TiCrN/MoS2 multi-element anti-wear lubricating coating tool and preparation process thereof

A technology of lubricating coating and preparation process, which is applied in the field of TiCrN/MoS2 multi-element anti-friction lubricating coating tool and its preparation process, can solve the problem that the service life of the tool cannot meet the needs of actual use, and the service life of the tool coating flank coating Not long, the service life of the tool needs to be further improved, etc., to achieve the effect of increasing the use range, high hardness, and reducing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

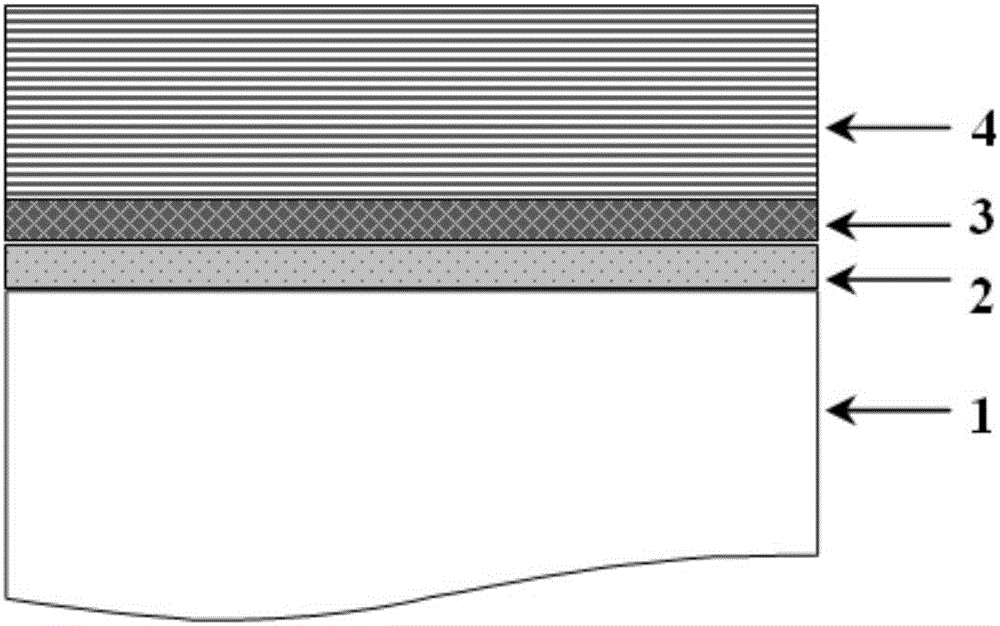

[0021] A TiCrN / MoS 2 Multi-element anti-friction lubricating coating tool, the tool is an ordinary milling insert, and its base material is: cemented carbide YT15. The deposition method is a composite coating prepared by arc plating and intermediate frequency magnetron sputtering composite coating method, including 1 Ti target arc target, 1 Cr target arc target, and 2 MoS 2 Magnetron sputtering target: Ti transition layer, Ti / Cr transition layer, TiCrN (arc ion plating) and MoS deposited by arc ion plating 2 Composite coating (magnetron sputtering), its preparation process is:

[0022] (1) Pretreatment: Polish the surface of the tool base to remove surface oil, rust and other impurities, then put them in alcohol and acetone in turn, ultrasonically clean for 30 minutes each, remove oil and other attachments on the tool surface, and dry them quickly with a hair dryer Put it into the coating machine, vacuum to 7.0~8.0×10 -3 Pa, heat to 300°C, keep warm for 30-35min;

[0023] ...

Embodiment 2

[0029] A TiCrN / MoS 2 Multi-element anti-friction lubricating coating tool, the tool is an ordinary twist drill, and its tool base material is: high-speed steel W18Cr4V. The deposition method is a composite coating prepared by arc plating and intermediate frequency magnetron sputtering composite coating method, including 1 Ti target arc target, 1 Cr target arc target, and 2 MoS 2 Magnetron sputtering target: Ti transition layer, Ti / Cr transition layer, TiCrN (arc ion plating) and MoS deposited by arc ion plating 2 Composite coating (magnetron sputtering), its preparation process is:

[0030] (1) Pretreatment: Polish the surface of the tool base to remove surface oil, rust and other impurities, then put them in alcohol and acetone in turn, ultrasonically clean for 30 minutes each, remove oil and other attachments on the tool surface, and dry them quickly with a hair dryer Put it into the coating machine, vacuum to 7.0~8.0×10 -3 Pa, heat to 300°C, keep warm for 30-35min;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com