degraded and left in a blood vessel cavity after the stent is degraded are solved; according to the method, activation hydrophilic treatment is carried out on the surface of the polymer bracket, so as to improve affinity between the polymer base body and the developing coating and effectively solve the coating dropping problem; besides, a protective coating which is slow in degradation rate is coated on the surface of the developing coating, so that too quick degradation of the developing coating is prevented, and therefore, follow-up can be still carried out in the later stage of implanting.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

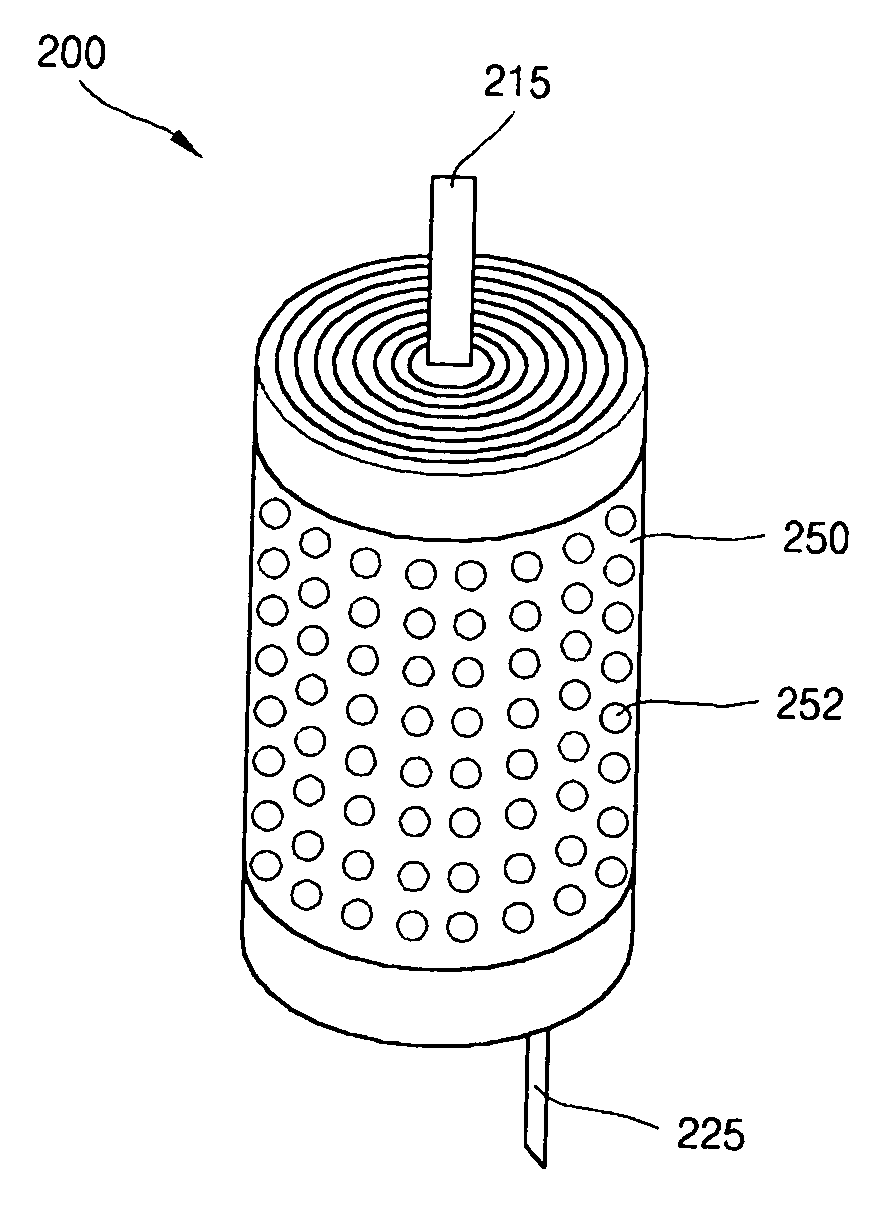

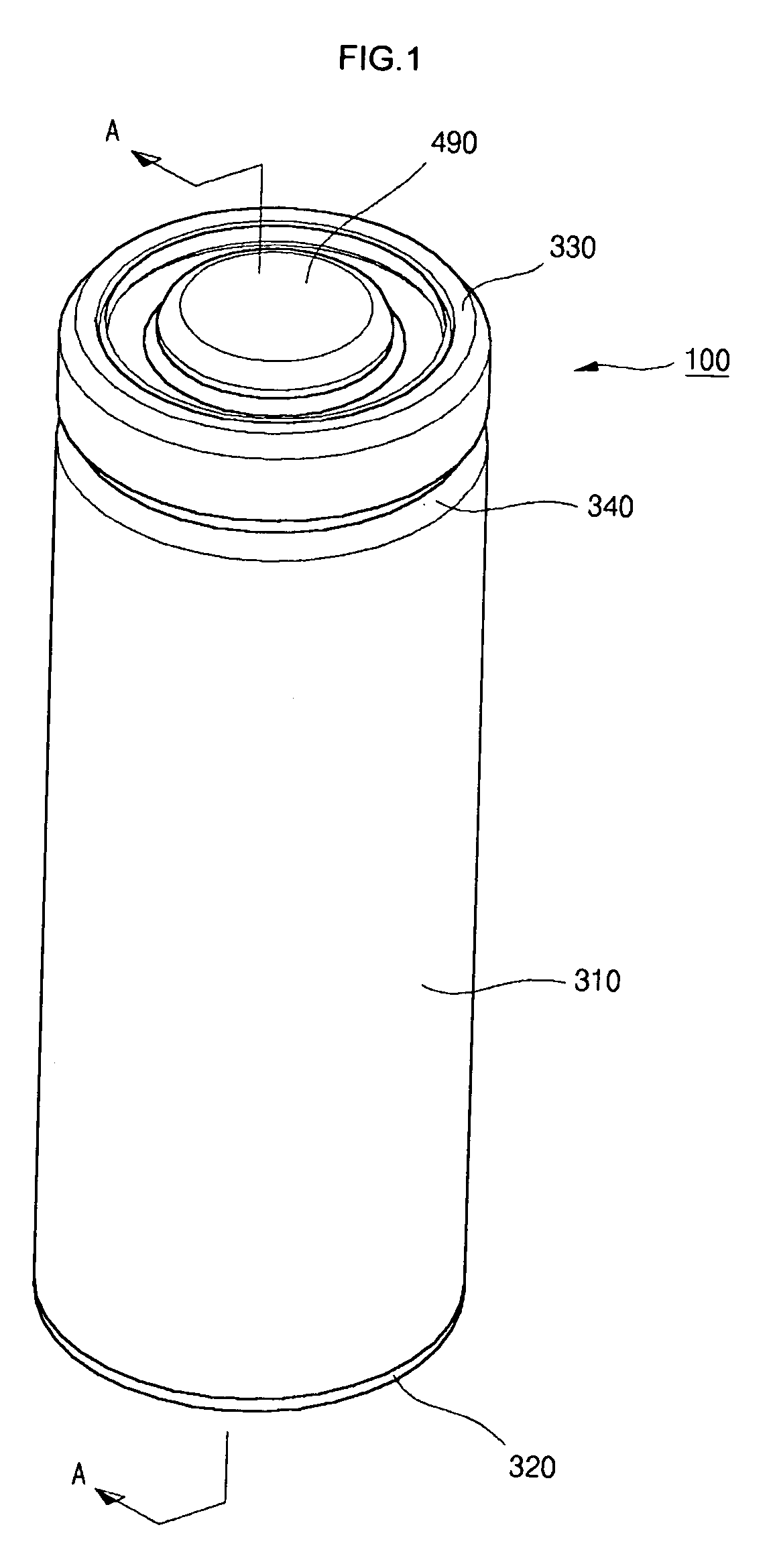

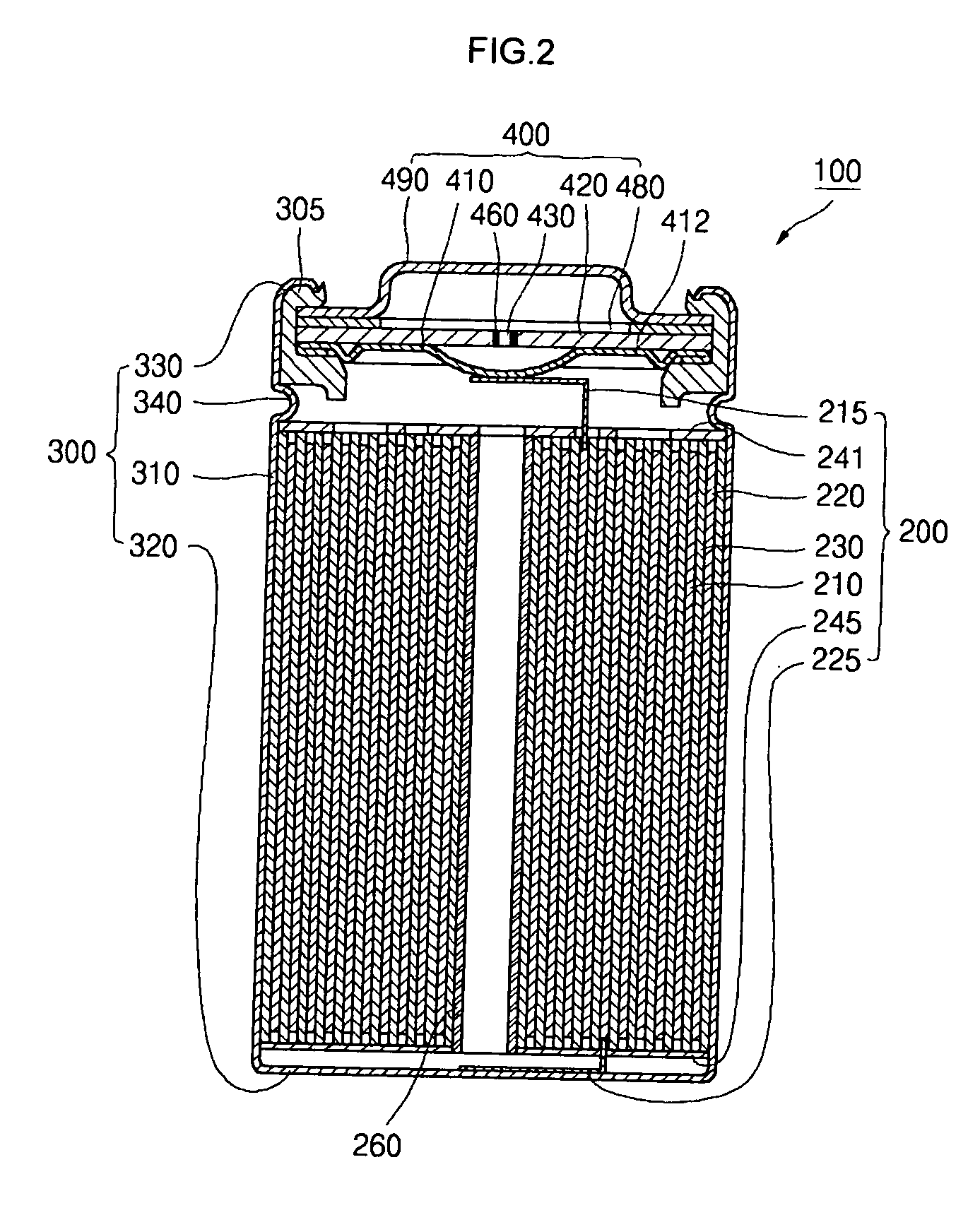

Lithium ion secondary battery

ActiveUS20070154804A1Improving impregnation of electrolyteExcellent impregnationFinal product manufactureSmall-sized cells cases/jacketsLithiumEngineering

Electrode assemblies easily impregnated with an electrolyte are provided. A sealing tape attached to the outer circumference of the electrode assembly comprises a material having an affinity for the electrolyte. Alternatively, the entire sealing tape or a portion of the tape is coated with the material. In another alternative, the surface of the sealing tape is rough, thereby improving wetting of the tape by the electrolyte and diffusion of the electrolyte into the tape. In another embodiment, first and second insulating plates comprise a material having an affinity for the electrolyte. In another alternative, the insulating plates comprise a mixture of a material having an affinity for the electrolyte and polypropylene or polyethylene. Alternatively, the surfaces of the insulating plates are coated with the material or with a surfactant that reduces the surface tension of the electrolyte.

Owner:SAMSUNG SDI CO LTD

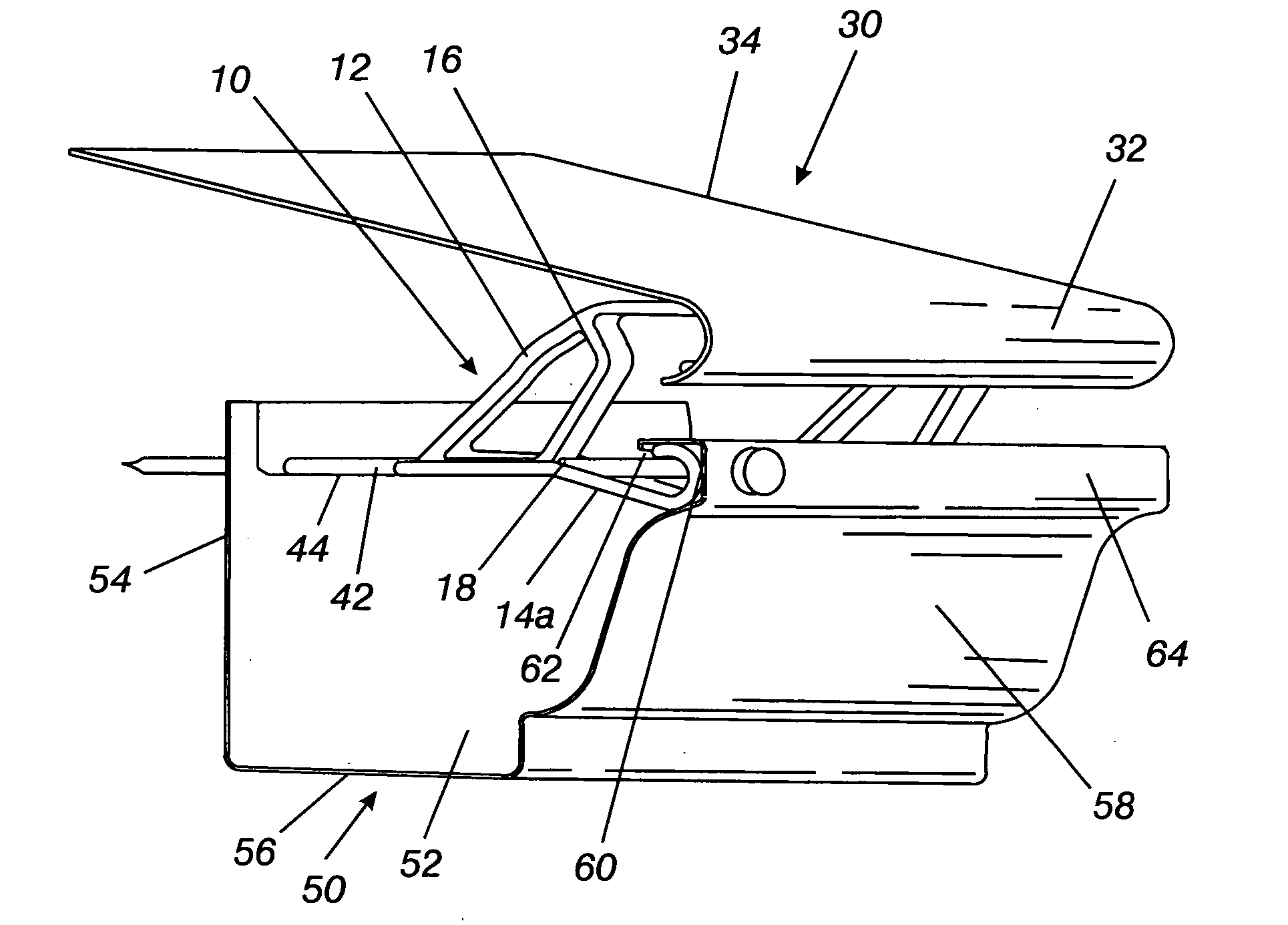

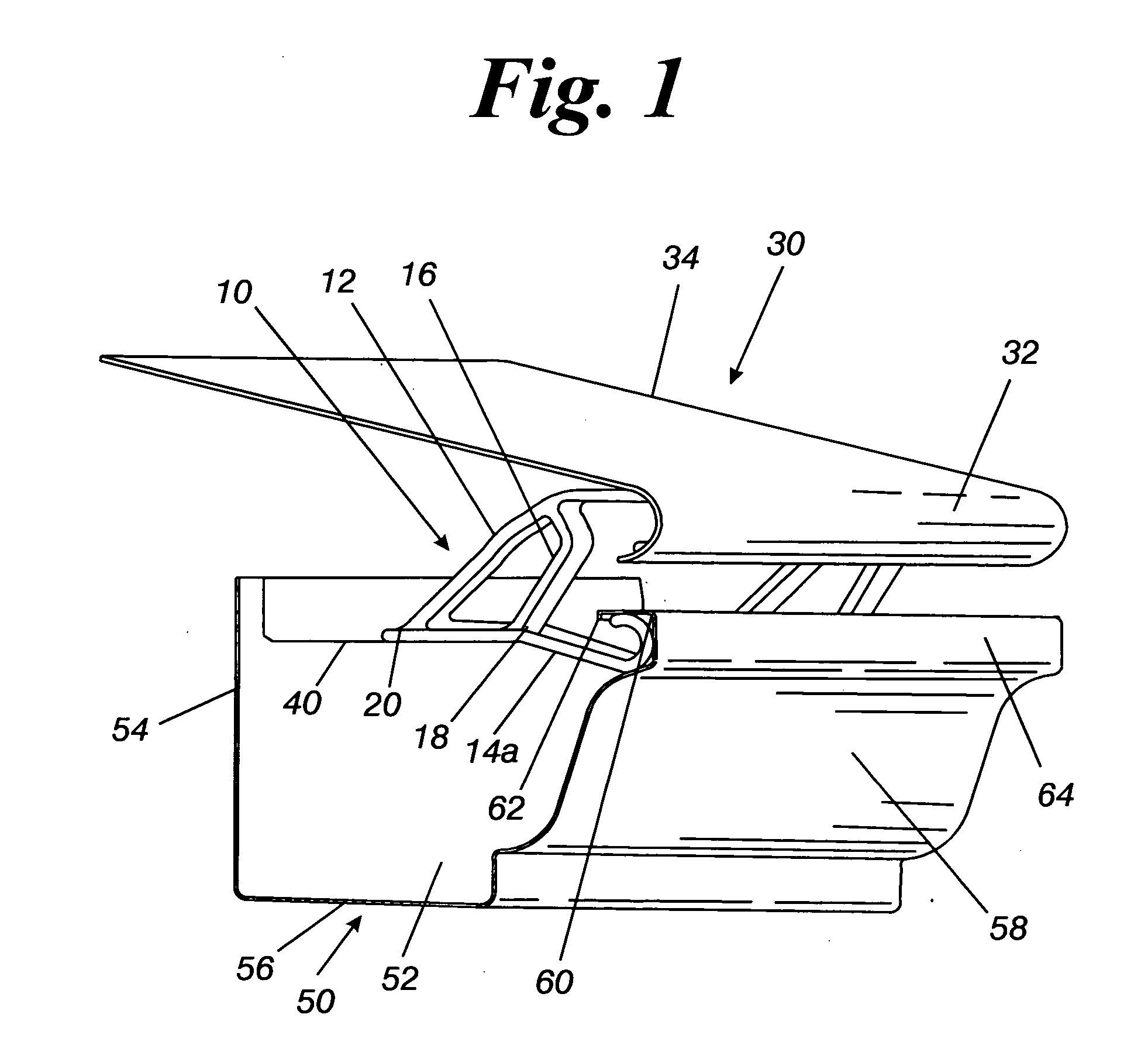

Support structure for gutter cover

A structure for mounting a gutter cover on a new rain gutter or an existing rain gutter, wherein the gutter cover prevents debris from entering the gutter. The cover support structure is comprised of a lifting strut that supports the leading hooked frontal edge of a gutter cover, two stabilizing struts that interlock with the hooked edge of a frontal rim of a gutter trough, a connecting strut that connects the lifting strut to the stabilizing struts, and a junction where the lifting strut and stabilizing struts converge.

Owner:RICHARD THOMAS ROY +1

Methanol gasoline rubber anti-swelling agent

InactiveCN101613629AEasy to useLow costLiquid carbonaceous fuelsFuel additivesSulfonatePolymer science

The invention relates to a methanol gasoline rubber anti-swelling agent and belongs to the field of alcohol ether fuel additives. The methanol gasoline rubber anti-swelling agent consists of 30 to 60 percent of fatty alcohol, 10 to 30 percent of calcium petroleum sulfonate, 8 to 20 percent of sulfonate, 7 to 18 percent of synthetic calcium sulfonate salt and 2 to 15 percent of alkylphenol calcium salt in percentage by weight. 0.012 to 0.028 percent of industrial product of the methanol gasoline rubber anti-swelling agent is added in methanol gasoline with different brands of between M15 and M100 and can reduce the volume swelling of the rubber by 40 to 46 percent. After methanol gasoline added with the methanol gasoline rubber anti-swelling agent is used in an automobile, the driving journey is 50,000 kilometers; compared with the methanol gasoline without methanol gasoline rubber anti-swelling agent, the test shows that the volume swelling of the rubber is reduced by 45 to 50 percent. Compared with lead-free gasoline, the test shows that the swelling rate of the methanol gasoline added with the methanol gasoline rubber anti-swelling agent is equal to that of the lead-free gasoline and achieves the equivalent effect with the lead-free gasoline. The methanol gasoline rubber anti-swelling agent has the characteristics of low cost, easy preparation, convenient use, good effect and the like.

Owner:占小玲

Production method of wire netting transparent electromagnetic shielding layer material

InactiveCN101316500ALow costIncrease profitMagnetic/electric field screeningMetallic material coating processesElectromagnetic shieldingColor changes

The invention relates to a method for preparing a transparent electromagnet shielding layer material with a metal wire mesh. The shielding material comprises a surface electricity-conducting material and an electricity-conducting composite material. The method comprises steps that: stretching, the metal wire mesh and a resin film are pretreated; the pretreated metal wire mesh is put into a corrosive liquid for corrosion, namely, oxide treatment; the color change of the metal wire mesh is watched; the blackening is regulated by sodium polyacrylate in the corrosive liquid and changes with the content of the sodium polyacrylate; cleaning treatment is carried out after the corrosion and the metal wire mesh are gelatinized and cured; a film is laid flatly on a glass plate and evenly coated with the resin; the corroded metal wire mesh is laid on the resin-coated film, and then the metal wire mesh is coated with resin and covered with another film which is pressed with another glass plate after air bubbles are removed; then placing for 24 hours, the resin is cured naturally, or the curing is realized in a drying oven. The material produced by the method of the invention is applied to military technologies (for example: electronic warfare technology and stealth technology, safety products and various electronic products for civil use.

Owner:HARBIN INST OF TECH

Metallic undercoating for solder materials

InactiveUS20020047217A1Easy to produceEasily be wettedSemiconductor/solid-state device detailsSolid-state devicesTitaniumDiffusion barrier

A semiconductor substrate has an underbump metallization for solder materials. The semiconductor substrate has applied thereto a titanium layer serving as a diffusion barrier and as a wettable surface for the solder-material bump. The solder-material bump is adapted to be applied directly to said diffusion barrier.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Lotioned fibrous web having a short water absorption time

InactiveUS20050100573A1Easy to wetExcellent sinking behaviour in waterBiocidePowder deliveryFiberEmulsion

A fibrous web, in particular tissue web treated with a lotion composition based on an O / W emulsion comprising: (A) at least one oil; (B) an (O / W) emulsifier or (O / W) emulsifier combination; and (C) 6 to 30 weight % of water; wherein the weight % values relate to the total weight of the lotion composition. Since in the above lotion composition the external phase is aqueous, a web treated therewith can easily be wet by water and does not float on the water if it is to be disposed in a toilet.

Owner:ESSITY OPERATIONS MANNHEIM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com