Motor stator punching sheet processing system

A processing system and motor stator technology, which is used in metal processing equipment, manufacturing stator/rotor bodies, positioning devices, etc., can solve problems such as motor short circuit and radial movement of stator punching pieces, avoid rotation deflection, and improve accuracy. , avoid the effect of separation and fault

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

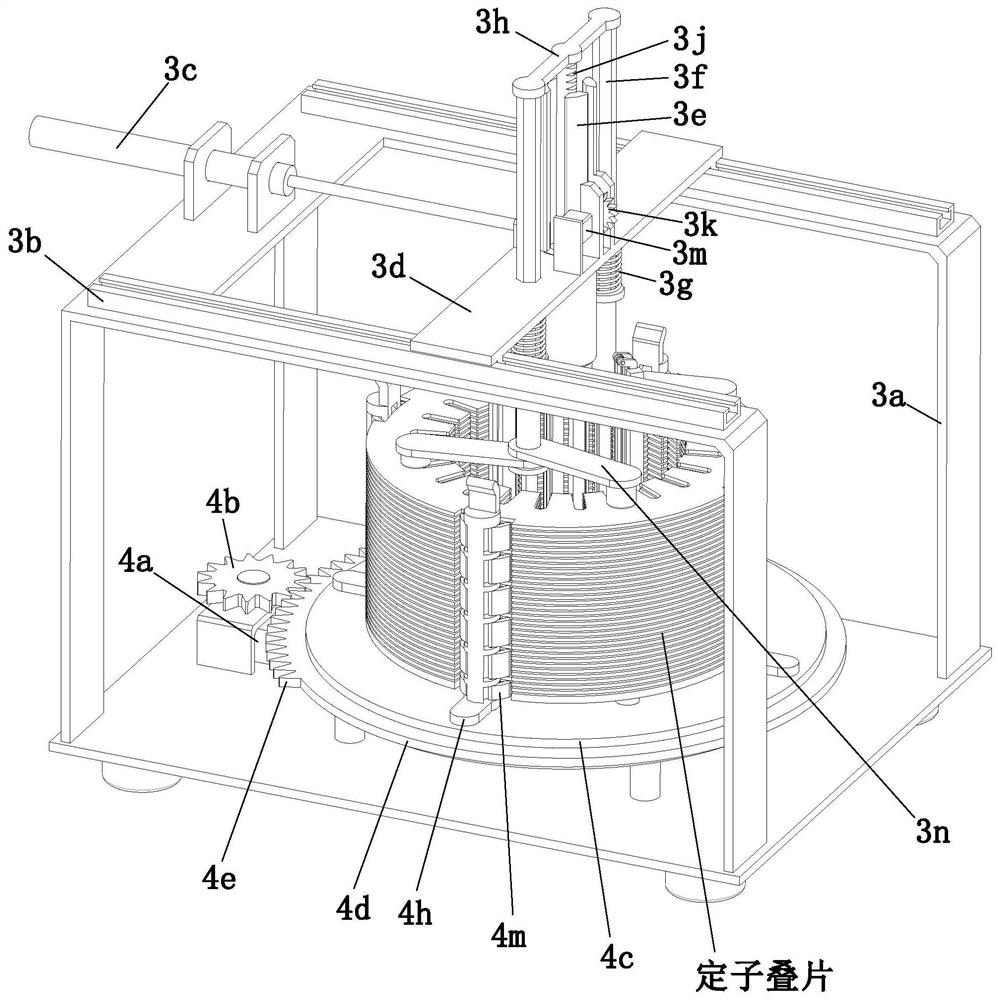

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0028] A motor stator stamping processing system, comprising an installation base plate 1, support feet 2, a positioning mechanism 3, an assembly mechanism 4 and a support mechanism 5, the corners around the lower end of the installation base plate 1 are evenly installed with support feet 2, and the installation base plate 1 A positioning mechanism 3 is installed on the upper end of the positioning mechanism 3, an assembly mechanism 4 is installed on the installation base plate 1 below the positioning mechanism 3, and a support mechanism 5 is installed on the assembly mechanism 4.

[0029]The assembly mechanism 4 includes a limit motor 4a, a limit gear 4b, a limit swivel 4c, a limit turntable 4d, a limit ring gear 4e, an arc groove 4f, a limit chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com