Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Low traction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

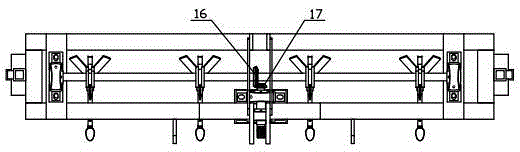

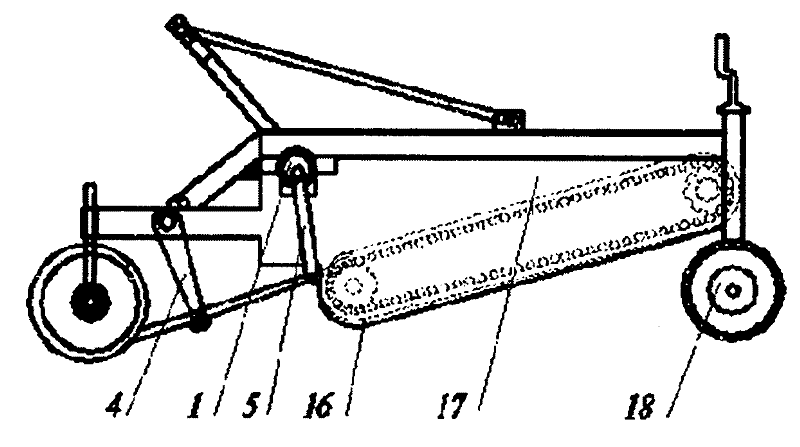

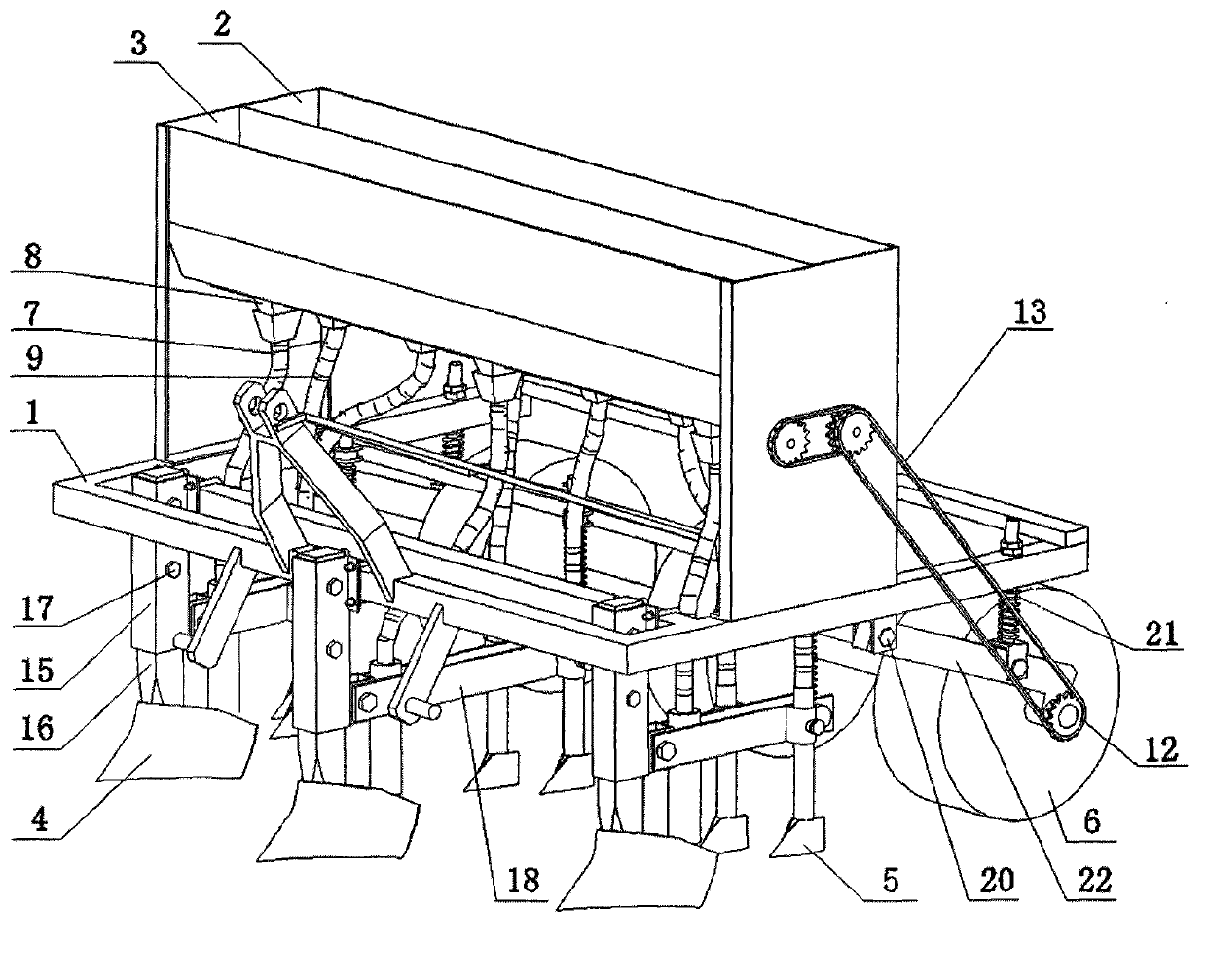

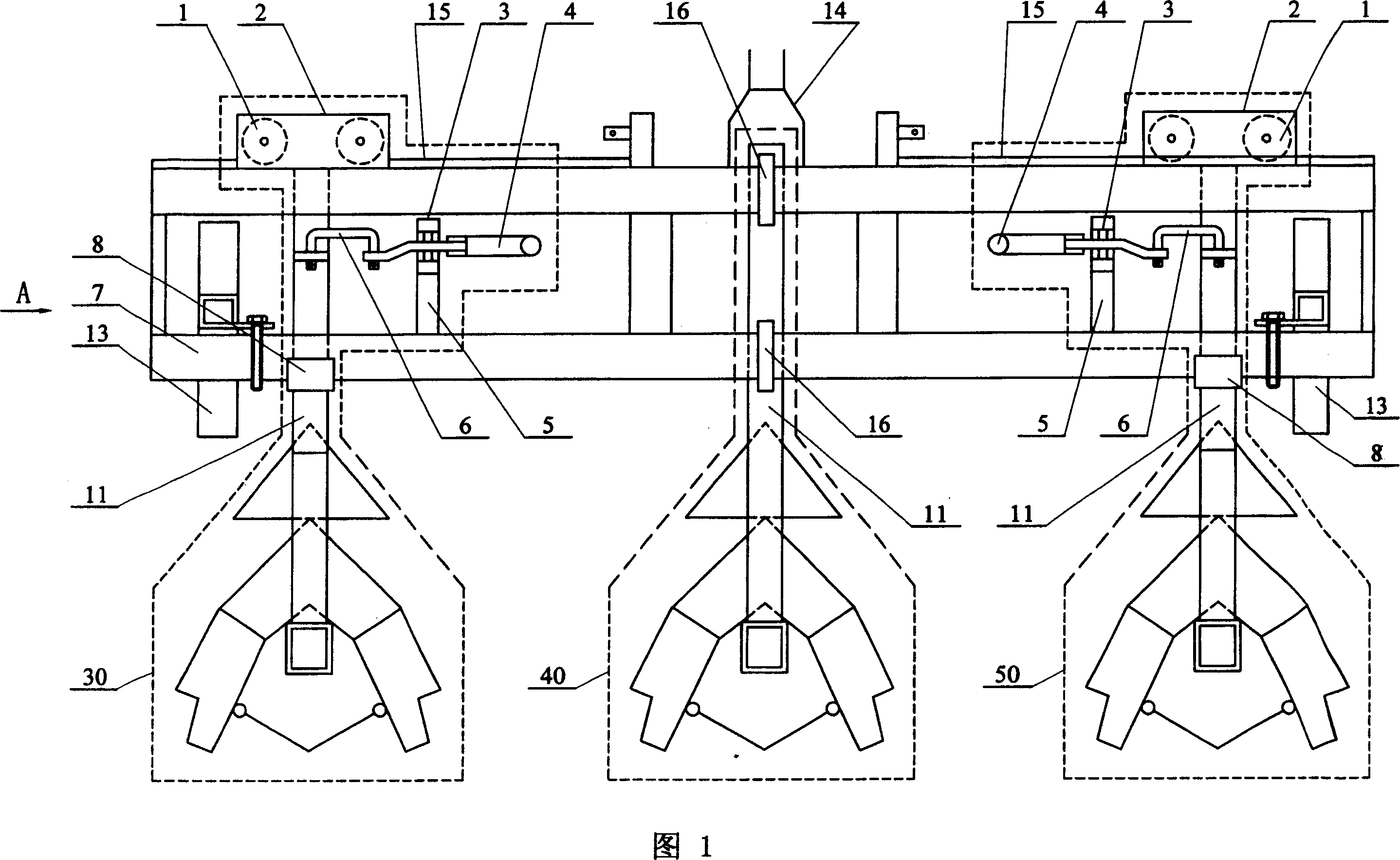

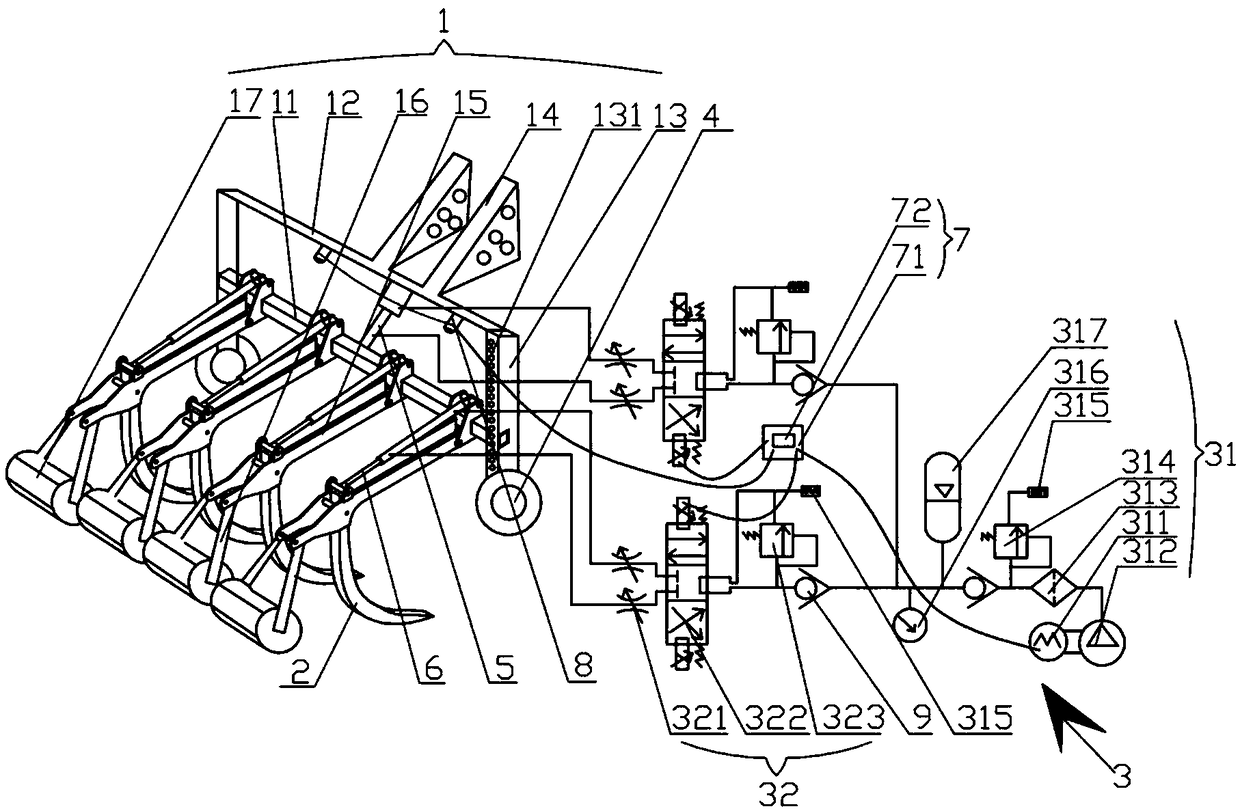

Vibration subsoiling fertilizer applicator

InactiveCN102132642AEccentric structure is compact and simpleLow traction resistanceSpadesSoil-working equipmentsAgricultural engineeringTractor

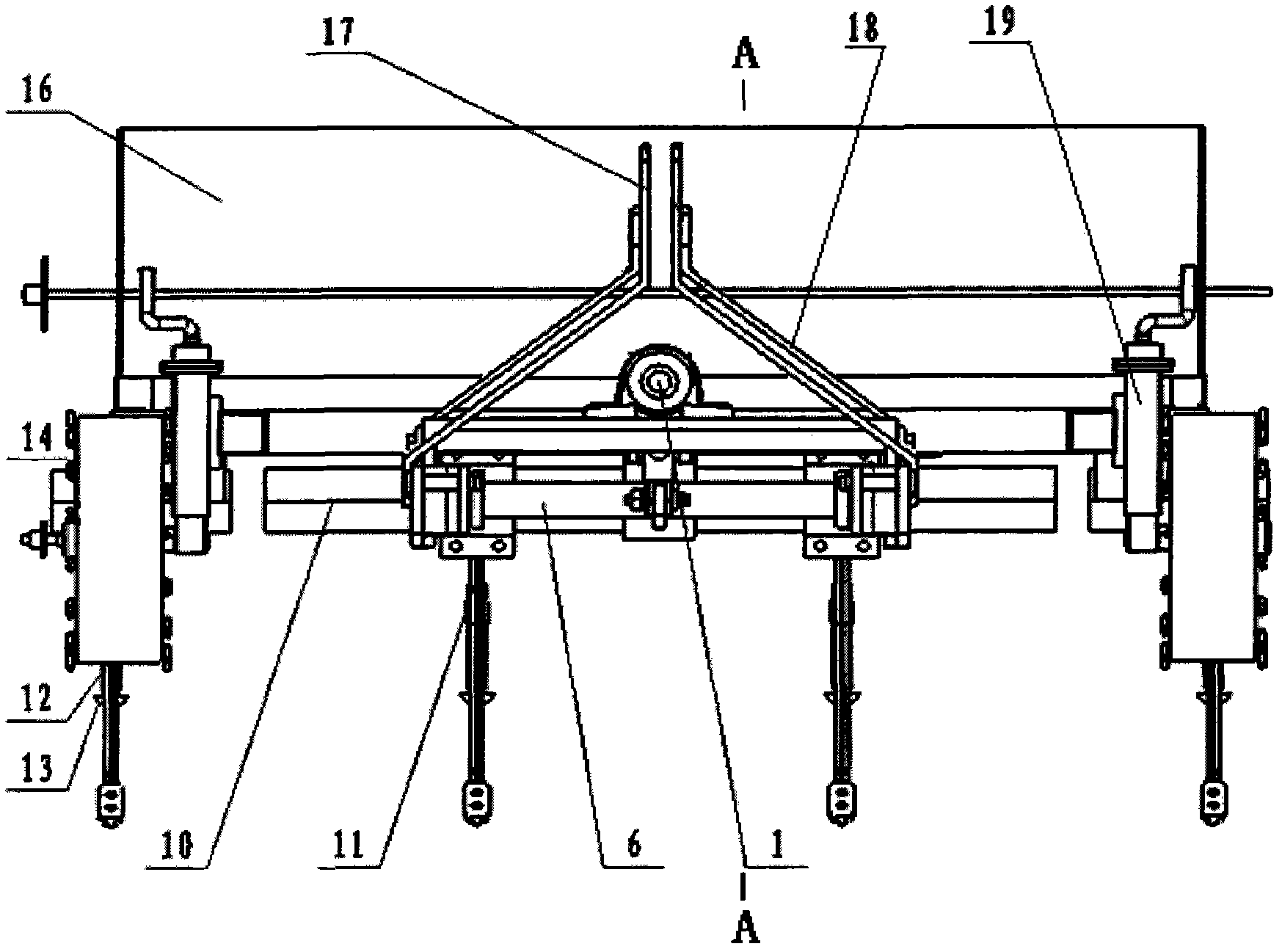

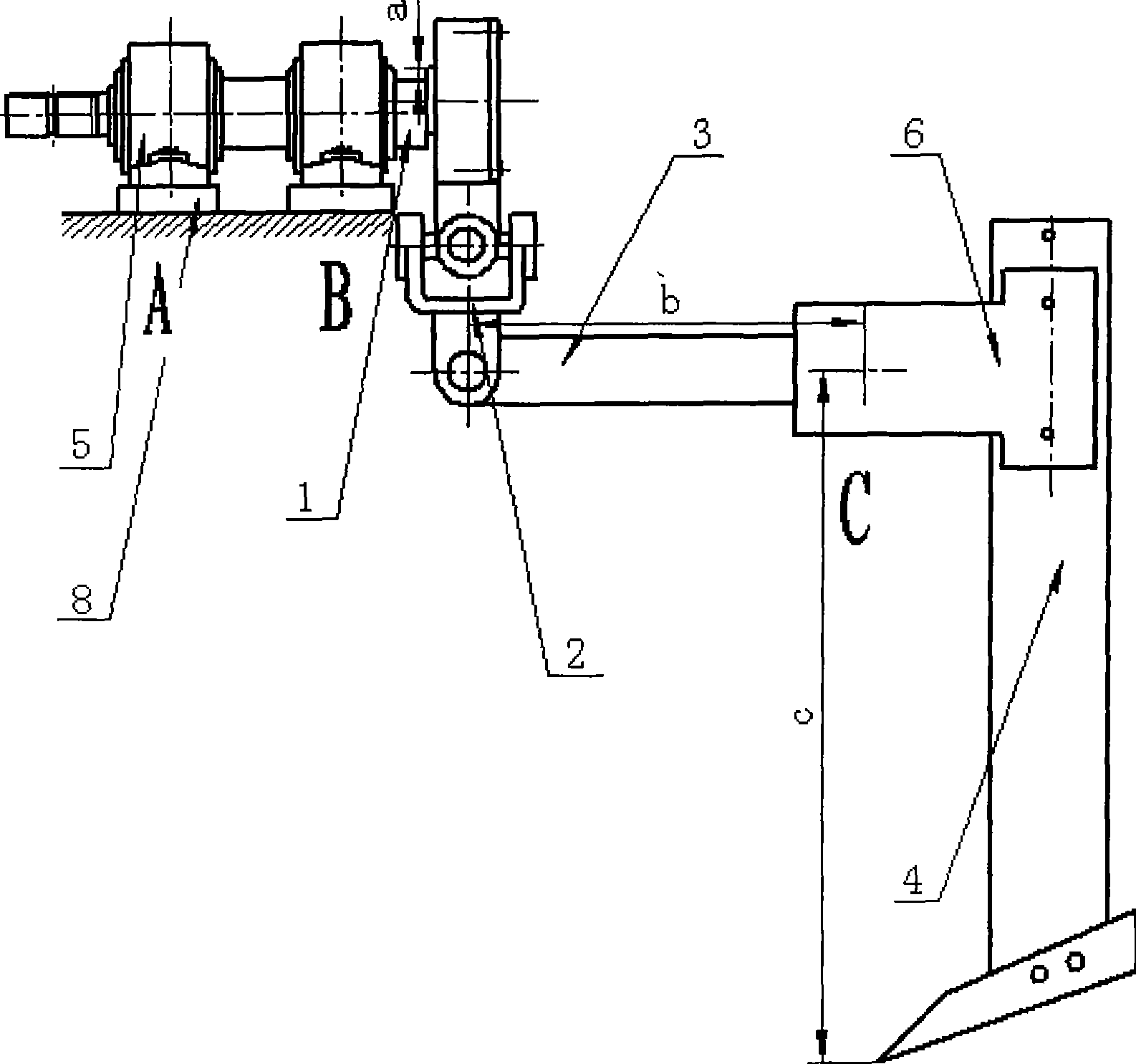

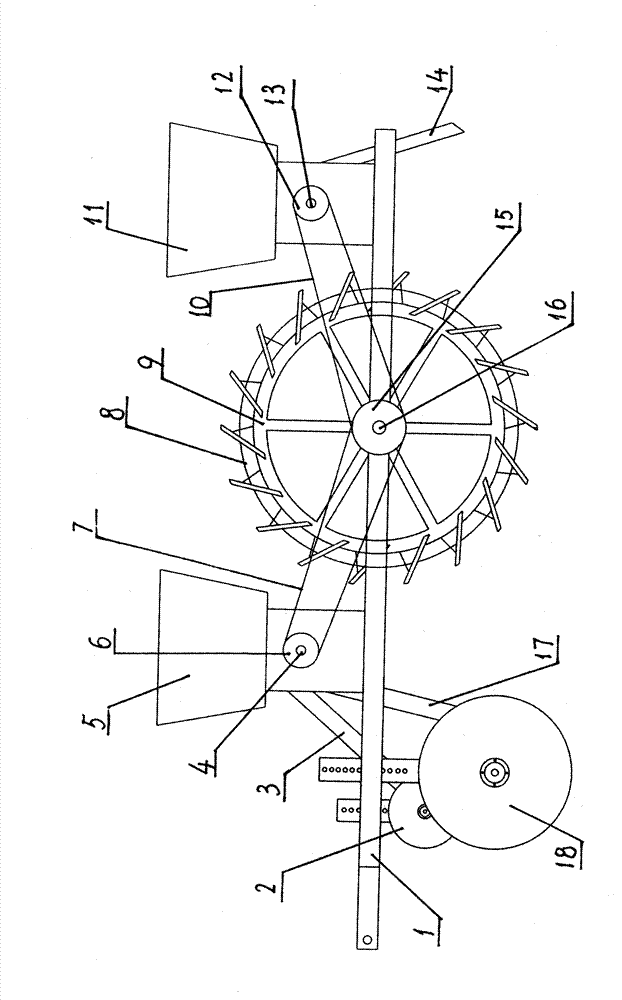

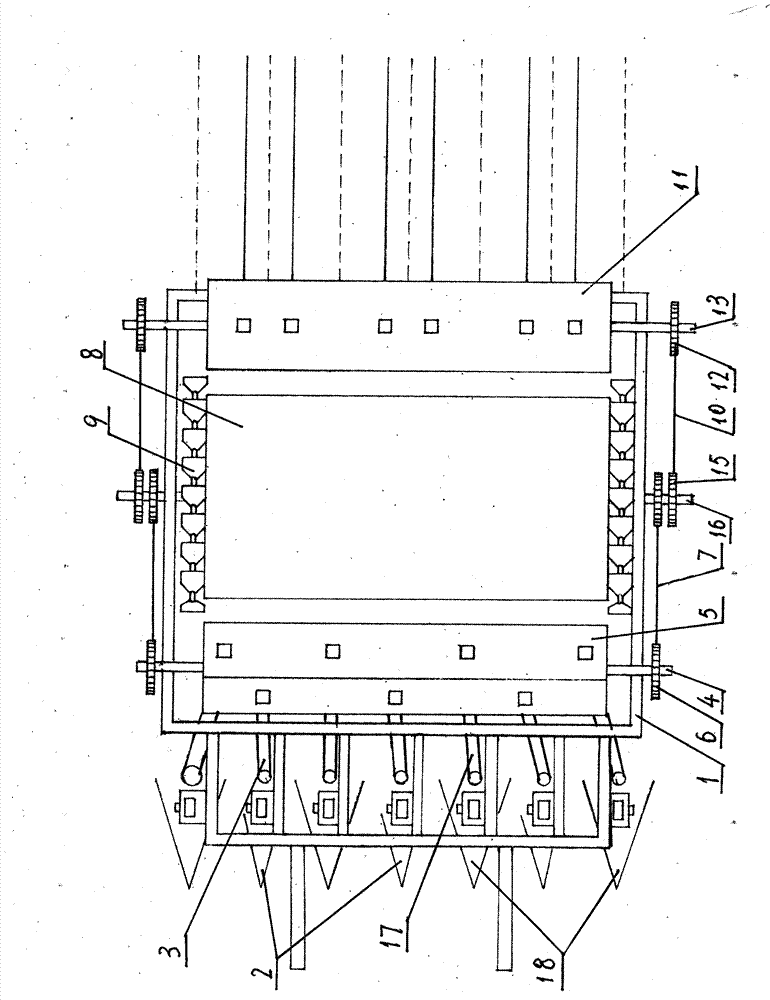

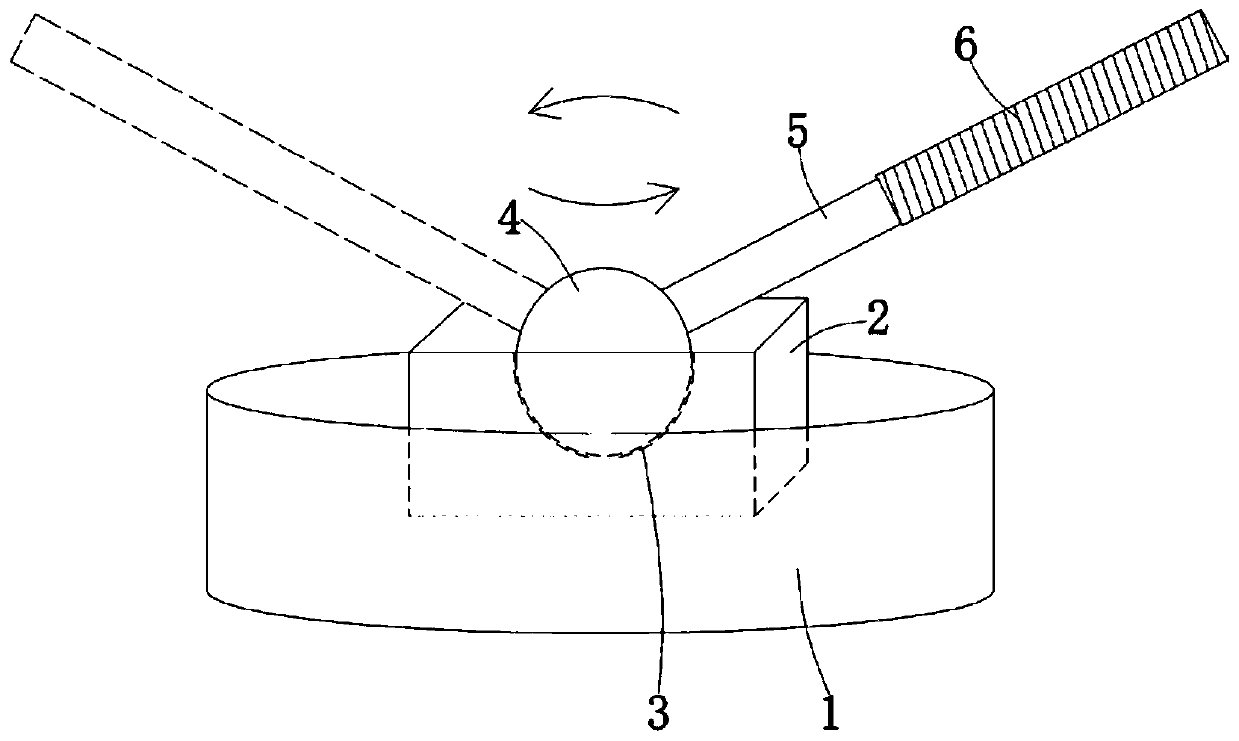

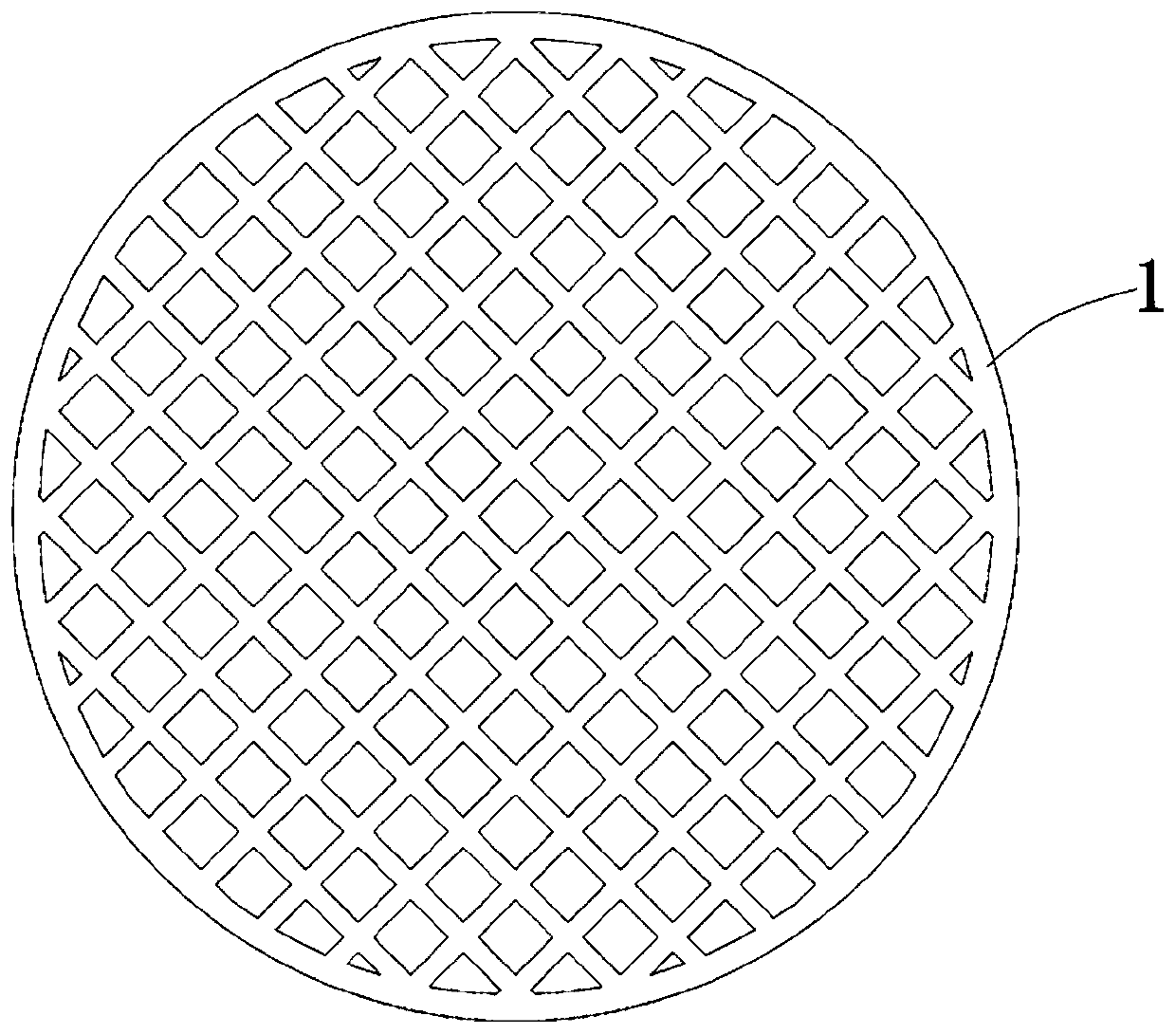

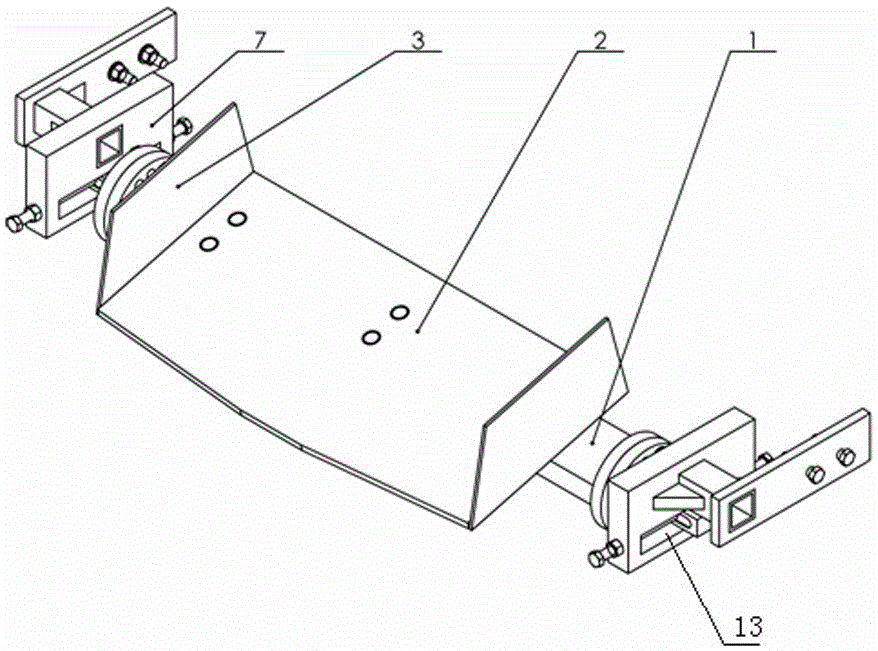

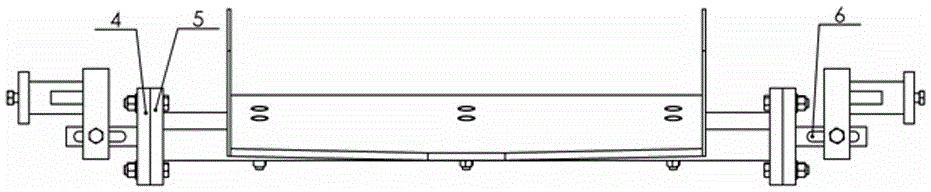

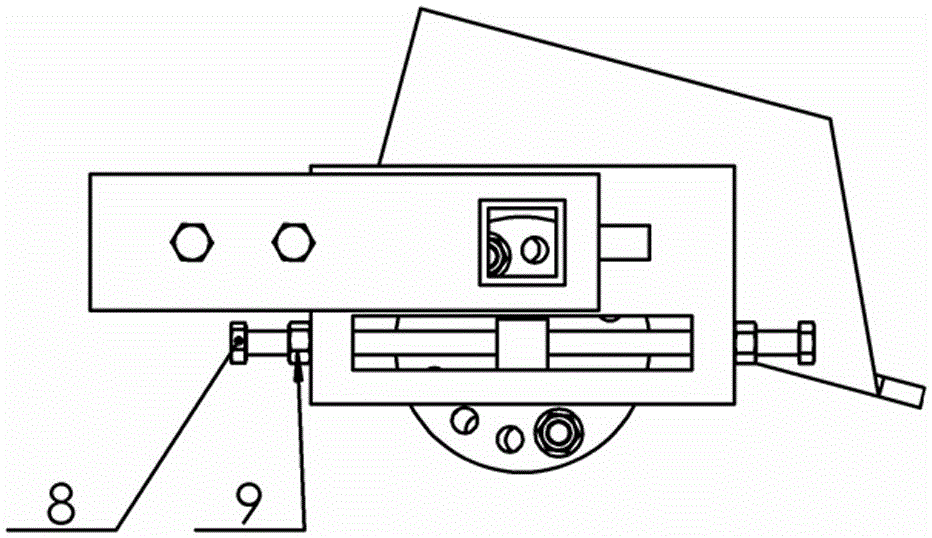

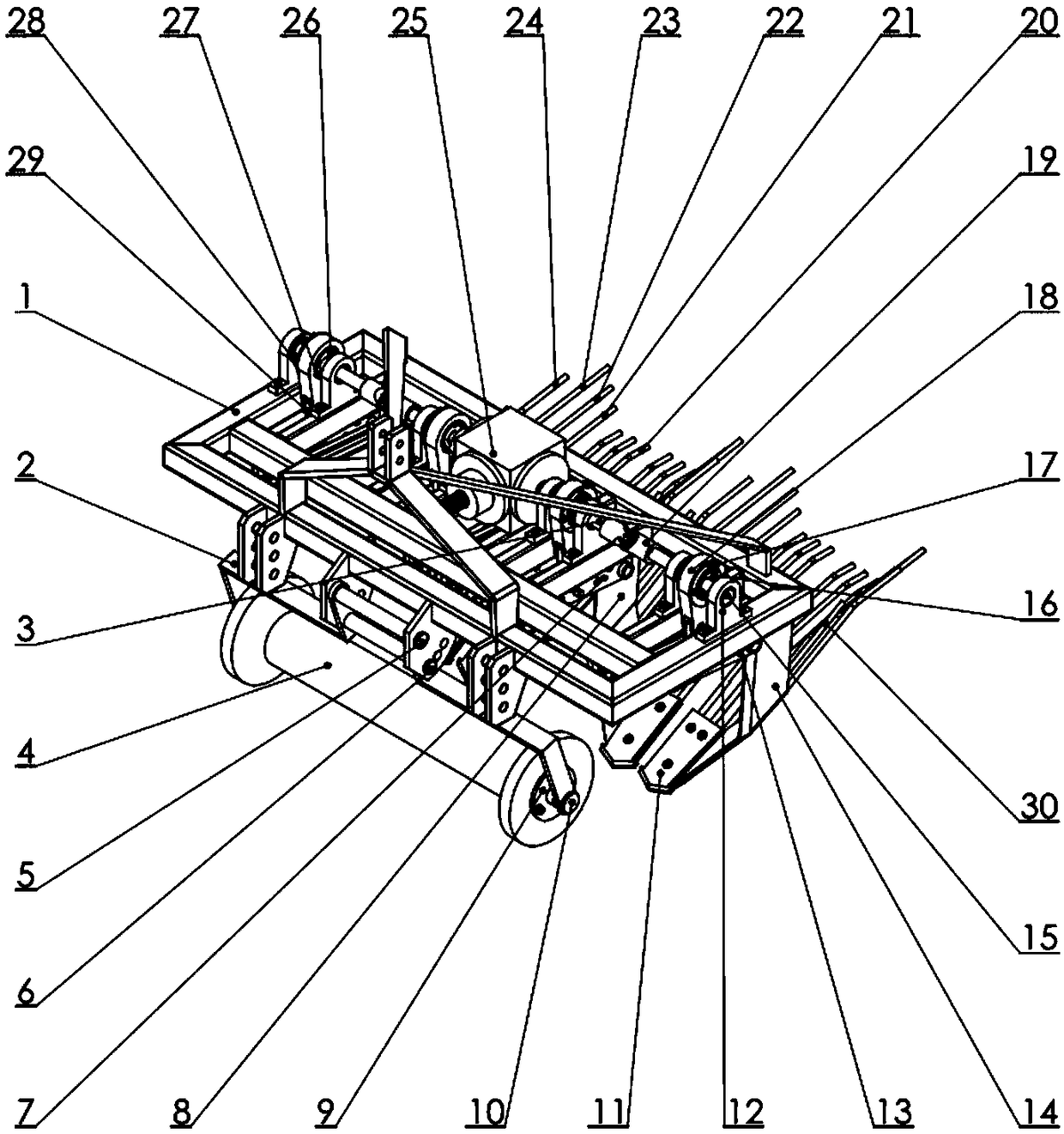

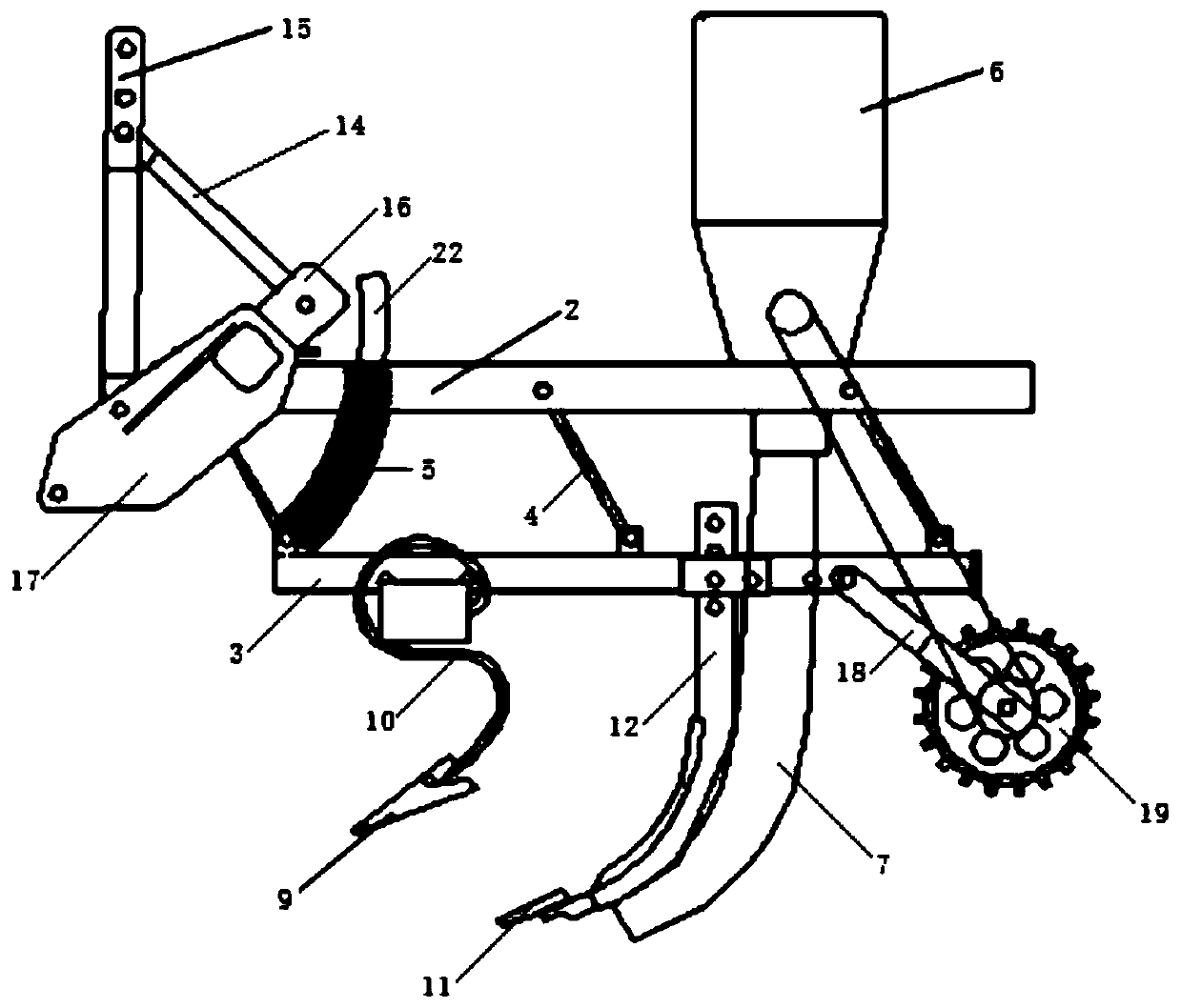

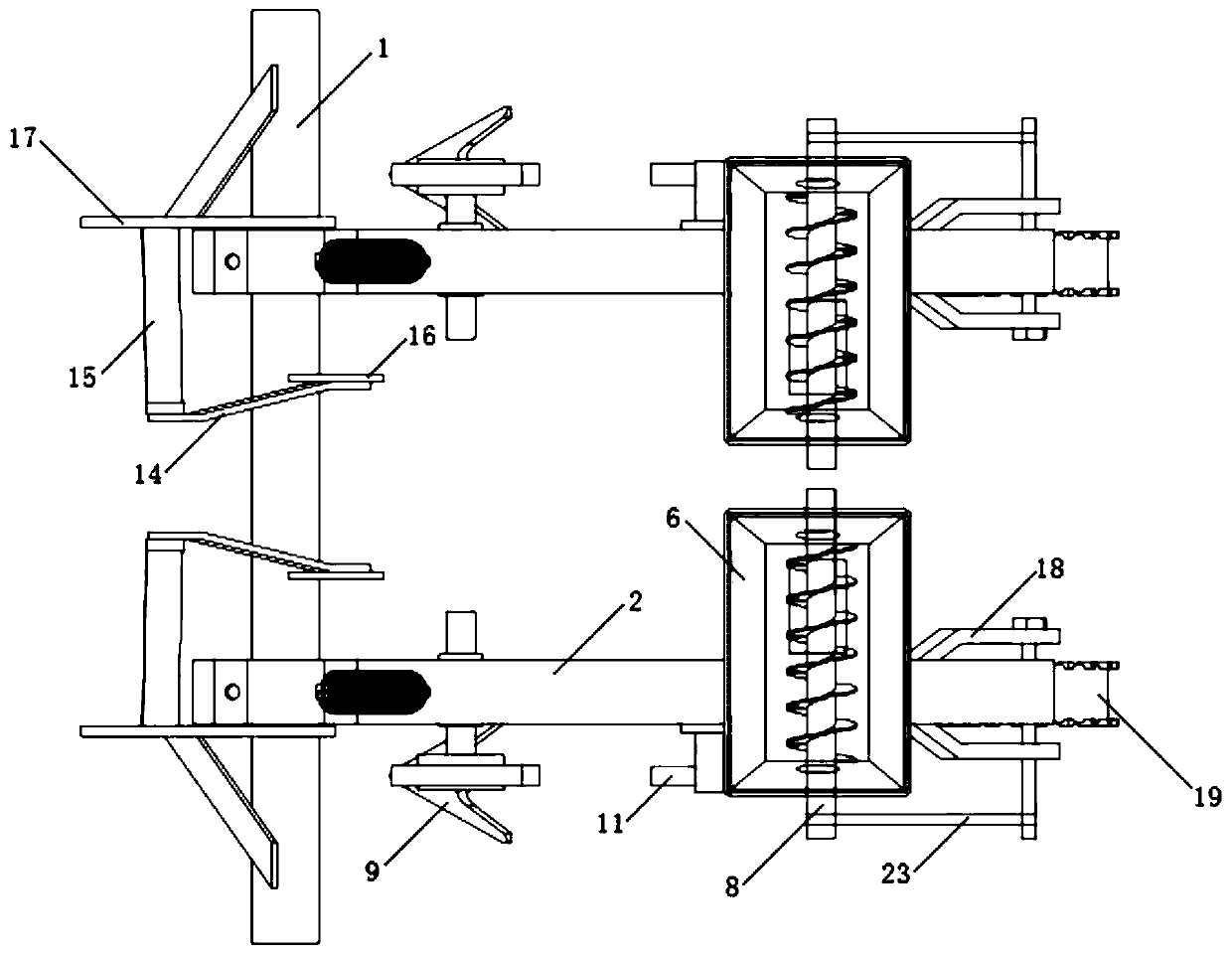

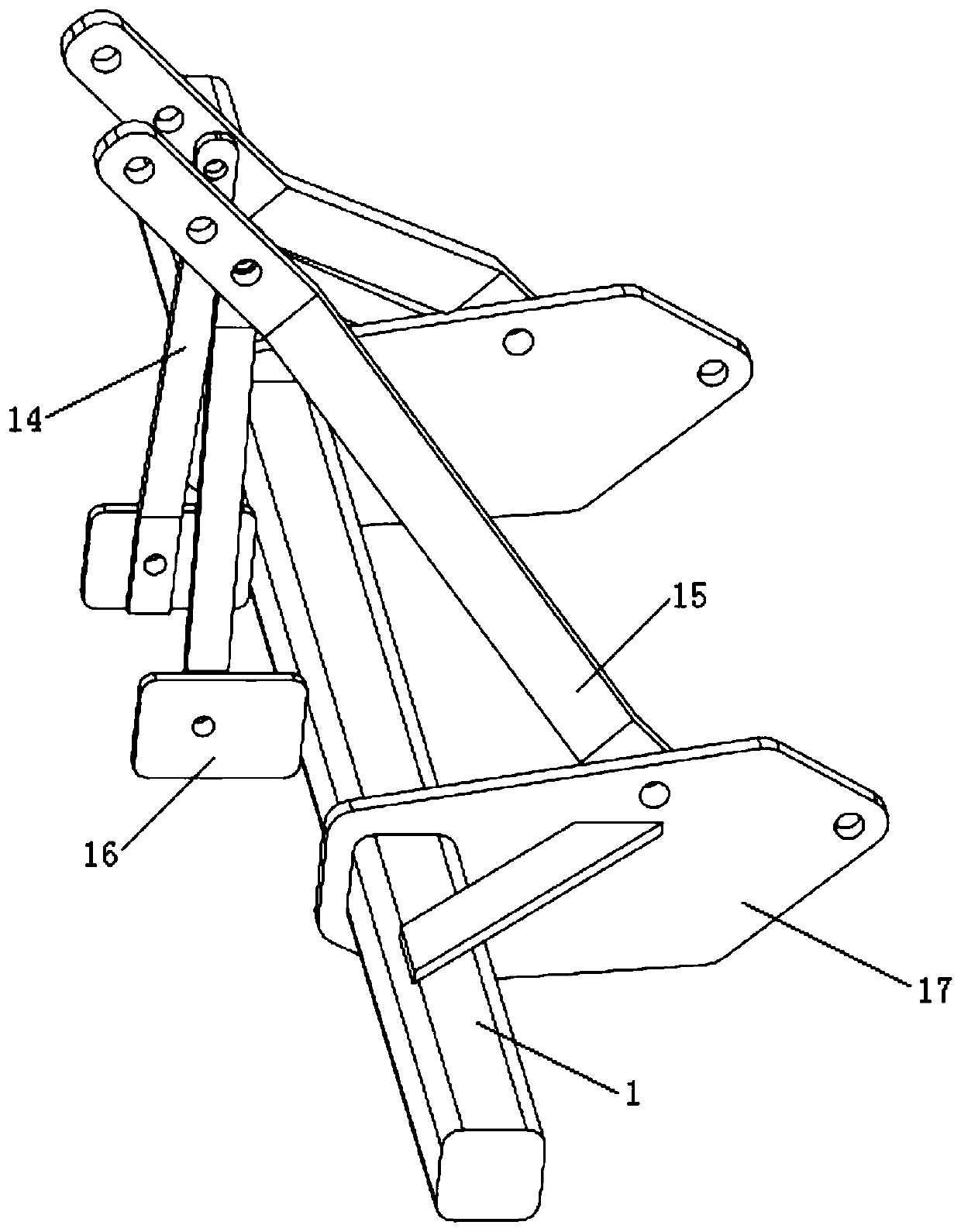

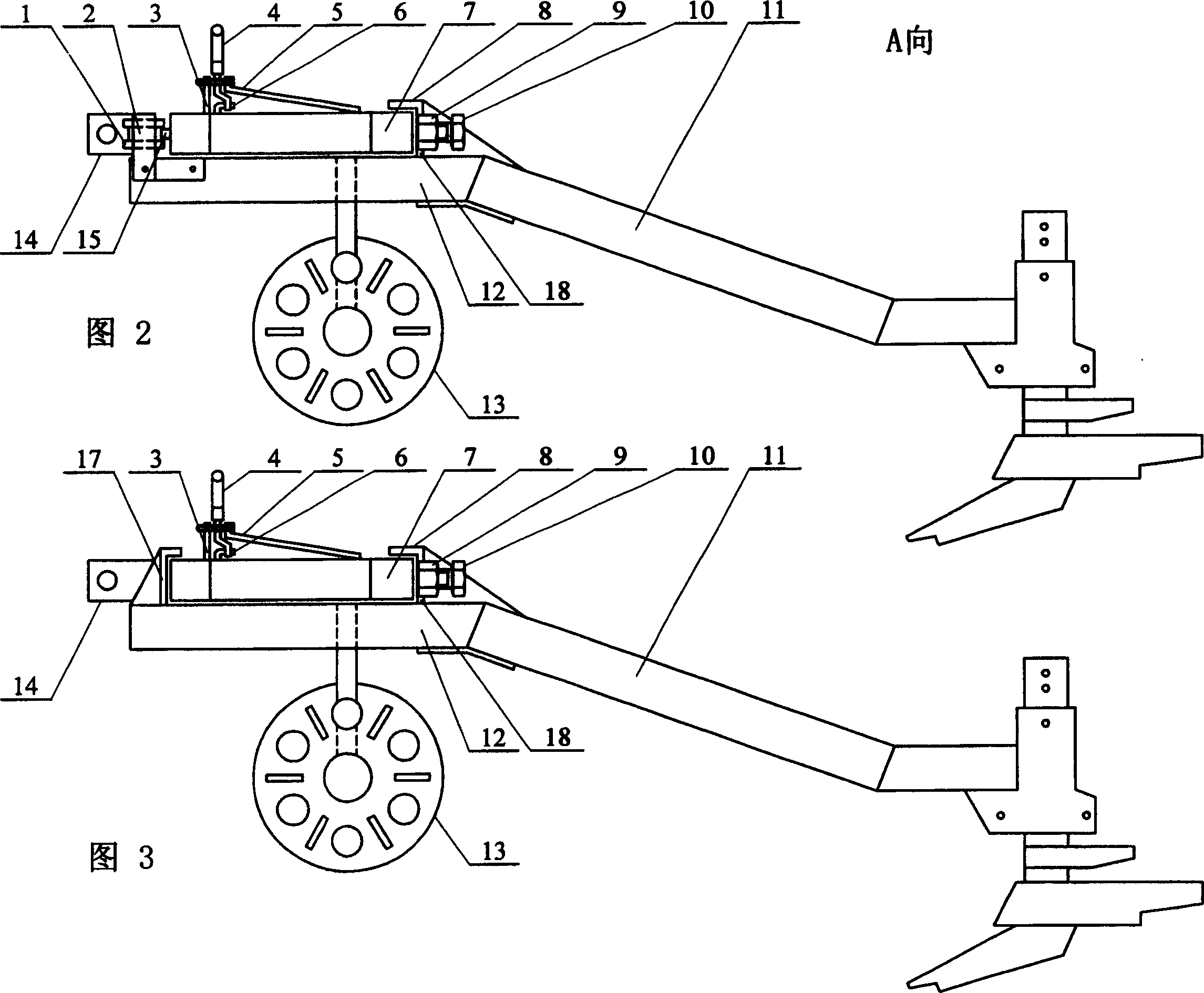

The invention relates to a vibration subsoiling fertilizer applicator, and belongs to the field of agricultural machines. The vibration subsoiling fertilizer applicator comprises a vibration subsoiling device, a depth control device, a fertilizer applying device and a traction device, wherein the vibration subsoiling device is arranged on the middle part of a machine frame and the rear parts on both sides of the machine frame and is connected with a power output shaft of a tractor; the depth control device is arranged on both sides of the machine frame; the fertilizer applying device is arranged on the rear part of the machine frame; and the traction device is arranged on the front part of the machine frame and is connected with a traction device of the tractor. In the vibration subsoiling fertilizer applicator, an eccentric mechanism has a bridge type structure of an eccentric shaft, an eccentric section of the eccentric shaft is in the middle, and both ends of the eccentric shaft are supported by bearings; the pressure applied by the eccentric shaft onto the bearings at both ends is reduced, so that the length of the eccentric shaft is shortened, and the eccentric mechanism is compact and simple; and in the vibration subsoiling device, a mode that part of subsoiling shovels vibrates actively is adopted, namely the subsoiling shovels in middle rows vibrate actively to loose soil, and the subsoiling shovels in two side rows vibrate passivity, so the vibration subsoiling device can loose the soil by vibrating and play the damping effect. The vibration subsoiling fertilizer applicator is suitable for the intertillage operation of subsoiling soil preparation and crops.

Owner:CHINA AGRI UNIV

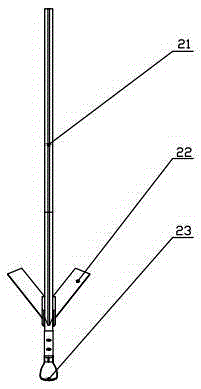

Vibration deep subsoiler

InactiveCN105393654ASimple structureLow failure rateSoil-working equipmentsPloughsDrive shaftAgricultural engineering

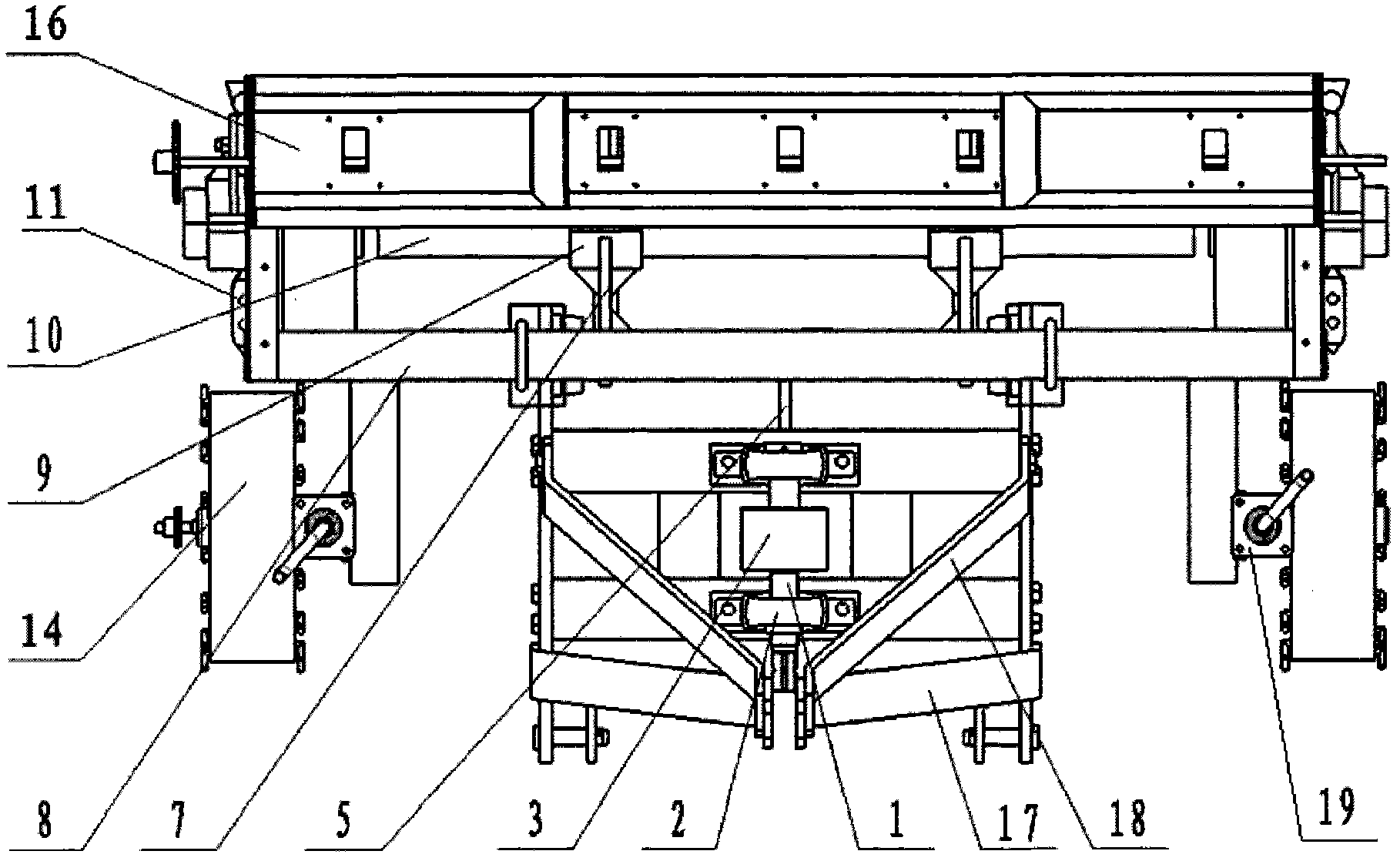

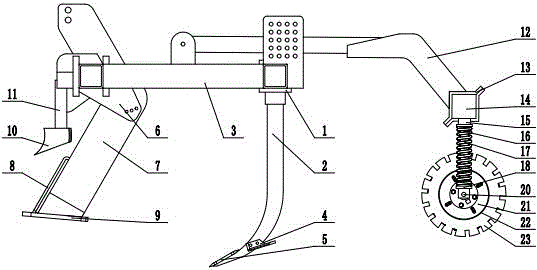

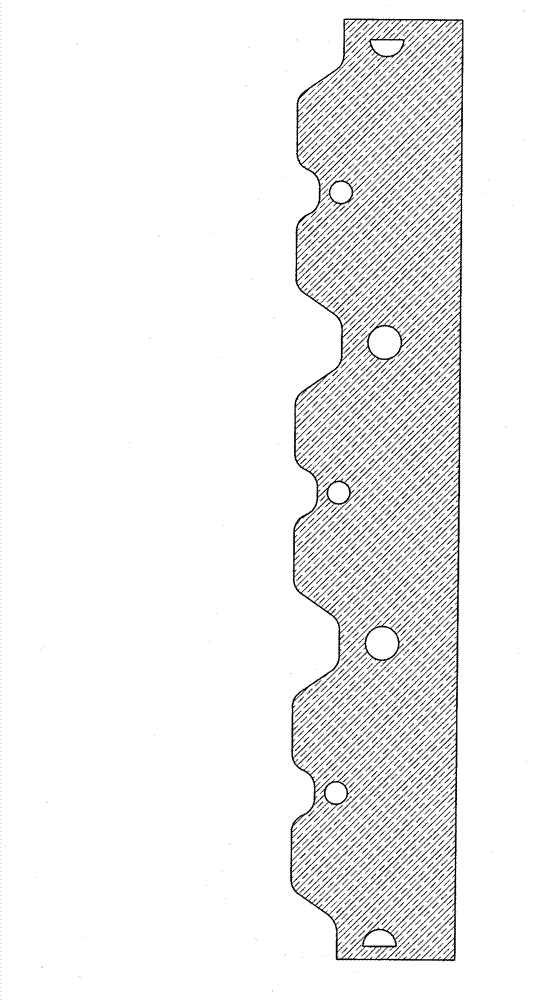

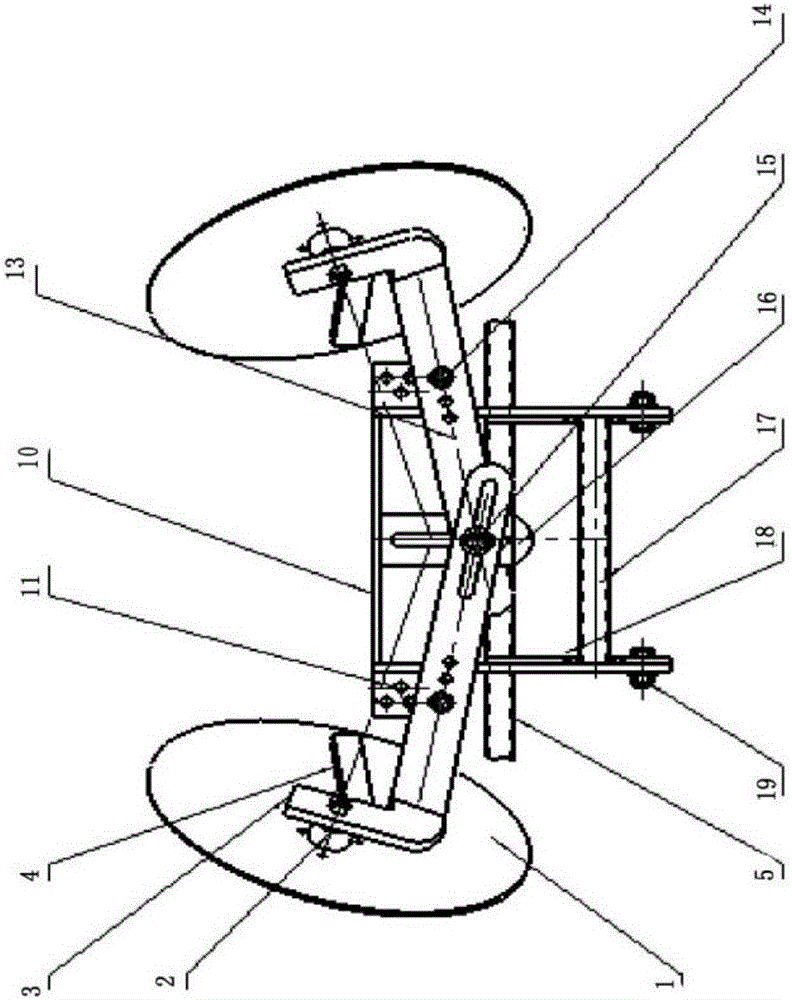

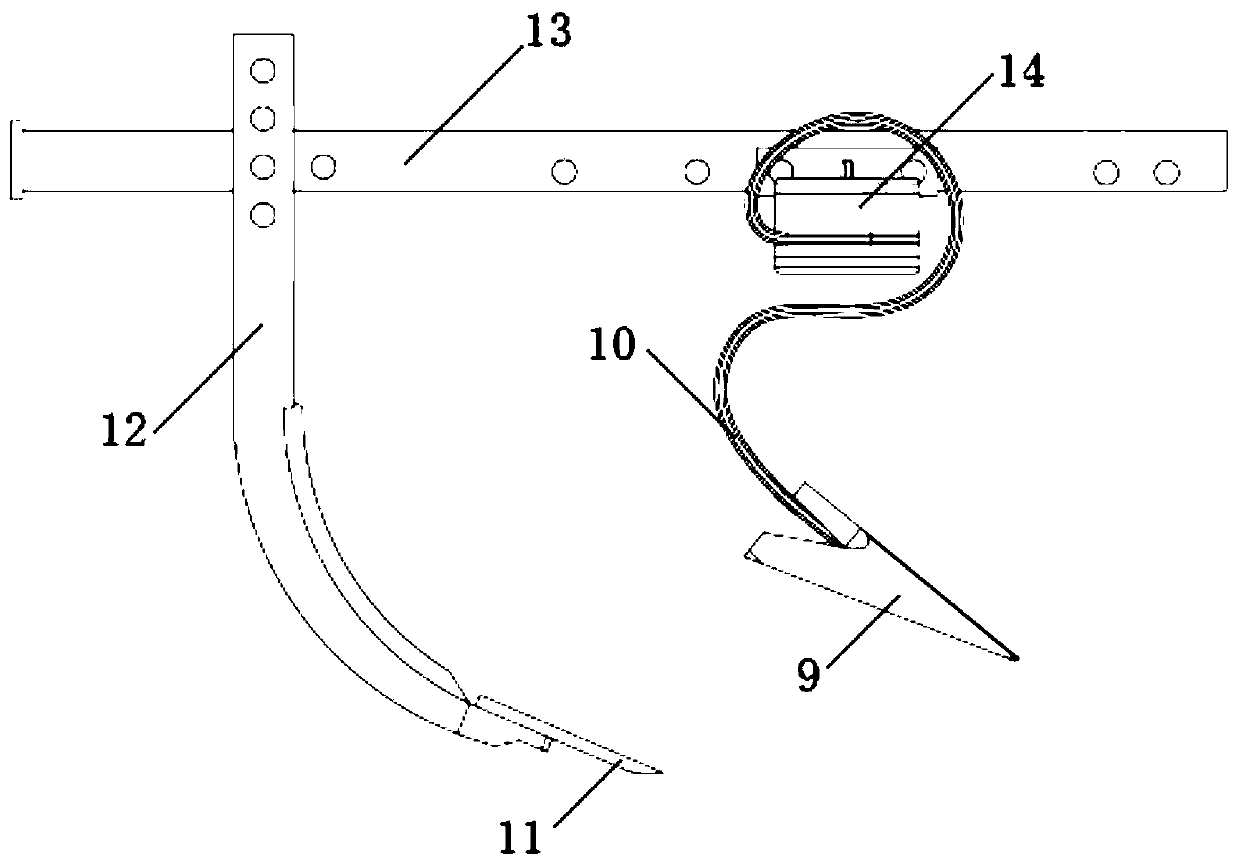

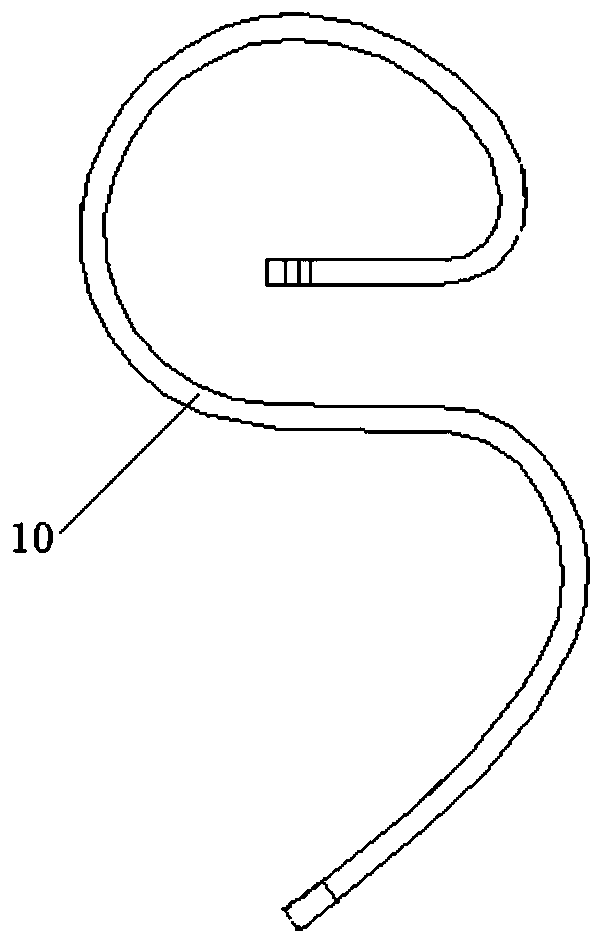

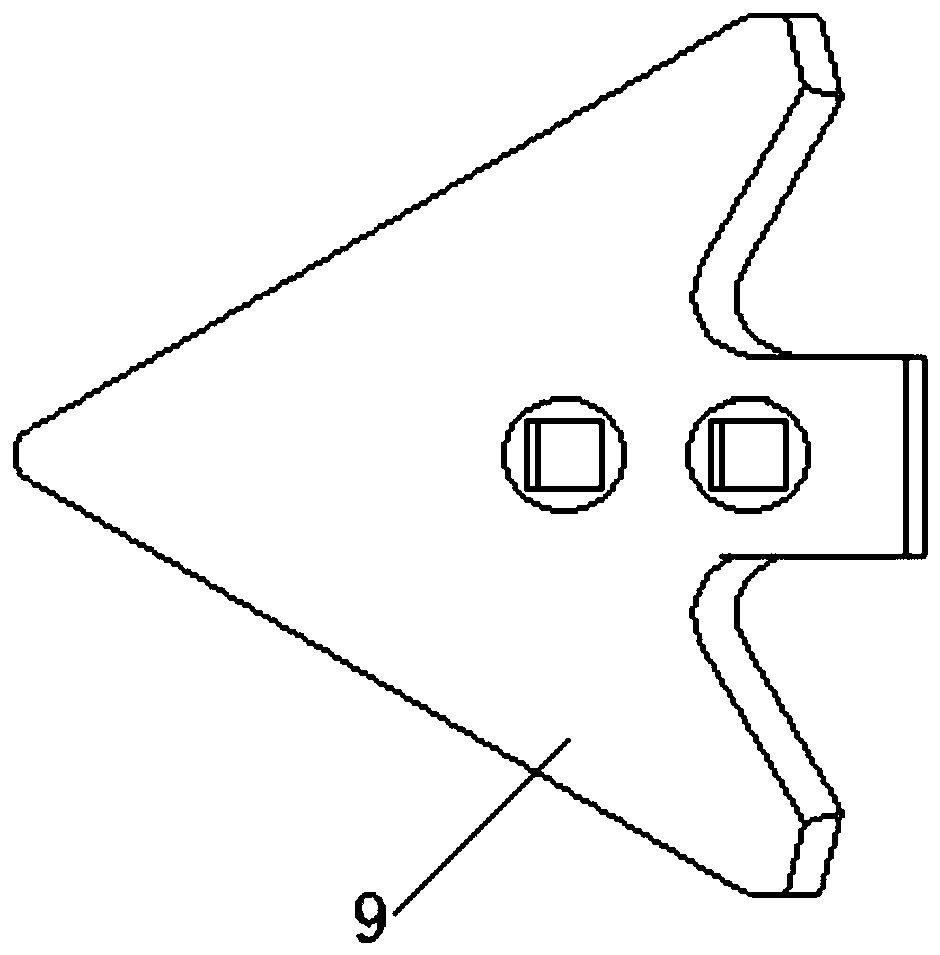

The invention relates to cultivation machinery loosening soil and deepening cultivation thickness, in particular relates to a vibration deep subsoiler and belongs to the field of agricultural machinery. A vibration deep subsoiler comprises a rack, a vibration deep subsoiling device, depth control devices and a traction device, wherein the vibration deep subsoiling device is arranged in the middle of the rack and connected with a power output shaft of a tractor; the depth control devices are arranged on two sides of the rack; and the traction device is mounted on the front part of the rack and connected with the traction device of the tractor. Cam sliding block mechanisms are employed in the vibration deep subsoiler; I-shaped grooves are formed in the sides of cams; deep subsoilers are connected with the cam sliding block mechanisms; cams are installed on a transmission shaft; the mechanism is compact and simple; each subsoiler tip is in a spoon-shaped structure; wing shovels are arranged on two sides of each subsoiler handle, so soil can be subsoiled and deep subsoiling area can be increased; and the vibration deep subsoiler is suitable for soil deep subsoiling and crop intertillage work.

Owner:SHIHEZI UNIVERSITY

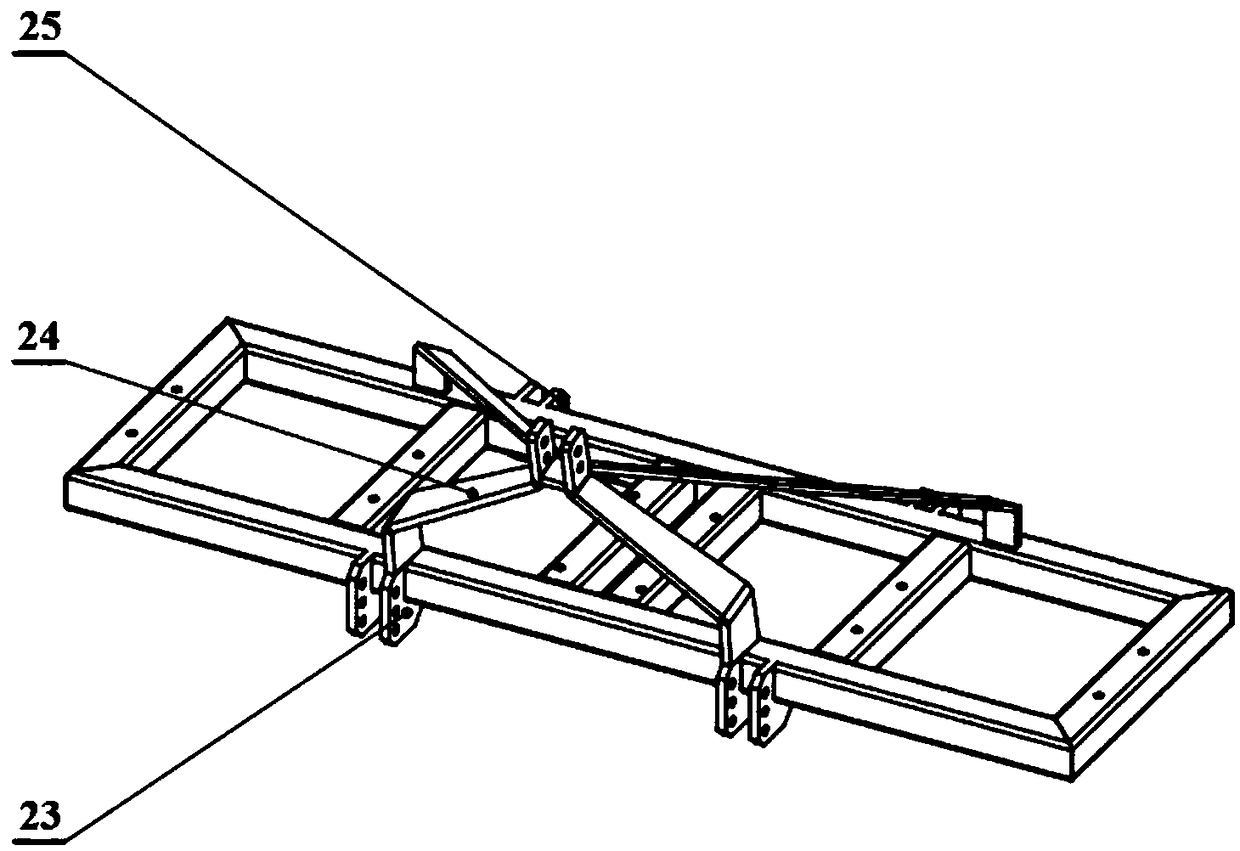

Hydraulic self-induced vibration subsoiler

InactiveCN104604365AAdjust the entry depthReduce physical discomfort and other problemsPloughsAgricultural engineeringTractor

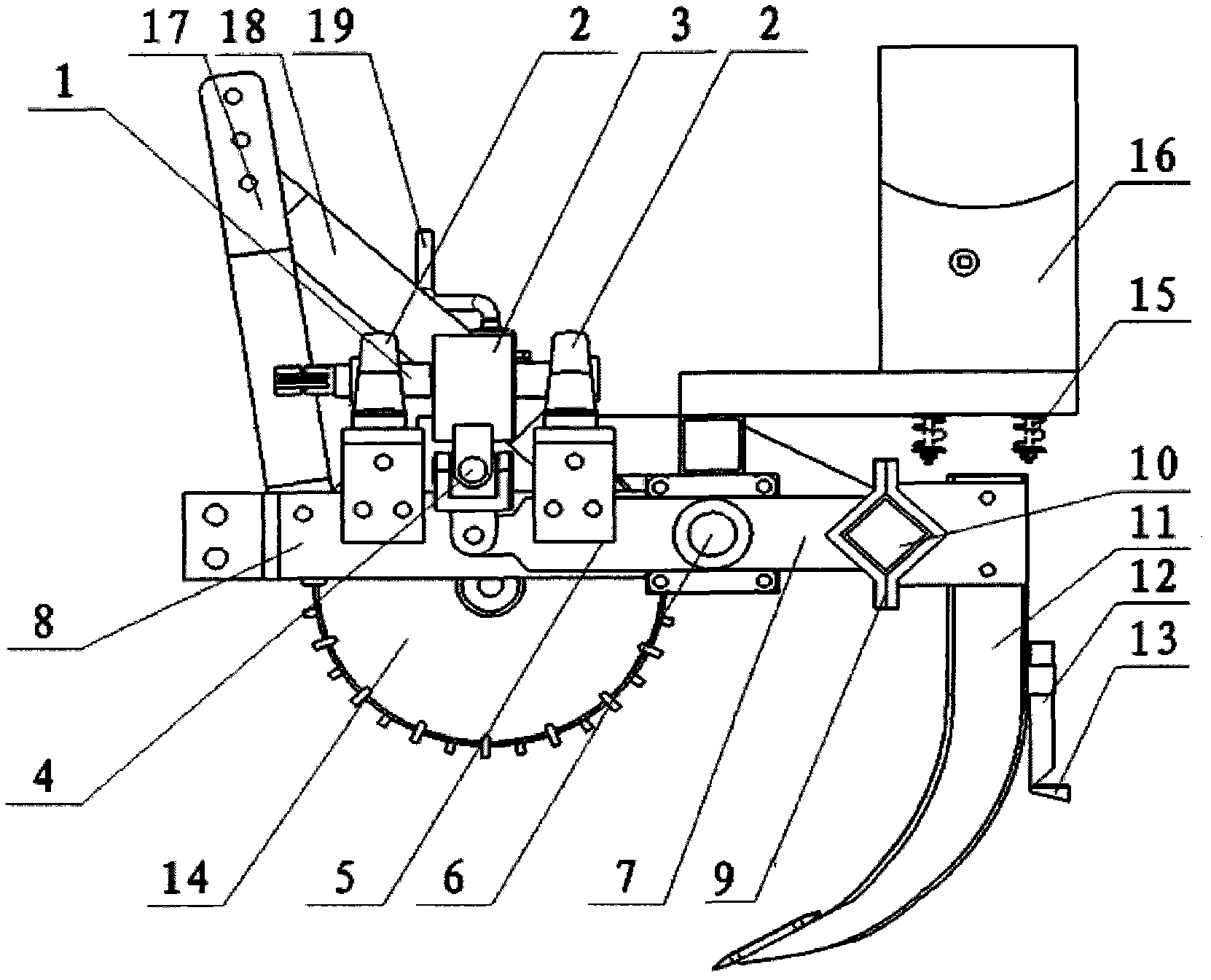

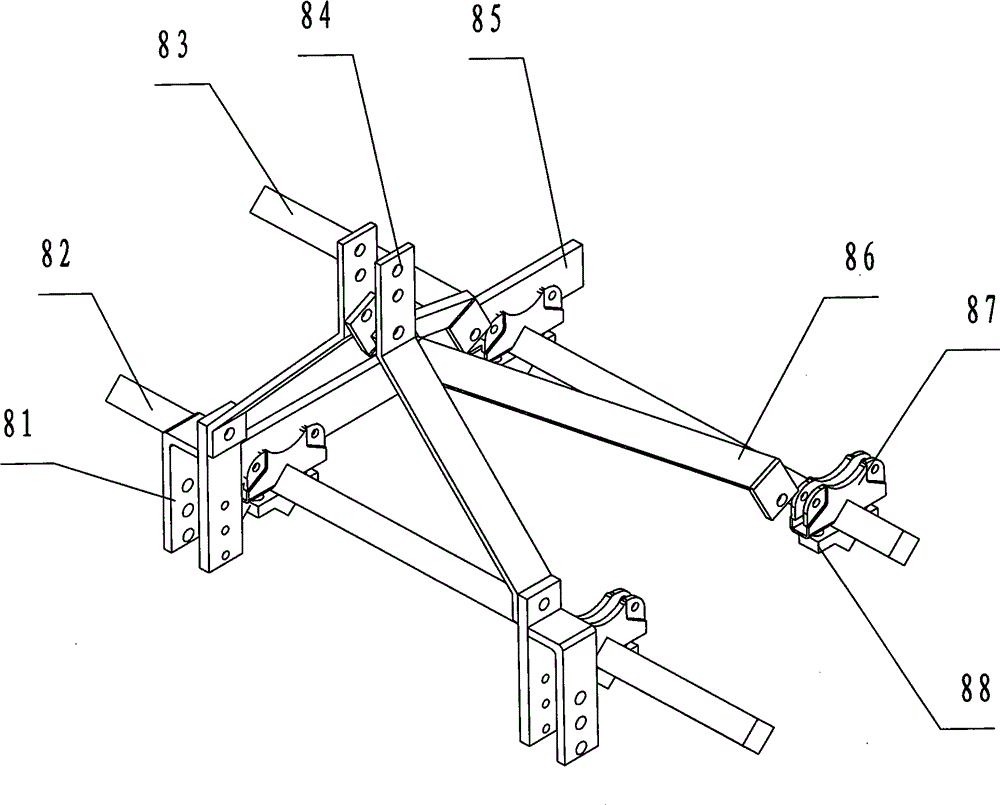

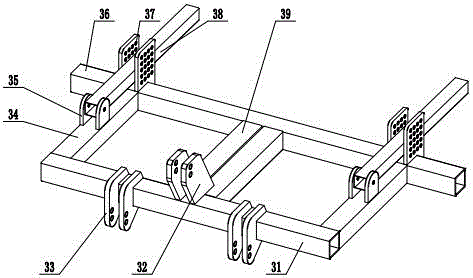

The invention relates to a hydraulic self-induced vibration subsoiler. The hydraulic self-induced vibration subsoiler is characterized by comprising a machine frame and a subsoiling device, wherein the subsoiling device is arranged at the bottom of the machine frame, the machine frame is composed of suspension pair plates, a front beam, a rear beam, an inclined traction rod, a cross beam, a cross traction rod, U-shaped groove fixing pieces and V-shaped locking pieces, and the subsoiling device is composed of shovel points, shovel wings and shovel handles. According to the hydraulic self-induced vibration subsoiler, the stretch and retraction amount of vibration springs is controlled and adjusted through hydraulic oil, the embedded depths of all subsoiling shovels are effectively adjusted, in this way, the tilling depth consistency is guaranteed during subsoiling, and the overall vibration which causes discomfort of a driver of a tractor and the like and is generated due to inconsistency of shake of mechanisms of the subsoiler is reduced; compared with a non-vibration subsoiler and a one-way vibration subsoiler under the same condition, during work, the traction resistance is remarkably reduced; to sum up, the hydraulic self-induced vibration subsoiler can reduce resistance and save energy and is good in operation effect and high in adaptability.

Owner:SHIHEZI UNIVERSITY

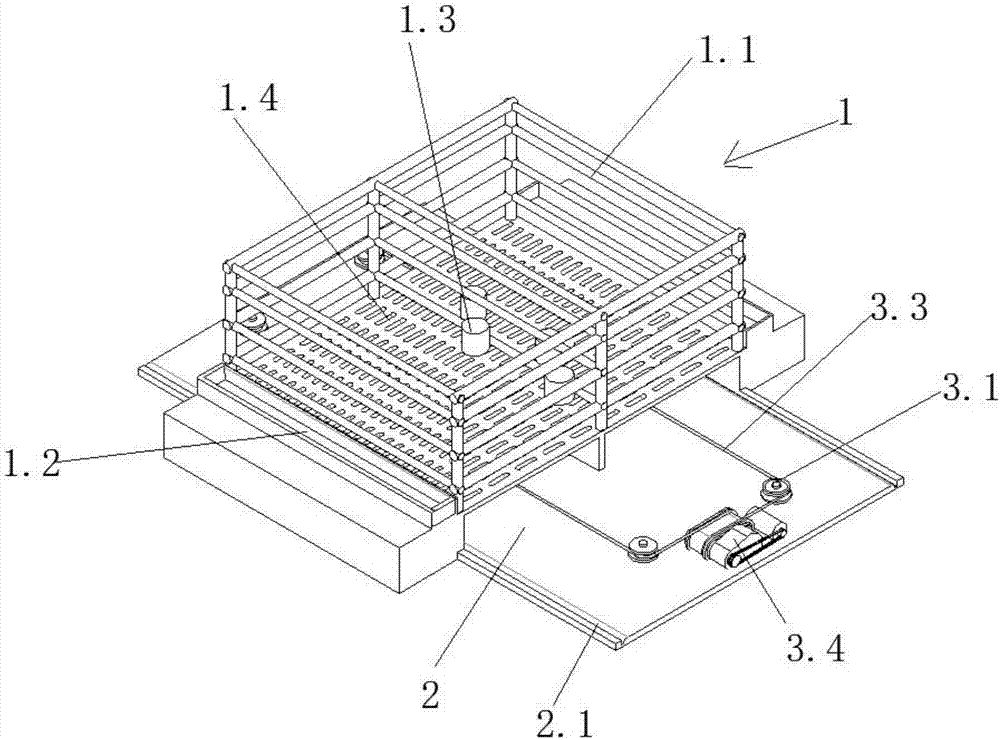

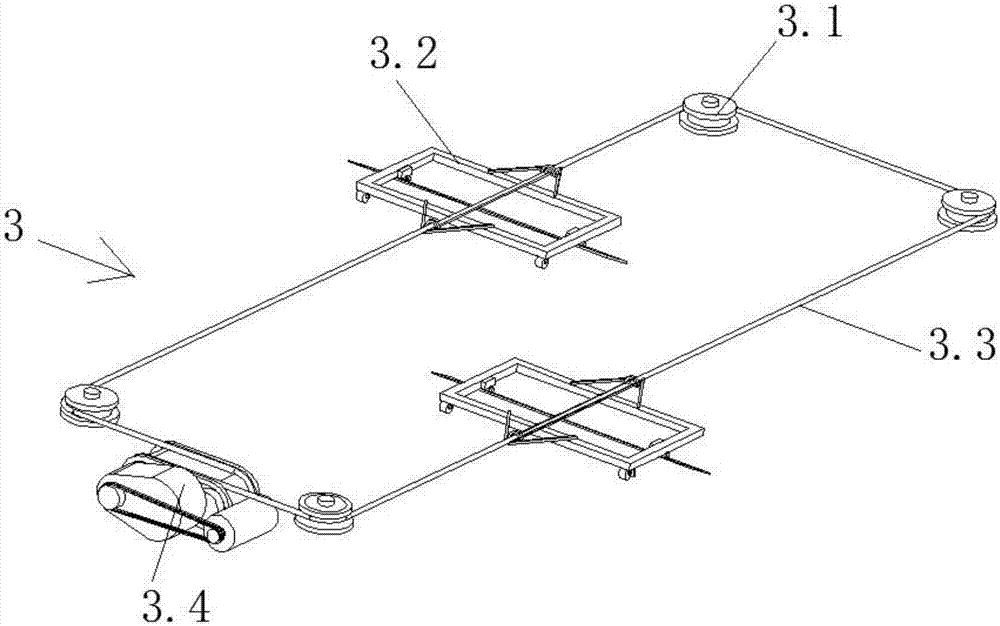

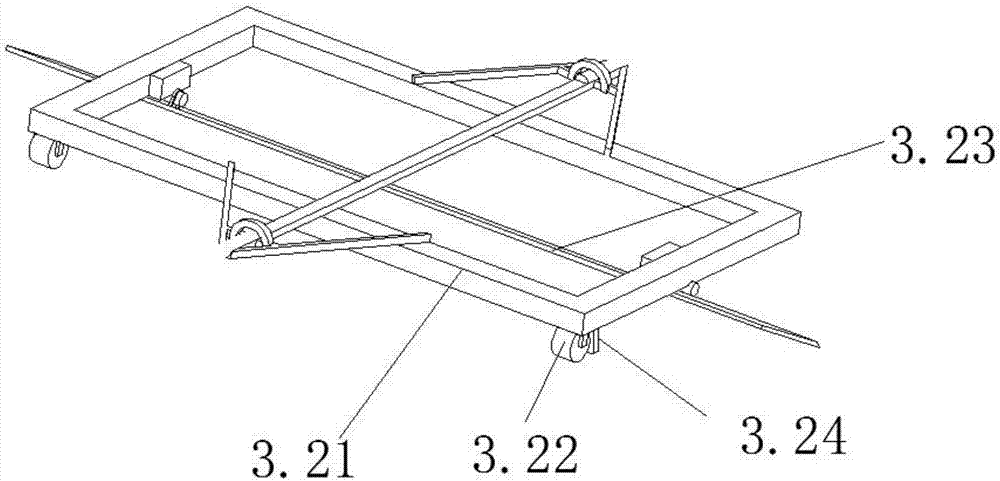

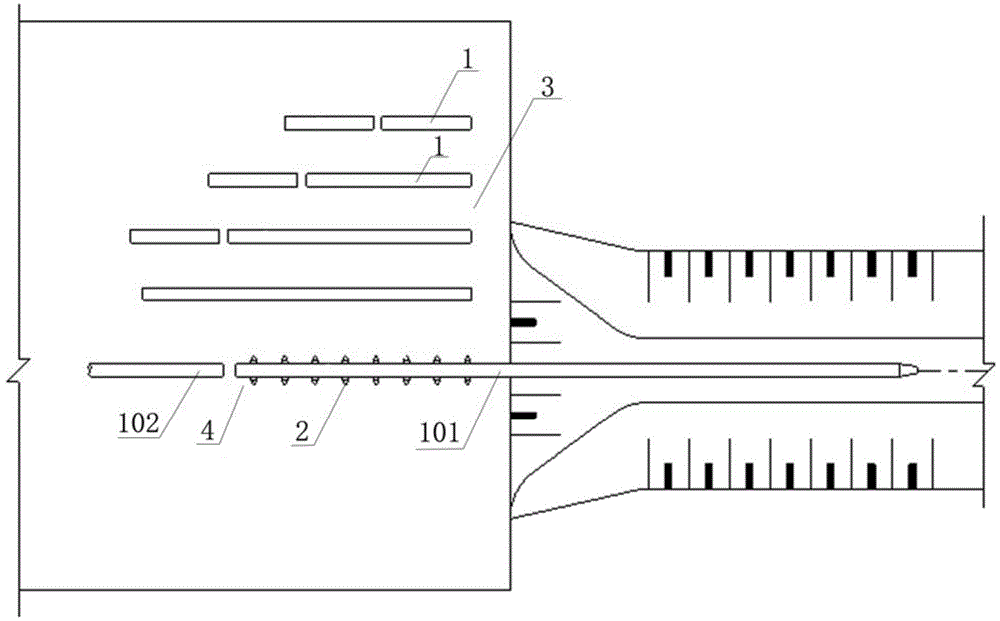

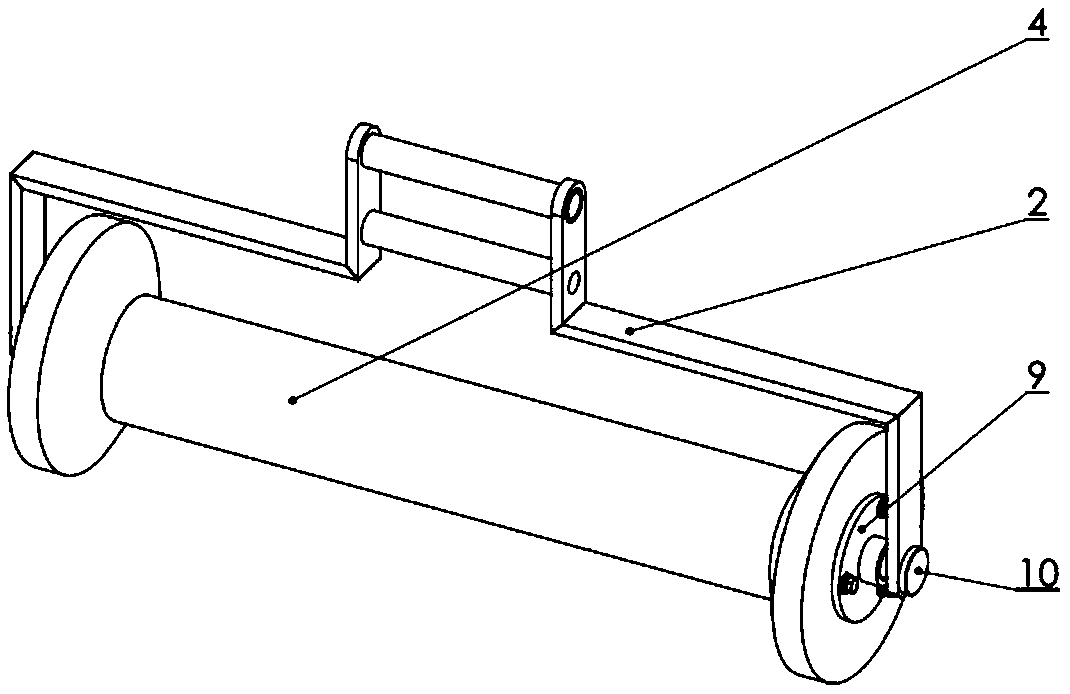

Optical fiber hoisting and laying device

ActiveCN109019141ALow traction resistanceAvoid random dropsFilament handlingOptical fibre/cable installationManual tractionEngineering

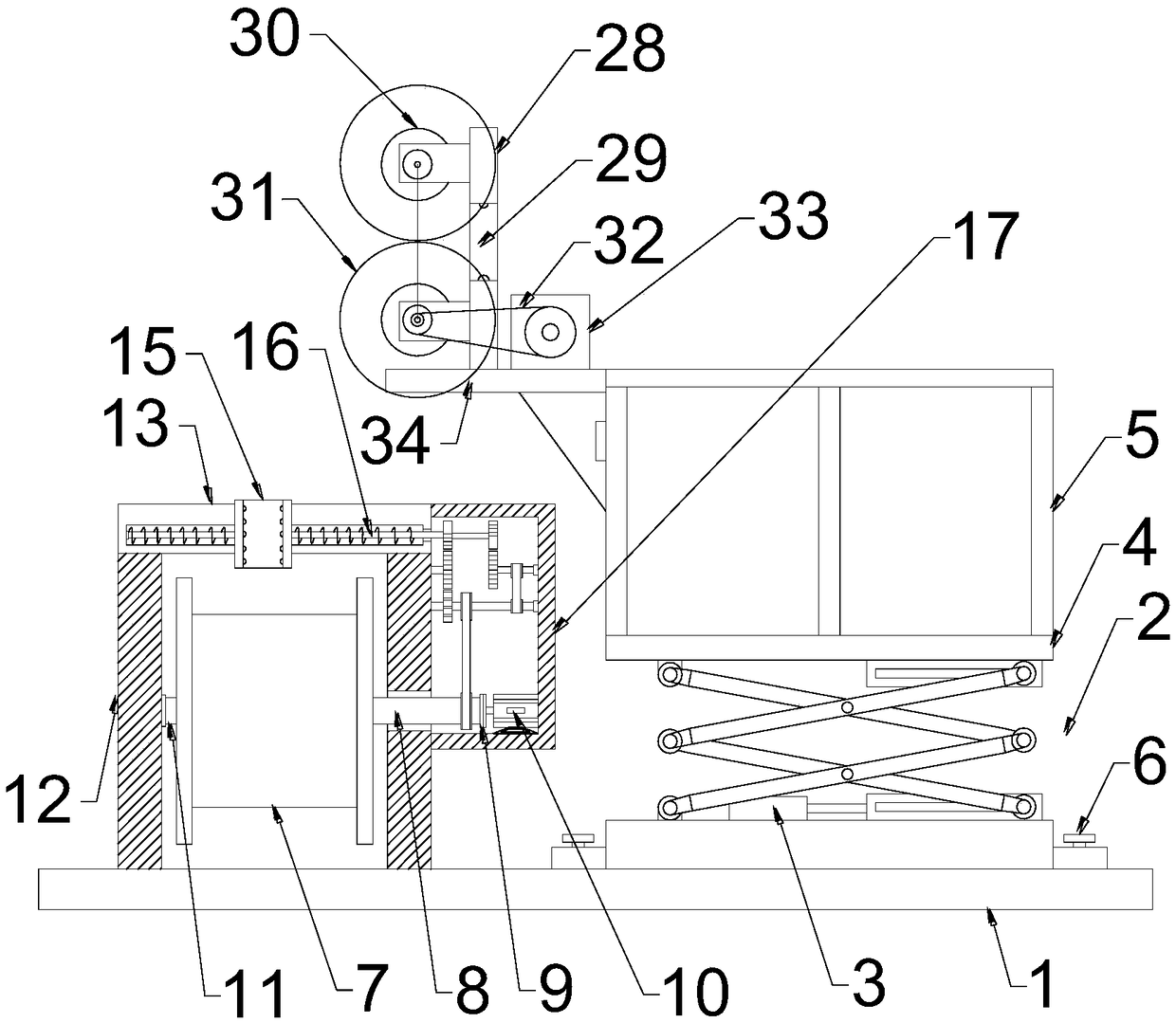

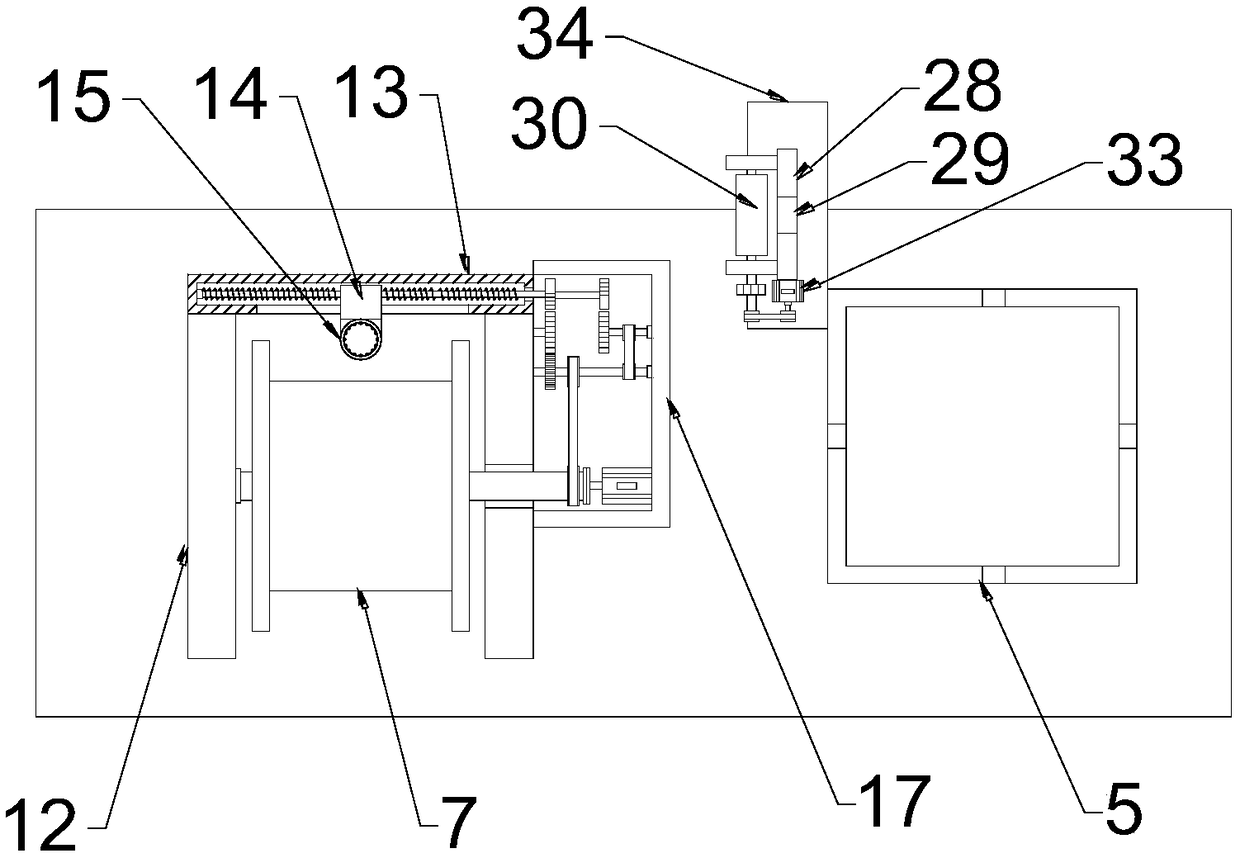

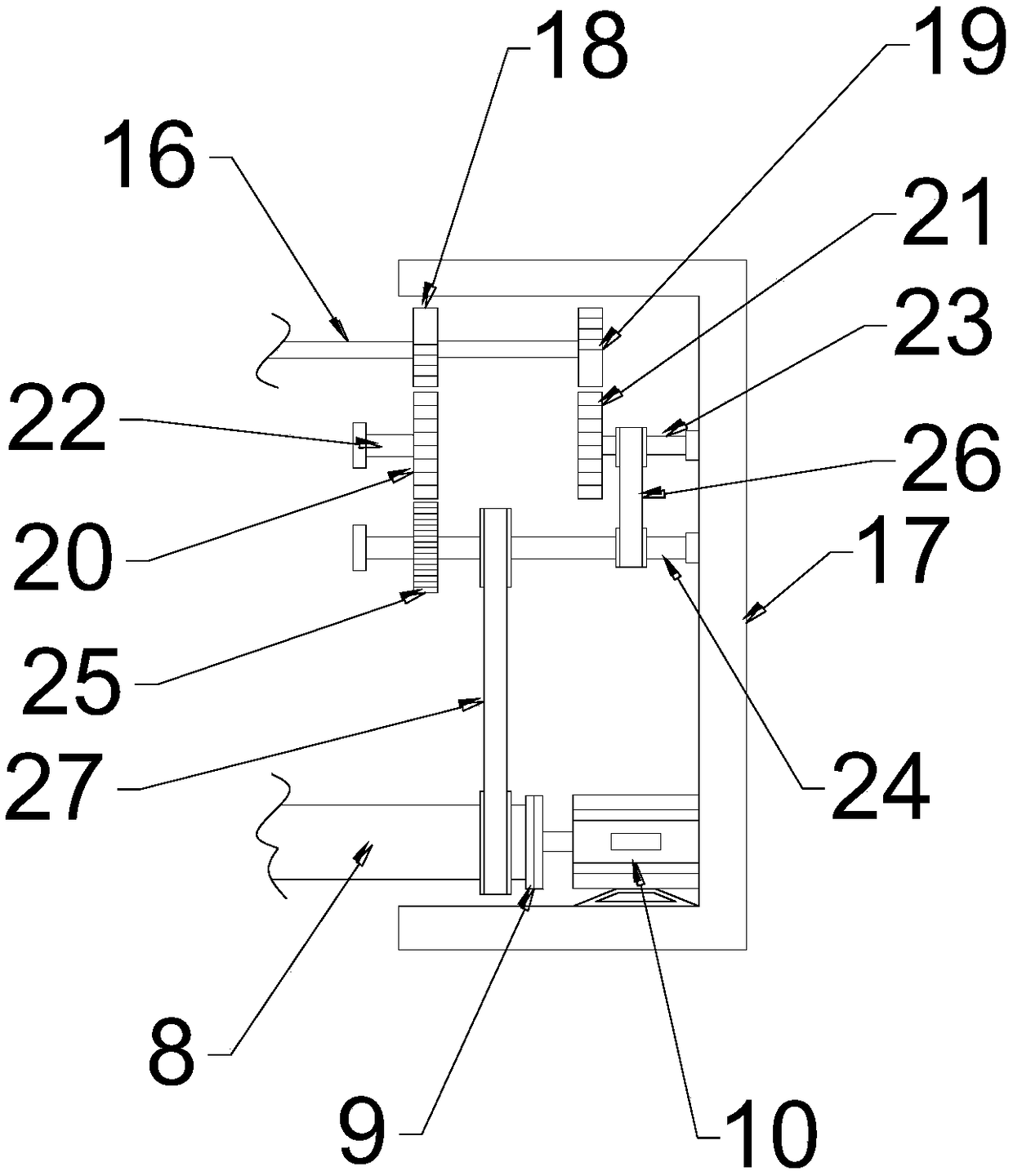

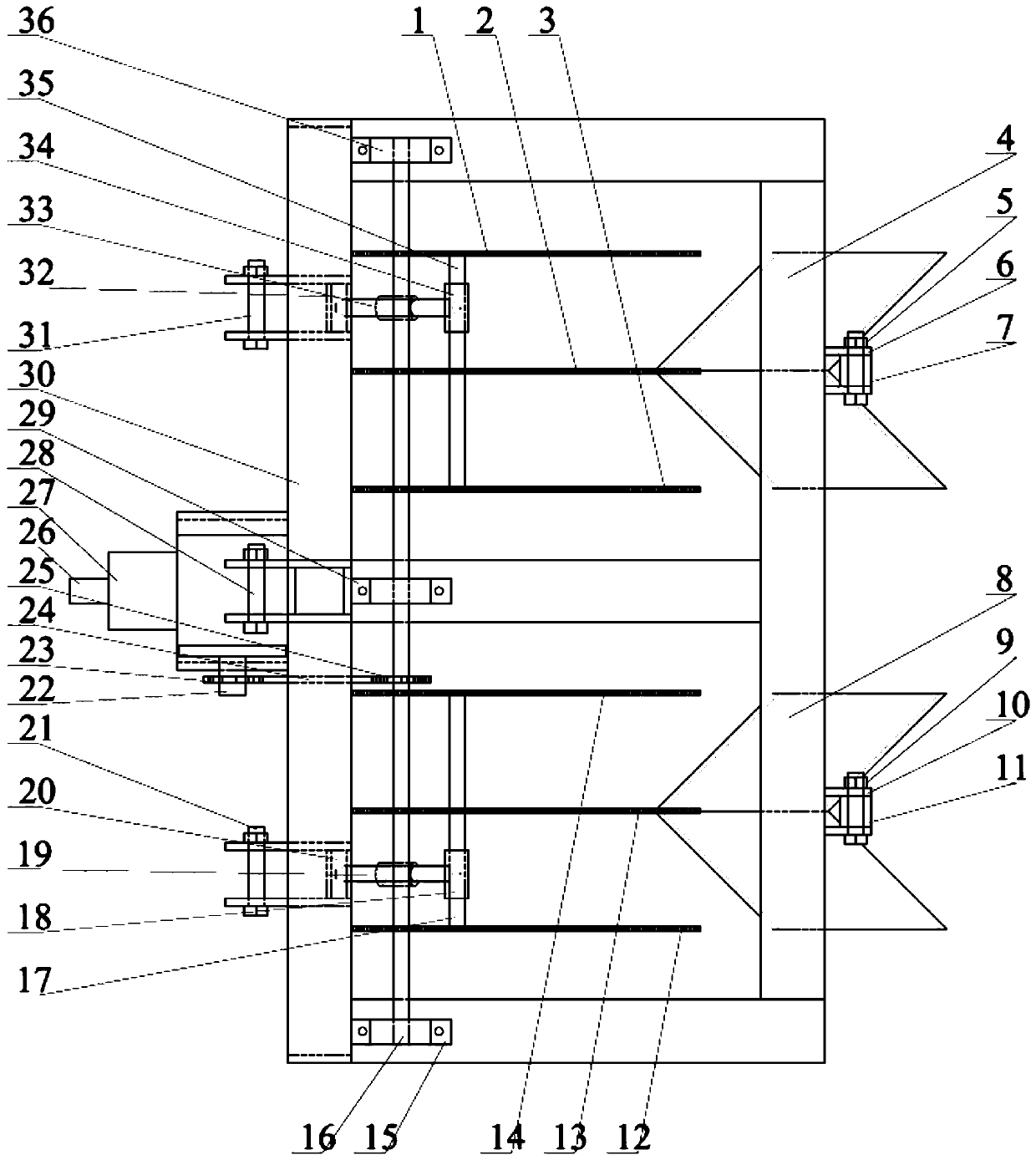

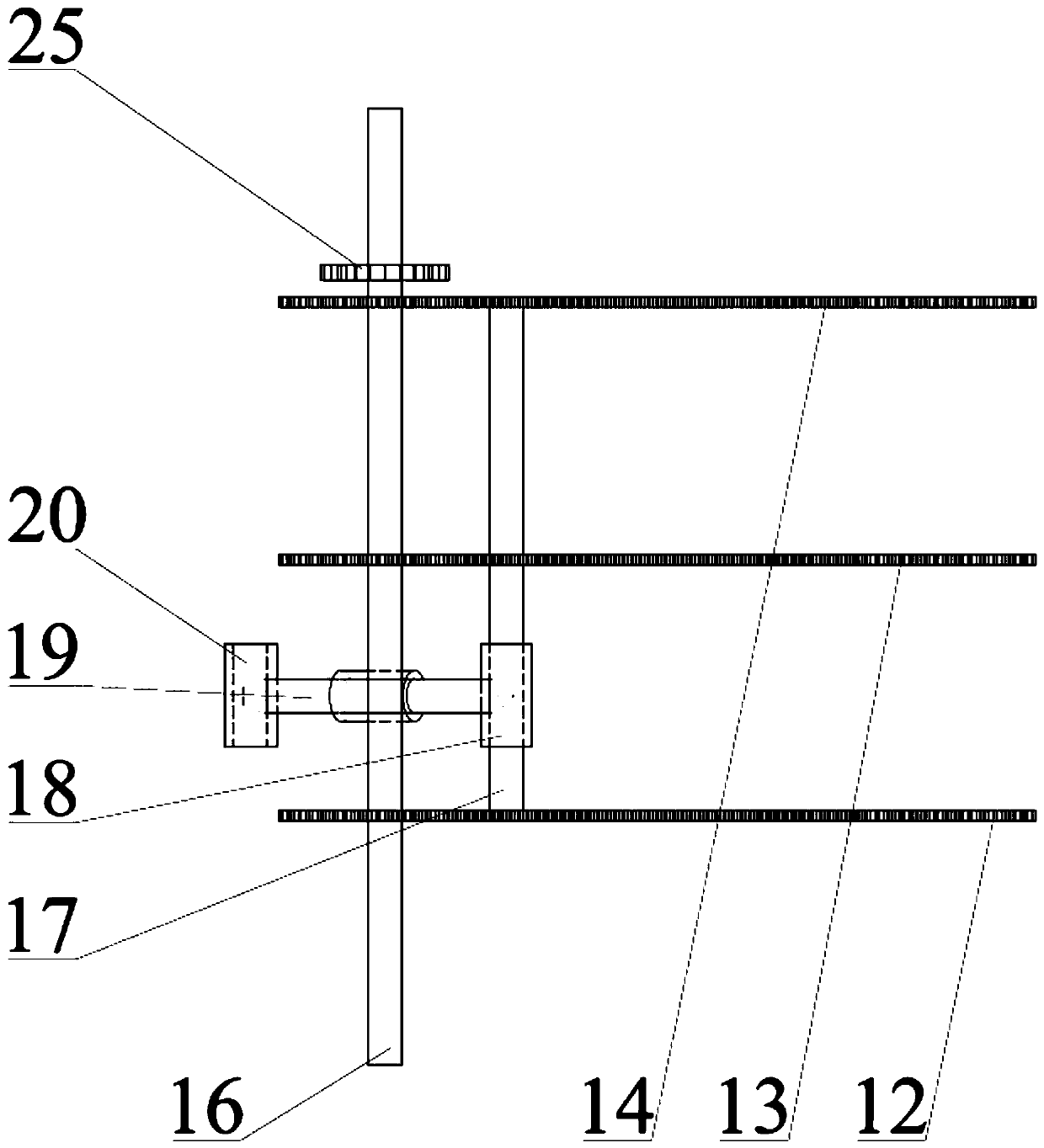

The invention discloses an optical fiber hoisting and laying device. The optical fiber hoisting and laying device comprises a tool base, a scissor fork type lifting table, a laying winding mechanism and a traction mechanism, the scissor fork type lifting table is arranged on the right side of the tool base, the laying winding mechanism is arranged on the left side of the scissor fork type liftingtable, the traction mechanism is arranged on the left side of a guardrail, the traction mechanism comprises a guide plate, the guide plate is vertically arranged, and a mounting plate is perpendicularly and fixedly connected with the bottom of the guide plate. According to the optical fiber hoisting and laying device, a guide ring and a gear transmission mechanism are arranged, so that when the optical cable is released by an optical fiber winding roll, the guide ring moves synchronously and transversely in a reciprocating mode, then the traction resistance of the optical cable is smaller, theoptical cable can be prevented from falling off at will, and the optical cable is protected; and traction rollers rotating oppositely are arranged, so that the optical cable is pulled to a high position, the optical cable is pulled to the high position in a labor-saving mode, hoisting and fixing are facilitated, compared with manual traction, the optical fiber hoisting and laying device is labor-saving and efficient, the optical fiber hoisting and laying device is driven by an external truck to move, efficient hoisting and laying are carried out, so that the hoisting and laying efficiency ofthe optical cable is remarkably improved.

Owner:重庆知行知识产权服务有限公司

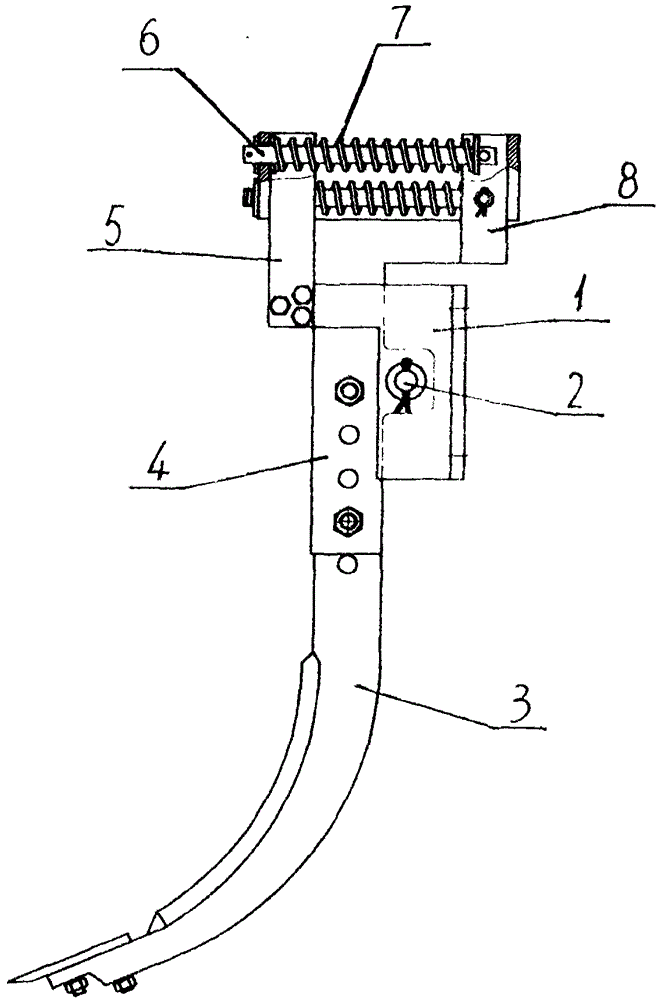

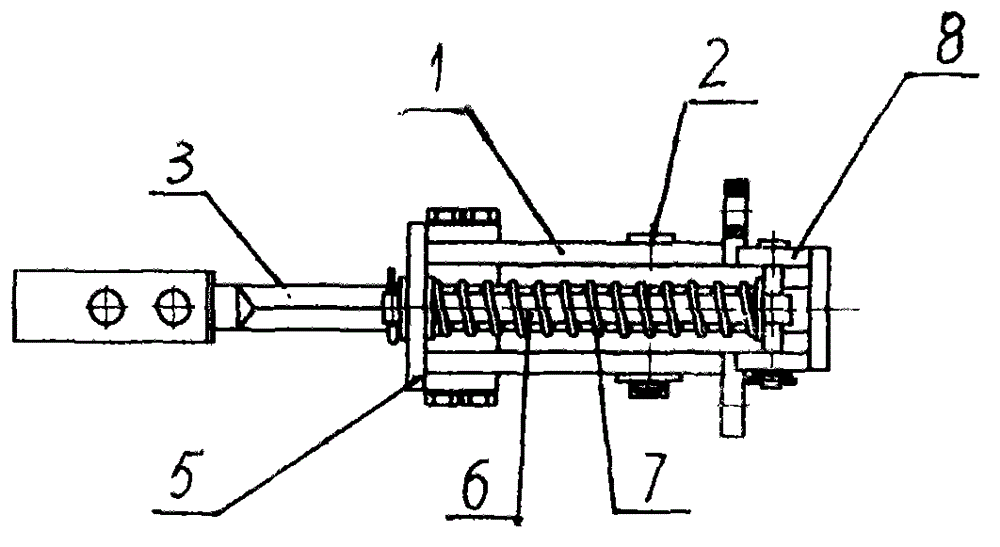

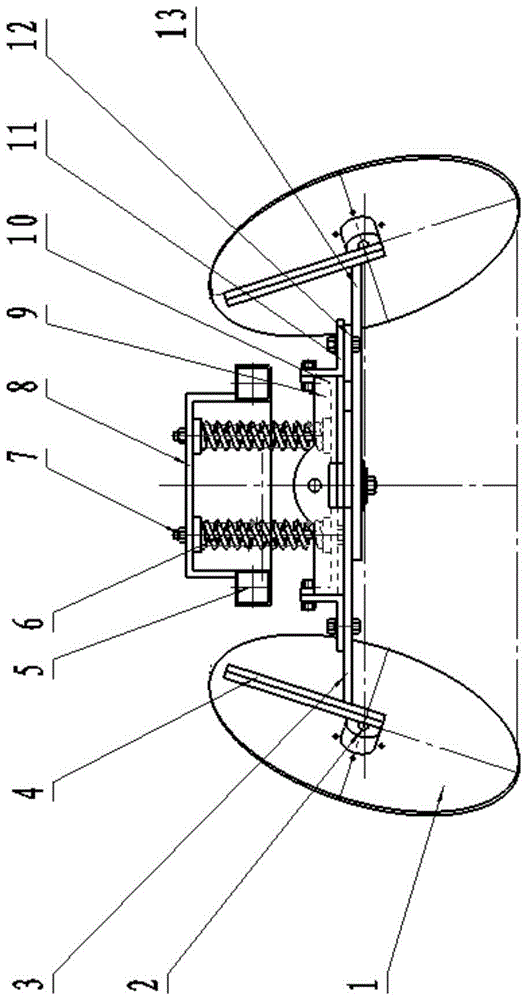

Vibration mechanism of vibrating subsoiler

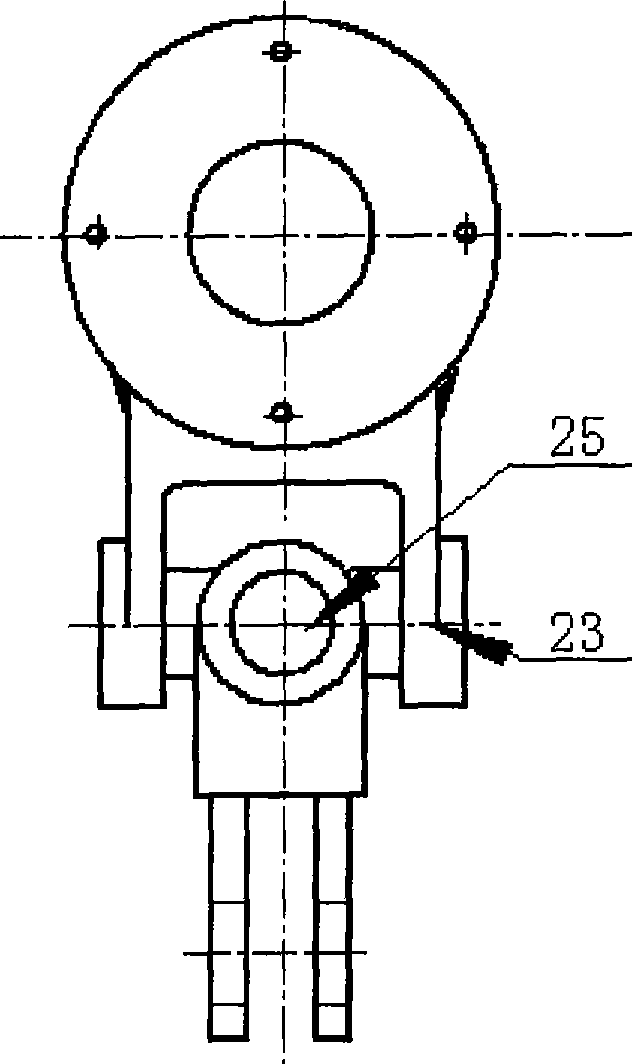

The invention relates to a vibrating mechanism for a vibrating subsoiler. The vibrating mechanism is characterized by comprising an eccentric shaft, a cross-shaped shaft coupling, a lever and sub-soiling shovels; one end of the eccentric shaft is a hexagonus spline shaft end, the other end is an eccentric shaft end, and the eccentric shaft is a cantilever shaft formed by being supported by two bearing seats; the spline shaft end of the eccentric shaft is connected with the power output shaft of a tractor through the shaft coupling, and the eccentric shaft end of the eccentric shaft is articulated with the cross-shaped shaft coupling through a bearing and a clip spring; the lower end of the cross-shaped shaft coupling is hinged at one end of the lever, a pair of overhanging arms is arranged at the other end of the lever, and the sub-soiling shovels are vertically fixed on the pair of the overhanging arms. Due to the adoption of the lever principle, the penetration angles of the sub-soiling shovels are changeable, so that the sub-soiling shovels penetrate through the soil more easily, the resistance of the soil to the shovel surfaces is reduced, and the tractive resistance of the vibrating subsoiler is further reduced. The invention is widely applied to various vibrating subsoilers.

Owner:CHINA AGRI UNIV

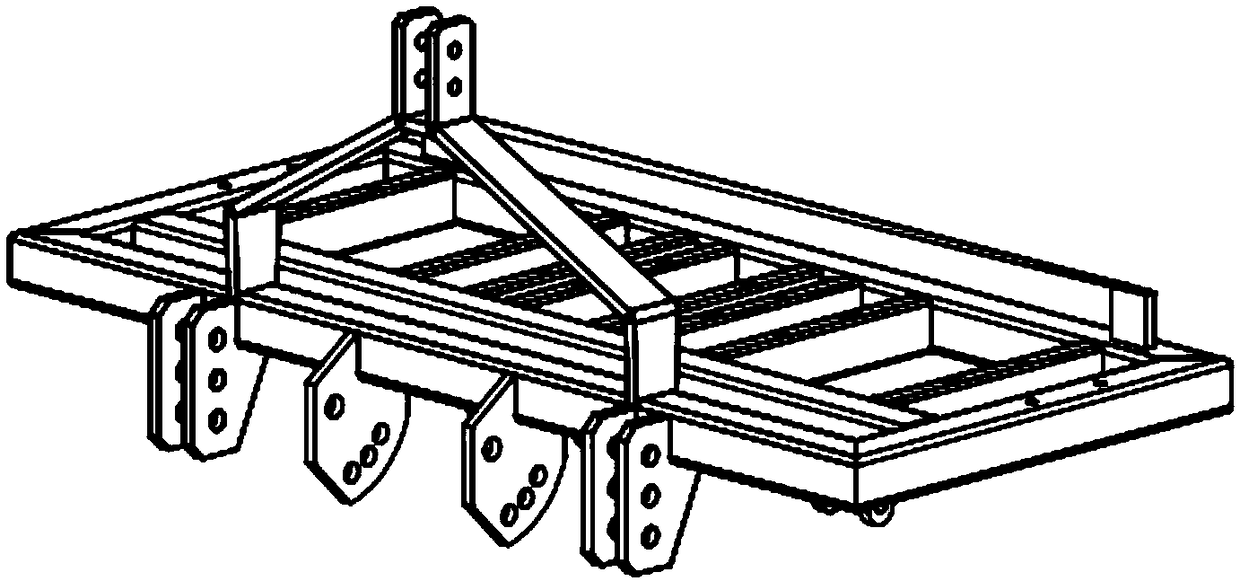

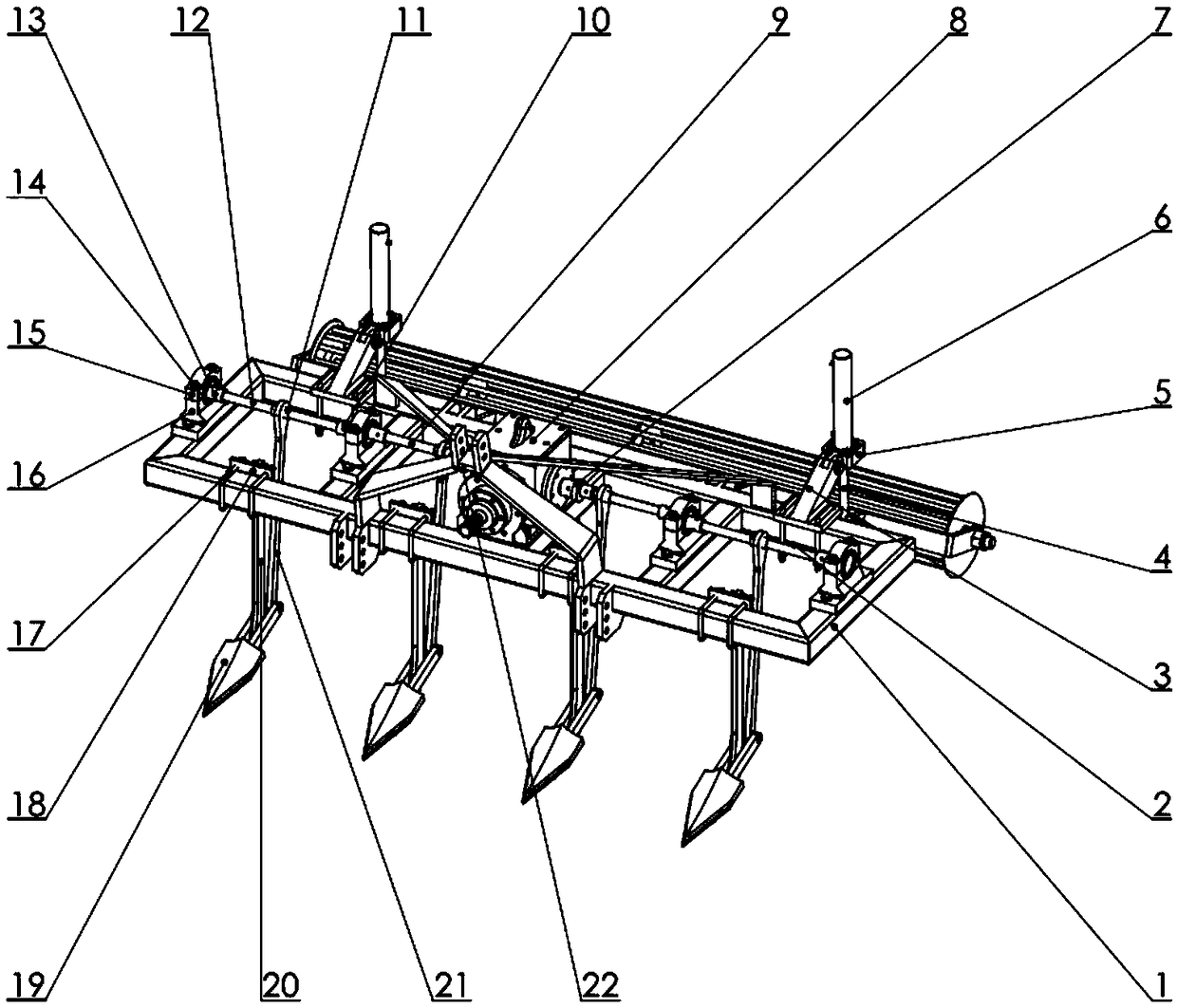

Combined deep scarification and land preparation machine

InactiveCN105981496ALow traction resistanceGuaranteed profilingSpadesSaving energy measuresConventional tillageScarification

The invention relates to a combined deep scarification and land preparation machine which is characterized by comprising a rack, a full-direction deep scarification device and a turnover device, wherein the turnover device is arranged in front of the full-direction deep scarification device; the rack consists of a front beam, an upper suspended plate, lower suspended plates, transverse beams, fixed transverse beams, fixing plates, limiting plates, a rear beam and support beams; a partial deep scarification device is arranged on the rear beam; a soil crushing depth limiting device is arranged behind the support beams. According to the combined deep scarification and land preparation machine, a shallow layer and a conventional tillage mellow soil layer are loosened by using the turnover device, subsequently deep soil is cut by using the full-direction deep scarification device and is crushed by using the partial deep scarification device, furthermore the ploughed soil is crushed and flattened by using disc cutters in the soil crushing depth limiting device. In a word, by adopting the combined deep scarification and land preparation machine, combined soil preparation, shallow layer turnover operation, single full-direction deep scarification operation and partial deep scarification operation can be achieved according to agricultural requirements of different crops, the effect of one-machine multi-functions is achieved, the resistance can be reduced, the energy can be saved, and a good operation effect can be achieved.

Owner:SHIHEZI UNIVERSITY

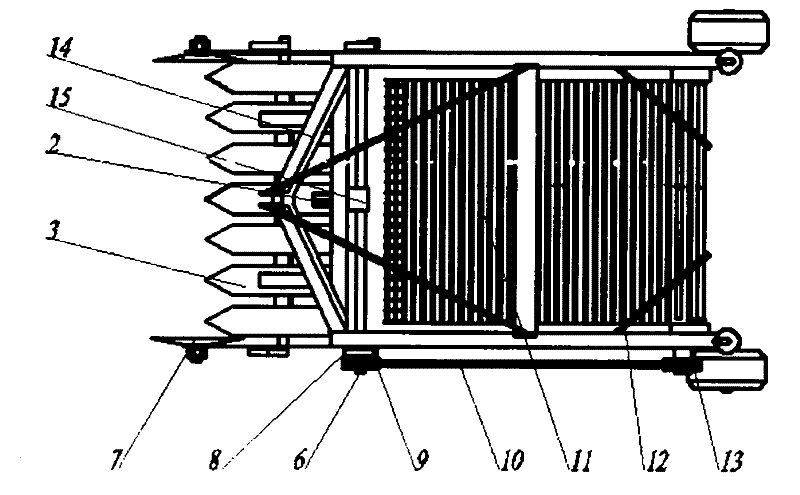

Device for automatically cleaning and transporting faeces in sheep house

InactiveCN107306802AClean up in timeEnsure long-term hygieneAnimal housingAutomatic transmissionFeces

The invention discloses a device for automatically cleaning and transporting feces from a sheep house, comprising a sheep house, a manure collection tank arranged at the bottom of the sheep house, and a gathering device provided at the bottom of the manure collection tank, and is characterized in that: the outside of the manure collection tank is provided with There is a track groove on the manure falling port. The height of the track groove is higher than the bottom surface of the septic tank. There are stoppers on the side of the track groove. Under the action of the gathering device, the feces are gathered and scraped to the falling At the manure outlet, the feces fall from the manure outlet, and the lower side of the manure outlet is provided with a manure receiving belt corresponding to the manure outlet. One end of the manure conveying belt is connected to the manure belt through the manure cleaning board, and the other end is passed through another The manure cleaning board is connected to the manure collecting tank, and then the manure is transported into the manure collecting tank. The manure collected and scraped by the device does not need to be cleaned manually, and is automatically transported to the manure collecting tank or other manure collecting equipment, avoiding manual shoveling The high-intensity work of manure and manure pulling effectively reduces the cost of breeding.

Owner:河南亚盛牧业股份有限公司

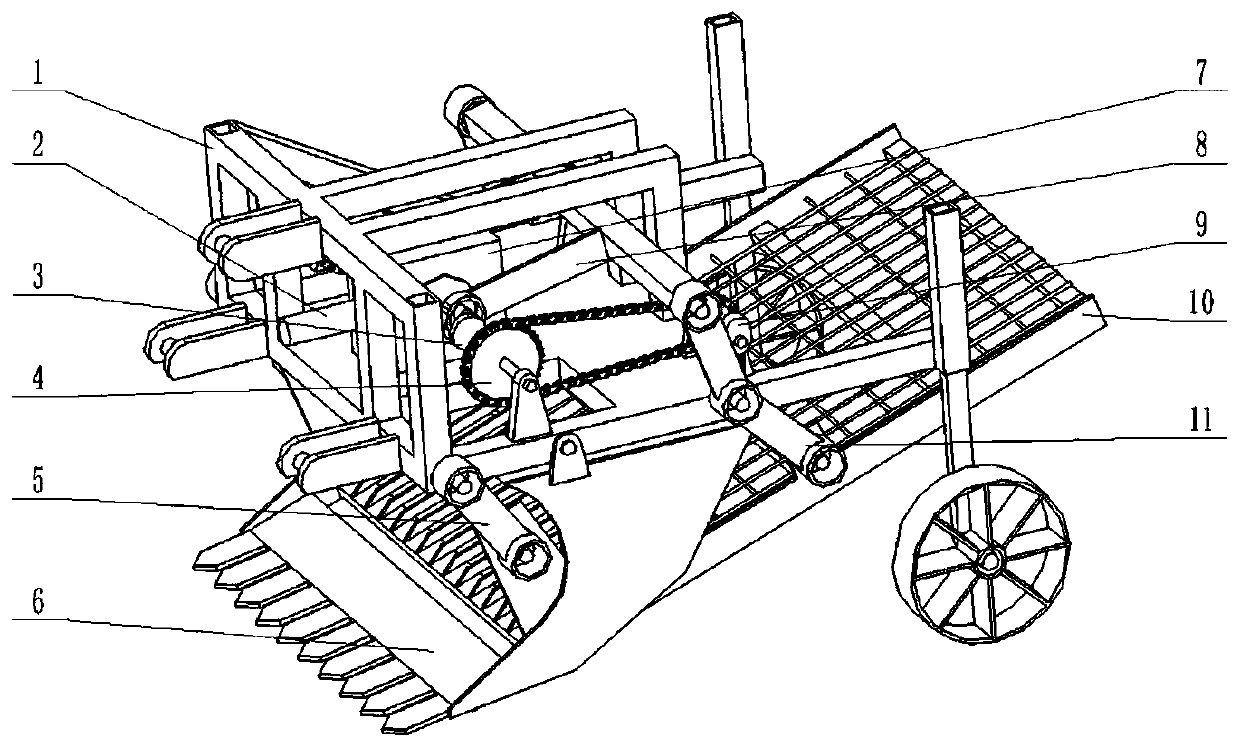

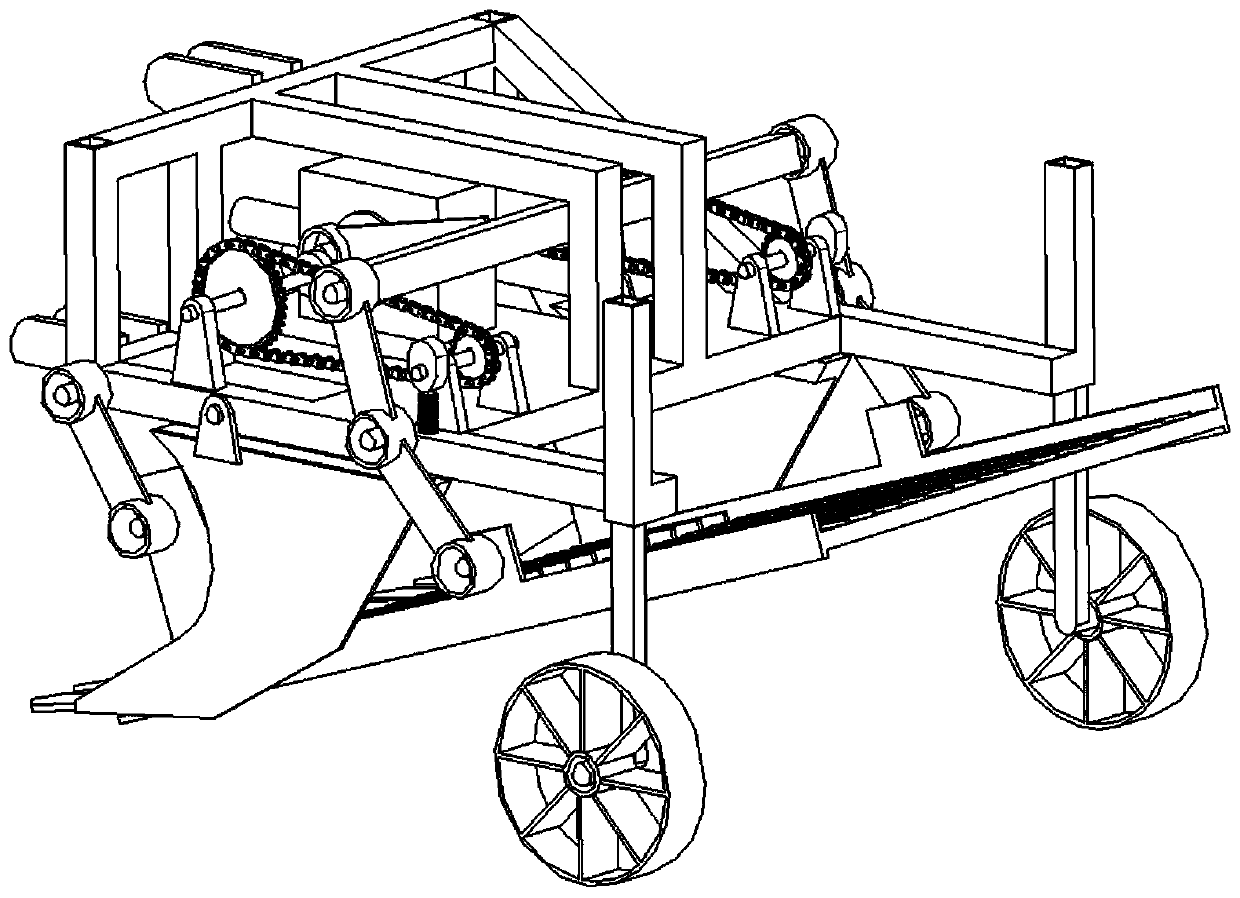

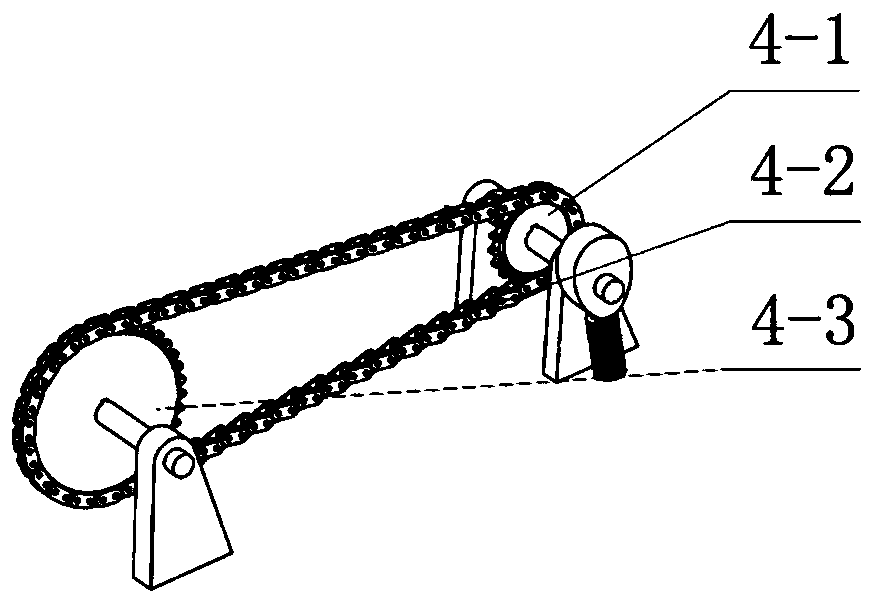

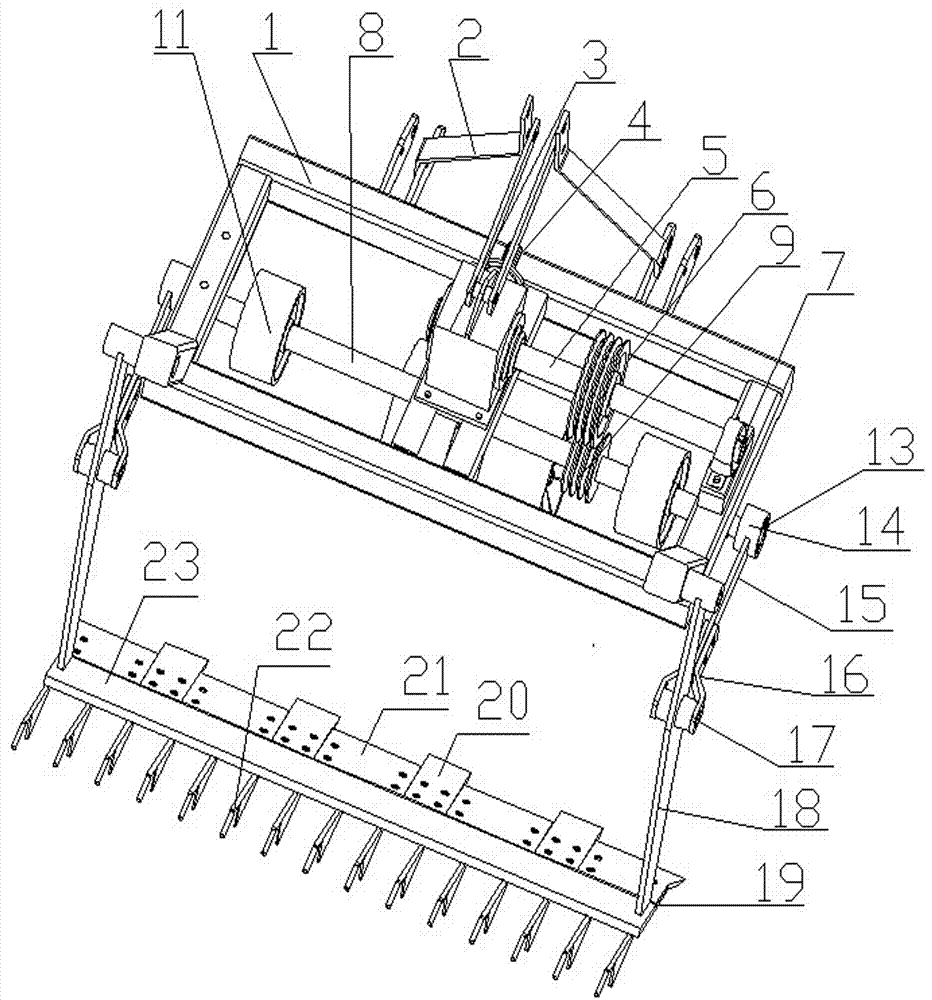

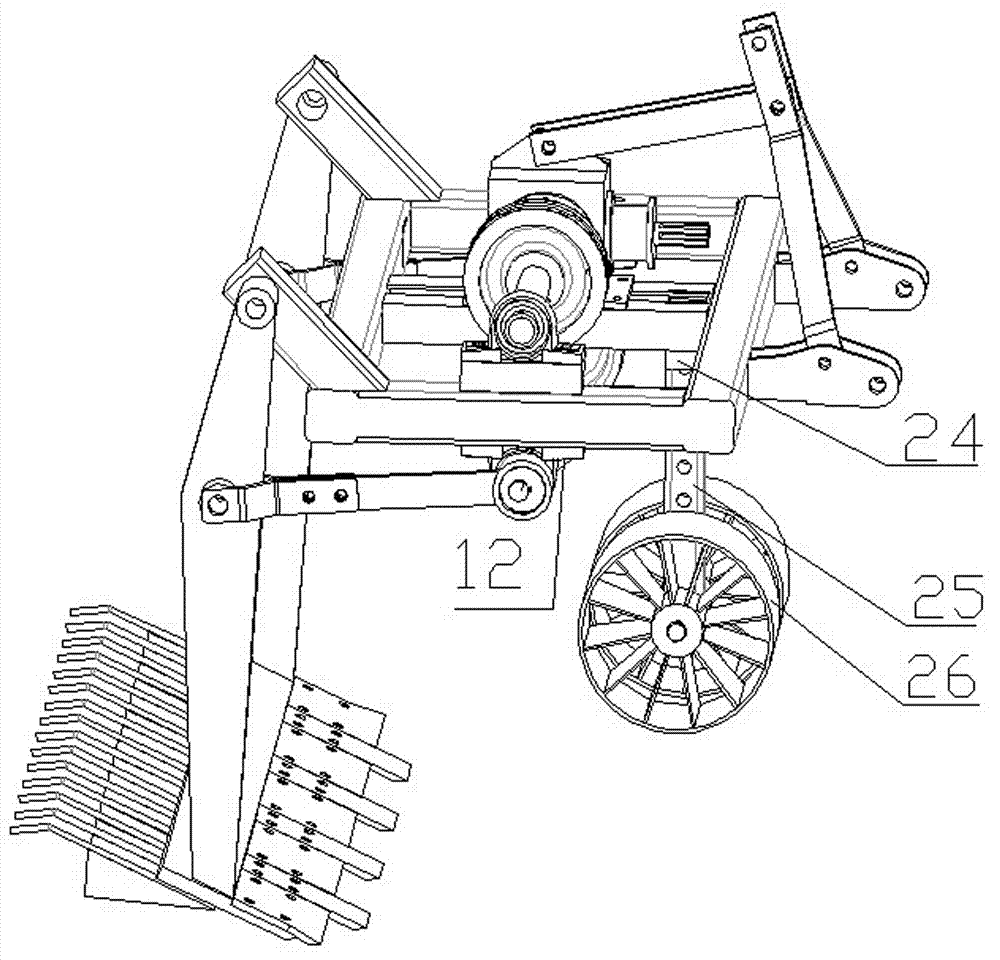

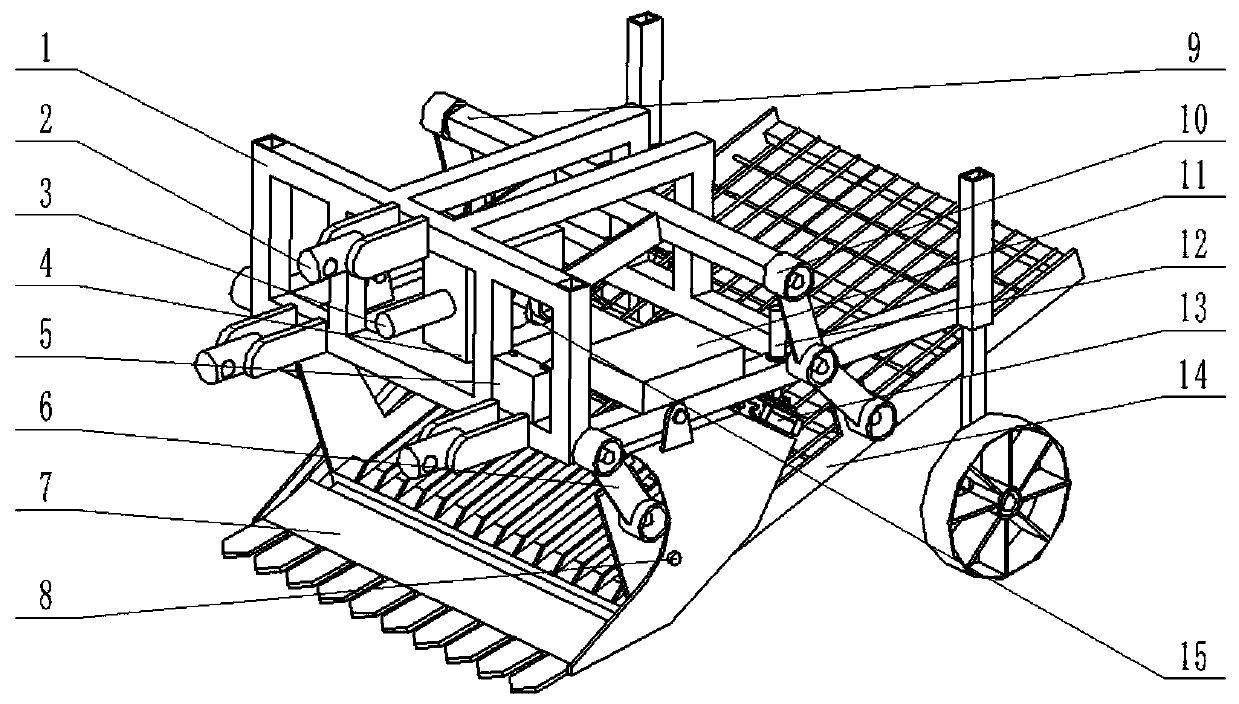

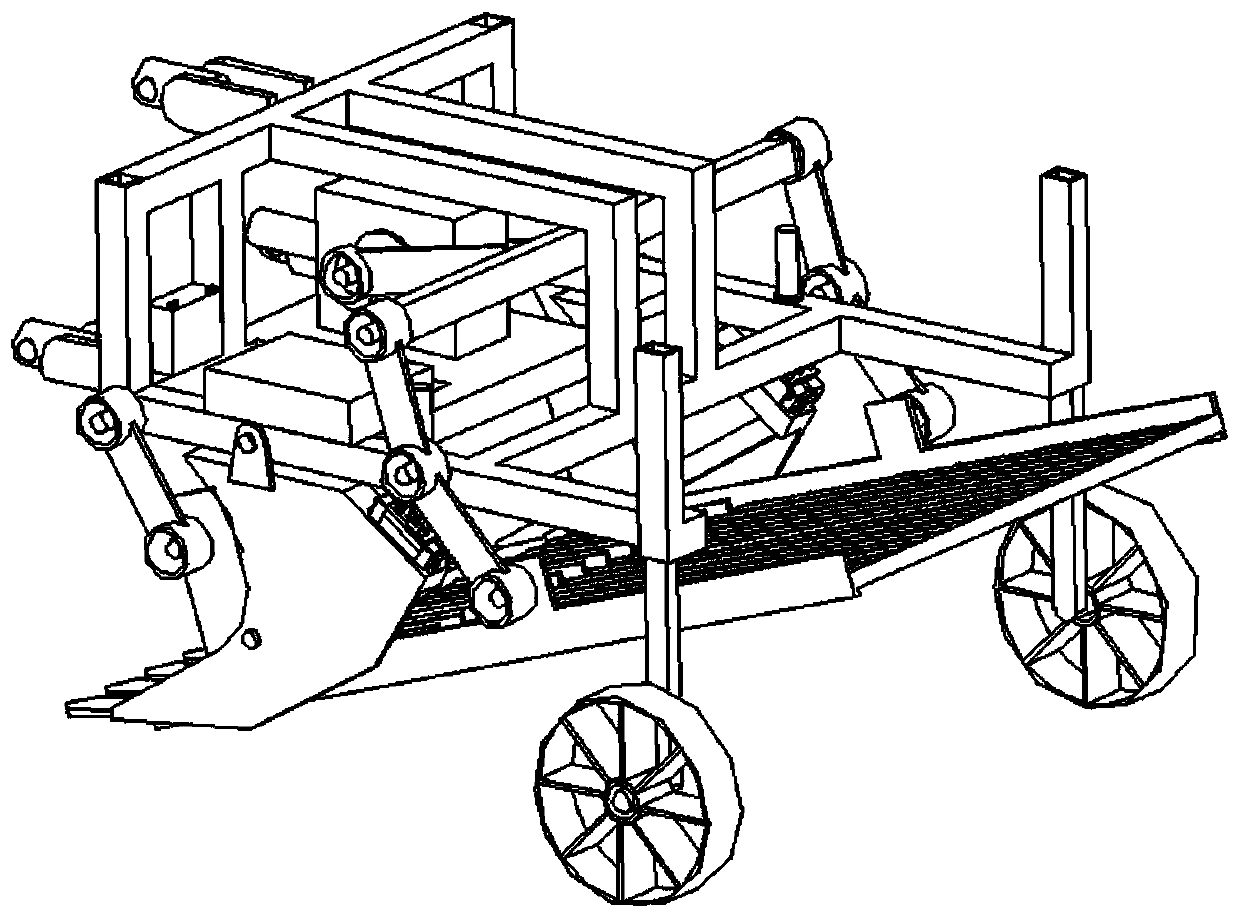

Movable shovel type potato excavator

InactiveCN102440112AIncreased ability to break down soilLow traction resistanceDiggersVibration amplitudeMechanical reliability

The invention relates to a potato excavator matched with a tractor for use, belonging to the field of agricultural machinery. The existing potato picker mainly adopts the fixed shovel excavating mode, thus having the problems of large consuming traction force, poor soil breaking property, serious blocking condition and poor soil and potato separating effect, and the like. A vibration type potato excavator is good in soil breaking property and small in traction resistance, but the vibration amplitude of the whole potato excavator is large, so that the potato damaging rate is high in the separating process, and the work reliability of the whole excavator is low. The movable shovel type potato excavator adopts a novel movable shovel type extracting mechanism, due to the reciprocating motion of an excavating shovel, the breakage capability of a soil-potato excavating object is enhanced, the traction resistance is reduced, the soil-potato separating effect is improved, and the mechanical reliability is high. A lifting chain screen type separating mechanism is adopted, the potato damaging rate in the separating process is reduced, and the work reliability of the whole excavator is high. The potato excavator is suitable for clay and clay loam with severer soil hardening, and is also widely applied to sand and loessial soil easy to cultivate.

Owner:GANSU AGRI UNIV

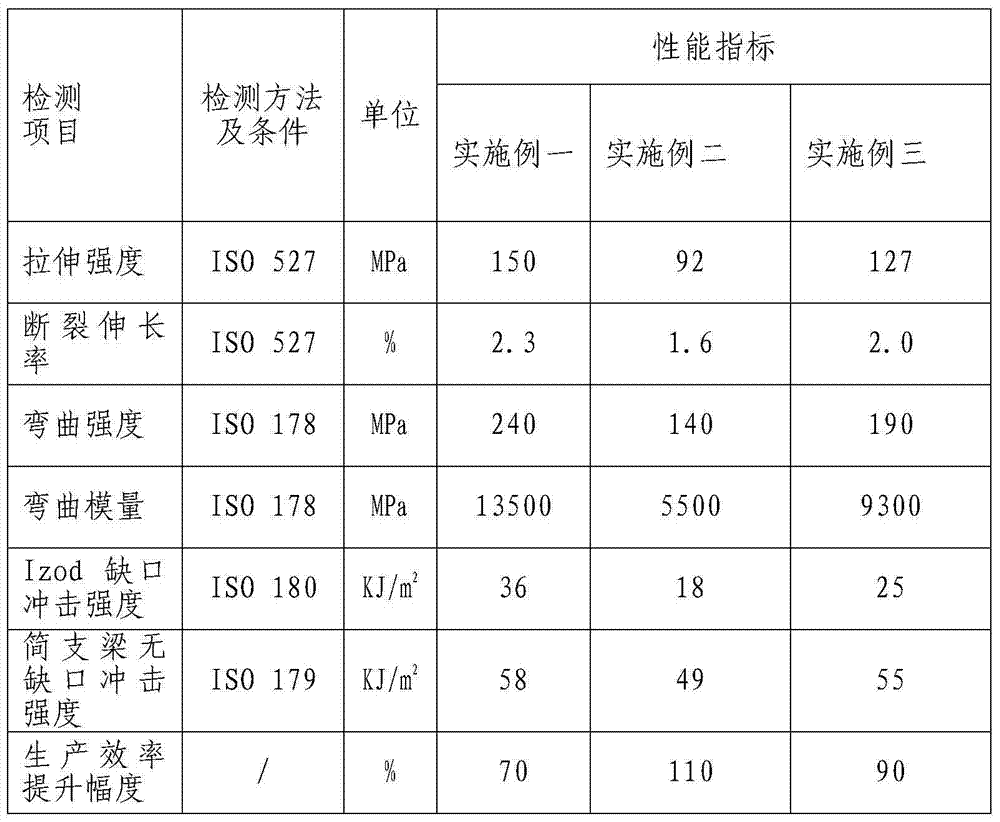

Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

The invention relates to a material and a preparation method thereof, and particularly relates to a long glass fiber reinforced polypropylene material adopting a foaming technique and a preparation method thereof, belonging to the technical field of materials. The long glass fiber reinforced polypropylene material comprises the following components by mass percent: 30-75wt% of polypropylene, 20-60wt% of long glass fiber, 0.5-5wt% of chemical foaming agent and 1-5wt% of compatibilizer. The viscosity of the resin is further reduced by adopting a micro-foaming technology, meanwhile, the chance that a glass fiber strong dispersing device reduces or avoids direct contact of a glass fiber bundle and a roller or a convex part is reduced, the damage to the glass fiber is reduced, and the traction resistance of a material bar is reduced. The long glass fiber reinforced polypropylene material has the beneficial effects that the product performance, quality stability and production efficiency are improved when the impregnation effect on the glass fiber caused by polypropylene resin is ensured.

Owner:NANJING JULONG SCI&TECH CO LTD

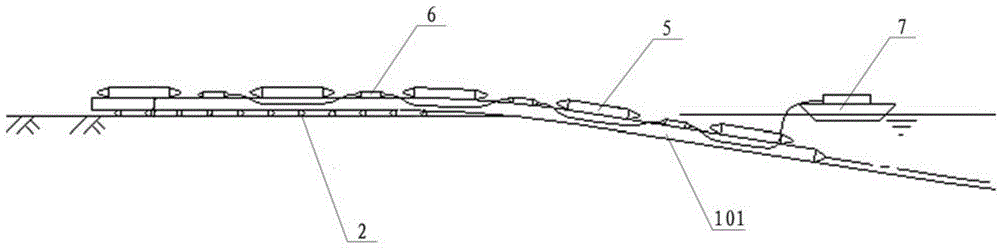

Designing method for sea-crossing steel sinking pipeline

The invention discloses a designing method for a sea-crossing steel sinking pipeline. The designing method for the sea-crossing steel sinking pipeline comprises the following steps: (1) determining the arrangement of a pipeline route according to the terrain of a seabed, wherein the sea-crossing steel sinking pipeline comprises two upwards-bent sections and two downwards-bent sections, which are on the same plane and have the same curvature radius; (2) calculating a design curvature radius: calculating the design curvature radius according to the strength and the stress characteristics of a pipeline material and a specification, and determining the arc lengths of the upwards-bent and downwards-bent sections according to the arrangement of the pipeline route and the design curvature radius; (3) digging a foundation trench matched with the pipeline route in the seabed on the basis of the arrangement of the pipeline route and the design curvature radius; (4) constructing and dragging the pipeline, and ensuring that the curvature radius of the sinking pipeline is equal to the design curvature radius. According to the designing method for the sea-crossing steel sinking pipeline, the shortcomings of a conventional bottom towing method are overcome, and the designing method for the sea-crossing steel sinking pipeline is safer and more suitable.

Owner:广东省水利电力勘测设计研究院有限公司

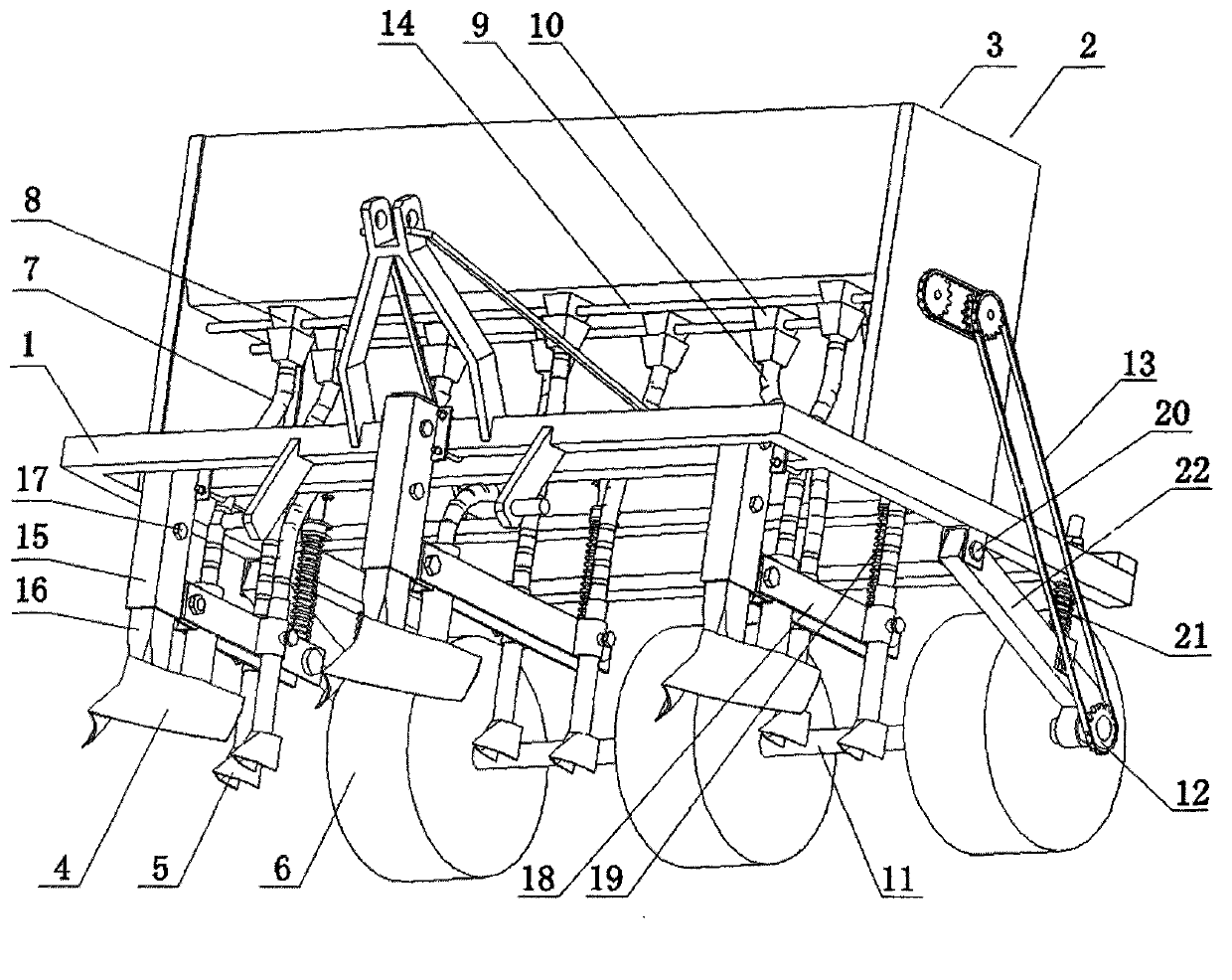

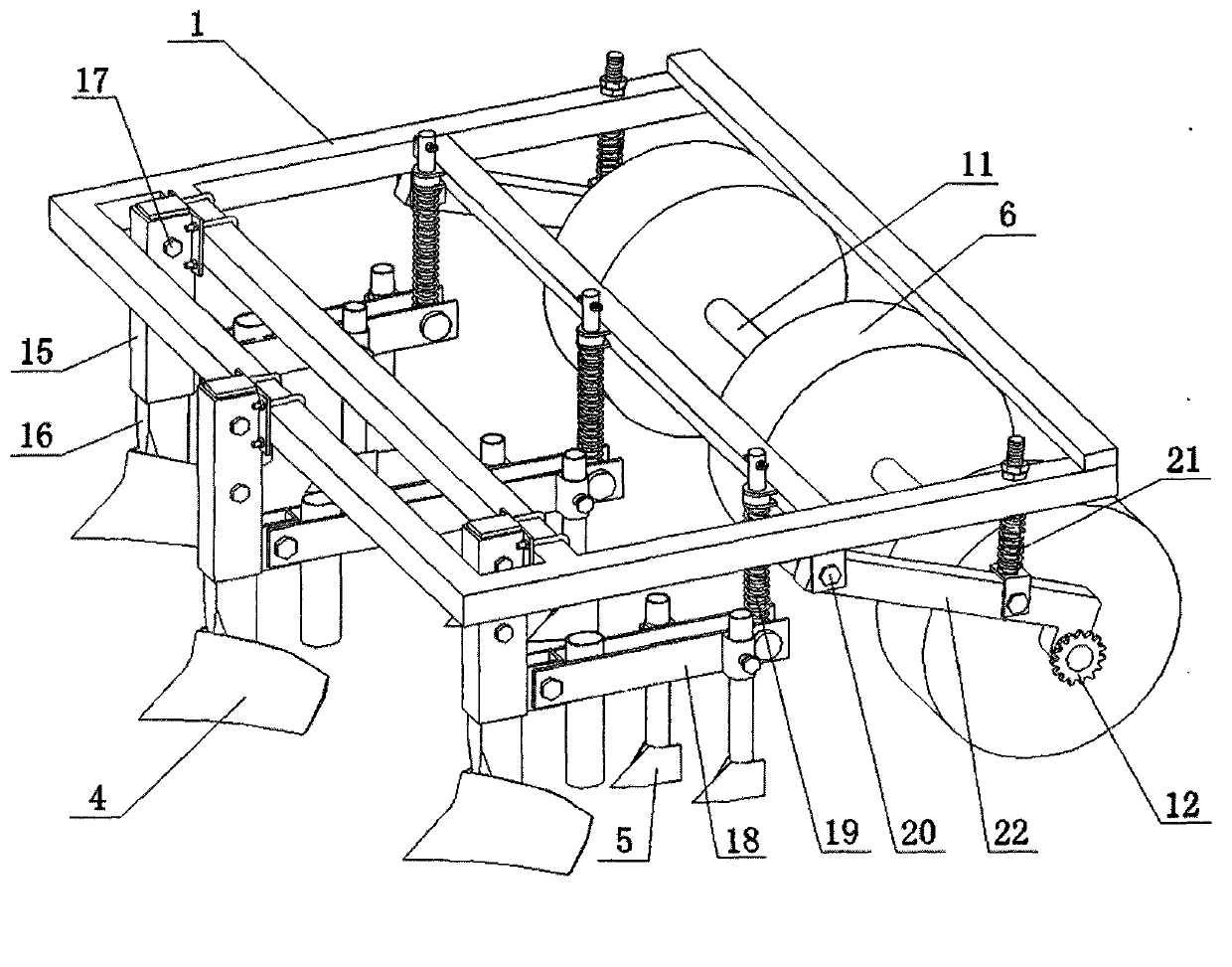

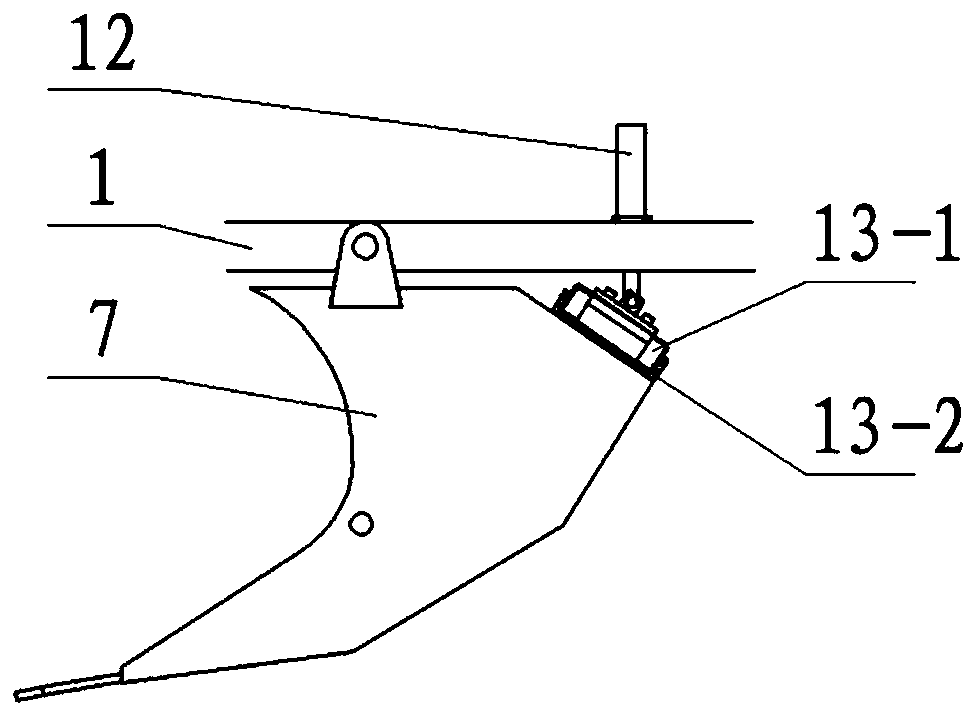

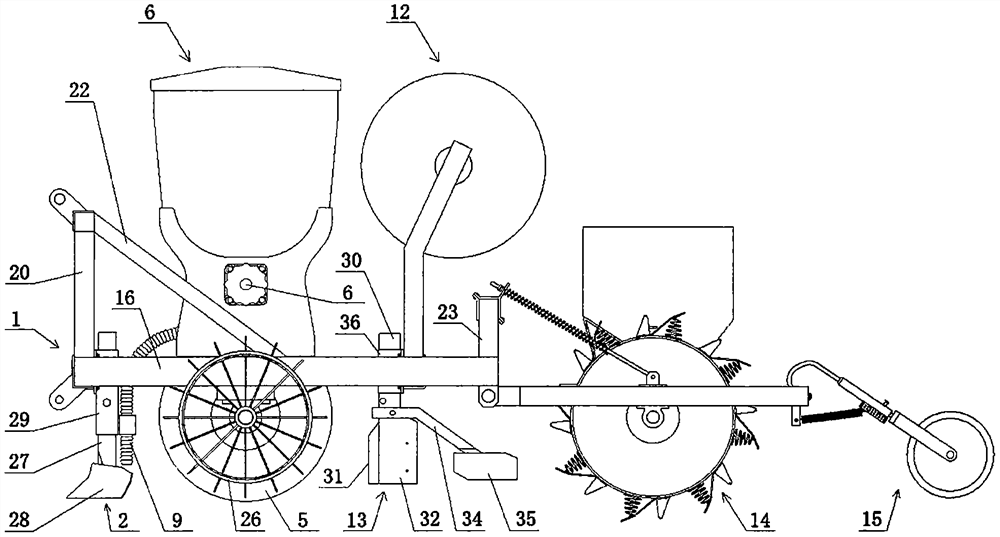

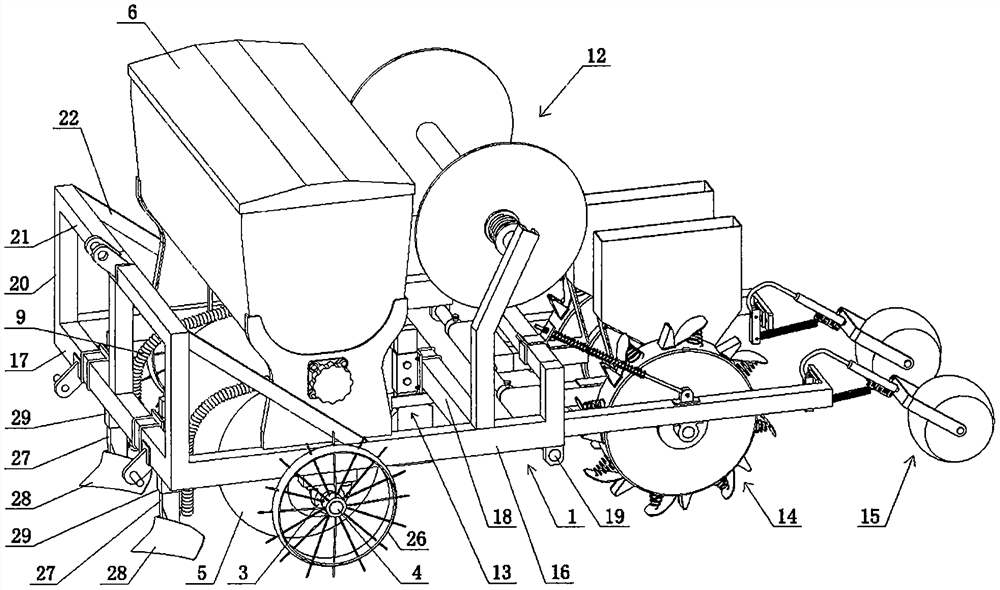

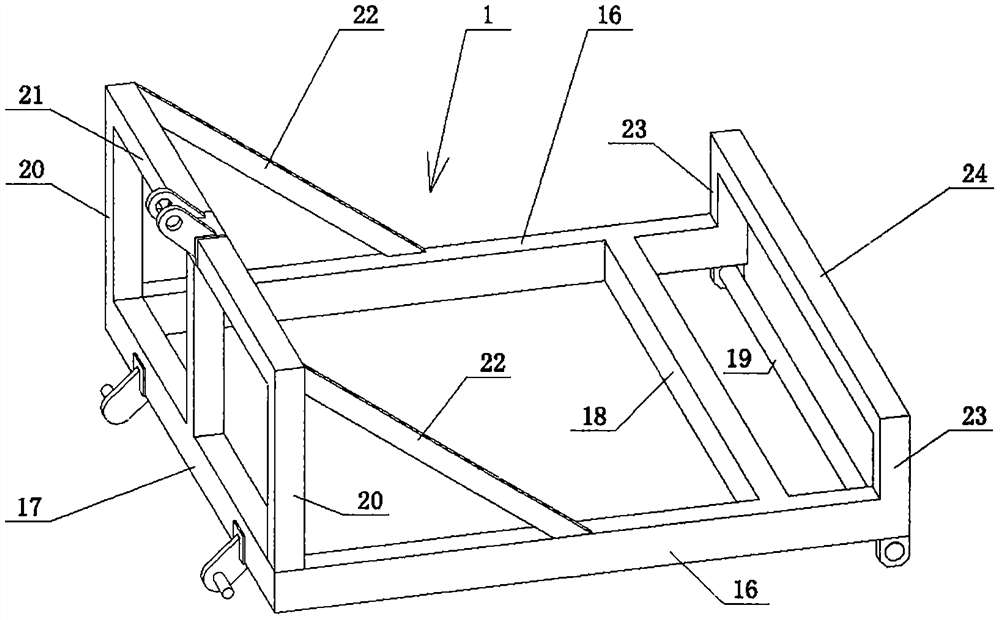

Large-ridge double-row buckwheat sowing machine

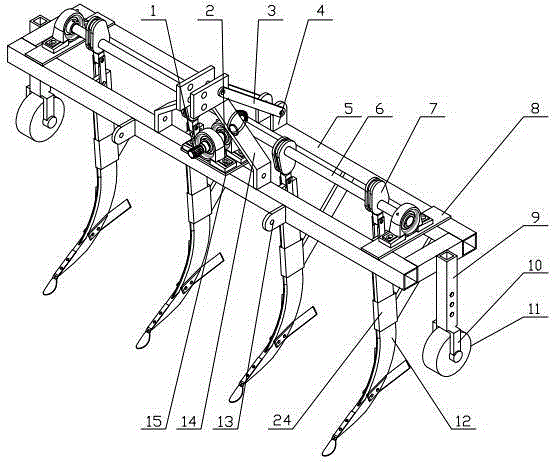

InactiveCN103098592ARealize the sowing operationSimple structurePlantingFurrow making/coveringPolygonum fagopyrumDrive shaft

The invention discloses a large-ridge double-row buckwheat sowing machine, which comprises a frame, a seed box and a fertilizer box are arranged over the frame, an operation mechanism with 1-6 ridges is arranged at equal interval under the frame, the operation mechanism of each ridge comprises a fertilize opener, two sowing openers and a ; the fertilize opener of each ridge is arranged at the front part of the frame, two sowing openers are arranged at the rear part of the fertilize opener, the repressing roller is arranged at the rear part of two sowing openers; each fertilize opener is communicated with a fertilizer shifting device arranged at the bottom of the fertilizer box through a fertilizer discharge pipeline; each sowing opener is communicated with a seed shifting device arranged at the bottom of the seed box through a seed discharge pipeline; and the fertilizer shifting device and the seed shifting device are connected by driving a repressing shaft, a sprocket wheel, a chain and a transmission shaft through the repressing roller. The large-ridge double-row buckwheat sowing machine has the advantages of simple structure, uniform seed falling, consistent depth and good operation quality, and can realize the large-ridge double-row sowing.

Owner:赤峰市农牧科学研究院

Wheel type rice wide-narrow-line direct seeding fertilization combined machine

InactiveCN102783290AReduce Churn LossImprove utilization efficiencyPlantingDirect seeding machinesDrive wheelAgricultural engineering

The invention relates to a wheel type rice wide-narrow-line direct seeding fertilization combined machine, which belongs to agriculture machinery. Shallow and deep fertilization double-disc furrow opening devices, a fertilizer box, a paddy field driving wheel axle and a seed box are sequentially arranged on a machine frame from the front side to the back side, a driving double-chain wheel, the paddy field driving wheel and a compression roller are fixedly arranged on the paddy field driving wheel axle, the fertilizer box is respectively communicated with the shallow and deep fertilization double-disc furrow opening devices through shallow and deep fertilization pipes, a fertilizer discharge driving chain is sheathed on the driving double-chain wheel and a fertilizer discharge wheel arranged on a fertilizer discharge device shaft, a seed discharge driving chain is sheathed on the driving double-chain wheel and a seed discharge chain wheel arranged on a seed discharge device shaft, and a seed discharge and seed conveying pipe is arranged on the lower side part of the seed box. The wheel type rice wide-narrow-line direct seeding fertilization combined machine has the advantages that the design is novel and reasonable, the structure is simple, the traction resistance is small, the operation items are many, the operation quality is good, the fault is few, the efficiency is high, and the synchronous combined operation of the rice direct seeding and fertilization and the wide-narrow line fertilization operation depth regulation can be realized.

Owner:宋永魁

Traction device bonded to impacted teeth

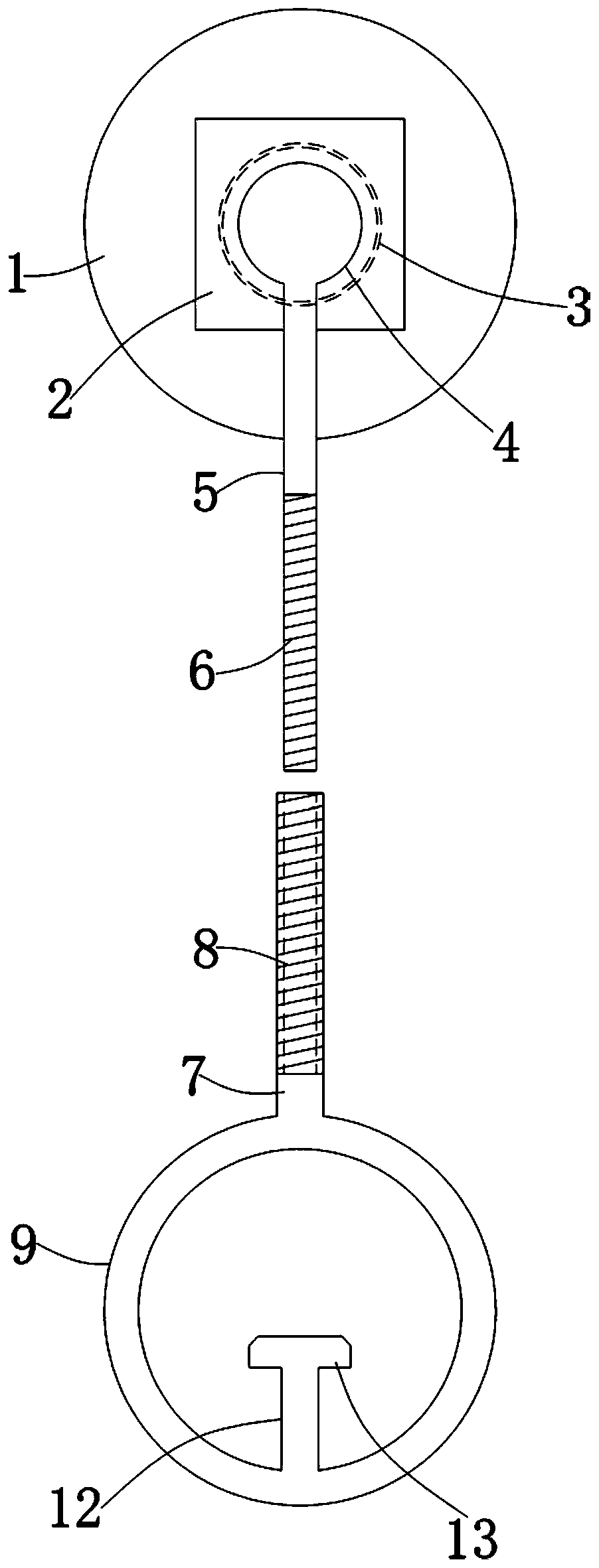

The invention provides a traction device bonded to impacted teeth. A ceramic bottom plate can be bonded onto the impacted teeth, a stainless steel plate is arranged on the ceramic bottom plate, a stainless steel ball is sunken in a concave ball groove of the stainless steel plate and can make rotary motion in the concave ball groove, a stainless steel rod is arranged at the top of the stainless steel ball, and an external thread is arranged on the upper half part of the stainless steel rod. A length adjusting unit comprises a stainless steel adjusting rod, the top of the stainless steel adjusting rod is inwards provided with an internal thread, the internal thread of the stainless steel adjusting rod is in matched connection with the external thread of the stainless steel rod, and a stainless steel ring is arranged at the bottom end of the stainless steel adjusting rod and connected with a fixed orthodontic appliance through an elastic chain or an auxiliary arch. The stainless steel adjusting rod can play a role in fixing and adjusting the length of the traction device so as to meet the requirement for traction of the impacted teeth at different depths. The traction device is smallin size, stimulation to surrounding tissue is little, and the comfort of a patient is good. Manufacturing is simple and standardized, and batch production is easy.

Owner:李佳岭

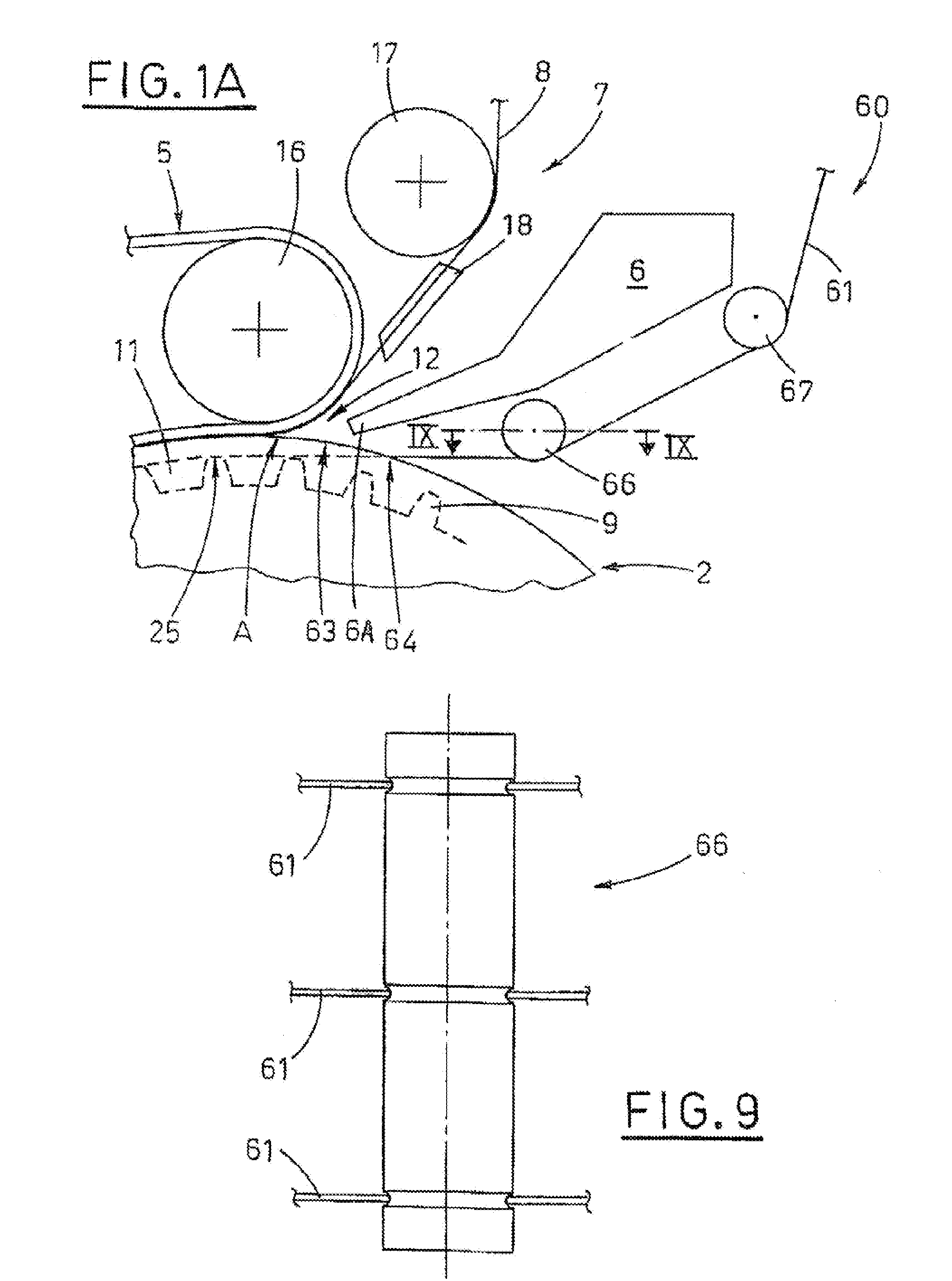

Cogged belt for conveying articles and/or for power transmission, and a method and an apparatus for realising the cogged belt

ActiveUS20110241251A1Improve the immunityLow traction resistanceV-beltsTailstocks/centresLongitudinal developmentEngineering

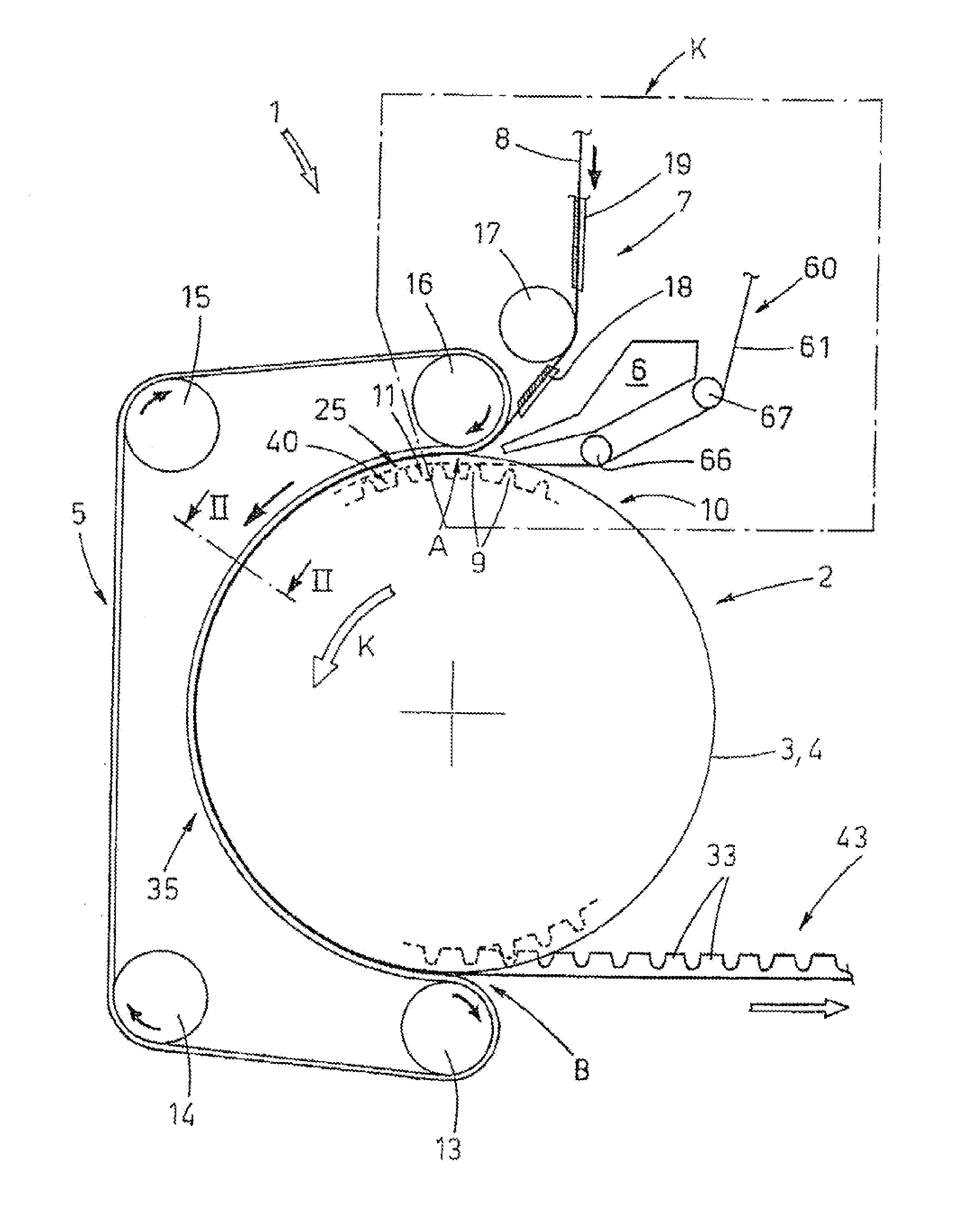

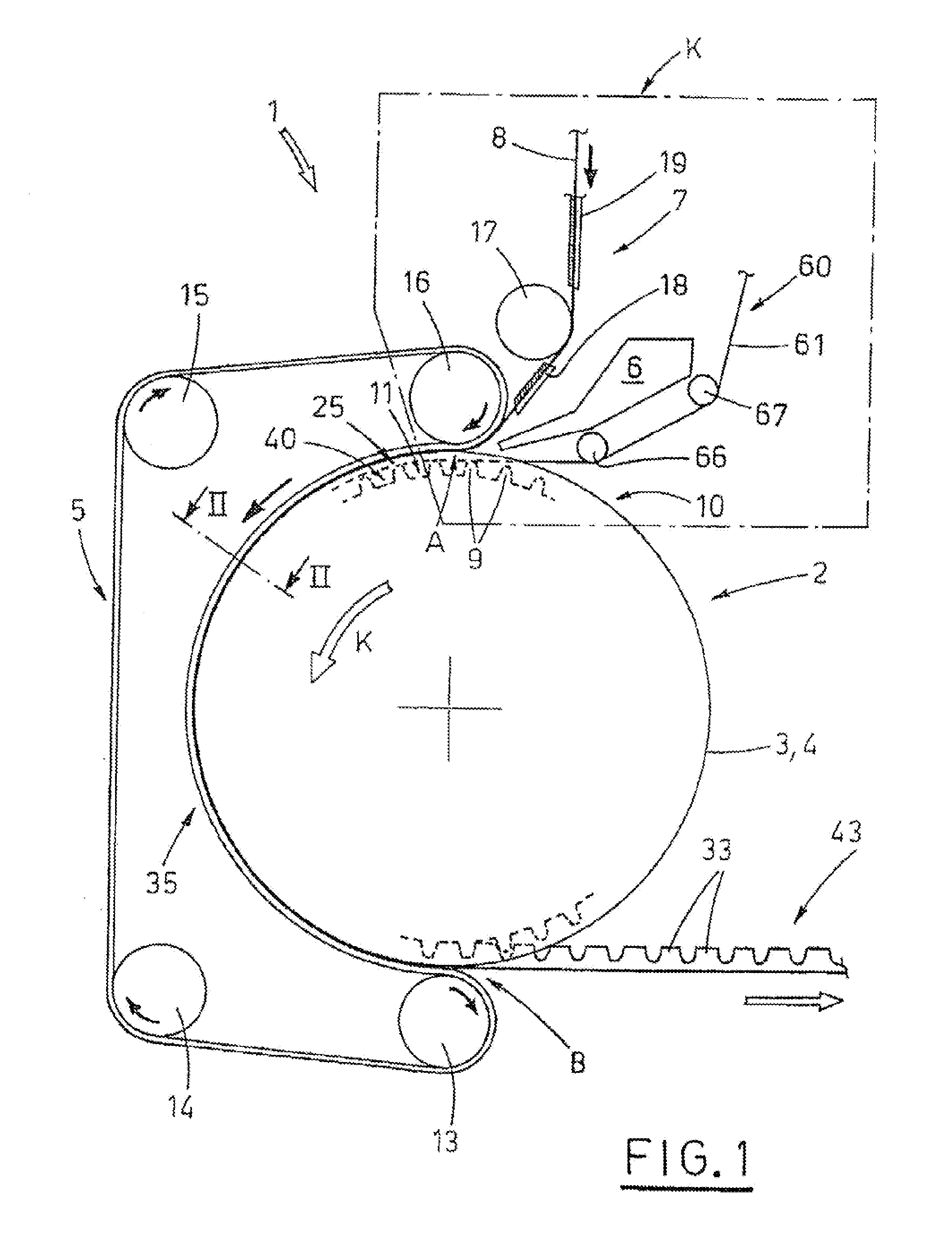

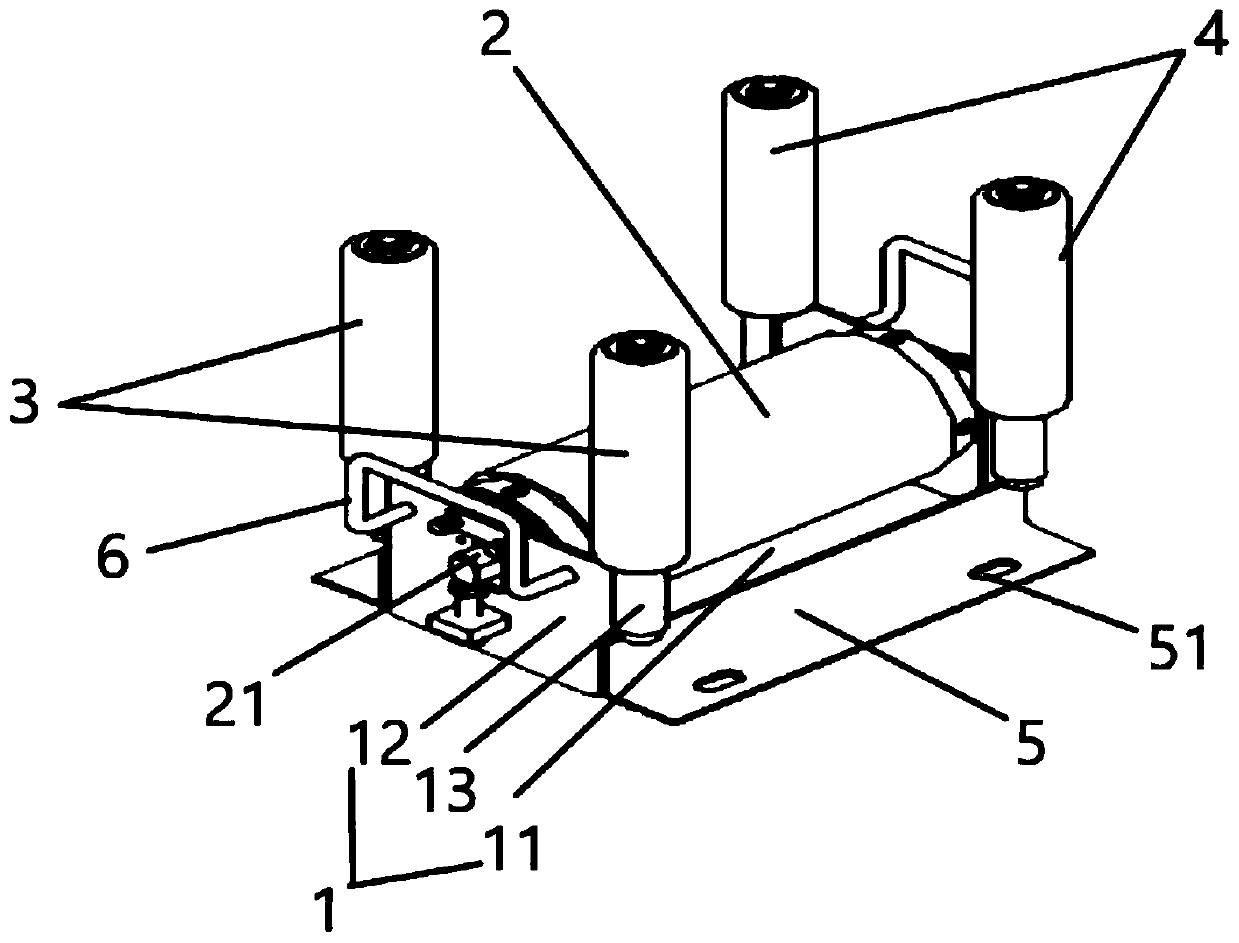

The invention relates to a cogged belt for conveying articles and / or for power transmission, and a method and an apparatus for realisation thereof. The cogged belt (30, 50) comprises: a prefabricated belt (8) comprising a textile or a meshed net; and a covering (26) made of a thermoplastic or heat-hardening material fixed in a single body by fusion to the prefabricated belt (8) and substantially entirely covering a side of the prefabricated belt (8), the covering (26) forming a cogged profile (43). The cogged belt (30, 50) can further comprise at least a cord-shaped reinforcing core (61) at least partially incorporated in the covering (26). The method includes use of a mould (10) which is: mobile, exhibits a longitudinal development and comprises a succession of spaces (11, 11A, 11B) for containment of molten thermoplastic or heat-hardening material, the method comprising stages of: supplying a prefabricated belt (8) which faces the spaces (11, 11A, 11B) and advances at a same velocity as the mobile mould (10), and supplies molten thermoplastic or heat-hardening material into the spaces (11, 11A, 11B) in order to enable formation of a single body (30, 50). An additional stage of the method further includes supplying at least a reinforcing core (61) to be incorporated in the single body (30, 50). The apparatus comprises: a cogged pulley (2) activated by actuator organs; two lateral sides (3, 4) fixed to heads of the pulley (2); a contrast belt (5) facing a circular sector of the pulley (2); a supply device (6) of molten thermoplastic or heat-hardening material; a first station (7) for supplying a prefabricated belt (8), and an additional second station (60) for supplying at least a reinforcing core (61).

Owner:VISION TECH SRL

Vibration digging shovel for long-rhizome crops

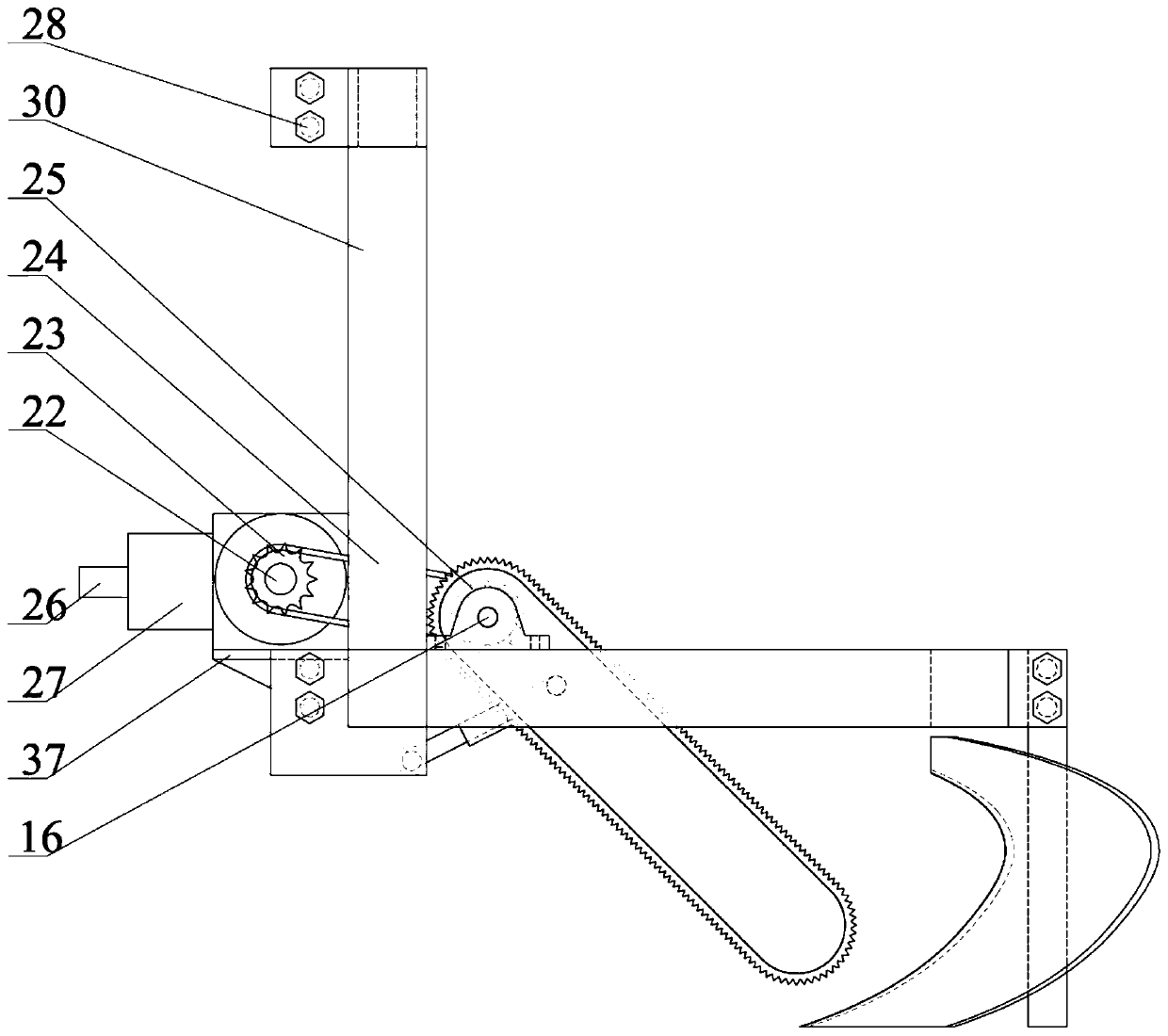

InactiveCN110036750ALow traction resistanceIncrease working depthSpadesPloughsReciprocating motionEngineering

The invention relates to the technical field of agricultural machinery, in particular to a vibration digging shovel which is driven by a cam mechanism and suitable for harvesting long-rhizome crops. The vibration digging shovel comprises a frame and is characterized in that a vibration digging shovel body is hinged to the frame, a gearbox is mounted on the frame, the power of the gearbox is inputthrough a tractor gearbox power output shaft and then output through a power output crank shaft, the power output crank shaft transmits the power to a vibration screen swing rod and a chain transmission mechanism at the same time, the chain transmission mechanism transmits the power to the cam transmission mechanism, and the cam transmission mechanism transmits the power to the vibration digging shovel body to allow the vibration digging shovel body to move in a reciprocating manner. The vibration digging shovel has the advantages that the vibration digging shovel integrates multiple procedures such as vibration resistance reducing, vibration crushing, crop separation, soil loosening, soil screening and plowing; by the two-dimensional vibration with the advancing direction being 45 degreesand the travel being 10mm, the traction resistance of the vibration digging shovel is lowered effectively, and the operation depth and efficiency of the vibration digging shovel are increased.

Owner:JIANGSU UNIV

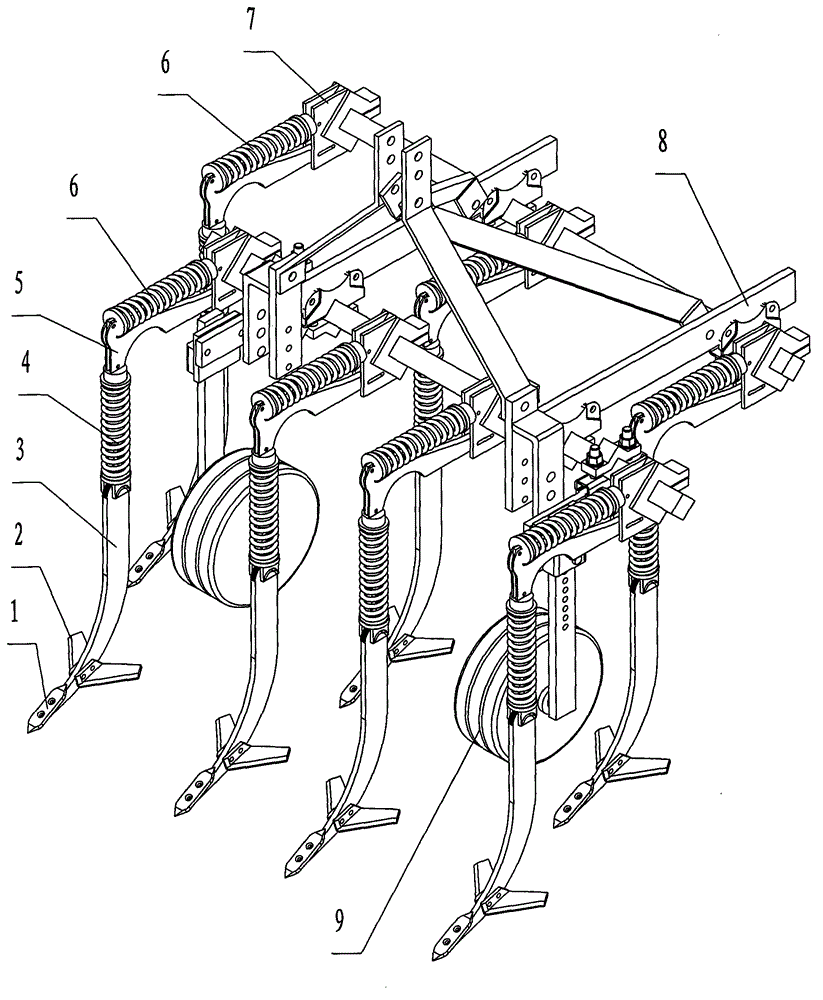

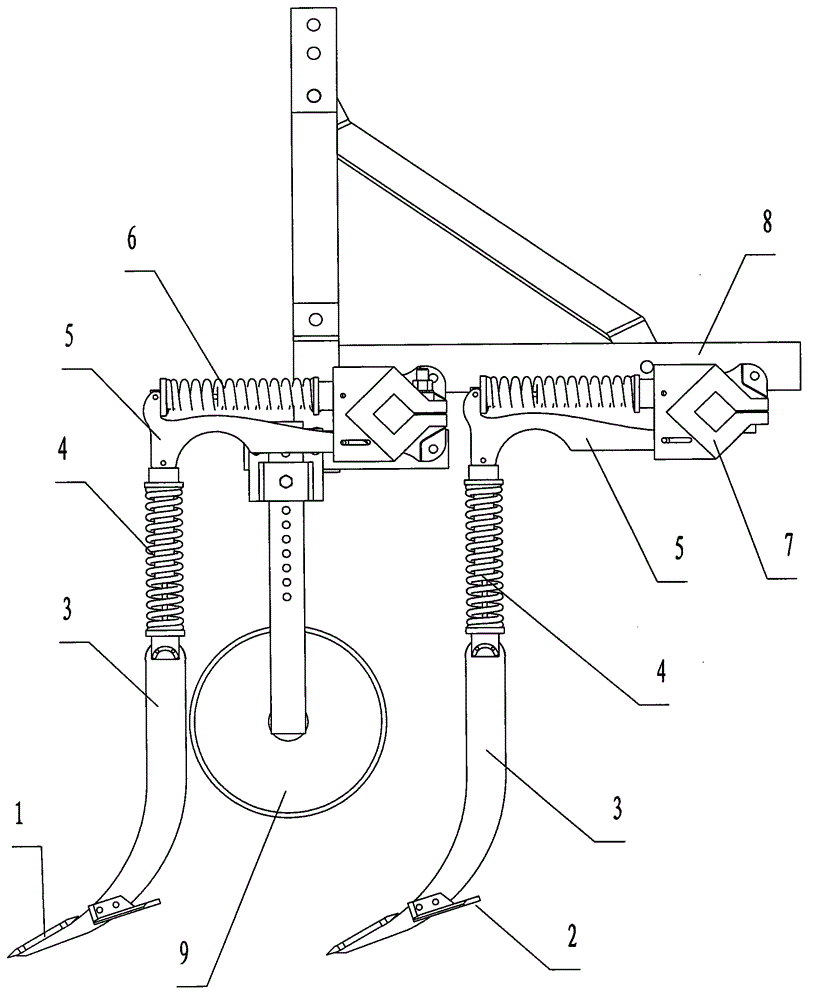

Elastic vibratory deep scarification unit

InactiveCN102907195ASimple structureReduce manufacturing costSoil-working equipmentsScarificationAgricultural engineering

The invention discloses an elastic vibratory deep scarification unit, which belongs to agricultural machinery. A shovel seat is arranged on an assembly rack through a pin shaft; a deep scarification and soil crushing assembly is assembled on the shovel seat; a spring pressure plate is fixedly arranged on the rear part of the upper end of the deep scarification and soil crushing assembly; a spring positioning plate is fixedly arranged on the upper part of the front end of the assembly rack; the front part of a spring shaft is inserted in the spring positioning plate in an axial movable manner; the rear end part of the spring shaft is hinged with the spring pressure plate; a pressure spring is sleeved on the spring shaft; and front and rear end faces of the pressure spring are contacted and matched with the spring positioning plate and the spring pressure plate respectively. The elastic vibratory deep scarification unit has the advantages of simple structure, low manufacturing cost, stable work, small traction resistance, high reliability, good deep scarification and soil crushing effects and wide application range.

Owner:黑龙江省农业机械运用研究所

Chiseling and shoveling type excavating machine of deep-rooted medicinal materials

A chiseling and shoveling type excavating machine of deep-rooted medicinal materials comprises a machine frame, a suspension bracket, a reversing and speed changing gearbox and a depth wheel, wherein the suspension bracket is arranged above the position in front of the machine frame, the depth wheel is arranged below the position in front of the machine frame, the reversing and speed changing gearbox is arranged in the middle of the position above the machine frame, a gearbox output shaft is arranged on one side of the reversing and speed changing gearbox, the other end of the gearbox output shaft is arranged on the machine frame, the gearbox output shaft is provided with a driving belt wheel which is matched with a driven belt wheel arranged on a driven main shaft, flywheels are arranged on two sides of the driven main shaft, eccentric bearings are arranged at the two ends of the driven main shaft and connected with connection rods which are connected with shoveling arms, the upper ends of the shoveling arms are connected with the machine frame, and the lower ends of the shoveling arms are connected with an excavating shovel. The high-frequency and low-amplitude chiseling and shoveling type excavating machine of deep-rooted medicinal materials has the advantages of being simple in structure, flexile, portable, and lower in manufacturing cost, and saving cost, and is suitable for excavating root stocks of traditional Chinese medicinal materials in small pieces of land in mountainous regions and plateau regions.

Owner:樊青山

Digging shovel used for harvesting potatoes

The invention relates to a digging shovel used for harvesting potatoes. The digging shovel can be detachably arranged on a shovel frame crossbeam, and can be adjusted by virtue of a shovel surface inclination angle adjusting mechanism and a shovel edge oblique angle adjusting mechanism so as to reduce traction resistance and power consumption during harvesting. The digging shovel provided by the invention has the advantages that during harvesting the potatoes, the shovel surface inclination angle and the shovel edge oblique angle of the digging shovel can be adjusted according to different harvesting conditions so as to reduce the traction resistance and the power consumption during harvesting as much as possible, and the digging shovel is simple in structure and is easy to implement.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Double-row four-shovel oscillating type cassava excavator

The invention relates to a double-row four-shovel oscillating type cassava excavator, pertaining to the field of agricultural machines. The double-row four-shovel oscillating type cassava excavator comprises a frame, a depth wheel assembly, an excavation shovel assembly and a power vibration mechanism. During operation, soil iswell separated from potatoes due to small soil turning amount, which causes little damage to soil potato tuberous roots. The soil is more highly adaptive to soil. Therefore, mechanized operation of harvest of soil potato tuberous roots is well achieved. The double-row four-shovel oscillating type cassava excavator adopts gear and shaft transmission, is great in power, reliable in operation, and easy and convenient in repair and maintenance. Oscillating-type excavation is adopted so that traction resistance is reduced and soil is better separated from potatoes. A separation rod welded at back ends of shovel handles so that reliability of separation of soil from potatoes is improved. Through a combination mode of a hanging hole in the front end of a depth wheel, a lower pull board of an eccentric assembly and an eccentric shaft sleeve, the excavation depth is achieved in a six-stage adjustable manner.

Owner:CHINA AGRI UNIV

Intelligent harvesting system for long rhizome crops

InactiveCN110235590ALow traction resistanceIncrease working depthDiggersAgricultural engineeringRhizome

The invention relates to the technical field of agricultural machinery, in particular to an intelligent harvesting system for long rhizome crops. The system reduces soil cutting resistance by enhancing two-dimensional vibration of a digging shovel; meanwhile, an intelligent control system is added to acquire a plurality of sensor signals in real time and adjust the vibration frequency of the digging shovel in real time so as to adapt to the tillage environment of different types of soil. The vibration digging shovel generates two-dimensional vibration under the pushing effect of a pneumatic excitation executor, the two-dimensional vibration effectively reduces the traction resistance of a harvester and simultaneously achieves a crushing effect on soil fed into the digging shovel, and thus convenience is provided for the subsequent separation of pesticide and the soil. The fed soil is separated from crops through vibration in a vibrating screen at the rear portion of the harvester.

Owner:JIANGSU UNIV

Shallow-buried drip irrigation furrow seeder

PendingCN112544152AComplete structureDrought resistance is remarkableSpadesClimate change adaptationSeederSoil science

The invention discloses a shallow-buried drip irrigation furrow seeder. The shallow-buried drip irrigation furrow seeder comprises a rack, a soil preparation mechanism, a fertilization mechanism, a tape laying mechanism and a seeding mechanism; the soil preparation mechanism comprises two ploughshares which are bilaterally symmetrically arranged at a front end of the rack, dig ditches downwards and divides soil to two sides to form furrows, soil preparation rollers are arranged at a middle lower part of the rack through soil preparation bearings and soil preparation shafts, a diameter of the soil preparation roller corresponding to a furrow position is large, and a diameter of the soil preparation roller corresponding to a ridge back position is small; the fertilization mechanism comprisesa fertilizer box and two fertilizer dischargers driven by a fertilizer discharging shaft, and lower ends of fertilizer discharging pipes are respectively connected to rear parts of the correspondingploughshares; the tape laying mechanism comprises a drip irrigation tape support and a drip irrigation tape laying device; and the seeding mechanism comprises duckbilled roller seeders connected to positions, corresponding to two furrows, of rear ends of the rack, and a compacting machine is connected to a rear portion of each duckbilled roller seeder. Seeds are sown in furrows, drip irrigation tapes are shallowly buried and laid on ridge backs of narrow rows, and the shallow-buried drip irrigation furrow seeder is suitable for a film-free shallow-buried drip irrigation furrow seeding operation.

Owner:赤峰市农牧科学研究院

Vibration deep soil-loosening fertilizer applicator

PendingCN111373892AAdd depthReduce adhesionSpadesAgricultural machinesSoil scienceMechanical engineering

The invention provides a vibration deep soil-loosening fertilizer applicator. The vibration deep soil-loosening fertilizer applicator comprises a frame, wherein the bottom part of the frame is provided with an elastic tooth type deep soil-loosening piece used for loosening upper-layer soil; a rigid deep soil-loosening piece used for loosening lower-layer soil is arranged behind the elastic tooth type deep soil-loosening piece; the elastic tooth type deep soil-loosening piece and the rigid deep soil-loosening piece are connected into a whole and fixedly arranged on the frame; a material deep burying mechanism fixedly arranged on the frame and used for deep fertilization is also arranged behind the rigid deep soil-loosening piece, and comprises a material box which is fixedly arranged on theframe; an auger used for controlling discharging is arranged at the bottom part of the material box; and a discharging pipe is fixedly arranged at the discharging end of the material box, and locatedbehind the rigid deep soil-loosening piece and used for deeply applying a fertilizer into deep loosened soil. According to the vibration deep soil-loosening fertilizer applicator provided by the invention, deep soil-loosening pieces are continuously driven to carry out deep soil loosening on soil by utilizing self-induced vibration factors like negative damping generated by soil cutting of deep soil-loosening pieces during tillage; meanwhile, the fertilizer application work can be completed, so uniform fertilizer addition at a large depth can be realized.

Owner:SHENYANG POLYTECHNIC UNIV

An adjustable disc ridge former

The invention provides an adjustable disc ridge former comprising discs, a left pull rod, a right pull rod, angle adjusting locating plates, compression springs, a central connecting plate and adjusting bolts and nuts. The ridge former can be used for ridge forming in the sowing period of potatoes and can also be used for ridge forming of field management in an early period of ridge culture of other crops. The ridge former is simple in structure and convenient to adjust; the ridge forming height and width can be adjusted according to the local agricultural requirements; the traction resistance is low, so that the tractor power consumption is saved and the production efficiency is increased; the whole device is simple in structure and low in cost and is in particular suitable for potato planting specialized households and farms.

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Shovel point vibration type subsoiler

ActiveCN108738404AEasy to manufacture and assembleReduce maintenance costsSoil-working equipmentsEngineeringControl theory

The invention relates to a shovel point vibration type subsoiler which comprises a rack, a plurality of vibration subsoiler assemblies, a vibration mechanism and a hydraulic depth-limiting-press wheelassembly; according to the shovel point vibration type subsoiler, the vibration mechanism manufacturing and assembling process is simple, and the maintenance cost is low; only a shovel point is an oscillation starting component, whole shovel vibration is not needed, and compared with other vibration subsoilers, more power consumption is lowered; the oscillation starting component is bilaterally symmetric, and the influence that shovel point vibration is transmitted to the rack, and then transmitted to a tractor is lowered. For different amplitude requirements, eccentric joints with differenteccentric distances can be prefabricated so as to be matched with different soil conditions. Meanwhile, at the rear part of the rack, the operation depth is regulated easily and reliably through a hydraulic depth limiting-press wheel assembly, and heavy work of manual regulation is avoided. The whole subsoiler is simple in structure and quite convenient to manufacture, assemble and maintain.

Owner:CHINA AGRI UNIV

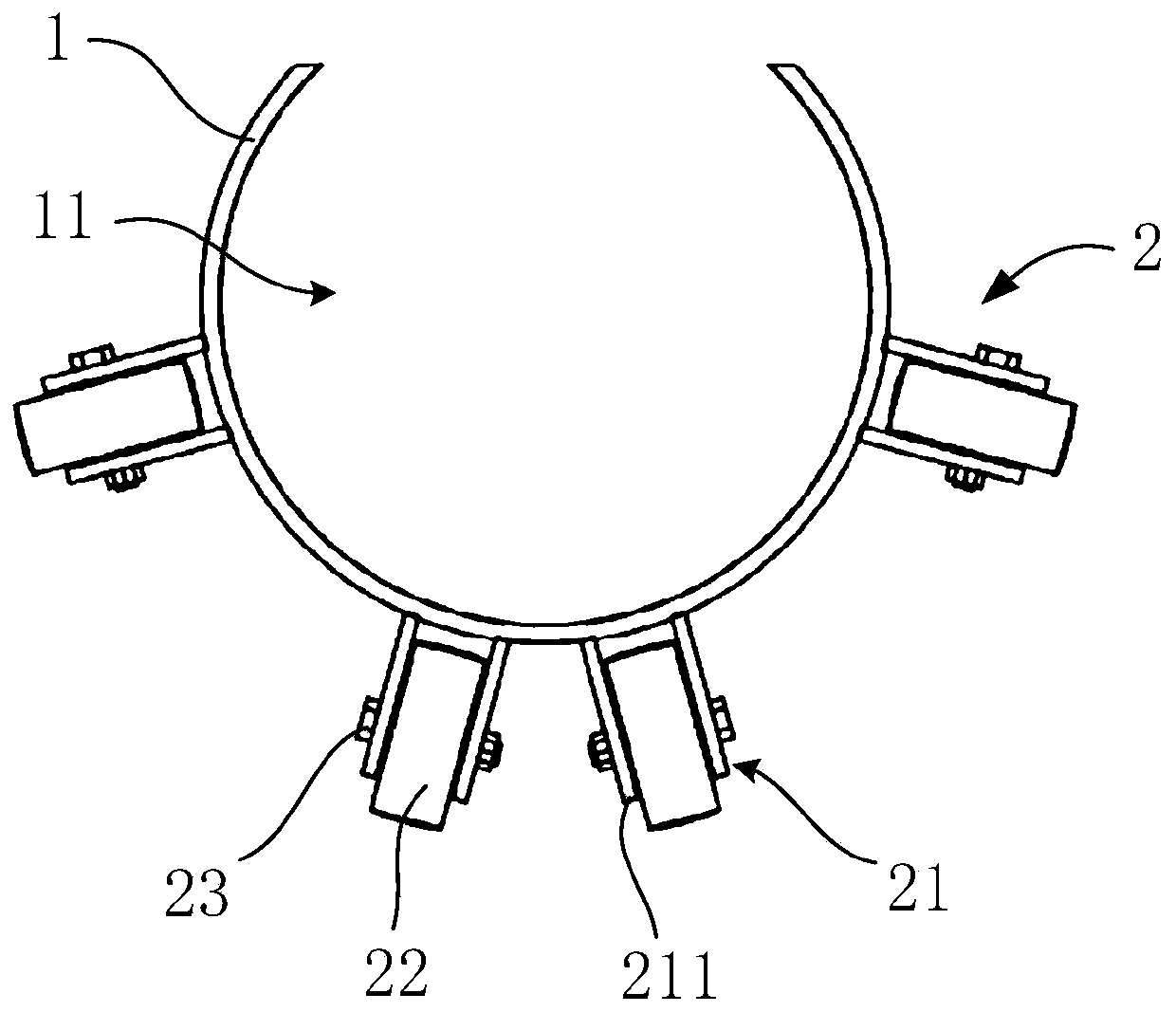

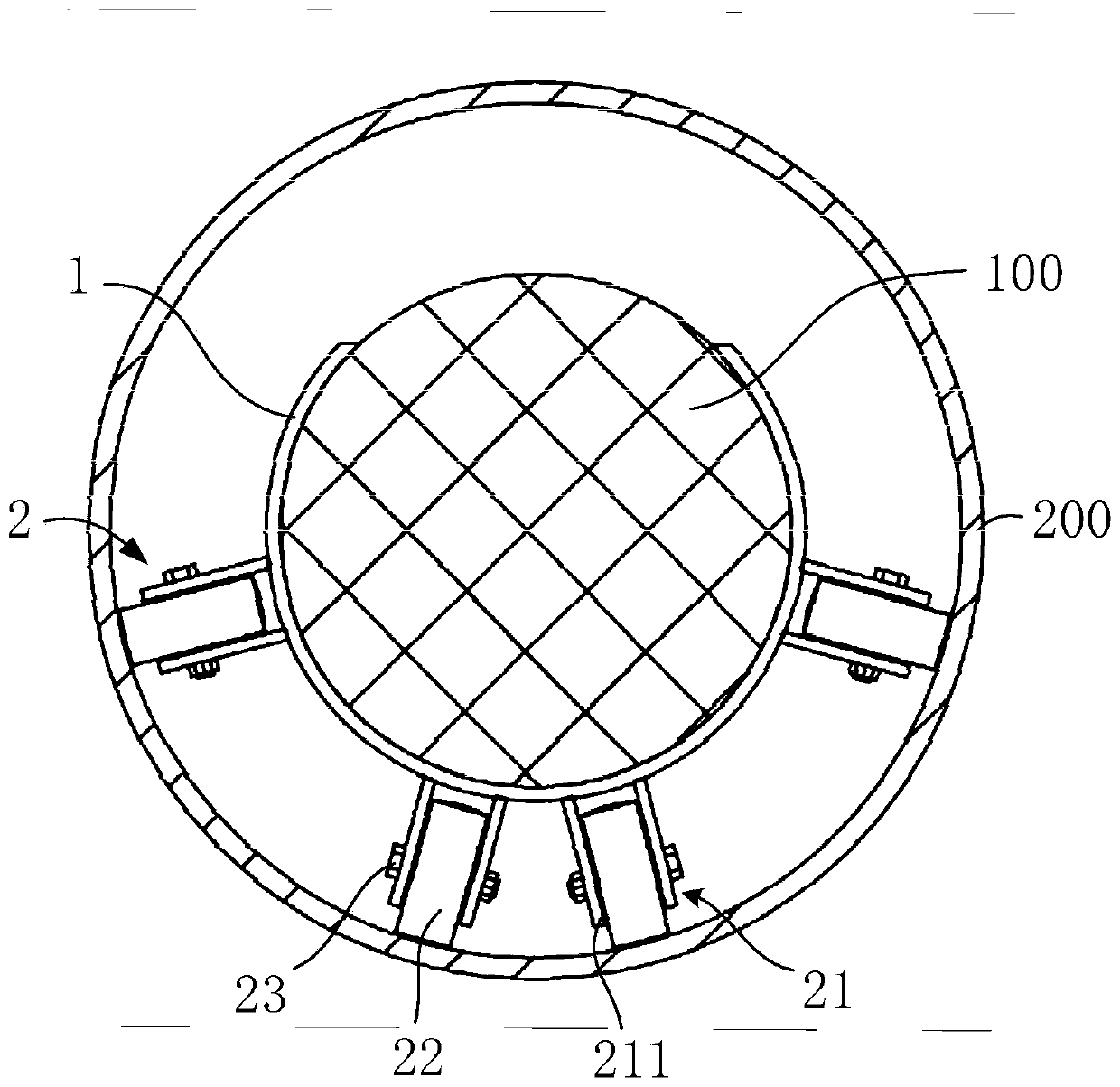

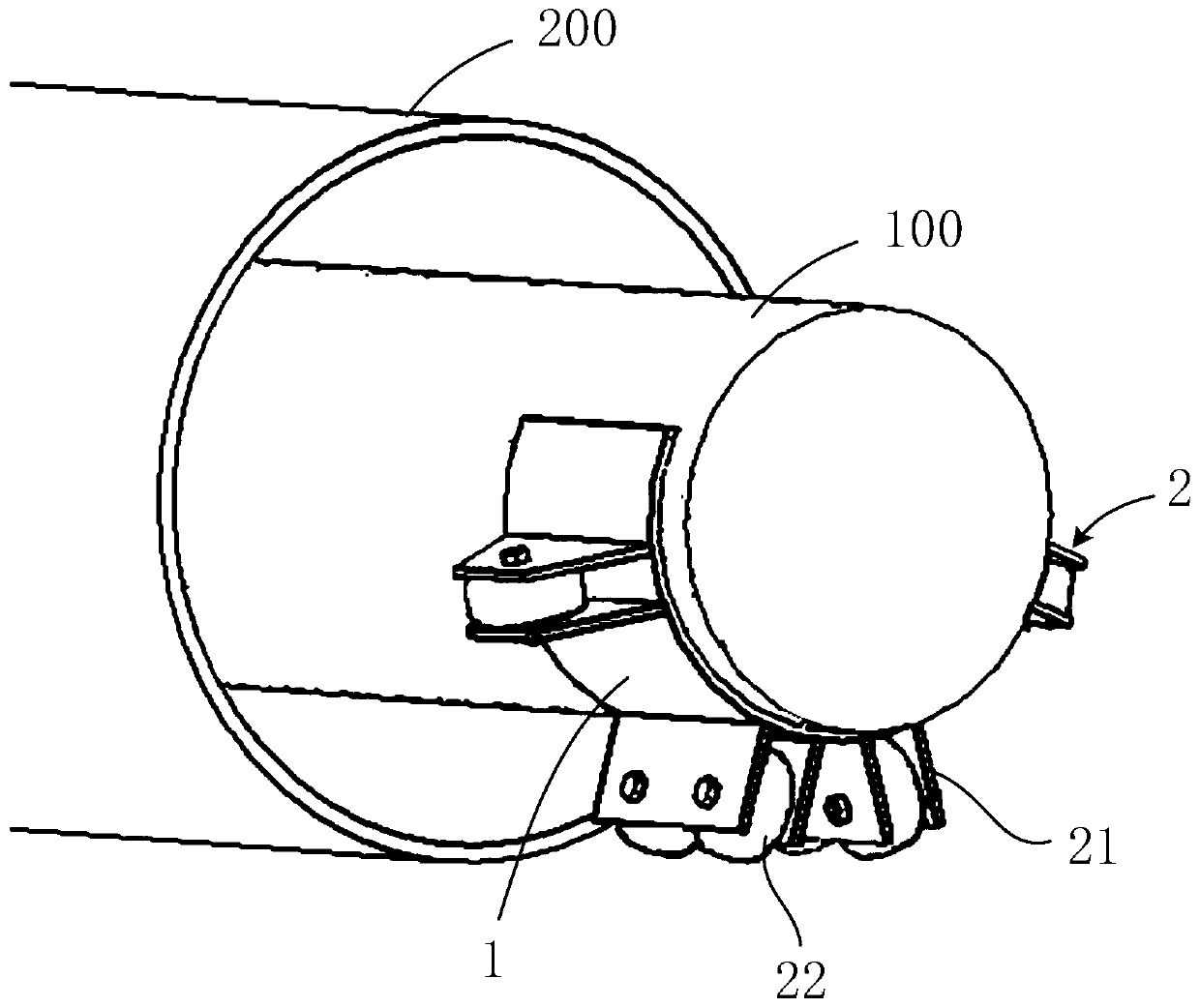

Pipe cable hoop and pipe cable laying assembly

PendingCN111146734AAvoid damageAvoid contactApparatus for laying cablesArchitectural engineeringIdler-wheel

The invention belongs to the technical field of cable laying, and discloses a pipe cable hoop and a pipe cable laying assembly. The pipe cable hoop comprises a hoop body and at least two supporting bodies, and the hoop body is provided with a notch part which can be adaptively connected with the outer wall of a cable; each supporting body comprises a supporting frame and idler wheels, wherein thesupporting frame is fixedly connected with the hoop body and extends towards the outer side of the hoop body, the idler wheels are arranged at the end, away from the hoop body, of the supporting frame, and the idler wheels are distributed in an arc shape to form an arc-shaped supporting part capable of abutting against the inner wall of a pipe for laying cables. The pipe cable hoop provided by theinvention can be connected to the outer wall of a to-be-laid cable through the notch part of the pipe cable hoop; when the cable is subjected to traction force to be arranged in the pipe in a penetrating mode, the idler wheels are connected with the inner wall of the pipe in a rolling mode, the hoop body is supported in the pipe, the cable borne by the hoop body is separated from the pipe, the cable can be prevented from making contact with the inner wall of the pipeline in the cable laying operation, the traction resistance is reduced, and the outer wall of the cable is prevented from beingdamaged.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST

Adjustable three-furrow plough

An adjustable three-share plough features that its central share is fixed to a frame-shape main beam by two U-shaped fasteners and its left and right share can slide on said main beam, so the distance between them can be adjusted according to the spacing between ridges for protecting crops.

Owner:赵秀锋

Saw blade and moldboard plow combined ditcher for hilly orchard

ActiveCN111512743AReduce disturbanceWith energy saving effectSpadesAgricultural machinesAgricultural engineeringStructural engineering

The invention discloses a saw blade and moldboard plow combined ditcher for a hilly orchard. The saw blade and moldboard plow combined ditcher comprises a rack, wherein a transmission mechanism is arranged on the rack; after being connected with a power source, the transmission mechanism drives a saw blade driving shaft to rotate; two groups of saw blades are arranged on the saw blade driving shaft; each group of saw blades comprises three saw blades; the saw blade driving shaft drives the two groups of saw blades to rotate; and two plow bodies are also arranged on the rack and are respectively positioned at the rear ends of the two groups of saw blades.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Layered deep-loosening mechanism and deep-loosening method thereof

PendingCN111373888AChange the state of being compactedChange the state of compactionPloughsStructural engineeringShovel

The invention provides a layered deep-loosening mechanism. The layered deep-loosening mechanism comprises a spring-tooth deep-loosening member for loosening the upper soil, wherein the rear, along thedeep-loosening direction of the spring-tooth deep-loosening member, of the spring-tooth deep-loosening member is provided with a rigid deep-loosening member for loosening the lower soil, the spring-tooth deep-loosening member comprises a double-wing shovel and an elastic shovel handle, the double-wing shovel is fixedly arranged at the lower end of the elastic shovel handle, the elastic shovel handle is an S-shaped spring-tooth deep-loosening shovel handle, the rigid deep-loosening member comprises a rigid shovel head and a rigid shovel handle, the rigid shovel head is fixedly arranged at thelower end of the rigid shovel handle, a shovel tip of the double-wing shovel is located above a shovel tip of the rigid shovel head, and the elastic shovel handle is connected with the rigid shovel handle as a whole through a connecting member. The invention discloses the layered deep-loosening mechanism that combines the spring-tooth deep-loosening shovel and the rigid deep-loosening shovel, canperform layered deep-loosening on the soil, and at the same time, can reduce traction resistance.

Owner:SHENYANG POLYTECHNIC UNIV

Electric cable traction device

PendingCN111217202AReduce resistanceResistance effortFilament handlingInsulation layerElectric cables

The embodiment of the invention discloses an electric cable traction device and relates to the technical field of line traction devices. The key point of the technical scheme is as follows: the electric cable traction device comprises a base, a traction guide wheel, a left guide wheel and a right guide wheel, wherein the traction guide wheel is rotatably connected to the upper side of the base, the axis of the traction guide wheel is horizontal, the left guide wheel and the right guide wheel are rotatably connected to the base, separately, the axes of the left guide wheel and the right guide wheel are vertical, and the left guide wheel and the right guide wheel are arranged in a spaced manner on two sides of the traction guide wheel in the axial direction of the traction guide wheel, so that an effect that it is more labor-saving to pull a cable is archived, and therefore, an insulation layer of the cable can be prevented from being damaged effectively.

Owner:TIANZE ELECTRIC POWER (TIANJIN) CO LTD

Air-pressure auto-excitation type vibrating subsoiler

ActiveCN108684234AReduce the impact of air pressure fluctuationsRapid responseSpadesPloughsControl systemAtmospheric pressure

Provided is an air-pressure auto-excitation type vibrating subsoiler. The subsoiler comprises a frame, multiple subsoiler shovels and an air pressure adjusting system; the frame includes a cross girder A, a cross girder B, depth limiting wheel supporting arms and suspension arms; a depth limiting wheel is arranged under each depth limiting wheel supporting arm, the cross girder A is arranged parallelly to the cross girder B, an air cylinder A used for adjusting the height of the cross girder A is also arranged between the cross girder A and the cross girder B, the subsoiler shovels are installed on the cross girder A, and the suspension arms are installed on the cross girder B; the subsoiler shovels are connected to the cross girder A through connecting arms capable of swinging up and down, air cylinders B are arranged on the connecting arms, and the` air pressure adjusting system includes an air pressure part and two air pressure control parts, wherein the two air pressure control parts are used for controlling the working states of the air cylinder A and air cylinder B respectively; an ultrasonic probe is arranged on the cross girder B and also connected to a central control system. By adopting air-pressure type auto-excitation vibration, fast adjustment of the rigidity of a vibration source can be achieved, the adaptability of the vibration source to different degrees of soil resistance is improved, and therefore the subsoiling effect is better improved.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com